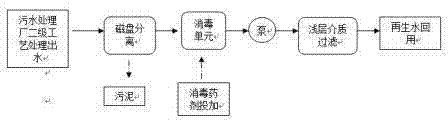

Method for producing regenerated water through combined process of magnetic separation and purification-shallow medium filtration

A medium filtration, combined process technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of unstable combined system, large area, complex structures, etc. , to achieve the effect of easy management and maintenance, small footprint and large amount of treated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This process is used to treat the secondary effluent of a municipal sewage treatment plant in depth, with a treatment scale of 40,000m 3 / d, water quality COD is 35 mg / L, suspended matter is 20 mg / L, total phosphorus is 1.4 mg / L, total nitrogen is 25 mg / L, ammonia nitrogen is 12 mg / L, and fecal E. coli is 40,000 / L. The raw water is pumped into the disk separation unit, and the agent is added in the equipment. Under the stirring state, 20g / m is added first. 3 Coagulate with polyaluminum chloride, then add 80mg / l magnetic seed with 6Gs remanence, mix, and then add 1g / m 3 Polyacrylamide (chemical formula 10 million) is coagulated to form flocs. After being purified and separated by the disk separation unit, the magnetic seeds contained in the sludge are recycled and reused, with a recovery rate of 98.5%; the effluent flows into the disinfection unit by gravity, and the Add sodium hypochlorite 4mg / L; the effluent is pumped into shallow medium for filtration, and the water ...

Embodiment 2

[0028] In this process comparison test, the secondary effluent of a sewage treatment plant in a county and town was selected. The treatment scale was 10,000 m3 / d. ~3mg / L, total nitrogen is 30 mg / L, ammonia nitrogen is 14 mg / L, fecal E. coli is 40000~60000 / L. Under the same water inflow and chemical conditions, the following three processes are used to treat the secondary effluent respectively. Process 1: Raw water is pumped into the disk separation unit, after treatment, it is pumped into the shallow medium for filtration, and finally flows into the disinfection unit by gravity and then the water is discharged ; Process 2: Raw water is pumped into the shallow medium for filtration, and after treatment, it flows into the disk separation unit, and finally flows into the disinfection unit by gravity; Process 3 (the process of the present invention): Raw water is pumped into the disk separation unit, and the treated water flows into the disinfection unit by gravity unit, and final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com