Garbage treatment method

A technology of garbage disposal and garbage, applied in grain processing, chemical instruments and methods, sieves, etc., can solve the problem of suboptimal operation effect, etc., and achieve ideal reaction activity, improved burnout rate, and less coal leakage from the grate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

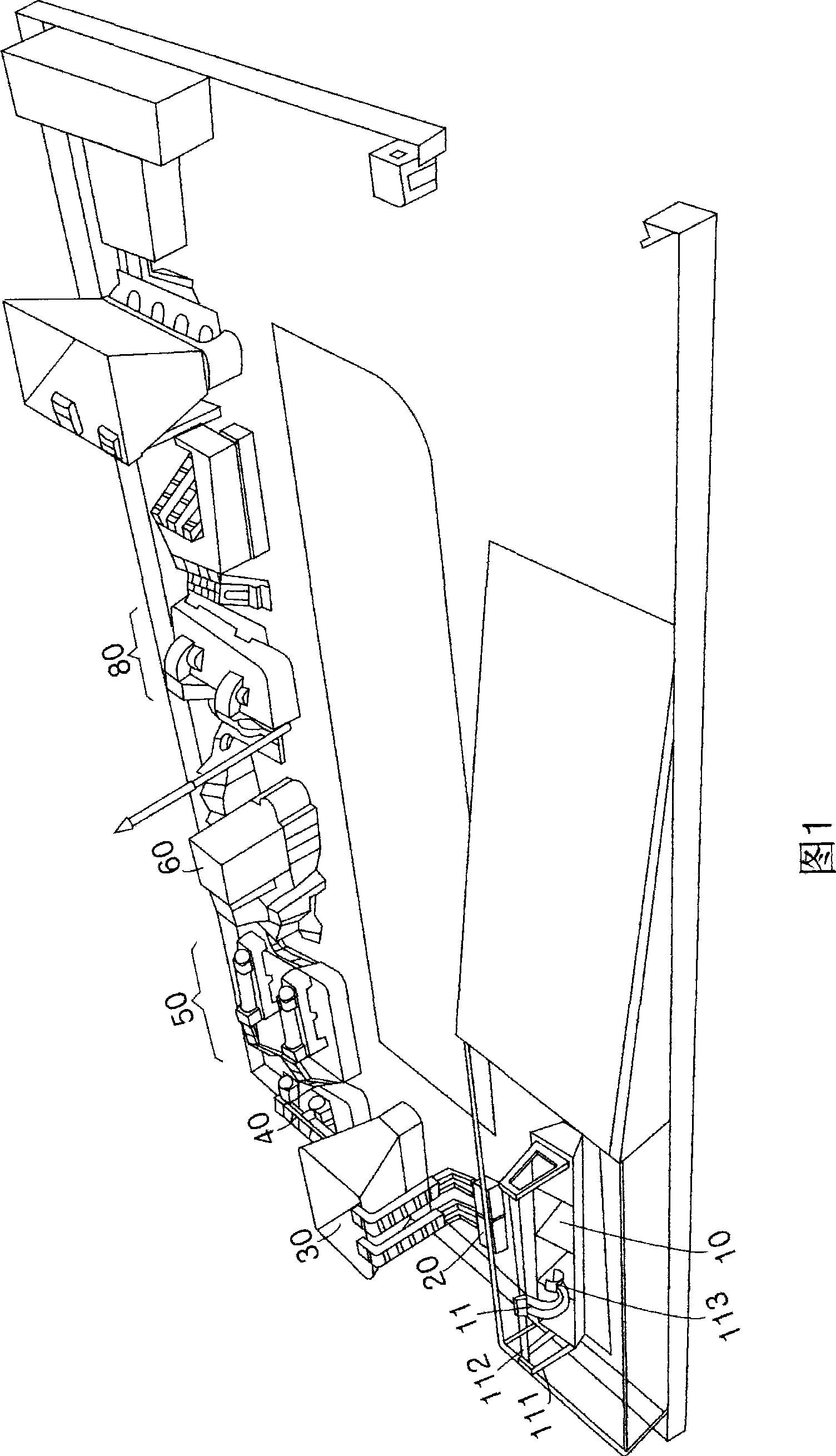

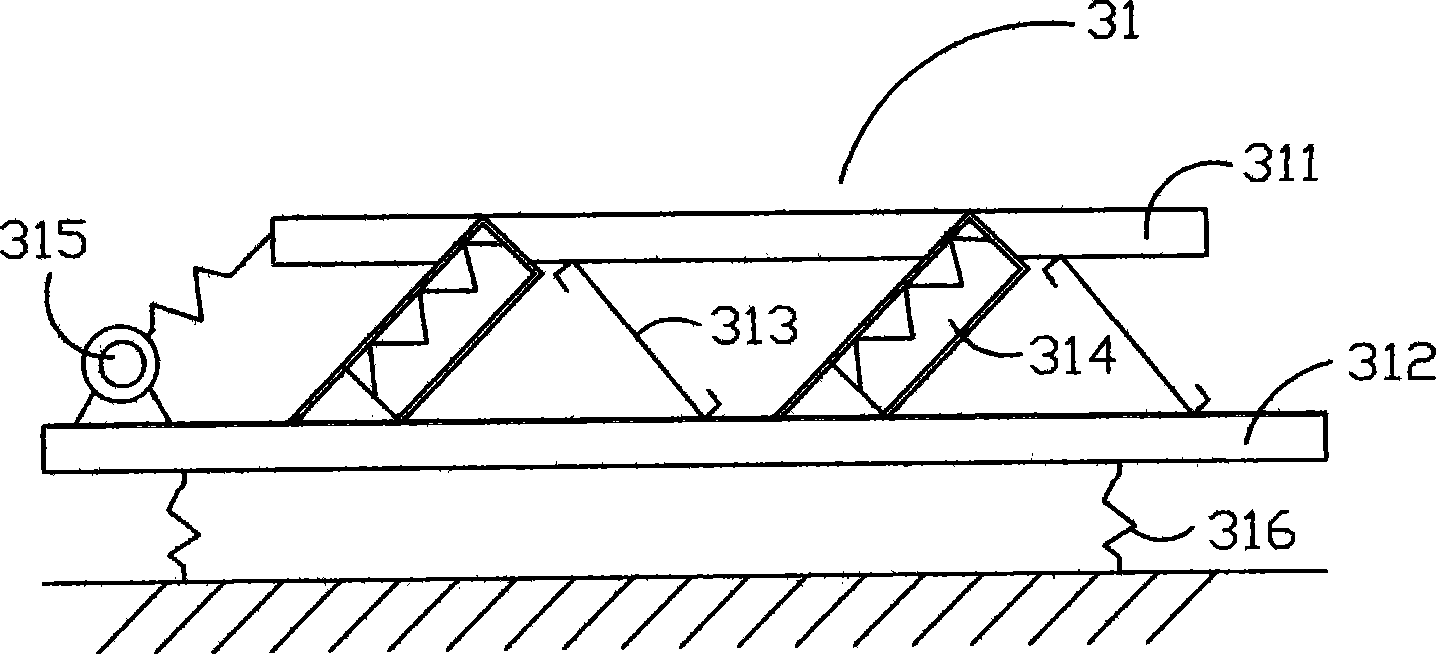

[0040] (As shown in Figures 1 to 10) a kind of garbage disposal method it mainly comprises the steps:

[0041] (As shown in Figure 1) The first step is to deodorize and sterilize the waste material, and add raw coal therein, and the waste material as mentioned above is domestic waste or waste after carbon-containing industrial and agricultural production and processing.

