Patents

Literature

56 results about "Antichlor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An antichlor is a substance used to decompose residual hypochloride or chlorine after chlorine-based bleaching, in order to prevent ongoing reactions with, and therefore damage to, the material that has been bleached. Antichlors include sodium bisulfite, potassium bisulfite, sodium metabisulfite, sodium thiosulfate, and hydrogen peroxide.

Process for preparing nano calcium hydroxide

The invention discloses a making method of nanometer calcium hydroxide, which comprises the following steps: adding water-soluble, macromolecular polymer PVA124, PEG6000, PAA-NH4, PVP, PVA124 on the main chain or branched chain with polarity oxygen-containing group or natural macromolecular crust amine as mould; shocking the mould for 1h through ultraviolet wave to mix completely; preparing nanometer calcium hydroxide with macromolecular coating layer in the NaOH, KOH or ammonia alkaline solution through cleaning, centrifuging and drying. The invention improves the stability and dispersibility of nanometer calcium hydroxide to realize the controllable synthesis, which can be used as antichlor, desulfurizer and high effective adjuvant.

Owner:FUJIAN NORMAL UNIV

Garbage treatment method

InactiveCN101362978AImprove heat transfer efficiencyHigh reactivitySievingScreeningMaterials preparationCombustion

The invention relates to a garbage disposal method, in particular to the garbage disposal method which takes original urban living garbage, wastes after the carbon-containing industrial and agricultural production and processing and high-grade raw coal as main raw materials and obtains a finished product fuel by carrying out the deodorization, the sterilization, the rough sorting, the first breaking, the dehydration, the drying, the second breaking and the material preparation, adding desulfurizer, antichlor, denitrogenating agent, activator, ignition agent and combustion improver for matching and carrying out the mixing, the stirring and the high-temperature forming.

Owner:深圳恒信华天环保科技有限公司

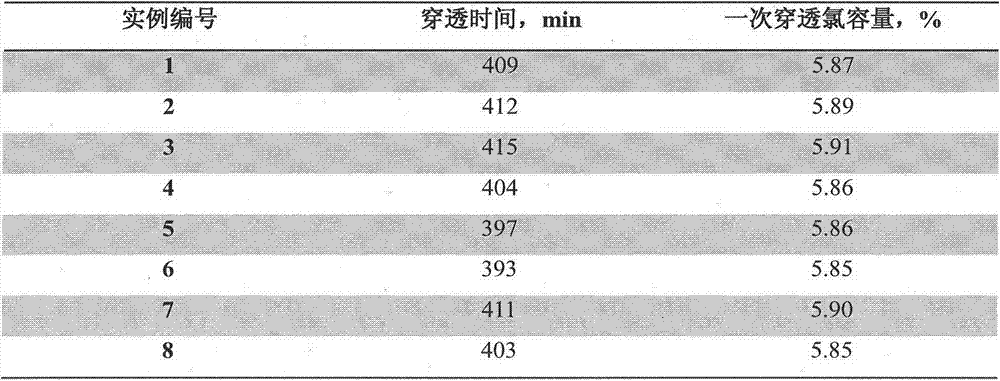

Antichlor for catalytic reforming regenerated gas and preparation method

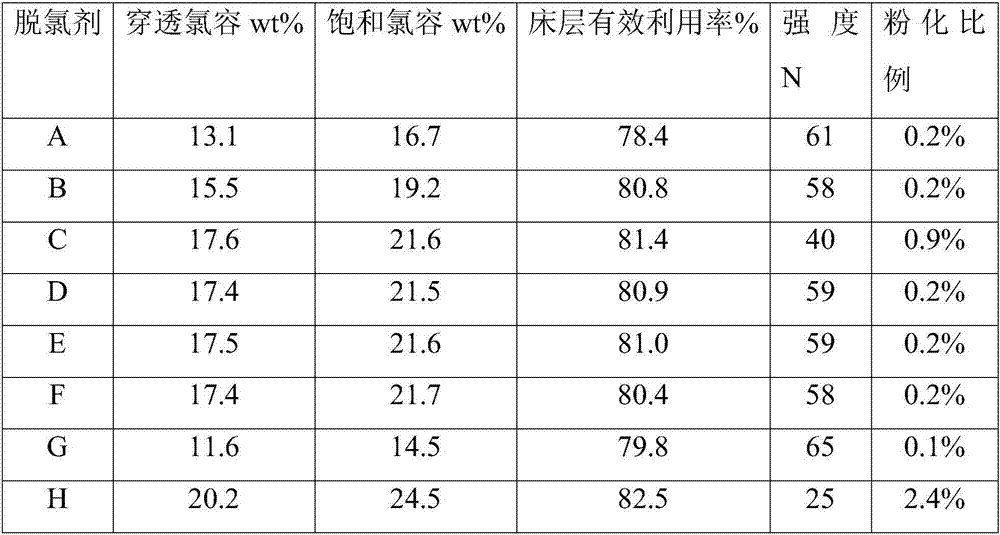

InactiveCN1800310AImprove purification effectHigh chlorine capacityGaseous mixture working upCatalytic reformingAntichlor

The invention discloses a catalytic reforming resurgent gas antichlor and it's preparing method. The antichlor comprises (by weight percent): Ca(OH)2 or CaO 30%-60%, MgCO3 or MgO 20%-30%, K2CO3 or KOH 10%-15%, foraminous zeolite or siallitic soil 5%-15%, alhydrogel powder or silicasol 5%-15%; The total of the raw materials are 100%. The suing range comprises: IFP-I type reforming regeneration craft, IFP- II type reforming regeneration craft, UOP type reforming regeneration craft and other types of reforming regeneration craft.

Owner:XIAN ORIGIN CHEM TECH

Purification technique for producing propylene by refinery plant

InactiveCN101255089ALower production productMeet the requirements of cracking propyleneChemical modification purification/separationSorbentAntichlor

The invention provides a purification process for propone produced in refinery, wherein the raw material is propone produced in refinery, and the process comprises: passing a carbonyl sulfide hydrolytic reactor containing carbonyl sulfide hydrolytic agent therein and a zinc oxide desulfurization reactor containing zinc oxide desulfurization agent therein; passing a fine desulfurization reactor containing fine desulfurization agent therein; passing a dechlorination reactor containing an inorganic antichlor and an organic antichlor; passing a dearsenization and dephosphorization reactor containing dearsenization and dephosphorization agents, passing a de- oxygen-containing and nitrogen-containing compound reactor containing oxygen-containing and nitrogen-containing compound adsorbents therein; obtaining a purified product. The product can take place cracking propone for polymerizing monomer and catalytically synthesizing organic compounds, to increase value of propone produced in refinery, and to expand the application ranges of propone produced in refinery.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for removing chlorine in manganese electrolyte or zinc electrolyte

InactiveCN102839283ASimple processEasy to operatePhotography auxillary processesProcess efficiency improvementElectrolysisDechlorinator

The invention relates to a method for removing chlorine in manganese electrolyte or zinc electrolyte. The method comprises the steps of: adding a certain quantity of bismuth (III)-containing antichlor into chloridion-containing manganese electrolyte or chloridion-containing zinc electrolyte by means of continuous stirring; adjusting the pH value of the solution at 1.0-5.0, so that the trivalent bismuth ions are hydrolyzed to generate insoluble bismuth oxychloride precipitate on the premise of chloridion; filtering, wherein the filter liquor is used for the follow-up electrolysis production technology; and regenerating filter residue bismuth oxychloride precipitate by an alkaline solution to generate bismuth hydroxide for recycling, and timely adding a small quantity of antichlor in the process of recycling to compensate the loss in the process of regeneration.

