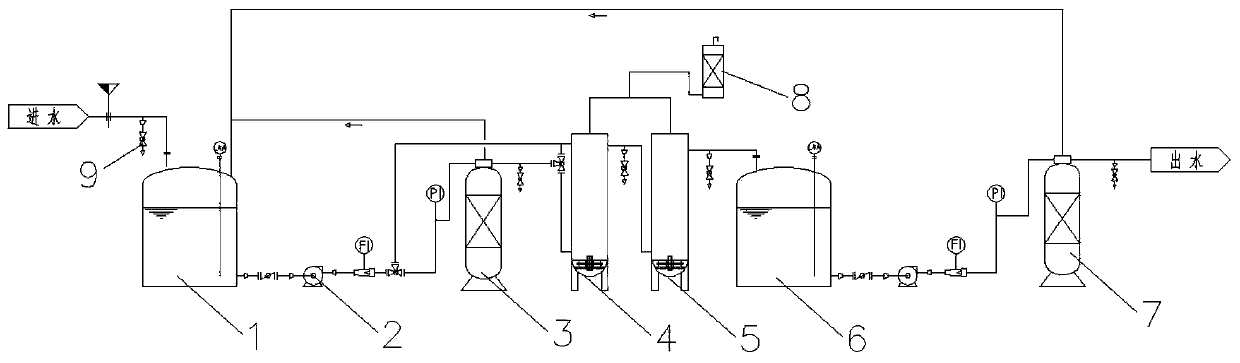

High-grade oxidization deep processing system of printing and dyeing wastewater C.E

A technology for advanced oxidation and printing and dyeing wastewater, applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, water/sewage treatment, etc. The effect of improving product utilization, simple overall structure, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

