A kind of method for removing chlorine from acid solution

A technology of acid solution and solution, which is applied in chemical instruments and methods, control of water treatment parameters, special treatment targets, etc., can solve the problems of high treatment cost, consumption, and high antimony residue, and achieve low treatment cost, simple process, and The effect of high chlorine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

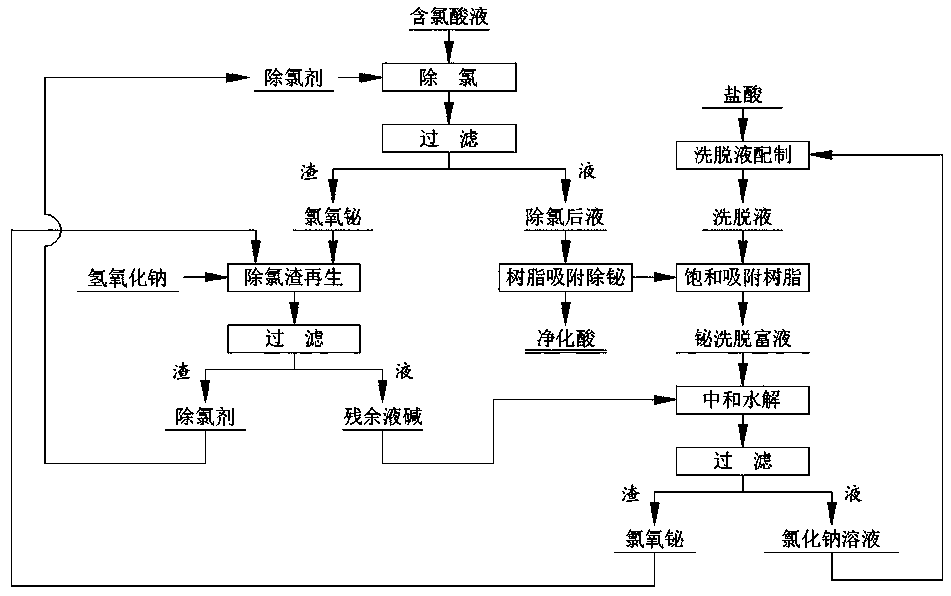

[0025] A kind of method of acidic solution dechlorination of the present invention, acidic solution adopts the waste acid of certain zinc smelter, and sulfuric acid is 8.5%, and chlorine is 3.5g / L, and this method flow process is as follows figure 1 shown, including the following steps:

[0026] (1) Dechlorination of acid solution: Take 200mL of the above waste acid in a beaker, start stirring, slowly add 6.0g of chlorine removal agent bismuth trioxide, and then stir for 2h. After the reaction, filter to obtain dechlorination slag (ie bismuth oxychloride) and dechlorination liquid.

[0027] After dechlorination, the chlorine content in the liquid is 41 mg / L, and the bismuth content is 790 mg / L. Among them, the chlorine removal rate is 98.8%.

[0028] (2) Chlorine removal slag regeneration: add 50mL of 200g / L sodium hydroxide solution to the chlorine removal slag, stir and react for 4 hours, then filter to obtain the regenerated chlorine removal agent (bismuth hydroxide) and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com