Liquid-phase antichlor and preparation method and application thereof

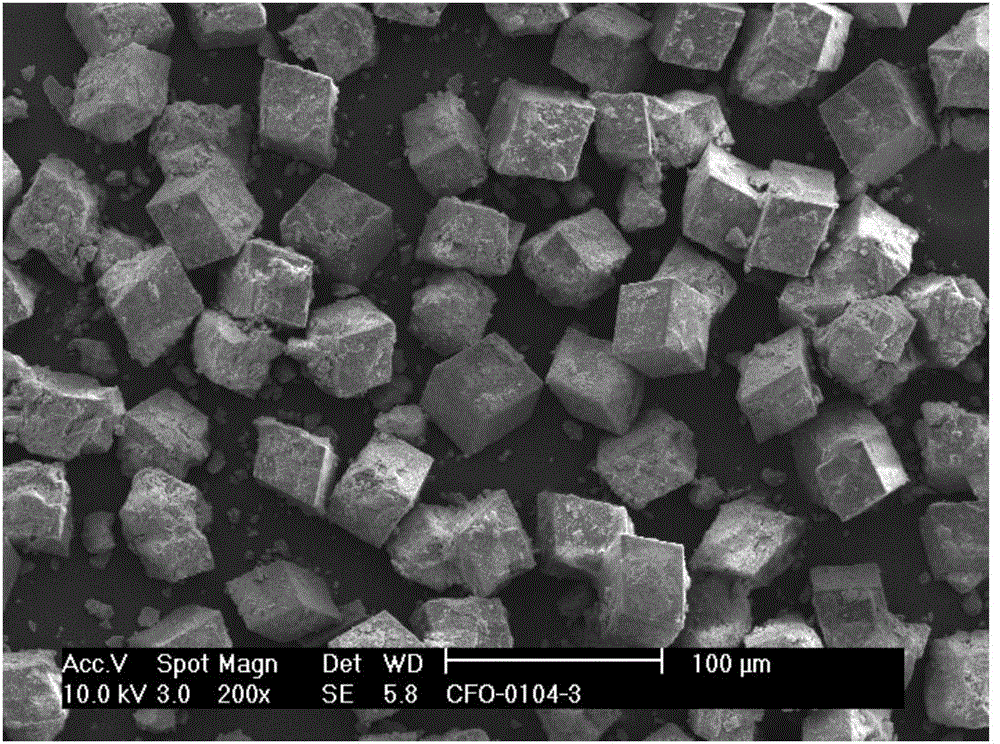

A dechlorination agent and liquid phase technology, which is applied in the field of liquid phase oil purification, can solve the problem of unsolved liquid phase dechlorination agent and other problems, and achieve the effects of neat crystal structure, high dechlorination and chlorine capacity, and improved structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