Owner:JISHOU UNIVERSITY

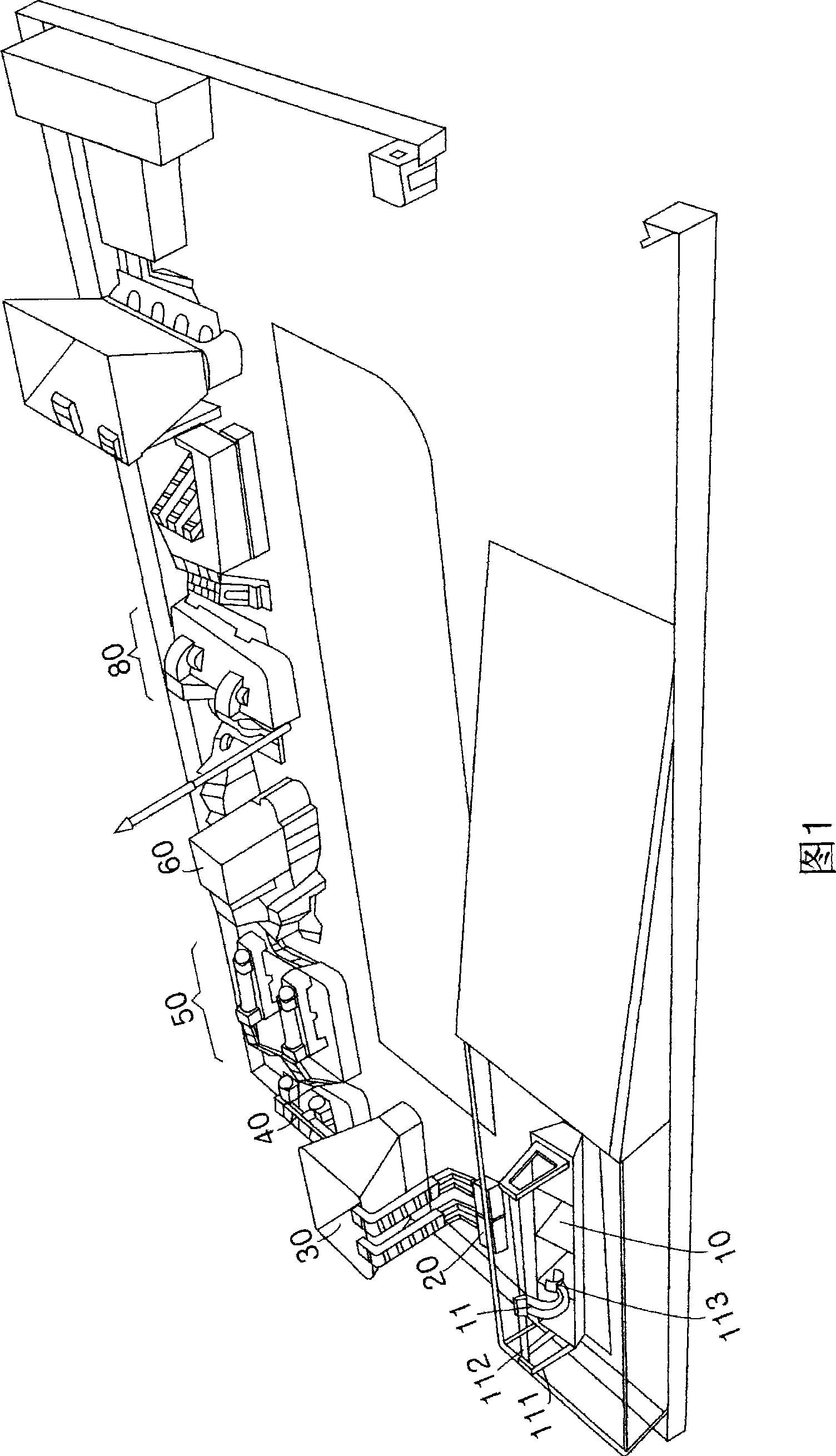

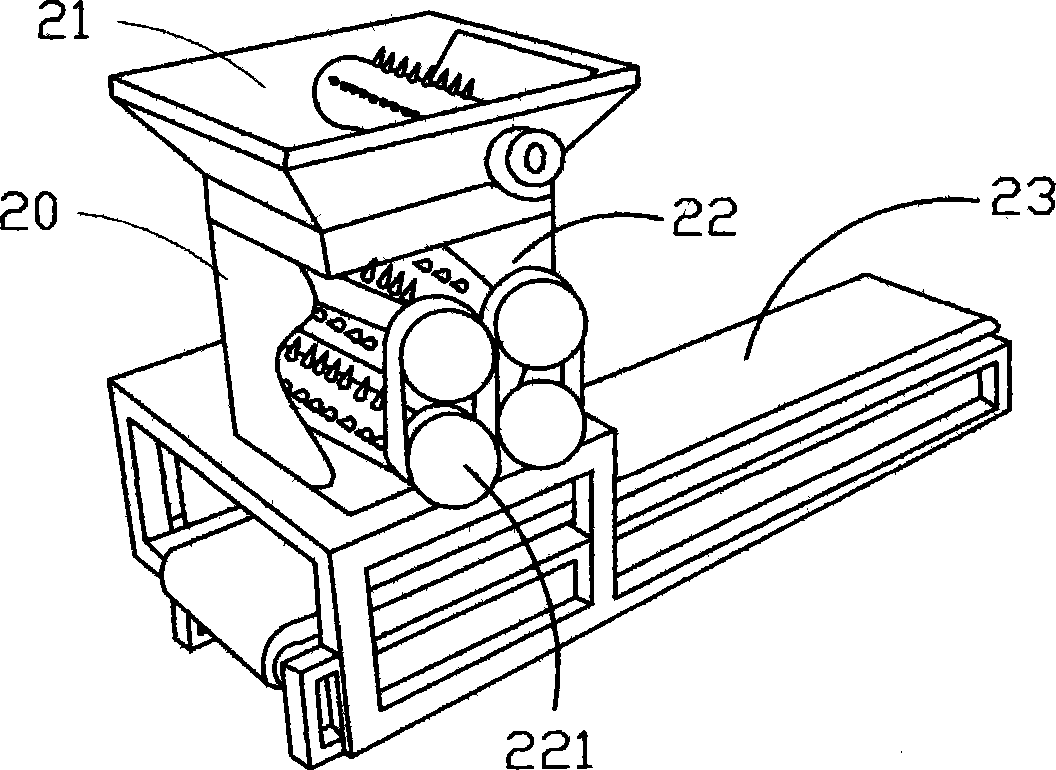

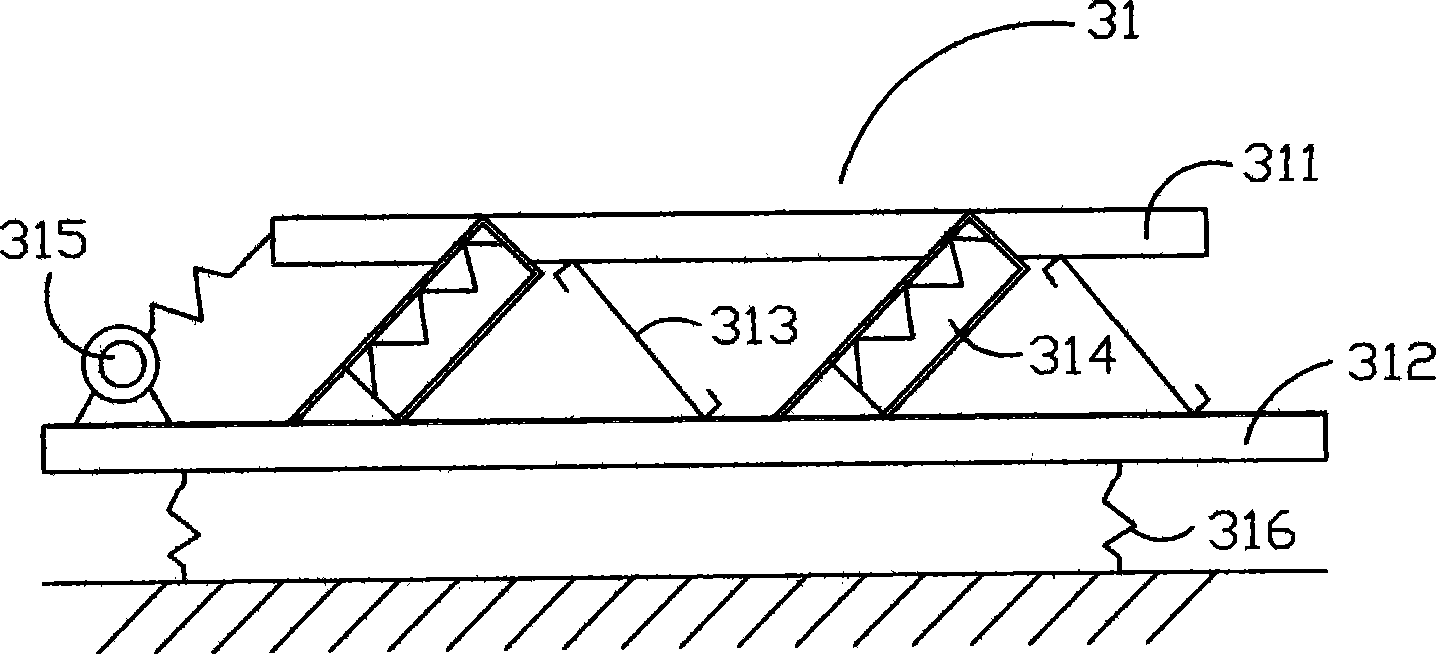

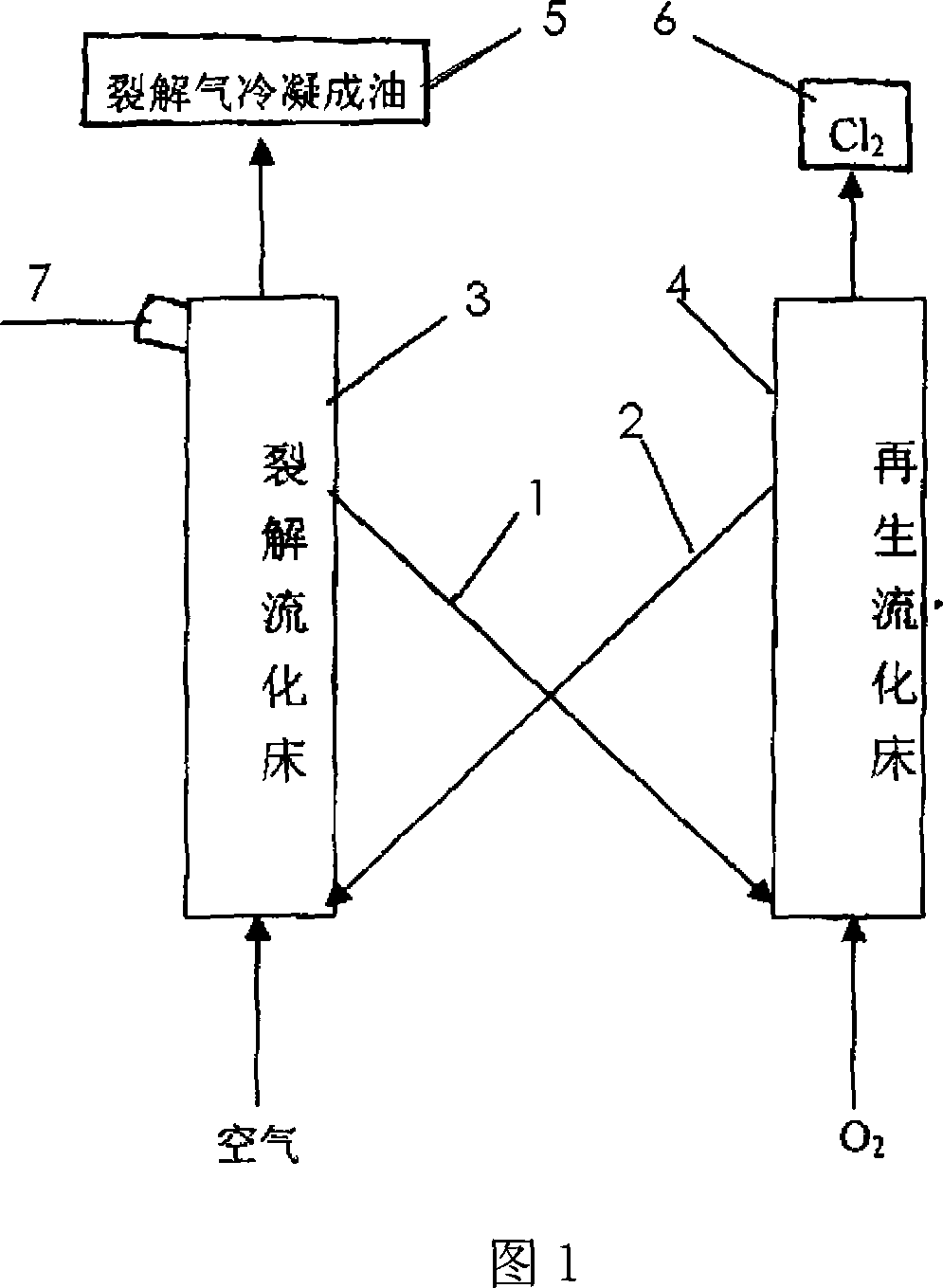

Method for full constituent utilizing resources of wastes of plastic containing chlorine in fluid bed

InactiveCN101050372AEfficient use ofHigh value utilizationLiquid hydrocarbon mixture productionAntichlorFluidized bed

This invention discloses a method for utilizing all components of chloric plastic waste in pyrolysis / regeneration double fluidized beds. The method comprises: removing HCl and pyrolyzing in the pyrolysis fluidized bed, and regenerating antichlor CuO and releasing Cl2 in the regeneration fluidized bed. The two fluidized beds are connected via a connecting pipe, and CuO / CuCl2 are fluidized between the two plastic decomposition, thus can prevent apparatus corrosion and effectively utilize chlorine-free oil product. CuCl2 produced by reaction between HCl and CuO can be regenerated into CuO, and can obtain Cl2 with a high added value.

