Preparation method of hydrotalcite-like compound-based powder explosion suppressant

A hydrotalcite-based, explosion-suppressing agent technology, which is applied in mining equipment, earthwork drilling, safety devices, etc., can solve the problems of environmental pollution, insufficient adsorption capacity of explosion energy, poor explosion-proof performance, etc., and achieve the goal of improving adsorption activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

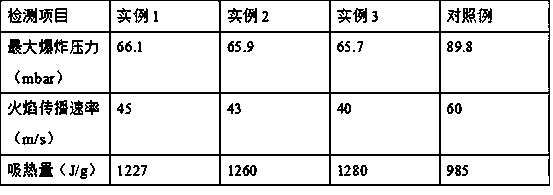

Examples

example 1

[0023] Weigh silkworm cocoons and put them into a tissue grinder to crush for 15 minutes to obtain crushed silk cocoons, soak the crushed silk cocoons with a dopamine solution with a mass fraction of 1% for 30 minutes, filter after the immersion, and separate to obtain filter residues, which are pretreated silk cocoons; In terms of parts, 15 parts of magnesium nitrate, 40 parts of aluminum nitrate, 20 parts of zinc nitrate and 200 parts of deionized water were mixed for 10 minutes to obtain a mixed solution, and the mixed solution and the above-mentioned pretreated silkworm cocoons were mixed in a mass ratio of 10:1. Put into the ultrasonic oscillator and react with the frequency oscillation of 25kHz for 1h to obtain the pre-reaction solution; the pre-reaction solution and the mass fraction are 30% ammonia and potassium carbonate to obtain the reaction solution after mixing the mass ratio of 13:4:1, and the reaction Liquid, sodium thiosulfate and potassium citrate are mixed in ...

example 2

[0025]Weigh silkworm cocoons and put them into a tissue grinder to crush for 18 minutes to obtain crushed silk cocoons, soak the crushed silk cocoons with a dopamine solution with a mass fraction of 1% for 35 minutes, filter after the immersion, and separate and obtain filter residues, which are pretreated silkworm cocoons; In terms of parts, 18 parts of magnesium nitrate, 45 parts of aluminum nitrate, 22 parts of zinc nitrate and 250 parts of deionized water were mixed for 13 minutes to obtain a mixed solution, and the mixed solution and the above-mentioned pretreated silkworm cocoons were mixed in a mass ratio of 10:1. Put into the ultrasonic oscillator and react with the frequency oscillation of 28kHz for 1h to obtain the pre-reaction solution; the pre-reaction solution and the mass fraction are 30% ammonia and potassium carbonate to obtain the reaction solution after mixing the pre-reaction solution with a mass ratio of 13:4:1, and the reaction liquid, sodium thiosulfate an...

example 3

[0027] Weigh silkworm cocoons and put them into a tissue grinder to crush them for 20 minutes to obtain crushed silk cocoons, soak the crushed silk cocoons with a dopamine solution with a mass fraction of 1% for 40 minutes, filter after the immersion, and separate and obtain filter residues, which are pretreated silk cocoons; In terms of parts, 20 parts of magnesium nitrate, 50 parts of aluminum nitrate, 23 parts of zinc nitrate and 300 parts of deionized water were mixed for 15 minutes to obtain a mixed solution, and the mixed solution and the above-mentioned pretreated silkworm cocoons were mixed in a mass ratio of 10:1. Put into the ultrasonic oscillator and react with the frequency of 30kHz for 2h to obtain the pre-reaction solution; the pre-reaction solution and the mass fraction of 30% ammonia and potassium carbonate are mixed to obtain the reaction solution in a mass ratio of 13:4:1, and the reaction Liquid, sodium thiosulfate and potassium citrate are mixed in a mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com