Method for recycling false selvedges of rapier loom

A technology of rapier looms and side yarns, which is applied in looms, textiles, textiles, and papermaking, and can solve problems such as wasting time, reducing production efficiency, and complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

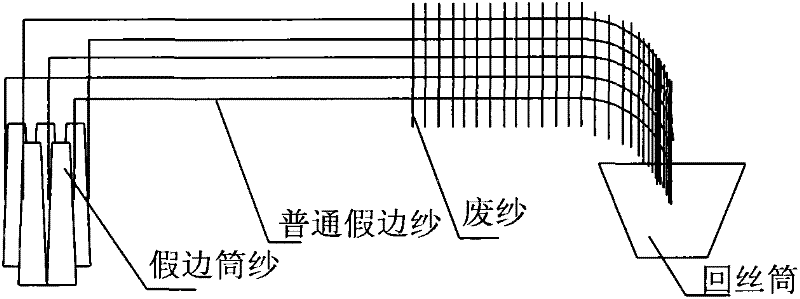

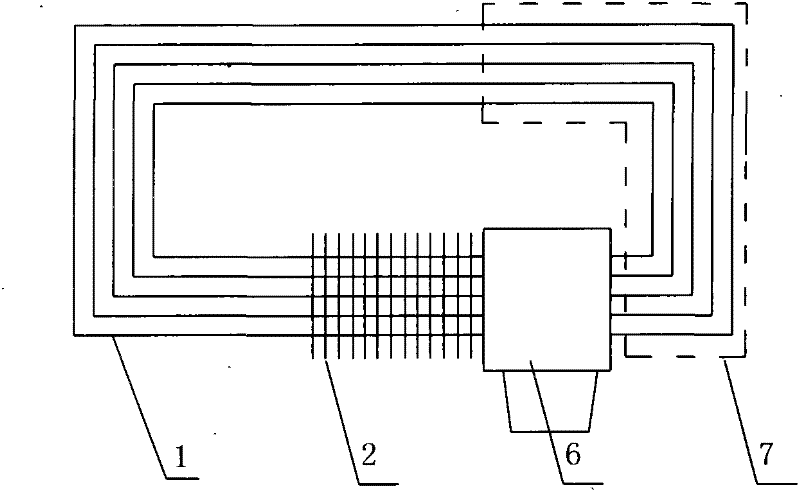

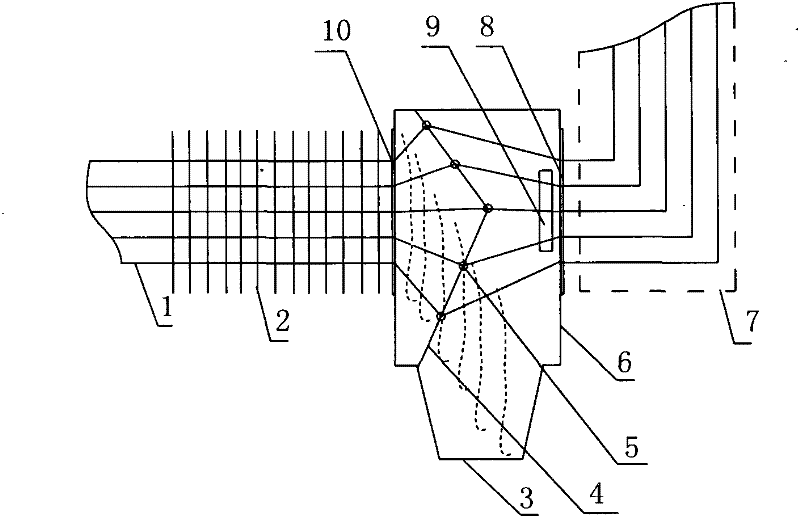

[0016] The method for recycling the false edge yarn of the rapier loom according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] The rapier loom false edge yarn recycling method of the present invention is to arrange the annular false edge yarn 1 and the dividing box 6 on the rapier loom, the dividing box 6 is arranged in the middle of the annular false edge yarn 1, and utilizes the annular false edge yarn The interweaving of yarn 1 and waste yarn 2 brings the waste yarn 2 into the yarn separation box 6, and the yarn separation box 6 removes the waste yarn 2 from the circular false edge yarn 1, and then enters the false edge yarn circulation channel 7 of the rapier loom Realize the recycling of the false side yarn; the dividing box 6 is provided with a dividing plate 4 and an induced draft fan 9, one side of the dividing box 6 is provided with an annular false side yarn inlet 10, and the other side is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com