Owner:TSINGHUA UNIV

Antichlor used for purifying reforming regeneration gas and preparation method of antichlor

ActiveCN105478000AHigh reactivityIncrease acidityGas treatmentDispersed particle separationMass ratioAntichlor

The invention provides an antichlor used for purifying reforming regeneration gas. The antichlor is prepared from, by mass, 85-90wt% of a composite oxide carrier and 10-15wt% of alkaline earth metal oxide. The composite oxide carrier is a mixture formed by Al2O3, SiO2 and ZrO2 at the mass ratio of 80:(80-100):(1-3), the specific surface area of the composite oxide carrier is 310-340 m<2> / g, and the total acid content is 0.31-0.45 mmol / g. According to the antichlor, composite oxide with a specific composition is adopted as the carrier, the total acid content of the carrier can be easily controlled within a proper range so that the bonding force between metal active components and the carrier can be regulated and controlled to be moderate, accordingly, it is guaranteed that the antichlor has both high chlorine capacity and high anti-hardening capability, and thus the antichlor has broad industrialized application prospects.

Owner:SHENYANG SANJUKAITE CATALYST

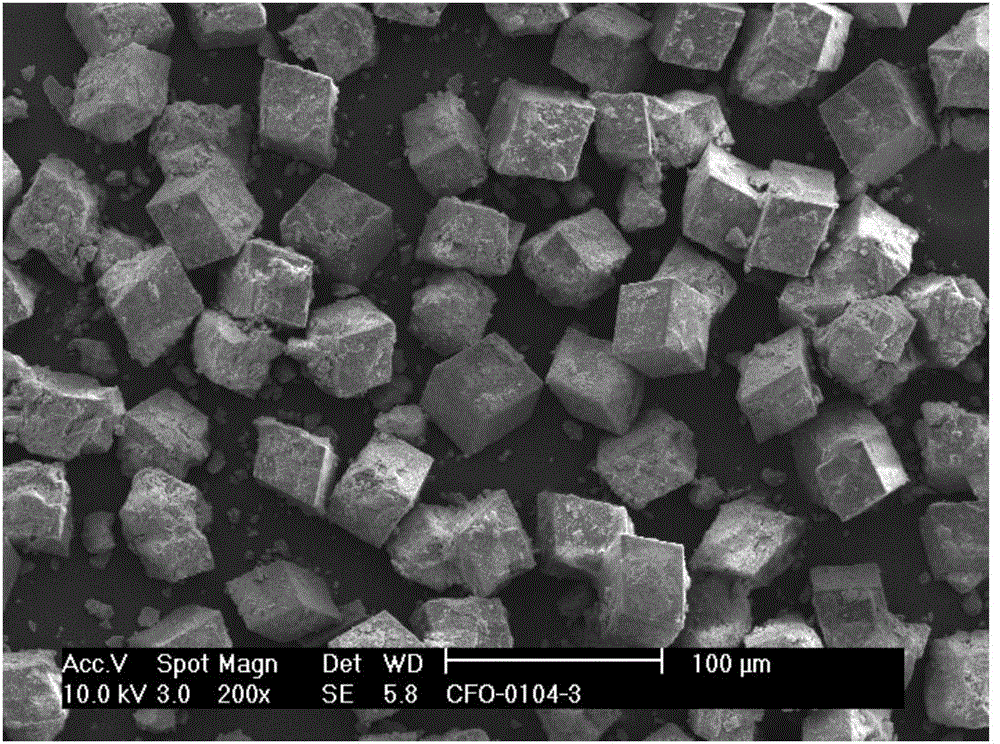

Method for eliminating chloro aromatic hydrocarbon through low-temperature catalytic combustion

InactiveCN103962134ASimple preparation processLow priceIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAntichlor

The invention discloses a method for eliminating chloro aromatic hydrocarbon through low-temperature catalytic combustion. The method comprises the following steps that precious metal-ruthenium is loaded on cerium oxide nanorods, nanocubes and nano regular octahedrons which are used as a carrier to be taken as a catalyst, air used as an oxidizing agent is introduced into a reactor, so that chloro aromatic hydrocarbons are completely combusted in the presence of the catalyst and are converted into carbon dioxide, hydrogen chloride and little chlorine gas, and the completely-combusted tail gas is emptied after being absorbed by dilute alkali solution to remove acid gas such as hydrogen chloride and chlorine gas. The used catalyst has high activity without byproduct generation and secondary pollution, strong chlorine poisoning resistance and long service life, is particularly suitable for eliminating halogen-containing organic compounds through complete low-temperature catalytic combustion, particularly eliminating easily-volatile chloro aromatic hydrocarbon contaminants.

Owner:EAST CHINA UNIV OF SCI & TECH

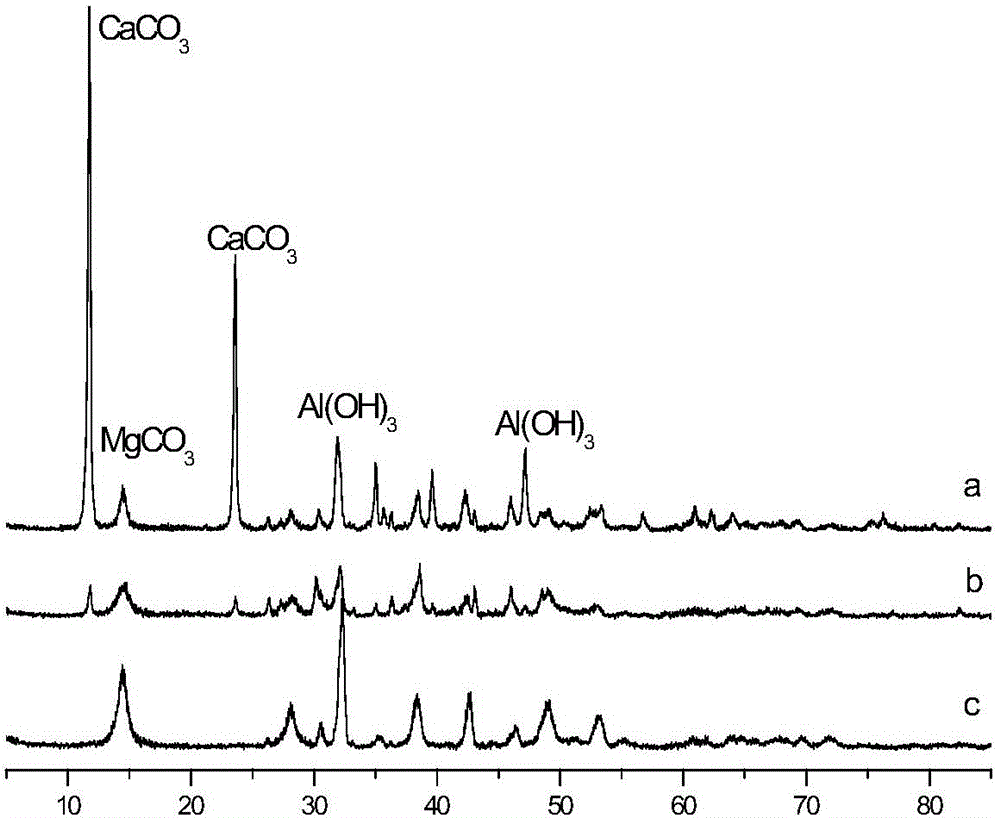

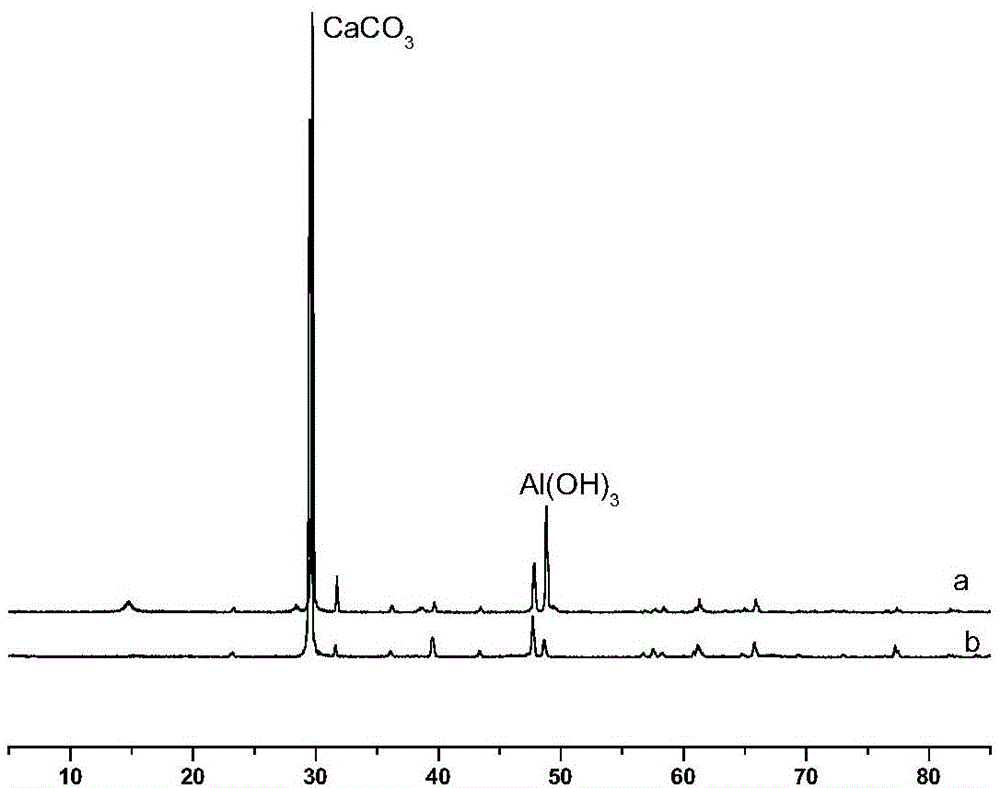

Antichlor and preparation method thereof

ActiveCN106861386ARaise the ratioEvenly dispersedGas treatmentDispersed particle separationAlkaline earth metalOrganic chloride compound

The invention discloses an antichlor and a preparation method thereof. The antichlor uses a composite oxide as a carrier to be loaded with oxides of alkali metal and / or alkaline earth; the composite oxide carrier contains theta aluminum oxide and calcium oxide. The composite oxide carrier is prepared by a coprecipitation method; calcium oxide is introduced into a carrier framework structure; the breakthrough chlorine content can reach 17.6 percent at the normal temperature. Through high-temperature roasting, the prepared aluminum oxide with the theta material phase structure reduces the surface hydroxyl quantity; the physical adsorption of HCl on the antichlor is reduced to the maximum degree; the phenomenon of antichlor surface acidity enhancement due to HCl physical adsorption concentration is reduced, so that the phenomenon of green oil generation through olefin polymerization due to acid catalysis is reduced; the phenomenon of organic chloride generation through reaction of olefin and HCl due to acid catalysis can be avoided. In addition, through the prepared composite oxide carrier, the intensity of the antichlor is obviously improved; the agglomeration or pulverization phenomenon under the water-containing steam work condition can be eliminated.

