Heat-resistant antistatic conductive polymer composite material and preparation method therefor and application thereof

A technology of conductive polymers and composite materials, applied in the field of conductive polymers, can solve the problems of difficult reprocessing, high brittleness of PPS, difficult processing of PEEK, etc., and achieves the effect of meeting the requirements of recycling and reuse, highlighting electrical conductivity and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

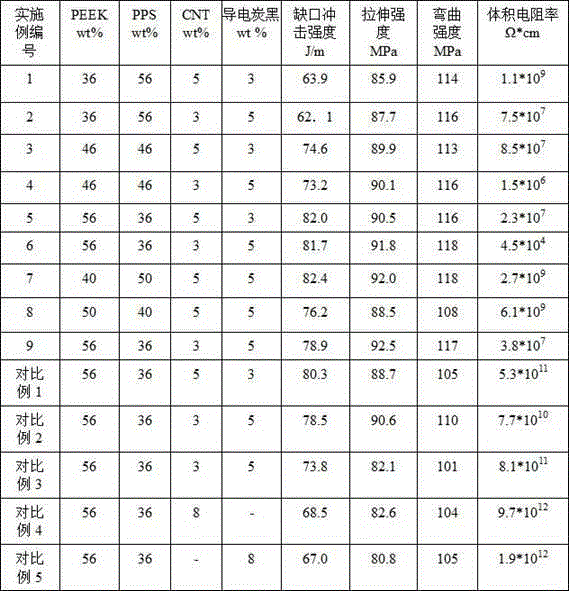

Embodiment 1

[0045] Proportioning is carried out according to the content of each component in Example 1 in Table 1, wherein the preparation steps are as follows:

[0046] S1. Dispersion treatment of carbon nanotubes: place the CNT powder in a 500ml spherical bottle, measure excess concentrated H 2 SO 4 concentrated HNO 3 Mixed solution (volume ratio H 2 SO 4 : HNO 3 =3:1) Pour into the spherical bottle until the powder is completely submerged, insert the condenser pipe of circulating water on it, heat it in the electric heating mantle, make the acid solution boil and reflux under the condition of passing cooling water for 0.5h, and then use The ceramic funnel lined with a septum membrane was washed and filtered under vacuum until the pH value was neutral, and then dried in an oven at ℃.

[0047] S2. Surface modification of conductive carbon black: place conductive carbon black in a 500ml spherical bottle, measure excess ammonium persulfate aqueous solution and pour into the spherical...

Embodiment 2

[0052] The preparation method is the same as in Example 1, and the distribution ratio of the components is shown in Table 1.

Embodiment 3

[0054] The preparation method is the same as in Example 1, and the distribution ratio of the components is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com