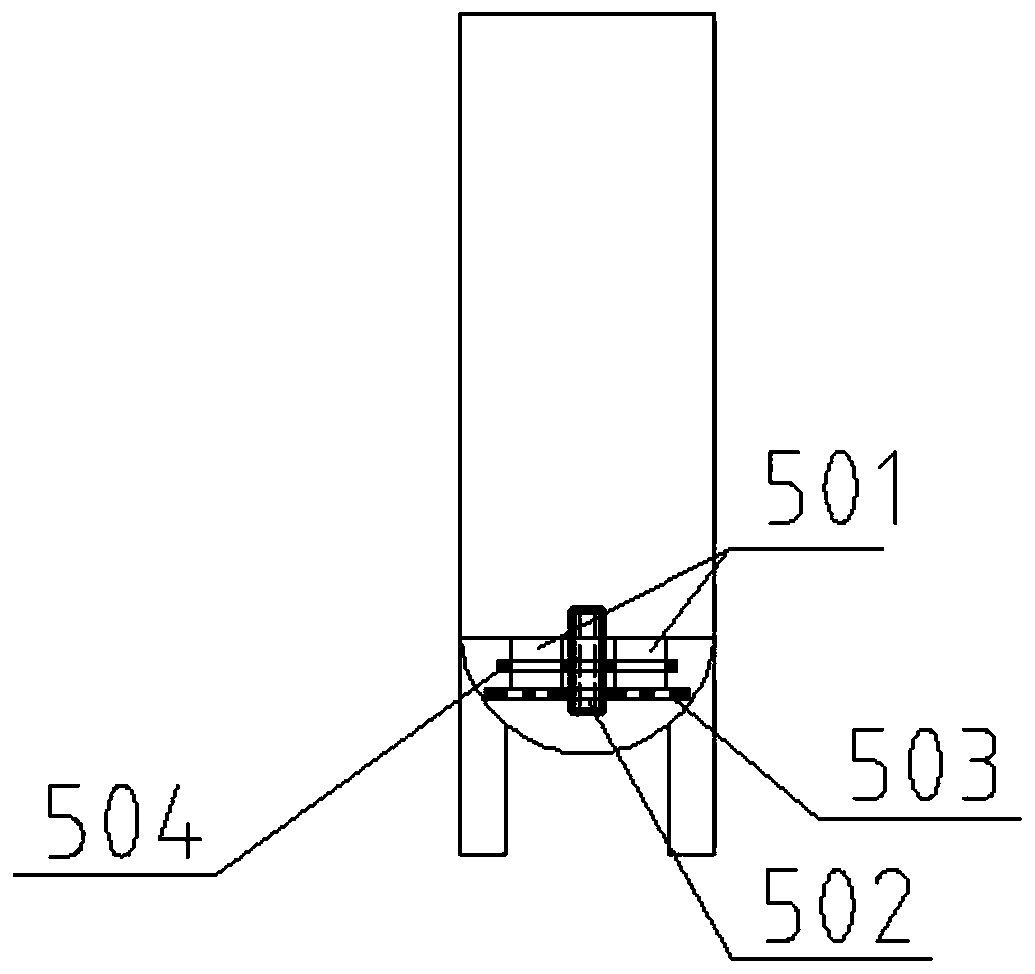

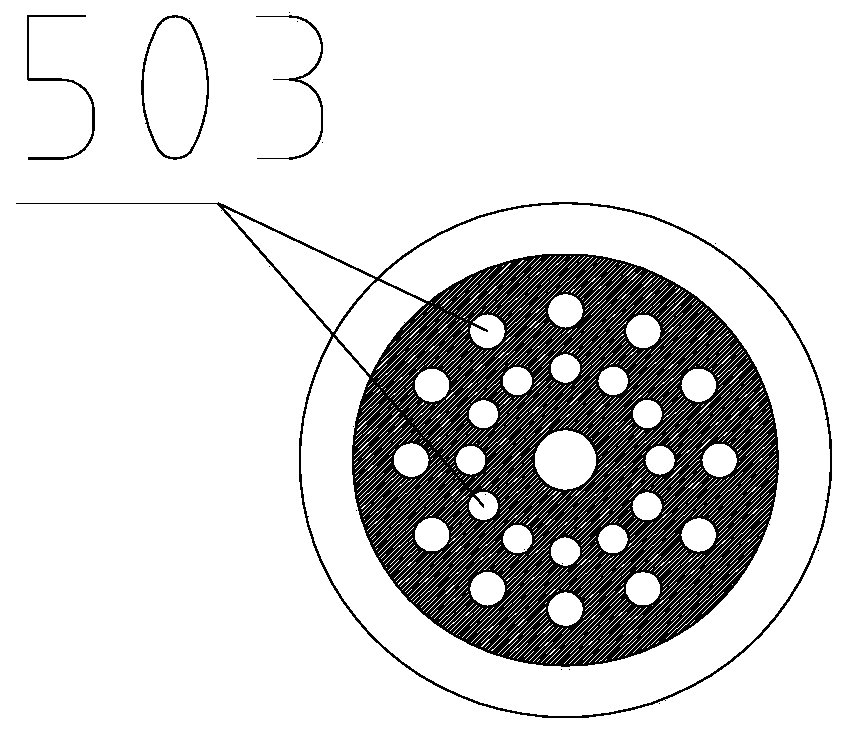

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Gas production and oxidant production test of the electrode group in the C.E electrolyzer

[0036] Test conditions: temperature 25°C, water sample configuration is distilled water + sulfuric acid, water sample volume is 2.5L, water sample TDS is 300mg / L, the results are shown in Table 1-3.

[0037] Table 1: 10×10cm electrode unit current, voltage and air flow

[0038]

[0039]Table 2: Oxidant output under different constant currents of 10×10cm electrode unit

[0040] Constant voltage V Reference current / A Oxidant production mg / cm 2 min

9 1.13-2.01 0.272-0.422 12 1.72-3.19 0.361-0.667 15 2.28-4.07 0.431-0.823

[0041] Table 3: Oxidant output under different constant pressures of 10×10cm electrode unit

[0042] Constant current A Reference voltage V Oxidant production mg / cm 2 min

3 2.87-24 0.536-0.655 4 3.4-24 0.719-0.879 5 4.14-24 0.874-1.069

[0043] It can be seen from Tabl...

Embodiment 2

[0048] Example 2: Energy consumption and cost analysis of the C.E electrolyzer in the existing ozone generator and the C.E advanced oxidation advanced treatment system of the printing and dyeing wastewater of the present invention

[0049] Refer to the technical parameters of the domestic well-known brand KCF-DT10.0 ozone generator for analysis. The ozone output of this model is 10kg / h, the installed power is 110kW, and the operating power is about 110×0.85=93.5kW, because the ozone generator The temperature will rise during operation, so the cooling device must be considered. According to the cooling method of the chiller, the ozone generator with an ozone output of 10kg needs to consider the cooling capacity of 100kW. Refer to the parameters of the air-cooled screw chiller. The installed power of the chiller is about It is 41.3kW, and the operating power is about 41.3×0.85=35.1kW. In addition, supporting nitrogen dosing devices, tail gas treatment devices, etc. are required,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com