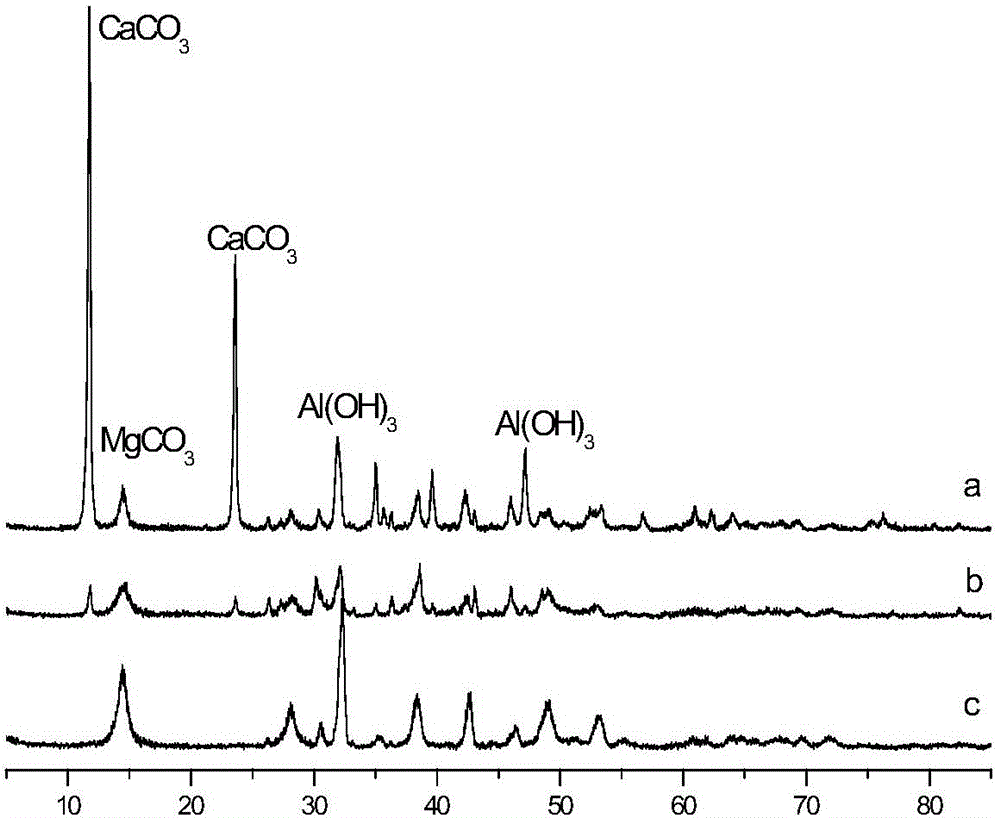

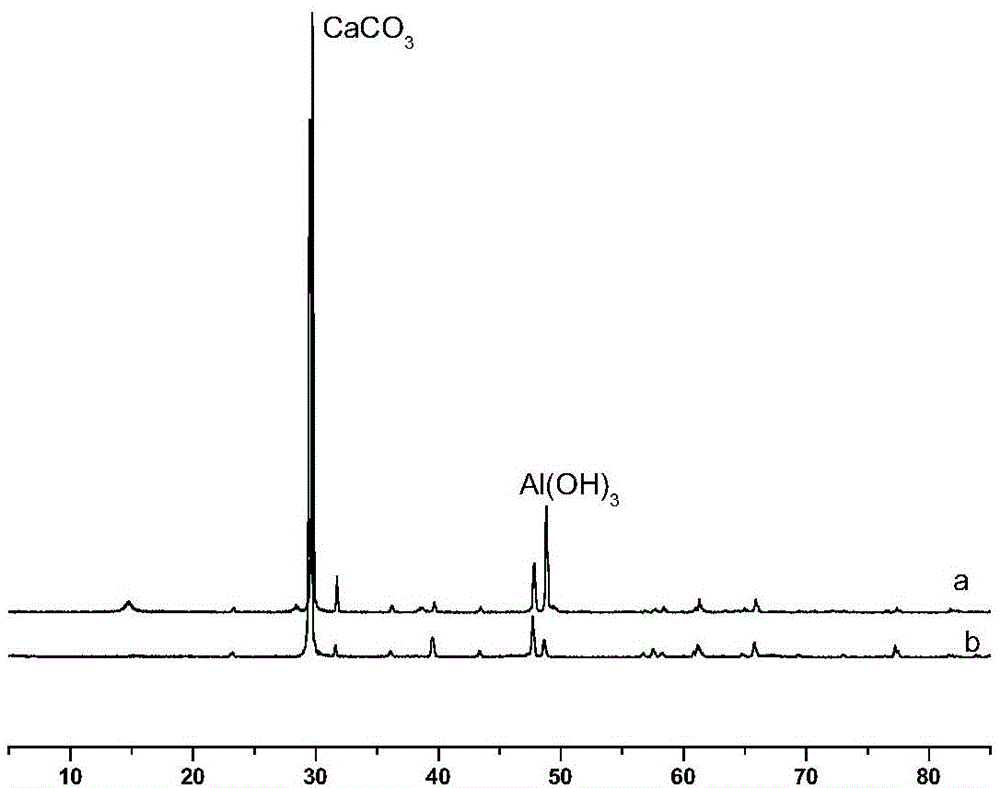

[0059] The preparation of embodiment 1 liquid phase dechlorination agent

[0060] Mg(NO 3 ) 2 ·6H 2 O, 3.5g of Ca(NO 3 ) 2 4H 2 O, 5g of Al 2 (SO 4 ) 3 18H 2 O. Add 6.7g of urea into a beaker containing 64.4g of distilled water, stir at room temperature for 15min, then place the solution in an autoclave for crystallization at 170°C for 6h, filter, wash and dry at 80°C for 3h Molded, and finally roasted in a tube furnace at 400°C for 0.5h to obtain the finished dechlorination agent A.

Embodiment 2

[0061] The preparation of embodiment 2 liquid phase dechlorination agent

[0062] Mg(SO 4 ) 2 ·7H 2 O, 2.1g of Ca(NO 3 ) 2 4H 2 O, 6.6g of Al(NO 3 ) 3 9H 2 O. Add 6.7g of ammonium carbonate to a beaker containing 64.4g of distilled water, stir at room temperature for 15min, then place the solution in an autoclave for crystallization at 140°C for 8h, filter and wash, then dry at 80°C for 3h After molding, it is finally baked in a tube furnace at 700°C for 1.5 hours to obtain the finished dechlorination agent B.

Embodiment 3

[0063] The preparation of embodiment 3 liquid phase dechlorination agent

[0064] Mg(SO 4 ) 2 ·7H 2 O, 2.0g of Ca(NO 3 ) 2 4H 2 O, 4.4g of Al(NO 3 ) 3 9H 2 O. Add 4.2g of urea into a beaker containing 64.4g of distilled water, stir at room temperature for 15min, then place the solution in an autoclave for crystallization at 170°C for 6h, filter, wash and dry at 80°C for 3h Molded, and finally roasted in a tube furnace at 450°C for 2.5 hours to obtain the finished dechlorination agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com