High temperature antichlor and preparation method thereof

A dechlorination agent, high temperature technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of unrealizable dechlorination agents, and achieve the effects of stable structure, good adsorption activity, and high chlorine capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 700g of Ca(NO 3 ) 2 or Ca(OH) 2 , 90g Al(NO 3 ), 210g of Al 2 Si 2 o 5 (OH) 4 , Grind the above materials to more than 200 meshes respectively, mix them well, add them into the reaction kettle, then add 12kg of deionized water, and quickly add 4mol / L-1 Na 2 CO 3 The solution evenly heated the reaction kettle at a rotation speed of 60 rpm, and raised the temperature from room temperature to 473K within 2 hours, and then kept the reaction kettle at a constant temperature of 473K for 48 hours. The obtained product was filtered, and the filtered solid product was washed with deionized water until neutral, and dried at 353K for 24 hours. The obtained solid is molded and granulated to obtain the desired dechlorination agent.

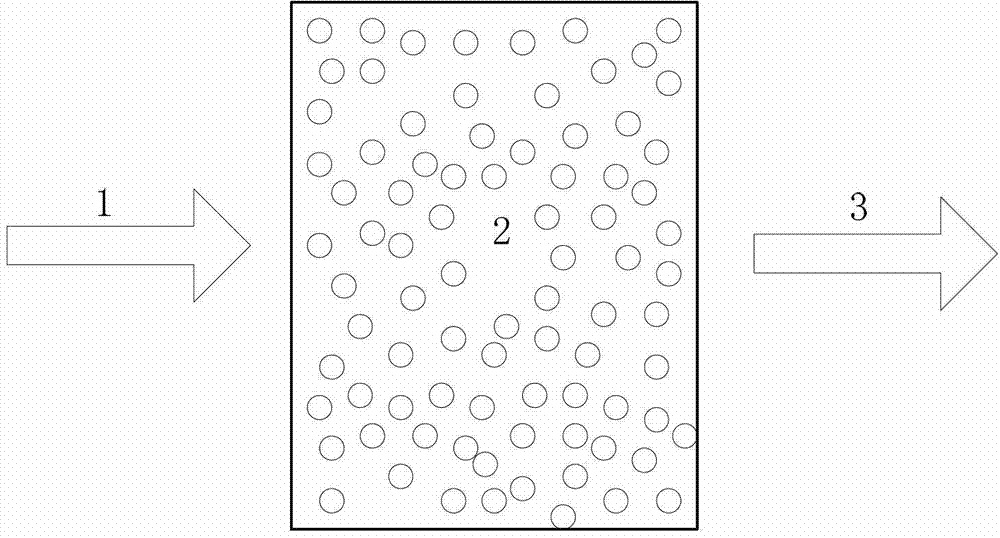

[0026] The prepared dechlorination agent is carried out dechlorination experiment, and the dechlorination agent passes such as figure 1 The process adsorbs chlorine-containing gas in flue gas, and the adsorbent reactor can be a moving be...

Embodiment 2

[0028] Weigh 510g of Ca(NO 3 ) 2 or Ca(OH) 2 , 170g Al(OH) 3 , 320g Al 2 Si 2 o 5 (OH) 4 , Grind the above materials to more than 200 mesh respectively, mix them well, add them into the reaction kettle, then add 12kg of deionized water, and quickly add 5mol / L-1 Na 2 CO 3 The solution evenly heated the reaction kettle at a rotation speed of 50 rpm, and raised the temperature from room temperature to 473K within 2 hours, and then kept the reaction kettle at a constant temperature of 473K for 48 hours. The obtained product was filtered, and the filtered solid product was washed with deionized water until neutral, and dried at 353K for 24 hours. The obtained solid is molded and granulated to obtain the desired dechlorination agent.

[0029] The prepared dechlorination agent is carried out dechlorination experiment, and the dechlorination agent passes such as figure 1 The process adsorbs chlorine-containing gas in flue gas, and the adsorbent reactor can be a moving bed, f...

Embodiment 3

[0031] Weigh 255g of Ca(NO 3 )2 or Ca(OH) 2 , 345g Al(OH) 3 , 400g Al 2 Si 2 o 5 (OH) 4 , respectively grind the above materials to more than 200 meshes, mix well, add to the reaction kettle, then add 12kg of deionized water, and quickly add 6mol / L-1 Na under the condition of magnetic stirring 2 CO 3 The solution evenly heated the reaction kettle at a rotation speed of 60 rpm, and raised the temperature from room temperature to 473K within 2 hours, and then kept the reaction kettle at a constant temperature of 473K for 48 hours. The obtained product was filtered, and the filtered solid product was washed with deionized water until neutral, and dried at 353K for 24 hours. The obtained solid is molded and granulated to obtain the desired dechlorination agent.

[0032] The prepared dechlorination agent is carried out dechlorination experiment, and the dechlorination agent passes such as figure 1 The process adsorbs chlorine-containing gas in flue gas, and the adsorbent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com