Antichloration of hydrocarbon chloride in waste water

A chlorinated hydrocarbon and dechlorination technology, which is applied in chemical instruments and methods, water pollutants, neutralized water/sewage treatment, etc., can solve the problems of secondary pollution and high cost of sewage treatment, and achieve the effect of high-efficiency dechlorination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

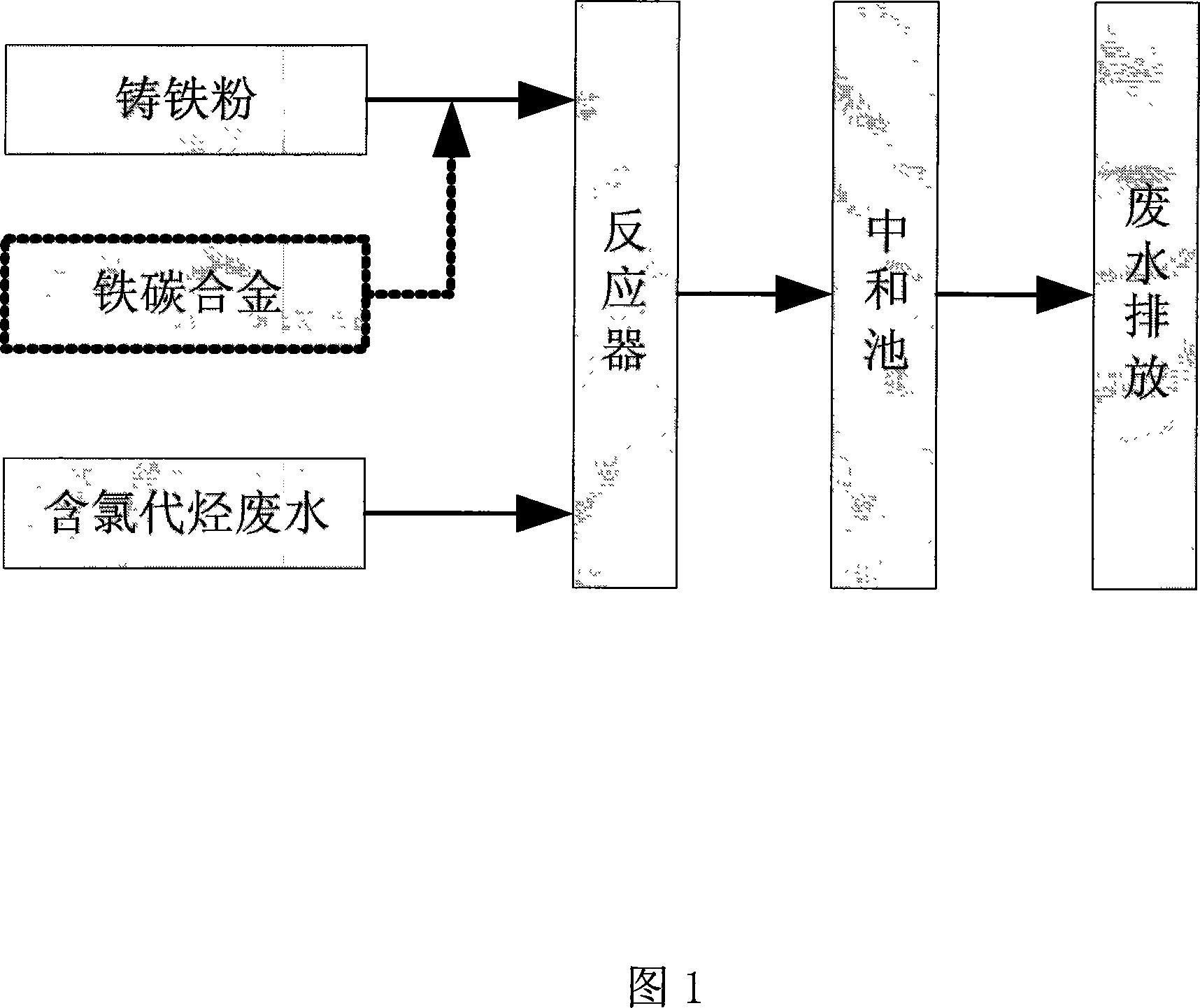

Image

Examples

Embodiment 1

[0021] Dechlorination agent: cast iron powder, particle size 100 mesh, dosage is 2-3kg per ton of water;

[0022] Dechlorination reaction operating conditions: normal temperature and pressure, pH 2.8, stirring, reaction residence time 4 hours;

[0023] Neutralizing flocculant: NaOH;

[0024] Neutralization and dechlorination operating conditions: normal temperature and pressure, PH 8.6;

[0025] Influent concentration: dichloromethane 20mg / L, chloroform 30mg / L, carbon tetrachloride 30mg / L

[0026] Treatment effluent concentration: dichloromethane 1.4mg / L, chloroform 1.9mg / L, carbon tetrachloride 0.9mg / L

Embodiment 2

[0028] Dechlorination agent: cast iron powder, particle size 80 mesh, dosage is 2-3kg per ton of water;

[0029] Dechlorination reaction operating conditions: normal temperature and pressure, pH 3.2, stirring, reaction residence time 3.5 hours;

[0030] Neutralizing flocculant: carbide slag;

[0031] Neutralization and dechlorination operating conditions: normal temperature and pressure, PH 7.8;

[0032] Influent concentration: dichloromethane 20mg / L, chloroform 30mg / L, carbon tetrachloride 30mg / L

[0033] Treatment effluent concentration: dichloromethane 1.6mg / L, chloroform 1.8mg / L, carbon tetrachloride 1.2mg / L

Embodiment 3

[0035] Dechlorination agent: cast iron powder, particle size 40-60 mesh, dosage 2-3kg per ton of water;

[0036] Dechlorination reaction operating conditions: normal temperature and pressure, pH 1.9, stirring, reaction residence time 4 hours;

[0037] Neutralizing flocculant: carbide slag;

[0038] Neutralization and dechlorination operating conditions: normal temperature and pressure, PH 8.2;

[0039] Influent concentration: tetrachlorethylene 50mg / L

[0040] Treatment effluent concentration: tetrachlorethylene 2.2mg / L

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com