Owner:WANHUA CHEM GRP CO LTD

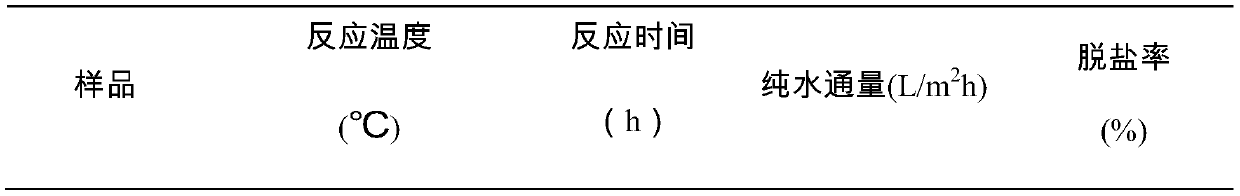

Liquid-phase antichlor and preparation method and application thereof

ActiveCN105749855AStable structureImprove structural stabilityOther chemical processesRefining with metal oxidesAntichlorHigh pressure

Liquid-phase antichlor is formed by a composite crystal structure comprising an active component and an auxiliary component.The active component is at least one of magnesium oxide, calcium oxide, magnesium carbonate and calcium carbonate.The auxiliary component is alumina or iron oxide.A preparation method of the liquid-phase antichlor includes the steps of a, preparing active component precursor, auxiliary component precursor and precipitator into reaction mixture; b, placing the mixture obtained in the step a into a high-pressure kettle, and stirring for crystallization for 3-8 hours under 130-190 DEG C in a sealed manner; c, filtering, washing, drying and forming the reaction products obtained in the step b; d, calcining the formed material obtained in the step c to obtain the finished antichlor.

Owner:PETROCHINA CO LTD

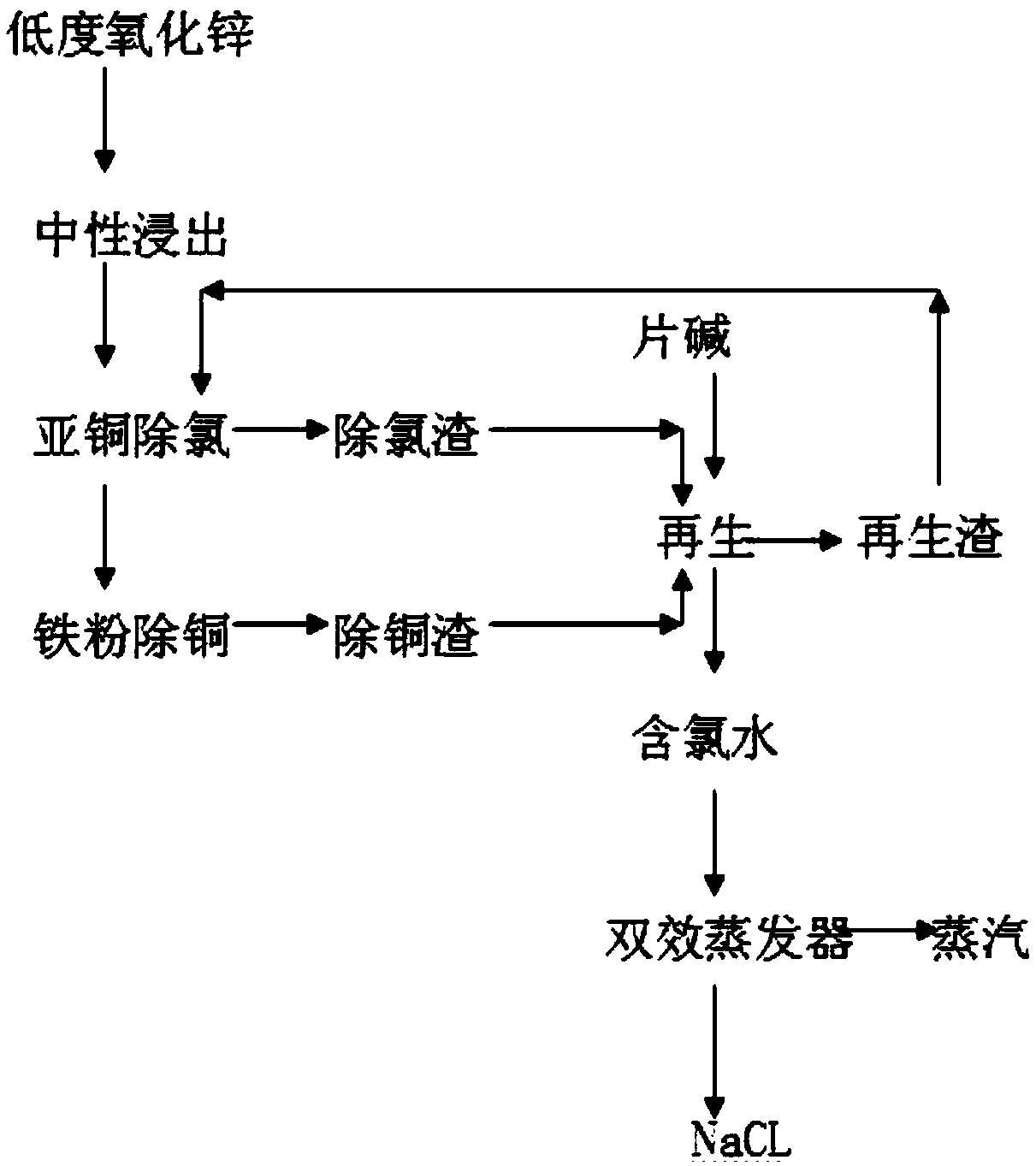

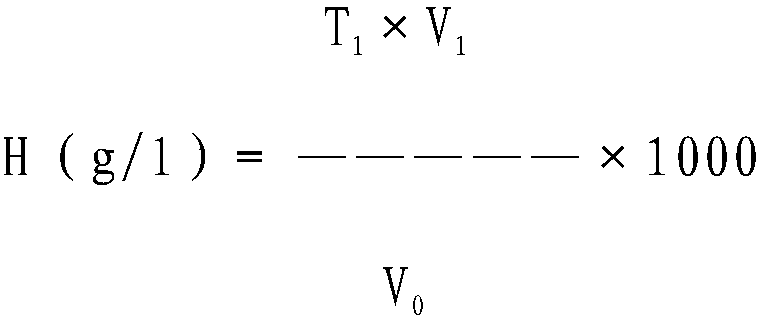

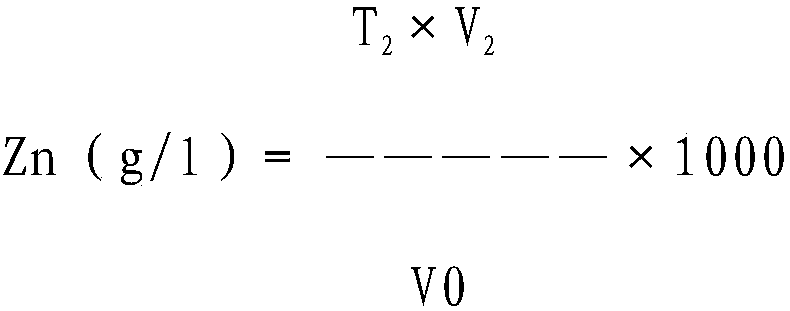

Zinc electrolyte dechlorination method

ActiveCN108300859AReduce chlorine contentIncrease costPhotography auxillary processesProcess efficiency improvementIon contentAntichlor

The invention discloses a zinc electrolyte dechlorination method. The zinc electrolyte dechlorination method includes the specific steps that low grade zinc oxide is subject to neutral leaching, thena leaching agent containing chlorine is injected into a dechlorination tank to be stirred, an antichlor, namely cuprous oxide is added in the stirring process, then industrial sulphuric acid is added,and dechlorination slag and dechlorination liquid are obtained; sampling is carried out for analysis of the copper content, iron powder is added according to the copper content, stirring is carried out while the iron powder is added, stirring lasts for 30 min-40 min, analysis of the copper content is carried out, filter pressing is carried out when the copper ion content is smaller than 0.1 g / L,and copper removal slag is obtained; the dechlorination slag and the copper removal slag are added into a reaction tank, then regenerated liquid is added, caustic soda flakes are added, the Ph is adjusted, a reaction is made for 3 h-4 h, and regenerated slag and a sodium chloride solution are obtained; and high chlorine water is added into the obtained sodium chloride solution, evaporation and concentration are firstly carried out to enable the high chlorine water to be close to a crystallization point of a sodium chloride, then cooling crystallization is carried out, sodium chloride powder and mother liquor are obtained through a separating machine, and the regenerated slag can be recycled. The zinc electrolyte dechlorination method has the advantages of being low in cost, high in efficiency, free of waste water, free of waste slag and free of waste gas.

Owner:岷山环能高科股份公司

High temperature antichlor and preparation method thereof

ActiveCN103041769AHigh adsorption activityImprove thermal stabilityOther chemical processesDispersed particle separationActive componentAntichlor

The invention discloses a high temperature antichlor and a preparation method thereof. The antichlor comprises one or more of Ca(NO3)2, Ca(OH)2, Mg(NO3)2, Cu(NO3)2 and Zn(NO3)2, aluminum salt of Al(NO3)3 or Al(OH)3, and 20-47% of clay taking Al2Si2O5(OH)4 as a primary component, wherein the one or more of Ca(NO3)2, Ca(OH)2, Mg(NO3)2, Cu(NO3)2 and Zn(NO3)2 is or are taken as active component or active components and the aluminum salt of Al(NO3)3 or Al(OH)3 is taken as a carrier and an additive. The invention further discloses the preparation method for the high temperature antichlor, and the preparation method comprises the steps of uniformly mixing the materials, adding into a reaction kettle for dissolving, rotating, heating, filtering, washing and drying, roasting, forming and pelletizing the obtained solid to obtain the high temperature antichlor. The prepared antichlor can be used for efficiently and deeply removing chlorine gas in smoke at the temperature of 723-1023 K DEG C, and the chlorine penetration capacity reaches more than 60%.

