Movable construction waste crushing device

A construction waste and crushing device technology, which is applied in the directions of magnetic separation, solid separation, and screening, etc., can solve the problems of large land expropriation fees, construction funds for garbage removal and transportation, high noise of the crushing device, and flying dust and sand. , achieve the effect of low working noise, simple and convenient use, and good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

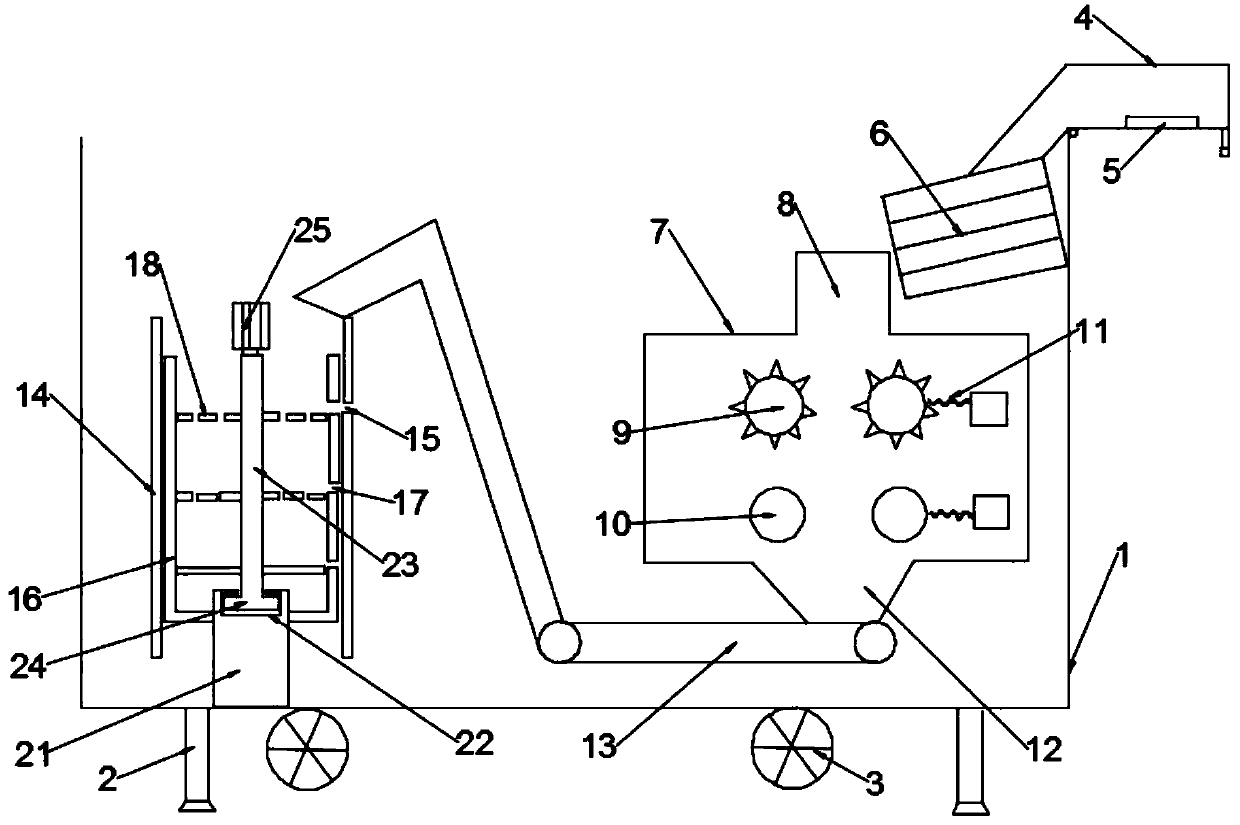

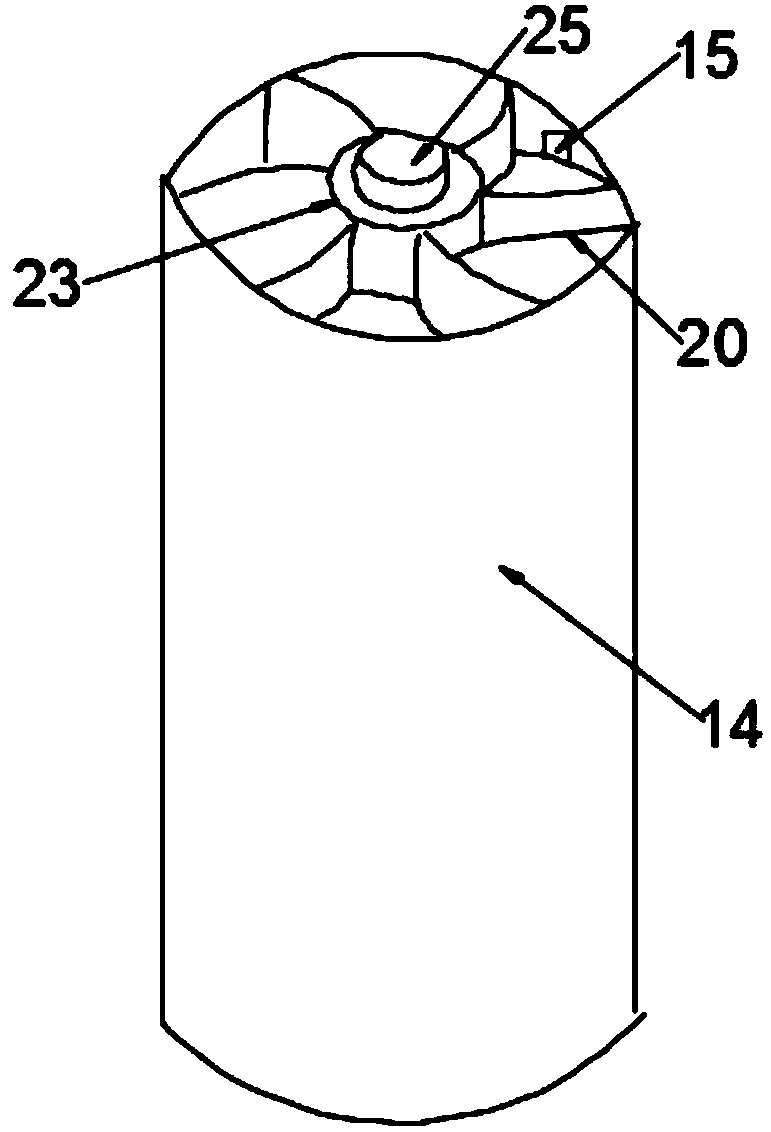

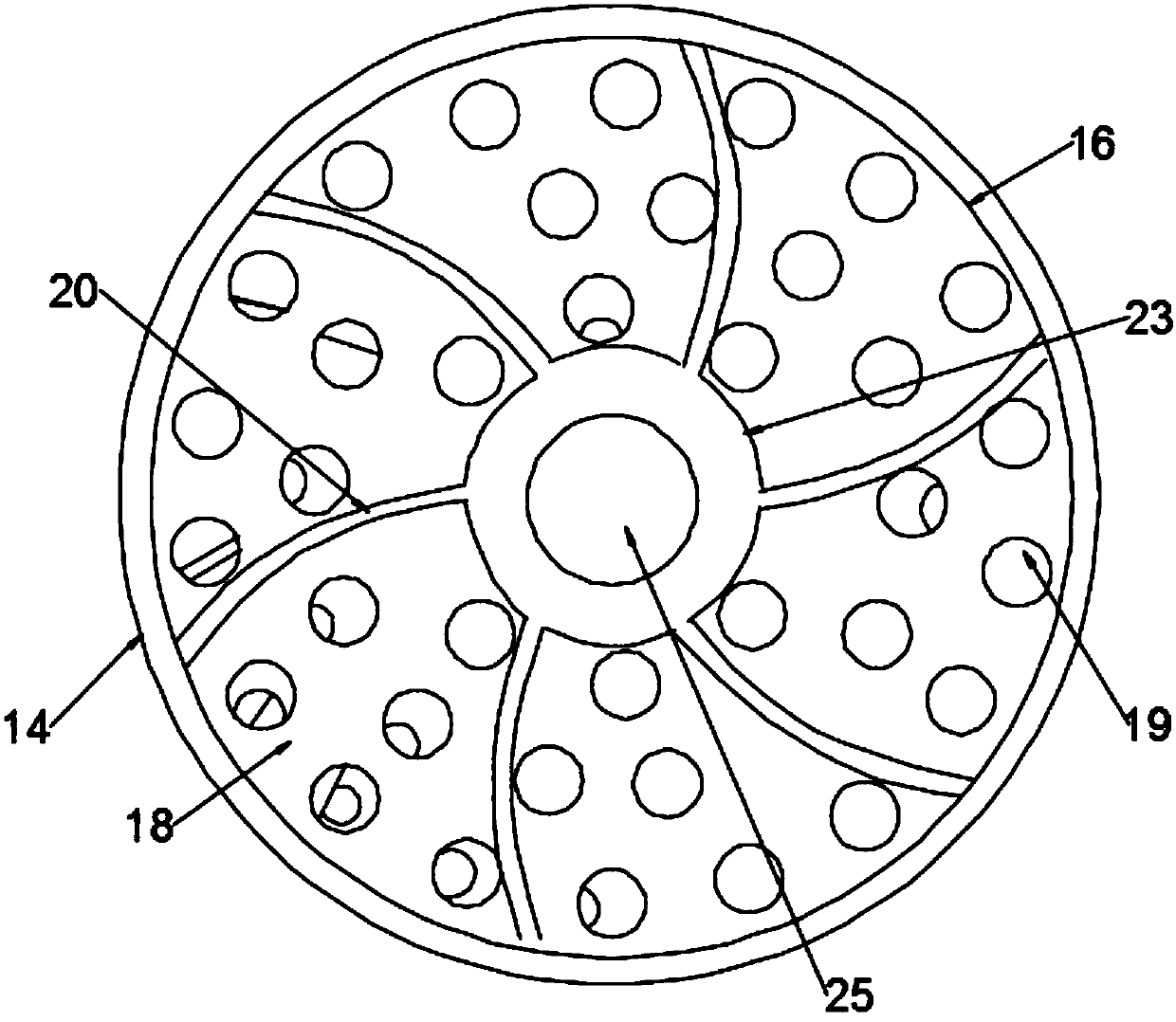

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0019] see Figure 1-3 , a mobile construction waste crushing device, comprising a vehicle frame 1, a feed pipe 4 and wheels 3, the wheels 3 are installed on the bottom of the vehicle frame 1, the feed pipe 4 is installed on the vehicle frame 1 and the feed pipe 4 An electromagnet 5 is installed inside, and a rolling distributor 6, a breaker 7, a chain bucket elevator 13 and a separating cylinder 14 are also installed in the frame 1, and the end of the feeding pipe 4 is provided with a rolling distributor towards the rolling distributor. The inclined plate of the machine 6, the crusher 7 includes a shell, a feeding port 8, a toothed roller 9, a smooth roller 10 and a crushing discharge port 12, and the output port of the rolling distributor 6 is connected with the feeding port 8 of the crusher 7 Generally speaking, the toothed roller 9 and the smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com