A water washing method for synchronous calcium fixation and dechlorination of waste incineration fly ash

A technology of waste incineration fly ash and fly ash, which is applied in the removal of solid waste and other directions, can solve the problems of restricting the disposal and utilization of waste salt, low decalcification efficiency, difficult separation of heavy metals, etc., and achieves the effect of reducing concentration and processing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

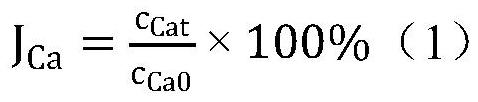

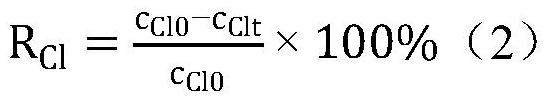

[0023] Example 1 Effect of molar ratio of sodium phosphate and sodium silicate on fly ash calcium solidification rate, heavy metal leaching reduction percentage, and chlorine elution rate

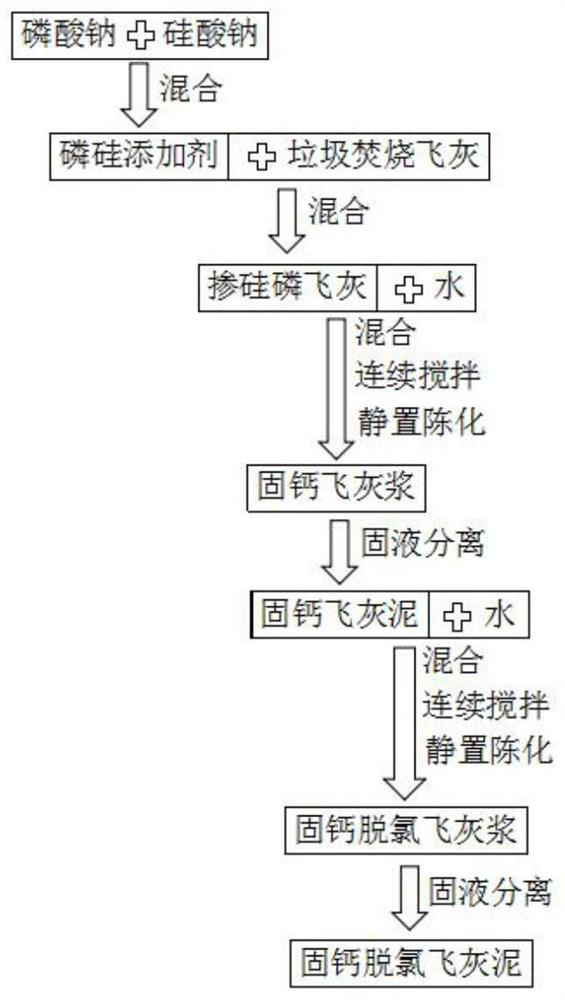

[0024] Disposal process of the present invention: according to sodium phosphate and sodium silicate molar ratio 0.5:10, 0.7:10, 0.9:10, 1:10, 2.5:10, 4:10, 4.5:10, 5:10, 6:10 respectively Sodium phosphate and sodium silicate were weighed and mixed to obtain nine groups of phosphorus silicon additives. According to the mass ratio of phosphorus-silicon additive and waste incineration fly ash of 2:100, the phosphorus-silicon additive and waste incineration fly ash were weighed and mixed to obtain nine groups of silicon-doped phosphorus fly ash. According to the liquid-solid ratio of 0.3:1, water and silicon-phosphorus-doped fly ash were weighed, mixed, stirred continuously for 1 hour, and left to age for 12 hours to obtain nine groups of calcium-fixed fly ash slurries. The calcium-fixed fly a...

Embodiment 2

[0042] Example 2 Effect of mass ratio of phosphorus silicon additive to waste incineration fly ash on fly ash calcium solidification rate, heavy metal leaching reduction percentage, and chlorine elution rate

[0043] Weigh sodium phosphate and sodium silicate respectively according to the molar ratio of sodium phosphate and sodium silicate of 4:10, and mix them to obtain the phosphorus silicon additive. Weigh phosphorus according to the mass ratio of phosphorus silicon additive to waste incineration fly ash 1:100, 1.5:100, 1.8:100, 2:100, 11:100, 20:100, 21:100, 23:100, 25:100 The silicon additive is mixed with waste incineration fly ash to obtain nine groups of silicon-phosphorus-doped fly ash. Water and silicon-phosphorus-doped fly ash were weighed according to the liquid-solid ratio of 0.6:1, mixed, stirred continuously for 3.5 hours, and left to age for 30 hours to obtain nine groups of calcium-fixed fly ash slurry. The nine groups of calcium-fixing fly ash are introduced...

Embodiment 3

[0052] Example 3 Effect of aging time on fly ash calcium solidification rate, heavy metal leaching reduction percentage, and chlorine elution rate

[0053] Weigh sodium phosphate and sodium silicate respectively according to the molar ratio of sodium phosphate and sodium silicate of 4:10, and mix them to obtain the phosphorus silicon additive. The phosphorus-silicon additive and the waste incineration fly ash were weighed and mixed according to the mass ratio of the phosphorus-silicon additive to the waste incineration fly ash of 20:100 to obtain the silicon-doped phosphorus fly ash. Weigh water and silicon-phosphorus-doped fly ash according to the liquid-to-solid ratio of 0.9:1, mix them, stir continuously for 6 hours, leave to stand and age for 6 hours, 8 hours, 10 hours, 12 hours, 30 hours, 48 hours, 54 hours, 60 hours and 66 hours respectively to obtain calcium-fixed fly ash. mortar. The calcium-fixing fly ash slurry is introduced into a centrifuge for solid-liquid sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com