Owner:SOUTHEAST UNIV

Preparation and application method of oil antichlor

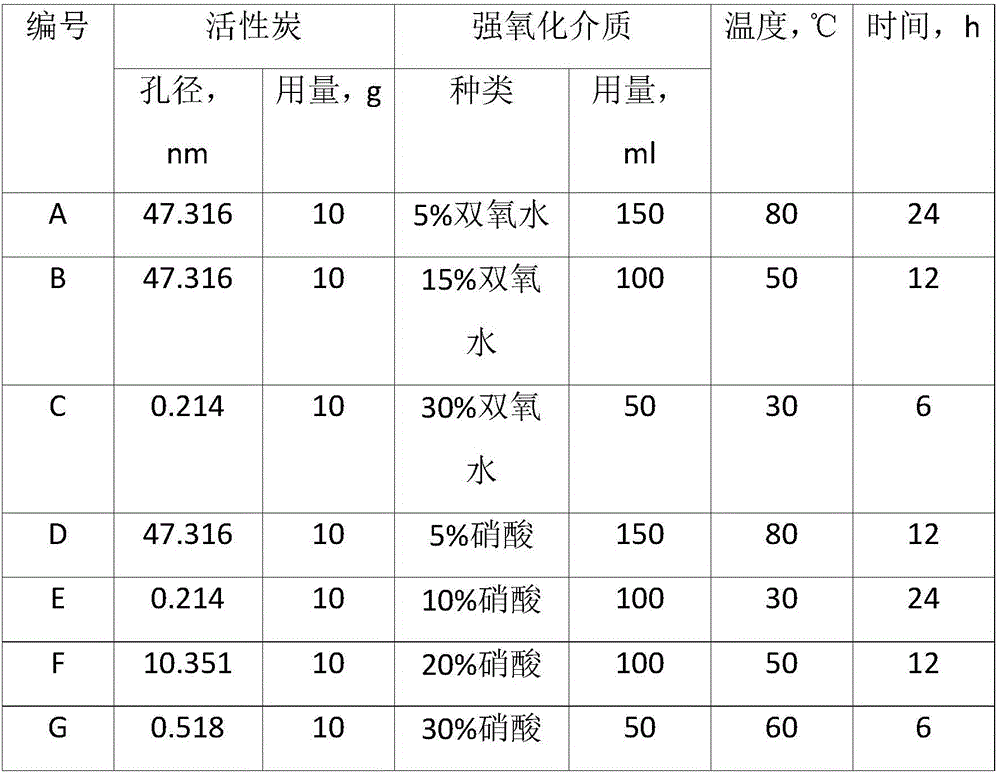

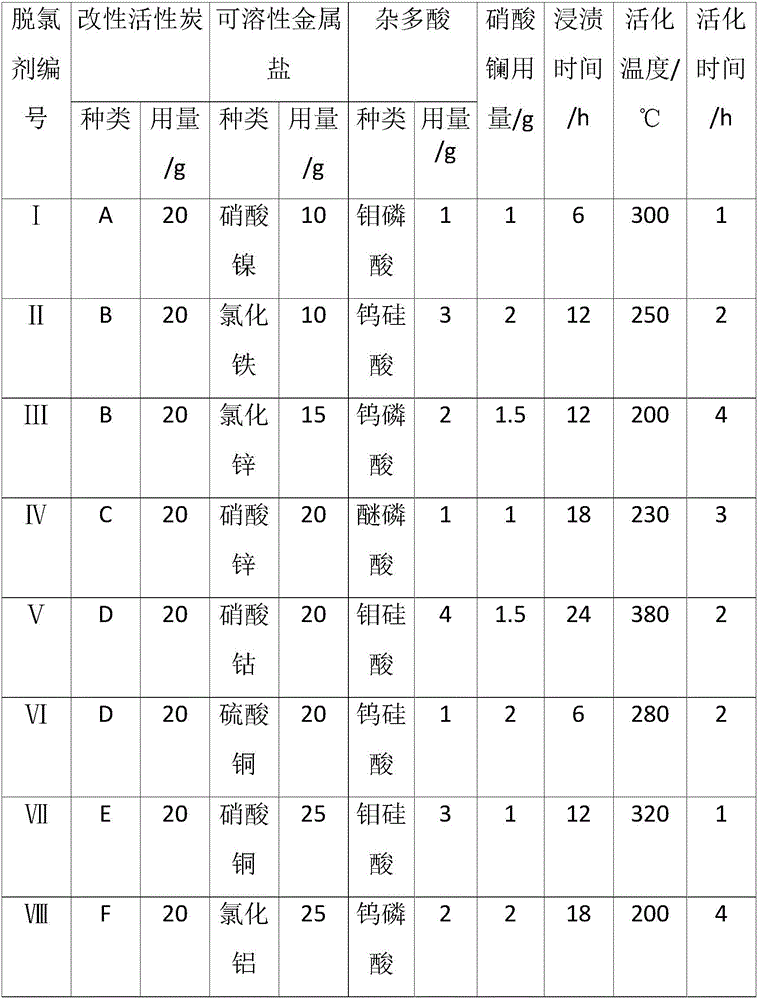

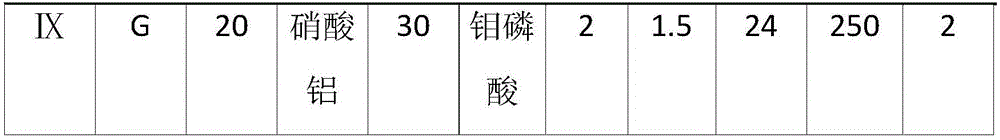

ActiveCN106554802ALarge specific surface areaRaw materials are easy to getRefining with non-metalsHydrocarbon oils treatmentActivated carbonOrganic chloride compound

The invention relates to a preparation and application method of an oil antichlor. Firstly, active carbon is added in a strong oxidant medium for oxidization modification to obtain modified active carbon, then, a mixed solution of soluble metal salt and other auxiliary agents is used for loading, and finally the loaded modified active carbon is dried and activated in a protective atmosphere or vacuum to obtain the antichlor product. The antichlor is excellent in selective adsorption and stability and good in dechlorination effect. In a mild condition, through the antichlor, an organic chloride in an oil product can be reduced to 0.2 ppm.

Owner:CESTOIL IND SERVICES SHENZHEN CO LTD +1

Method for manufacturing strontium ferrite rubber plastic magnetic powder with low chlorine content

InactiveCN101830693AReduce chlorine contentReduce churnInorganic material magnetismLoss rateStrontium carbonate

The invention relates to method for manufacturing strontium ferrite rubber plastic magnetic powder with low chlorine content, comprising the steps of: (1) taking 50-76% of iron ore concentrate powder, 10-30% of iron oxide red, 12-16% of strontium carbonate, 0-2% of calcium carbonate and 2-6% of strontium chloride for evenly mixing, and preparing into 7-15mm small balls; (2) presintering the small balls at 1100-1260 DEG C, carrying out heat preservation for 1-4h, cooling to the room temperature, and grinding into coarse powder of 4-8 microns; (3) adding antichlor with the weight accounting for 1-20% of the total weight of the coarse powder, grinding into power of 2-3 microns, stirring and cleaning the powder by water for 10-20min, and standing still; after the powder precipitates, removing the water at the upper layer; and finally, drying the precipitate at 180-400 DEG C, sieving at 70-80 meshes, and obtaining the strontium ferrite rubber plastic magnetic powder. The method combines dechlorination and crushing into grinding working procedure, reduces the chlorine content to 178ppm, saves the water consumption, and has the characteristics of simplifying the technique, being coarse in magnetic powder granularity, good processing performance, high magnetic property and low loss rate of magnetic powder.

Owner:MAGNETIC MATERIAL FACTORY MEIZHOU CITY GUANGDONG PROV

Method for reducing organic chloride content of hydrocarbon fuel oil

InactiveCN103484155AEfficient removalMild reaction conditionsTreatment with plural serial refining stagesHigh concentrationAntichlor

The invention discloses a method for reducing the organic chloride content of hydrocarbon fuel oil. The method comprises the following steps: step 1: carrying out dechlorination reaction; adding a dechlorinating agent and a resolvent into the hydrocarbon fuel oil according to a certain ratio; step 2: separating and purifying: performing atmospheric distillation on mixture after reaction and obtaining a fraction through collecting, namely a product with low chlorine content. Compared with the conventional antichlor, the antichlor used in the invention can effectively remove high-concentration organic chlorine compound in the hydrocarbon fuel oil. The reaction conditions are more moderate, and dechlorination reaction can be performed at a temperature below 110 DEG C, and can be achieved through common equipment. The operation process is simple. A stirring and heating device and a distillation separating device are mainly included, not only is the expansion easy, but also the investment cost is lowered to a greater degree. In addition, the raw material used in the invention adopts the hydrocarbon fuel oil not hydrochloric ether for replacement, so that the method provided by the invention is a representative for evaluation of the dechlorinating effect on the hydrocarbon fuel oil with higher organic chloride content.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preparing novel catalytic reduction dechlorinating agent

InactiveCN101147864AImprove dechlorination effectMetal/metal-oxides/metal-hydroxide catalystsAntichlorAlloy

The present invention provides a method for preparing new-type catalytic reduction antichlor. It is a method for preparing nano Ni-Fe dimetal composite catalytic reduction antichlor. It is characterized by that said antichlor can form NiB amorphous alloy cluster on the nano ferric oxide surface so as to raise antichloration property of ferric oxide.

