Antichlor and preparation method thereof

The technology of dechlorination agent and carrier is applied in the field of dechlorination agent and its preparation, which can solve the problems of dechlorination agent removal, dechlorination agent pulverization, excessive chloride, etc. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

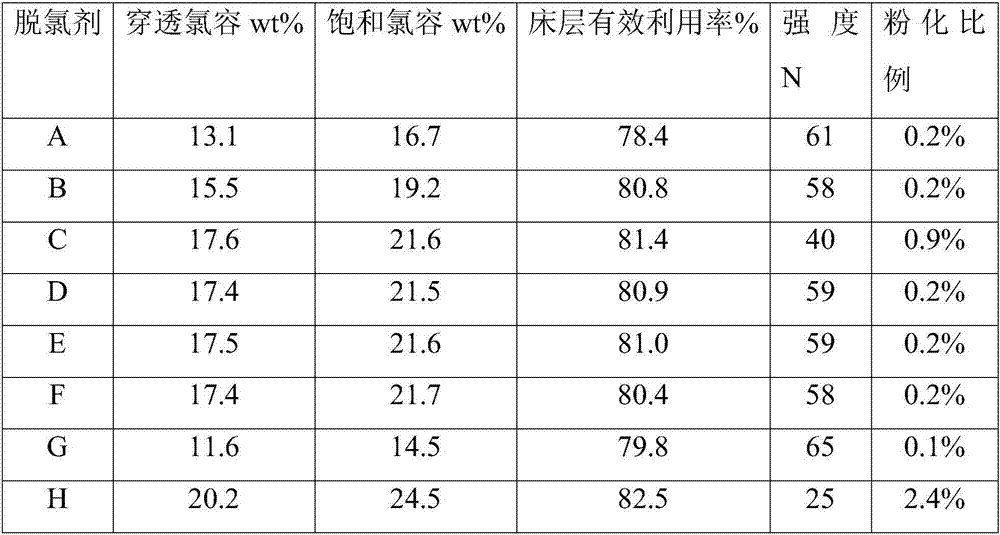

Examples

Embodiment 1

[0038] (1) Weigh 75g Al(NO 3 ) 3 9H 2 O, 1.18g Ca(NO 3 ) 3 4H 2 O was dissolved in 150ml of deionized water to form a solution, and stirred for 1 hour; the solution was heated to 50°C, and the pH was controlled to be 9 with 10wt% ammonia solution; after filtering, washing with deionized water, acidified with 12mol / L nitric acid solution Stir until the pH is 6, stir until it is in the form of a sol, and obtain the carrier slurry. Use a 5mL syringe to take the slurry, install a needle, and add the slurry dropwise to the oily ammonia column. The sol shrinks into a spherical gel, take out the gel ball, and heat at 120°C Drying under the same conditions for 12 hours, and calcining at 1100°C for 10 hours to obtain composite alumina carrier pellets, the crystal form of alumina is θ-type as detected by XRD;

[0039] (2) Weigh 2.65g Na 2 CO 3 Dissolve in 10ml of deionized water, make a solution and stir evenly, immerse the composite alumina carrier pellets prepared in step (1) i...

Embodiment 2

[0045] (1) Weigh 75g Al(NO 3 ) 3 9H 2 O, 2.36g Ca(NO 3 ) 3 4H 2 Dissolve O in 150ml of deionized water to form a solution, and stir for 1 hour; heat the solution to 50°C, and control the pH to 9 with 10wt% ammonia solution; filter, wash with deionized water, and acidify with 10mol / L nitric acid solution Stir until the pH is 6, stir until it is in the form of a sol, and obtain the carrier slurry. Use a 5mL syringe to take the slurry, install a needle, and add the slurry dropwise to the oily ammonia column. The sol shrinks into a spherical gel, take out the gel ball, and heat at 120°C Drying under the same conditions for 12 hours, and calcining at 1100°C for 10 hours to obtain composite alumina carrier pellets; XRD detection shows that the crystal form of alumina is θ type;

[0046] (2) Weigh 2.65g Na 2 CO 3 Dissolve in 10ml of deionized water, make a solution and stir evenly, immerse the composite alumina carrier pellets prepared in step (1) in equal volumes in the prepa...

Embodiment 3

[0050] (1) Weigh 75g Al(NO 3 ) 3 9H 2 O, 3.54g Ca(NO 3 ) 3 4H 2 O was dissolved in 150ml of deionized water to form a solution, and stirred for 1 hour; the solution was heated to 50°C, and the pH was controlled to be 9 with 10wt% ammonia solution; after filtering, washing with deionized water, acidified with 15mol / L nitric acid solution Stir until the pH is 5, stir until it is in the form of a sol, and obtain the carrier slurry, use a 5mL syringe to take the slurry, install a needle, add the slurry dropwise to the oily ammonia column, the sol shrinks into a spherical gel, take out the gel ball, and heat at 120°C Drying under the same conditions for 12 hours, and calcining at 1100°C for 10 hours to obtain composite alumina carrier pellets; XRD detection shows that the crystal form of alumina is θ type;

[0051] (2) Weigh 2.65g Na 2 CO 3 Dissolve in 10ml of deionized water, make a solution and stir evenly, immerse the composite alumina carrier pellets prepared in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com