[0042] Also, in the process of deodorization and sterilization as mentioned above, it is necessary to add deodorization and bactericide to the garbage raw material. The deodorization and bactericide are biological enzymes and calcium hypochlorite mixed with pure natural culture and microorganisms. The ratio of adding the deodorizing and bactericidal agent to the garbage raw material is 0.1-1% of the deodorizing and bactericidal agent per ton of the garbage raw material.

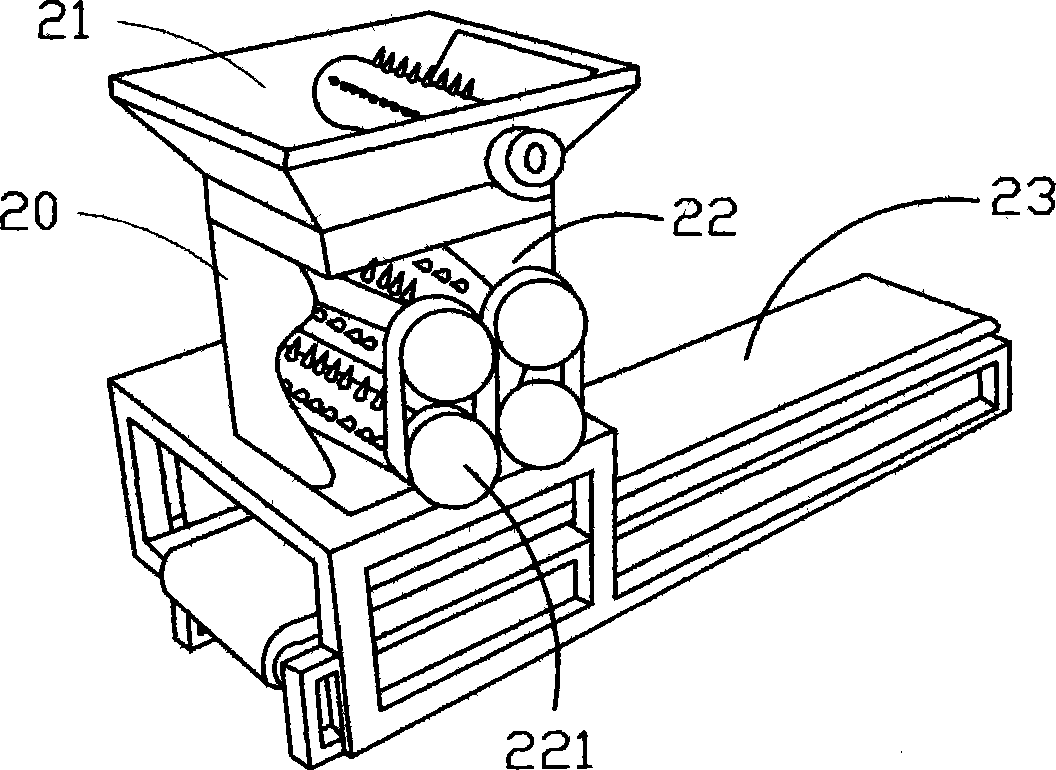

[0043] (As shown in Figures 1 to 2) In the second step, the waste material that has been deodorized and sterilized in the first step as des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com