Owner:NANKAI UNIV

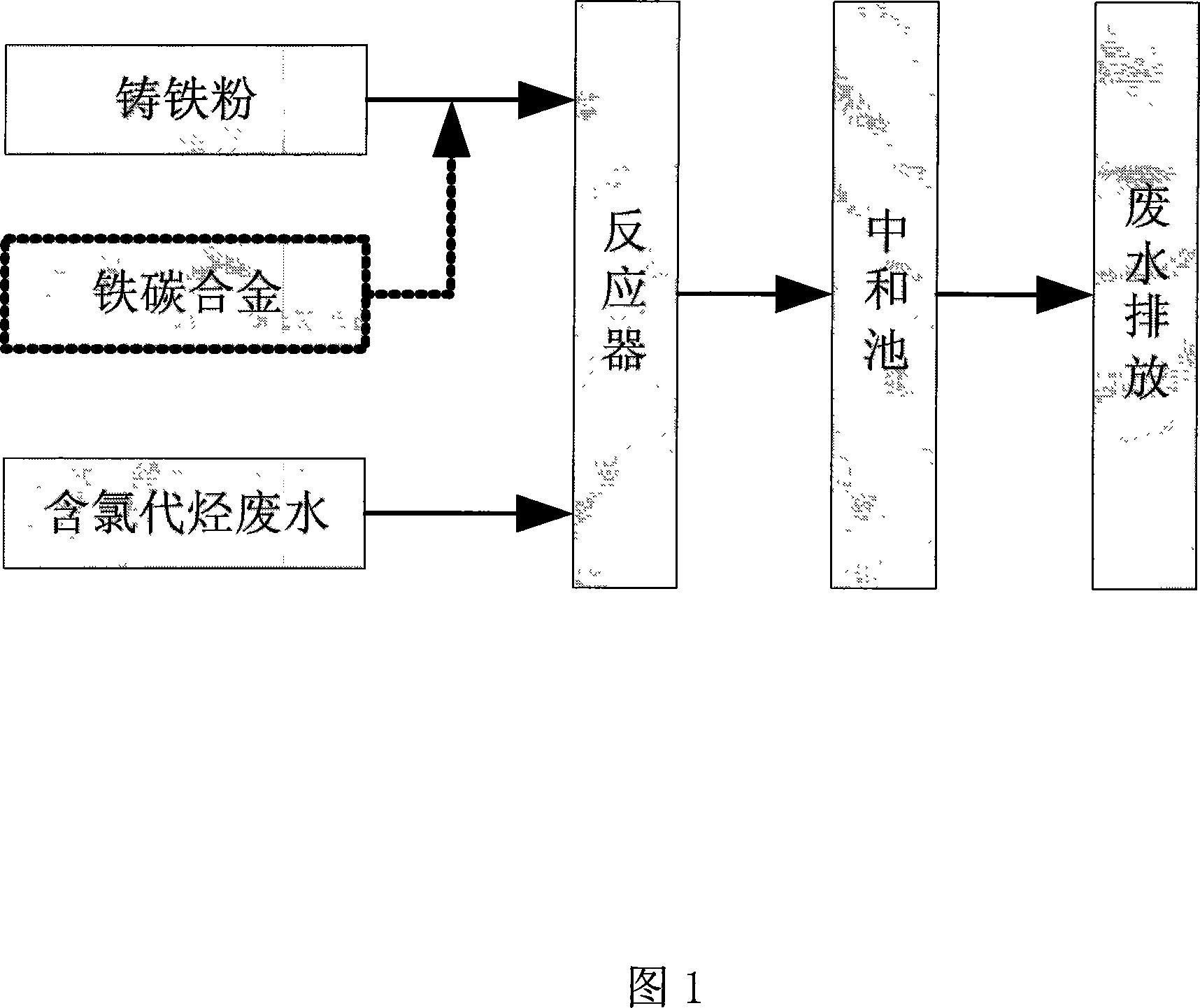

Antichloration of hydrocarbon chloride in waste water

InactiveCN101074133AEfficient dechlorinationWater contaminantsWater/sewage treatment by neutralisationIndustrial waste waterAntichlor

De-chlorination for chloro-hydrocarbon in industrial waste water is carried out by taking cast-iron powder or ferric-carbon alloy as antichlor, putting antichlor into reactor containing chloro-hydrocarbon industrial waste water, regulating reactive mixture pH between 1-5, reacting fully above 3 hrs at normal temperature and pressure, entering reacted waste water into neutralization pool, adding into base while neutralizing, flocculating while depositing, anti-chlorinating and discharging. The chloro-hydrocarbon to be treated includes methylene chloride, chloroform, carbon tetrachloride, vinyl chloride, tri-chloroethylene, carbon dichloride, chloro-fatty hydrocarbon and chloro-aryl radical.

Owner:ZHEJIANG QUHUA FLUOR CHEM +1

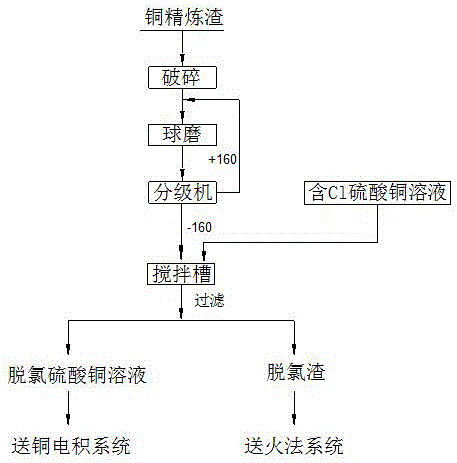

Method for removing chlorine in copper sulfate solution by copper refining slag

The invention discloses a method for removing chlorine in a copper sulfate solution by copper refining slag. The method for removing the chlorine in the copper sulfate solution by the copper refining slag comprises the following steps that the copper refining slag is smashed, ball-milled to a certain particle size, and then added into the copper sulfate solution containing the chlorine; and sub copper and chlorine ions in the copper refining slag are formed into cuprous chloride which is insoluble in acid, and after the cuprous chloride is filtered by a plate-and-frame press filter, a low chloride copper sulfate solution is obtained. The method can be widely used for removing the chlorine ions of all kinds of concentrations in the copper sulfate solution, the steps are easy, and operation is simple and convenient; the sources of antichlor are wide, production cost is low, secondary pollution is not generated in the whole production process, and chlorine removing slag can be returned to conduct fire melting to extract copper.

Owner:江西自立环保科技有限公司

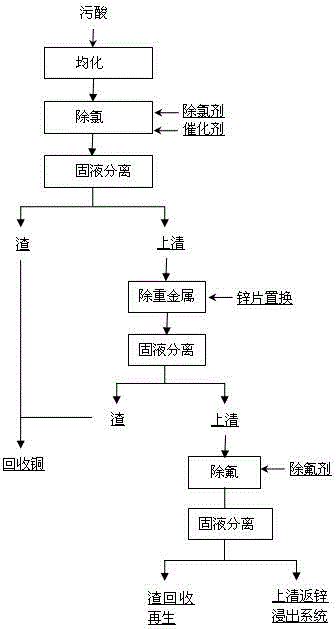

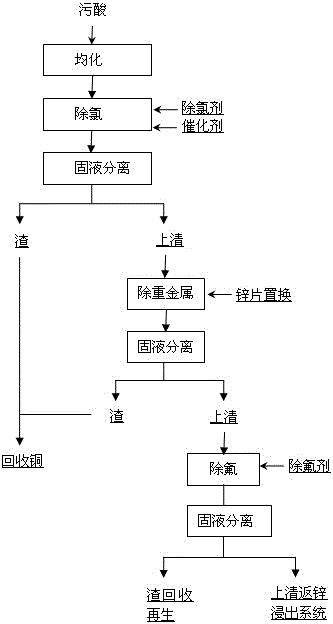

Novel method for purifying and repeatedly using lead and zinc smelting flue gas washing contaminated acid wastewater

ActiveCN104787927AReduce usageImprove resource recyclingMultistage water/sewage treatmentThree levelPregnant leach solution

The invention relates to a novel method for repeatedly using a lead and zinc smelting flue gas washing contaminated acid wastewater, subjected to removal of harmful elements such as fluorine, chlorine, arsenic and mercury through three-level purification treatment, by being directly returned to a zinc leaching related process. The novel method comprises the following steps: conducting dechlorination on the contaminated acid through an antichlor at normal temperature and normal pressure, displacing the filtrate through a zinc plate, conducting solid-liquid separation on the generated metal replacement, and finally repeatedly using the wastewater, subjected to the fluorine removal agent treatment to meet the leachate reuse requirements of the related zinc leaching related process, by being returned to the zinc leaching system. The novel method has the advantages that the production cost is low, the process is short, the resource recycling utilization rate is high, the energy consumption is low, waste is used to treat waste, and the environmental pollution is less.

Owner:湖南株冶环保科技有限公司

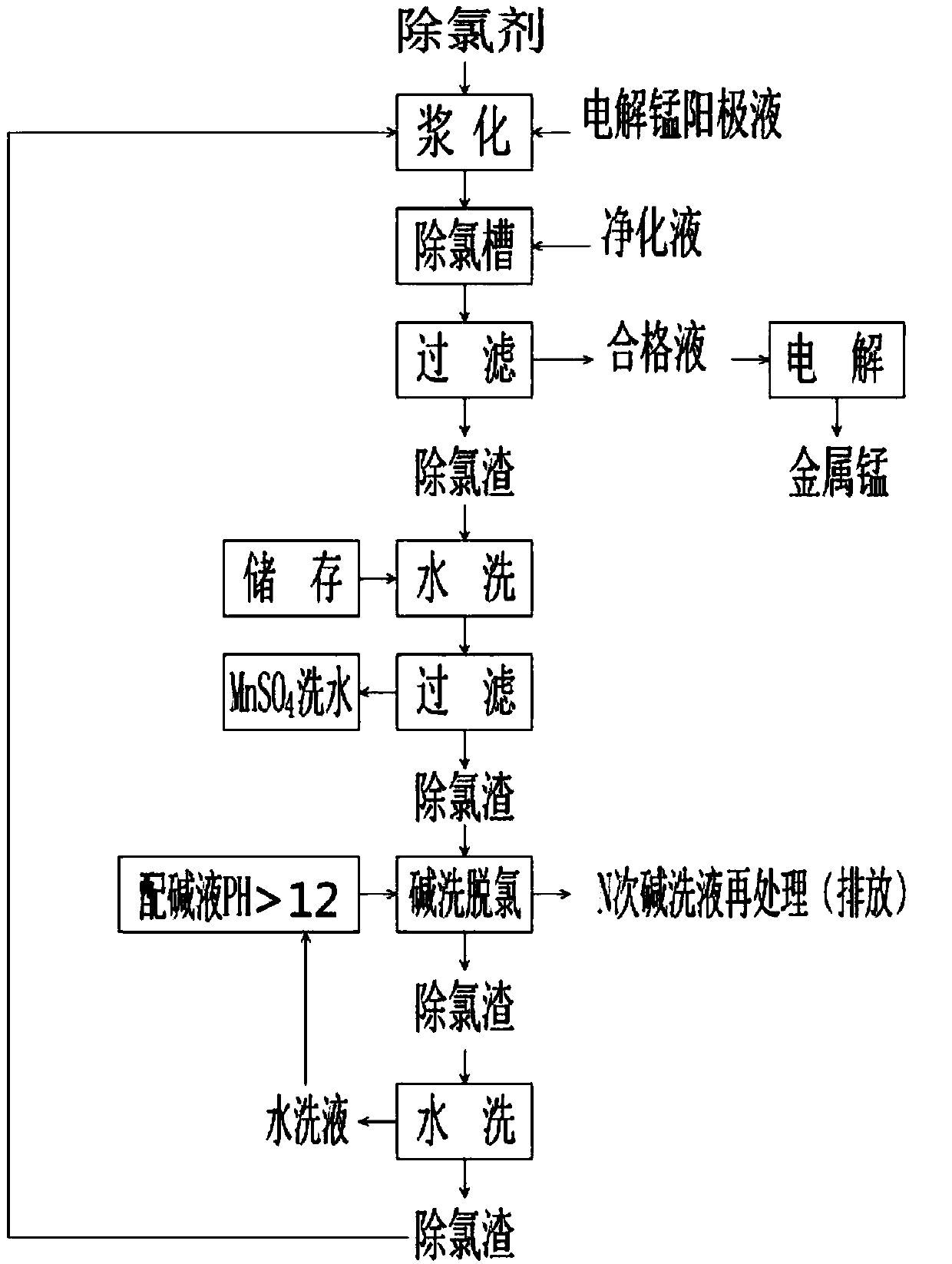

Method for removing chloride ions in electrolytic manganese solution

InactiveCN107630147AImpurities will not increaseSmall amount of chlorine slag removalProcess efficiency improvementElectrolysisSlag

The invention discloses a method for removing chloride ions in an electrolytic manganese solution. An R-Bi2O3 antichlor is added in an electrolytic manganese anode solution with the sulfur acid content being 30-40 g / l, stirring is conducted for 20-30 min, slurrying is conducted, slurry is added in a to-be-treated electrolytic manganese solution, and after sufficient stirring is conducted for 40-60min at the temperature ranging from 40 DEG C to 60 DEG C and with the stirring rate being 60 r / min, filtering is conducted; filter liquor is injected into a qualified liquid system, and metal manganese is obtained through electrolysis; R in the R-Bi2O3 antichlor is silicon dioxide and manganese oxide, and the adding mass of the R-Bi2O3 antichlor is 10-15 times of the mass of the chloride ions inthe electrolytic manganese solution; and removed filter slag is sequentially subjected to washing and filtering, the removed chloride slag is subjected to alkaline washing for dissolving and dechlorinating through alkaline liquor, filtering is conducted, the filter slag obtained after filtering is sequentially washed and filtered and then is added in a chloride slag removing acidification tank tobe recycled. By means of the method, chloride can be effectively and rapidly removed, the antichlor can be circularly reutilized, and cost is low.

