Photocatalytic Oxidative Degradation of Chlorophenol Pollutants by Sodium Vanadium Borate

A technology of photocatalytic oxidation and sodium vanadium borate, applied in water pollutants, chemical instruments and methods, light water/sewage treatment, etc., can solve the problems of high cost and large catalyst loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

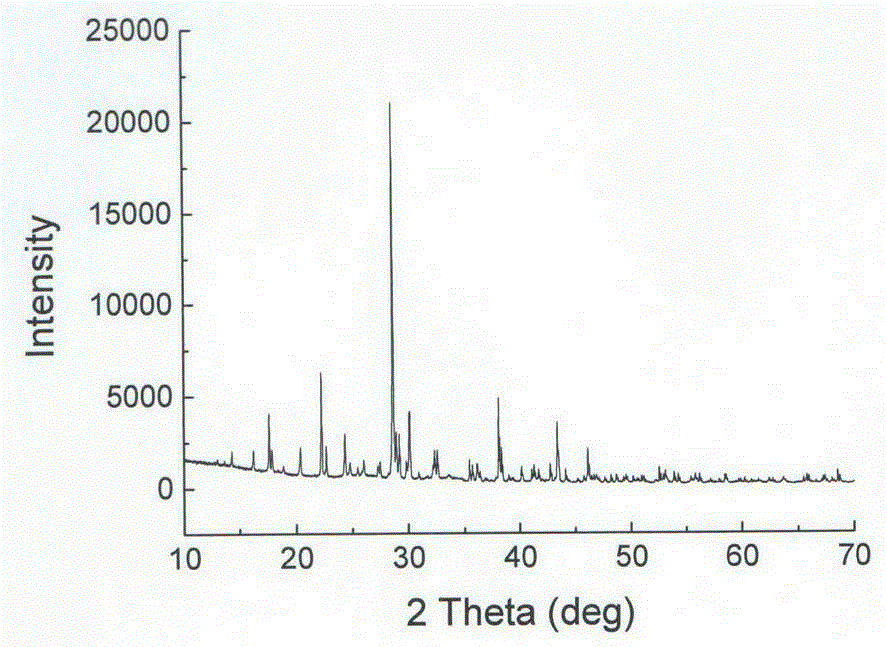

Image

Examples

Embodiment 1

[0020] Dissolve 2-chlorophenol in methanol to make the concentration 10g / L, take 2mL of the dissolved solution, put it in a beaker with a volume of 250mL, add water to dilute it to 20mg / L, and then place it in ultrasonic treatment for 60min, so that It is a homogeneous and stable solution;

[0021] Add 10 mg of sodium vanadium borate powder into the ultrasonically treated solution under light-shielding conditions, stir for 30 minutes, pipette 4 mL into a centrifuge tube, and store in the dark;

[0022] The temperature of the system is maintained at 25°C, and then the remaining solution system is irradiated under a xenon lamp that has stabilized luminescence at a wavelength of 420nm. The system is 10cm away from the outlet of the xenon lamp. 2 , sample 4mL every 1min;

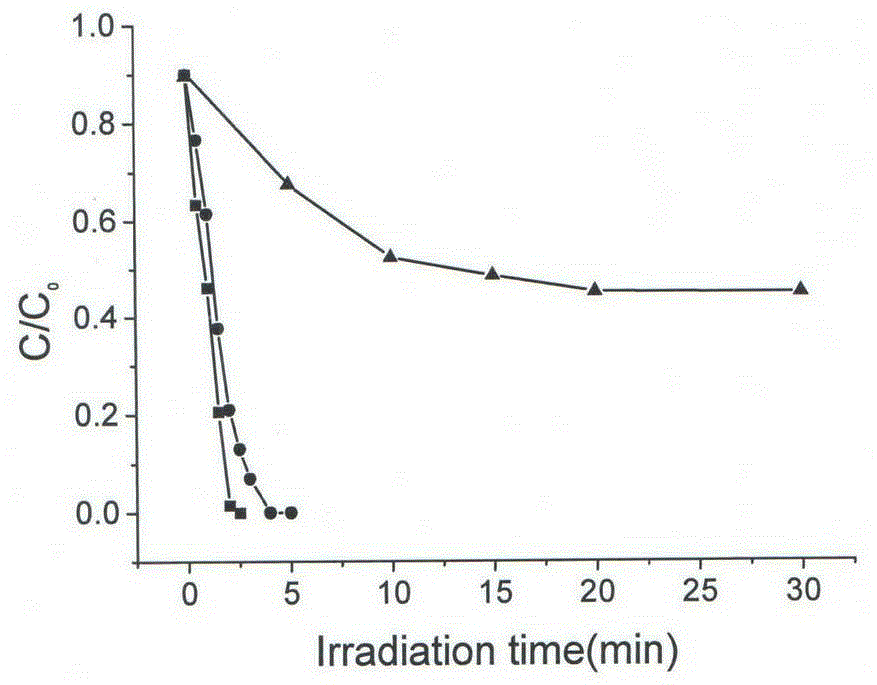

[0023] After centrifuging all the samples that have been taken out, take the supernatant, test the UV-Vis absorption spectrum and high-performance liquid chromatography of the material, and analyze the degradat...

Embodiment 2

[0025] Dissolve 2,4-dichlorophenol in methanol so that the concentration is 10g / L, take 0.5mL of the dissolved solution, put it in a beaker with a volume of 250mL, add water to dilute it to 50mg / L, and then place it in an ultrasonic Treat in medium for 60min to make it a uniform and stable solution;

[0026] Add 50 mg of sodium vanadium borate powder into the ultrasonically treated solution under light-shielding conditions, stir for 30 minutes, pipette 4 mL into a centrifuge tube, and store in the dark;

[0027] The temperature of the system is maintained at 25°C, and then the remaining solution system is irradiated at room temperature under natural light, and the energy density is 0.5-2mw / cm 2 , sample 4mL at intervals of 5 minutes;

[0028] After centrifuging all the samples that have been taken out, take the supernatant to test the UV-visible absorption spectrum and high-performance liquid chromatography of the material, analyze the degradation efficiency of pollutants and...

Embodiment 3

[0030] Dissolve 2,4,6-trichlorophenol in methanol to make the concentration 10g / L, take 5mL of the dissolved solution, put it in a 250mL beaker, add water to dilute it to 500mg / L, and place in Ultrasonic treatment for 60min to make it a uniform and stable solution;

[0031] Add 50 mg of sodium vanadium borate powder into the ultrasonically treated solution under light-shielding conditions, stir for 40 minutes, pipette 4 mL into a centrifuge tube, and store in the dark;

[0032] The temperature of the system is kept at room temperature 25°C, and then the remaining solution system is irradiated under a xenon lamp that has been stably emitting light, the wavelength is 420nm, the system is 10cm away from the outlet of the xenon lamp, the spot diameter of the xenon lamp is 50mm, and the energy density is 1218mw / cm 2 , sample 4mL at intervals of 0.5min;

[0033] After centrifuging all the samples that have been taken out, take the supernatant, test the UV-Vis absorption spectrum of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com