Owner:曹德忠

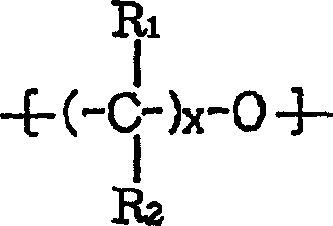

Polyacetal resin composition stable to chlorine and chlorides and arcicle prepared therefrom

Disclosed is a polyacetal resin composition stable to chlorine and chlorides, which is advantageous in terms of excellent thermal stability and chlorine resistance. The polyacetal resin composition consist of 100 parts by weight of polyoxymethylene or a copolymer thereof; 0.01-1.0 part by weight of an antioxidant; 0.01-1.0 part by weight of a thermal stabilizer; 0.01-10.0 parts by weight of metal hydroxide selected from among magnesium hydroxide, calcium hydroxide, barium hydroxide, cadmium hydroxide, aluminum hydroxide and combinations thereof; and 0.01-5.0 parts by weight of metal oxide selected from synthetic aluminum silicate, calcium oxide, magnesium oxide, aluminum oxide and magnesium aluminate. An article prepared from such a polyacetal resin composition is also disclosed.

Owner:KOREA ENG PLASTICS CO LTD

Antichlor for degrading organochloride and preparation thereof

The invention relates to a dechlorination agent for degrading an organic chloride, in particular to the dechlorination agent with active ingredients of coexisting zero-valent iron and composition metal oxide and a method for the production thereof, the preparation process comprises the preparation of a hydrotalcite-like material and the preparation of a composition metal oxide as well as a dechlorination implementing method. The hydrotalcite-like material has the chemical formula of: [M<2+>(1-x)M<3+>(x(OH)2]A(x / n)*mH2O, where the M<2+> can be a divalent metal ion such as Mg<2+>, Zn<2+> or Ni<2+>, the M<3+> is a trivalent metal ion such as Al<3+>, Cr<3+> or Fe<3+>, and the x is 0.2<=x<=0.4, A represents the interlayer anion such as CO3<2->, NO3<-> or Cl<->. The obtained hydrotalcite is positioned in a muffle furnace for being calcined for two to five hours at a temperature of between 250 and 600 DEG C so as to obtain the demanded composition metal oxide. The iron powder and composition metal oxide are positioned in an organic chlorides solution of between 10ppm and 800mg / L in a mass ratio of 10-25: 0.4-1, the constant temperature is maintained at 25 to 80 DEG C, the vibration is kept for two to eight hours at a rate from 200 to 800r / min, and the dechlorination rate reaches 70 percent to 98 percent. The dechlorination agent has advantages of high efficiency, low cost, non-toxicity and easy preparation, and can be used for degrading various organic chlorides.

Owner:BEIJING UNIV OF CHEM TECH

A kind of usage method of blast furnace gas dechlorination agent

ActiveCN104774654BLow priceDispersed particle separationGas purification with selectively adsorptive solidsAntichlorPotassium hydroxide

The invention provides an application method of a blast-furnace gas antichlor. The antichlor is mainly composed of cheap industrial limestone, commercial sodium carbonate, and potassium hydroxide. The formula and preparation technology of the antichlor are optimized. A disc balling machine is used to produce the antichlor balls. A fixed bed reactor is used to remove the HCl gas. If the HCl in blast-furnace gas reaches 1 ppm after the reactions, the antichlor is disabled. The provided application method of blast-furnace gas antichlor is developed according to the characteristics of a blast furnace iron smelting technology and equipment thereof.

Owner:HEBEI TIANZHU IRON & STEEL GRP CO LTD

A kind of lead and zinc smelting flue gas washing polluted acid wastewater purification and reuse method

ActiveCN104787927BReduce usageImprove resource recyclingMultistage water/sewage treatmentThree levelAntichlor

The invention relates to a novel method for repeatedly using a lead and zinc smelting flue gas washing contaminated acid wastewater, subjected to removal of harmful elements such as fluorine, chlorine, arsenic and mercury through three-level purification treatment, by being directly returned to a zinc leaching related process. The novel method comprises the following steps: conducting dechlorination on the contaminated acid through an antichlor at normal temperature and normal pressure, displacing the filtrate through a zinc plate, conducting solid-liquid separation on the generated metal replacement, and finally repeatedly using the wastewater, subjected to the fluorine removal agent treatment to meet the leachate reuse requirements of the related zinc leaching related process, by being returned to the zinc leaching system. The novel method has the advantages that the production cost is low, the process is short, the resource recycling utilization rate is high, the energy consumption is low, waste is used to treat waste, and the environmental pollution is less.

Owner:湖南株冶环保科技有限公司

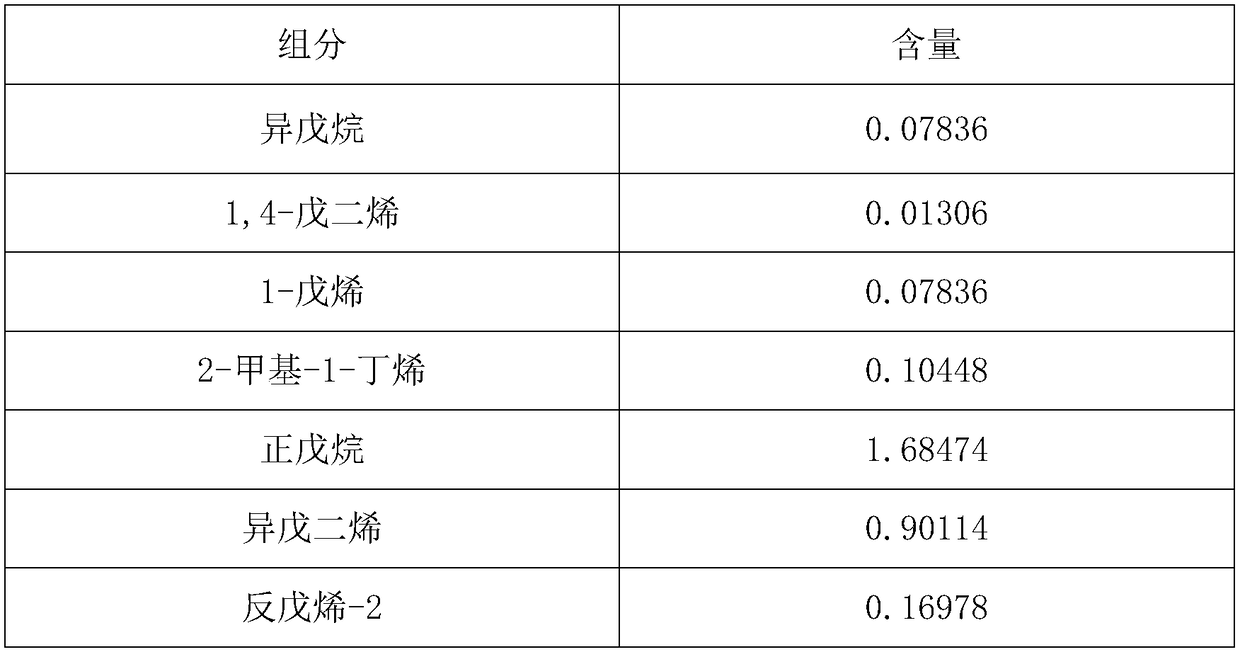

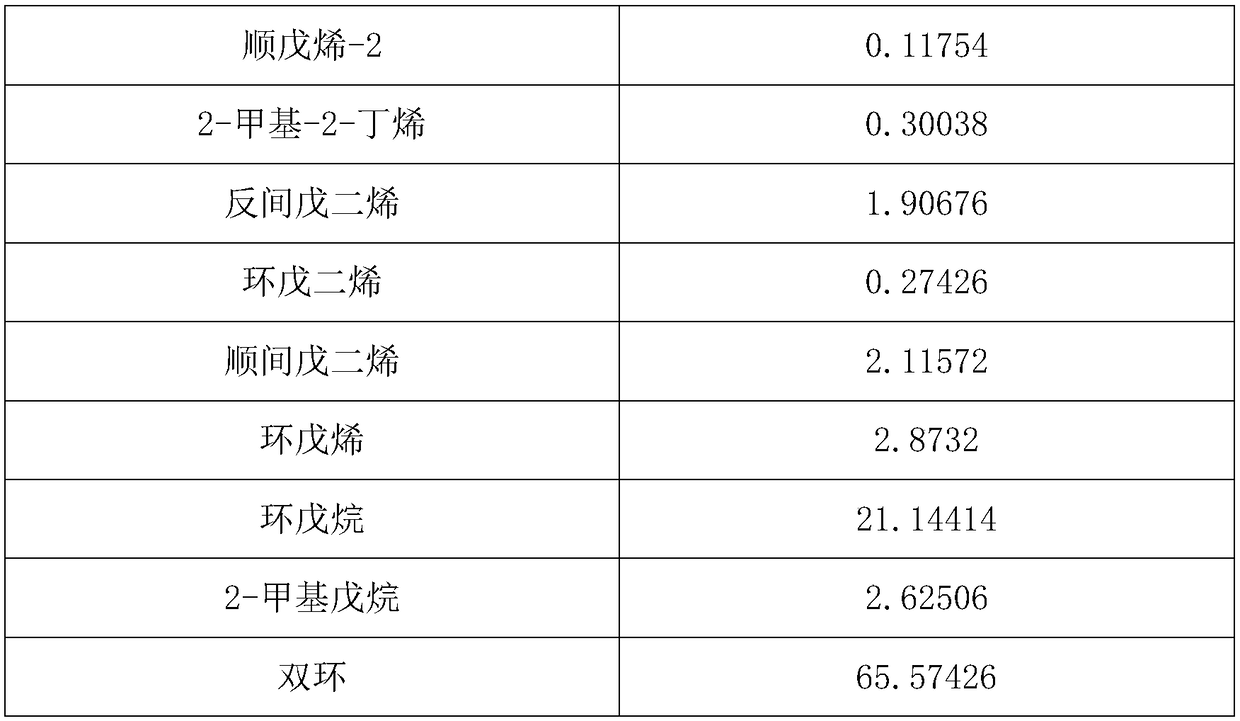

Composite antichlor as well as preparation and use method thereof

The invention provides a composite antichlor as well as a preparation and use method thereof. The composite antichlor comprises the following raw materials in parts by weight: 5-10 parts of sodium methylate, 25-35 parts of methanol, 5-10 parts of sodium hydroxide, 10-20 parts of sodium ethoxide, 10-15 parts of triethanolamine, 15-25 parts of phenylamine, 10-15 parts of triethylamine and 20-25 parts of diethylamine. The preparation method of the composite antichlor comprises the following steps: weighing raw materials, and stirring the raw materials in a reaction kettle, so as to obtain the composite antichlor. The use method of the composite antichlor comprises the following steps: putting a chlorine-containing material into the stirring reaction kettle with the composite antichlor, carrying out a reaction, and further carrying out separation. The composite antichlor provided by the invention is reasonable in formula, low in preparation cost, good in dechloridation effect, low in byproduct quantity, small in toxicity, not liable to volatilization, not liable to combusting and safe to use, chlorine in a C5 resin can be effectively desorbed, additional values of products can be increased, and later process operation can be facilitated.

Owner:濮阳市联众兴业化工有限公司

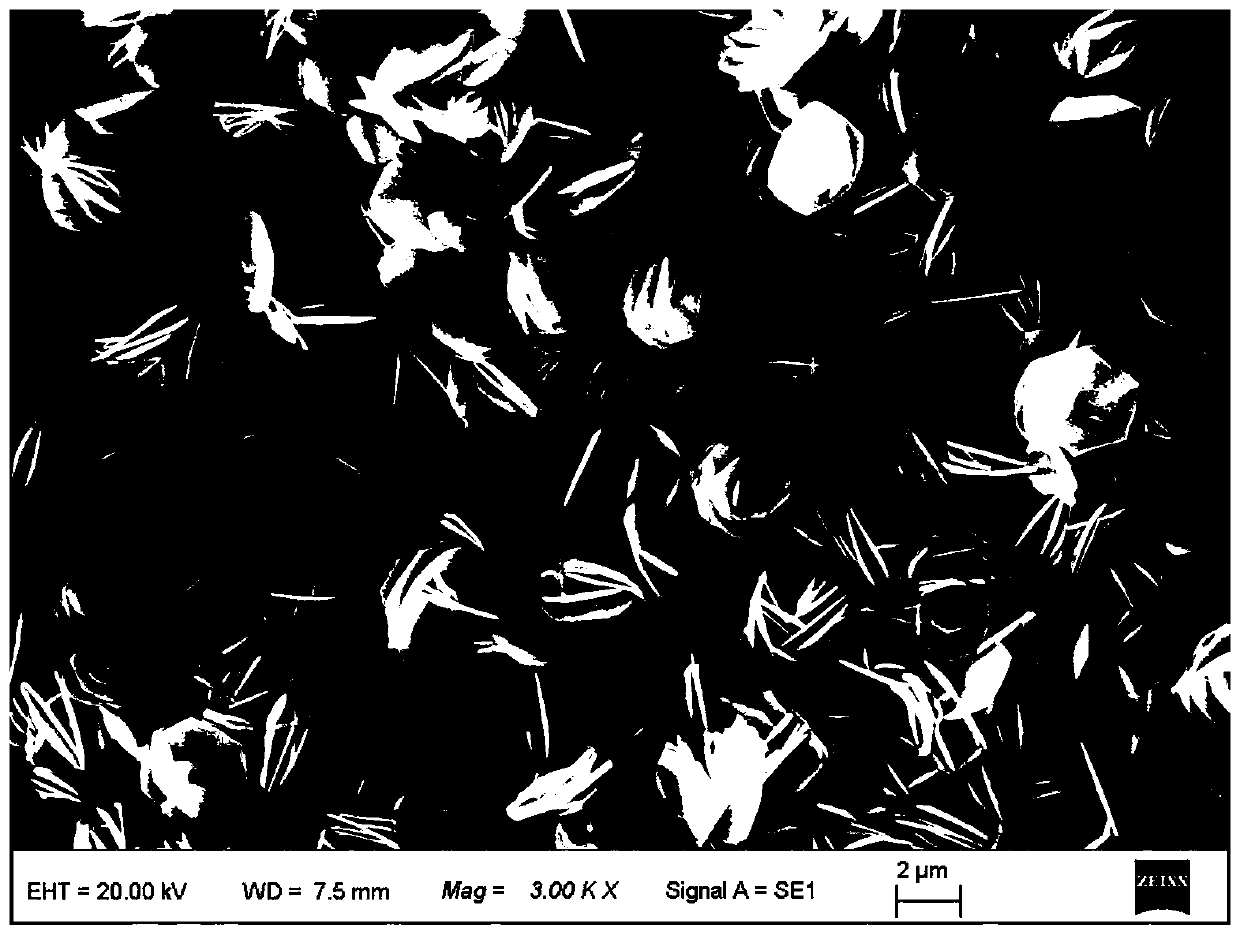

A kind of layered double metal hydroxide composite nanofiltration membrane and preparation method thereof

The invention provides a layered double hydroxide composite nano-filtration membrane and a preparation method thereof, and relates to the technical field of membranes. The composite nano-filtration membrane is obtained by modifying to generate a polydopamine functional layer on a base membrane firstly, and then constructing a double hydroxide functional cortex on the surface of a polydopamine-modified membrane in situ. Functional groups of a polydopamine-modified layer can improve the hydrophilcity, the permeability, the selectivity and the anti-pollution performance of the membrane, and can interact with a metal salt precursor, so as to promote the deposition and in-situ growth of the precursor on the surface of the membrane; the double hydroxide layer which is generated in an auxiliary manner is distributed uniformly, has stronger acting force with the base membrane, and is beneficial to the stability of the performance of the membrane. The construction of the double hydroxide functional cortex can be regulated and controlled effectively, which is beneficial to improving the water flux, the hydrophilcity and the chlorine resistance of the membrane. The overall preparation processhas the advantages of mild conditions and convenient operation; the composite nano-filtration membrane with excellent comprehensive performance is obtained, and has the prospect of industrial production and commercial application.

Owner:XIAMEN UNIV OF TECH

Antichlor for catalytic reforming regenerated gas and preparation method

InactiveCN100453147CImprove purification effectHigh chlorine capacityOther chemical processesDispersed particle separationCatalytic reformingAntichlor

The invention discloses a catalytic reforming resurgent gas antichlor and it's preparing method. The antichlor comprises (by weight percent): Ca(OH)2 or CaO 30%-60%, MgCO3 or MgO 20%-30%, K2CO3 or KOH 10%-15%, foraminous zeolite or siallitic soil 5%-15%, alhydrogel powder or silicasol 5%-15%; The total of the raw materials are 100%. The suing range comprises: IFP-I type reforming regeneration craft, IFP- II type reforming regeneration craft, UOP type reforming regeneration craft and other types of reforming regeneration craft.

Owner:XIAN ORIGIN CHEM TECH

Polyhexamethylene guanidine silver ion composite disinfectant

PendingCN113940357AReduce the concentration of silver ionsImprove the bactericidal effectBiocideFungicidesAntichlorPolyhexamethylene guanidine

The invention relates to a polyhexamethylene guanidine silver ion composite disinfectant, which comprises a water-soluble silver salt, polyhexamethylene guanidine hydrochloride and an anti-tarnish factor, wherein in the composite disinfectant, the concentration of the water-soluble silver salt is 5 mg / L to 50 mg / L, the concentration of the polyhexamethylene guanidine hydrochloride is 0.5 g / L to 5 g / L, the concentration of the anti-tarnish factor is 100 mg / L to 500 mg / L, and the anti-tarnish factor comprises a water-soluble amine compound. According to the polyhexamethylene guanidine silver ion composite disinfectant, the concentration of silver ions is reduced while an excellent sterilization effect can be achieved, and the polyhexamethylene guanidine silver ion composite disinfectant has good discoloration resistance, including non-discoloration at high temperature, non-discoloration under sunlight exposure, chlorine resistance and the like.

Owner:NUOVO FILM SUZHOU CHINA INC

High-temperature gas antichlor

InactiveCN109513302ASimple preparation processLow costGas treatmentDispersed particle separationCalcium hydroxideAntichlor

The invention relates to high-temperature gas antichlor. The antichlor is prepared from the following raw materials in parts by weight: 20-26 parts of clay, 12-17 parts of calcium carbonate, 8-12 parts of calcium oxide, 22-28 parts of calcium hydroxide and 10-15 parts of hydrotalcite. The antichlor is prepared by the following steps: weighing raw materials in the weight ratio, mixing, grinding, screening through a 100-mesh screen, and uniformly mixing; and extruding and molding the mixed material with water, drying and roasting at the temperature 600-750 DEG C for 2-4 hours. The process for preparing the gas antichlor is simple and has low cost; and the gas antichlor has stable performance, high chlorine tolerance and good purity, and can be widely applied to removal of hydrogen chloride in high-temperature fuel gas and high-temperature gas.

Owner:庄壮

High-stability catalyst for low-temperature catalytic combustion of chlorine-containing volatile organic compounds and preparation method of high-stability catalyst

ActiveCN112958071AGood activity at low temperatureHigh stability against chlorine poisoningHeterogenous catalyst chemical elementsIndirect carbon-dioxide mitigationChlorobenzenePtru catalyst

The invention discloses a high-stability catalyst for low-temperature catalytic combustion of chlorine-containing volatile organic compounds and a preparation method of the high-stability catalyst. The method can be used for preparing a composite transition metal oxide catalyst with good low-temperature activity and chlorine poisoning resistance, and belongs to the field of air pollution control. According to the method, transition metal elements niobium, cerium and chromium are adopted as catalytic components, and the oxidation-reduction capacity and the electronic structure of the catalyst are adjusted through the processes of coprecipitation, hydrothermal treatment, atmosphere heat treatment and the like. The catalytic properties of the active components of the prepared composite metal catalyst are correspondingly changed due to the change of the electronic structure, and the catalyst has high tolerance to chlorine species in the reaction process, has an excellent degradation effect on industrial chlorobenzene, and can be widely applied to treatment of other chlorine-containing volatile organic compounds.

Owner:SHANGHAI PROFOUND ENVIRONMENTAL TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com