Preparation and application method of oil antichlor

A dechlorination agent and oil technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, non-metallic refining, etc., can solve the problems of harsh operating conditions, cumbersome follow-up treatment, complicated preparation process, etc., and achieve increased reactivity, adsorption The effect of fast desorption rate and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 (preparation of modified activated carbon)

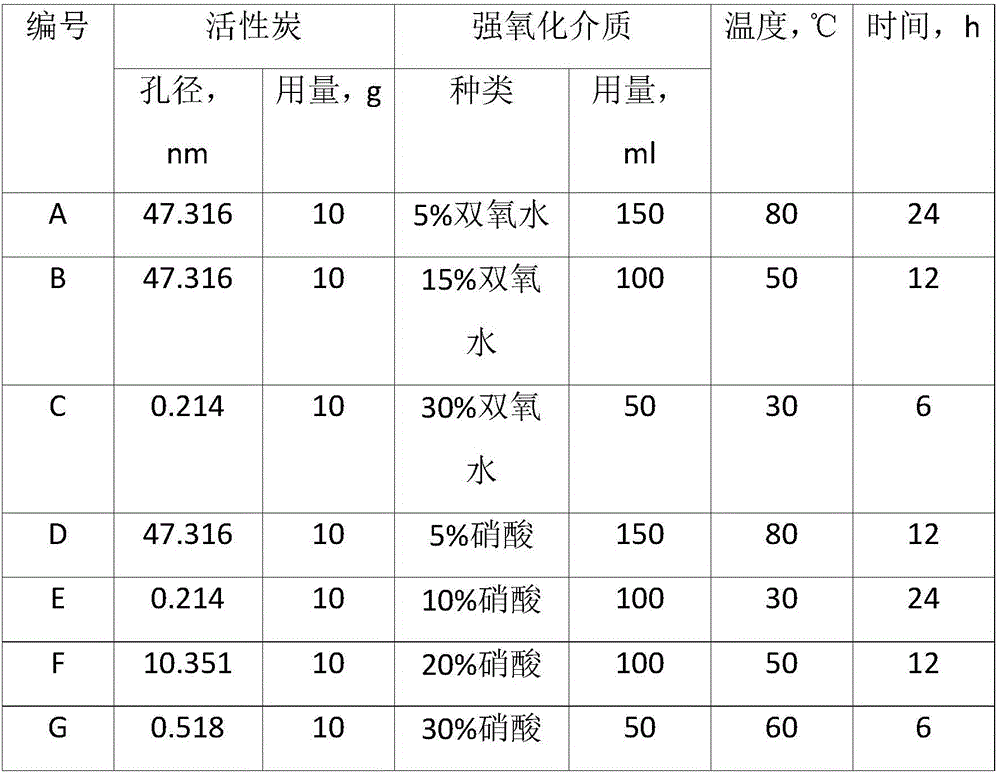

[0023] Prepare modified activated carbon according to the preparation conditions in A-G in Table 1. The steps are as follows: add activated carbon and strong oxidizing medium into a reactor with a reflux and stirring device, stir for several hours at a certain temperature, and then wash and dry to obtain modified activated carbon. activated carbon.

[0024] Table 1

[0025]

Embodiment 2

[0026] Embodiment 2 (preparation of dechlorination agent)

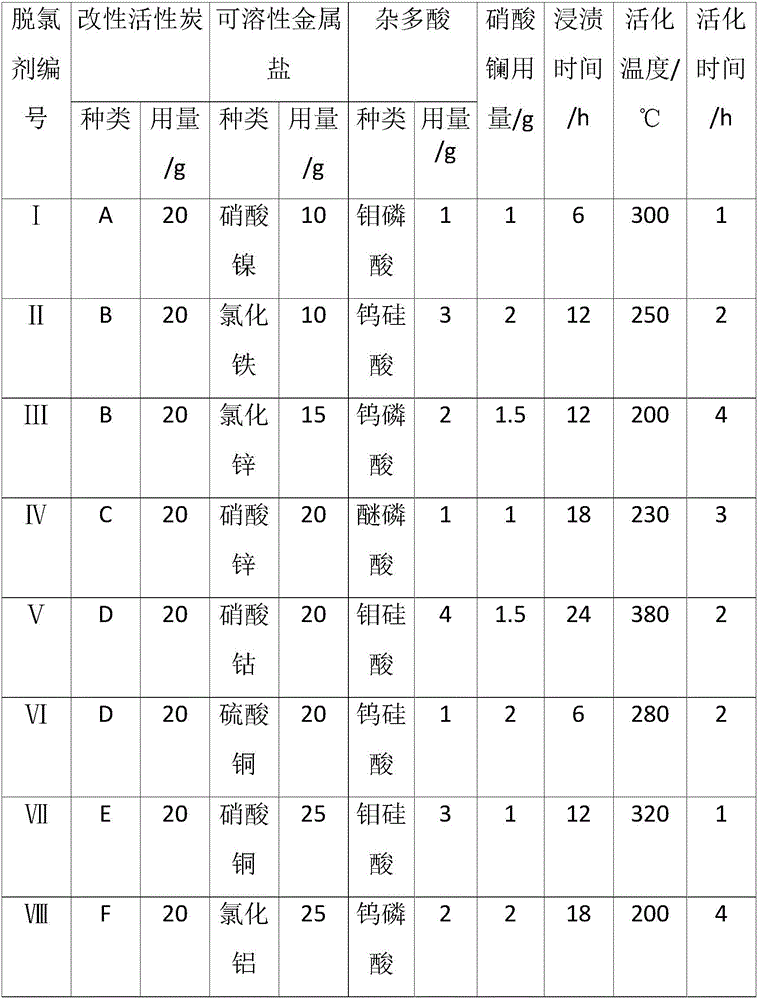

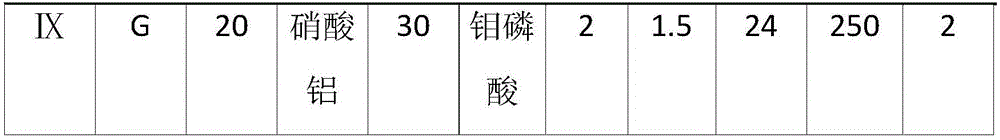

[0027] The modified activated carbons A-G prepared in Example 1 are immersed in mixed solutions prepared with various heteropolyacids, lanthanum nitrate and soluble main group or transition metal salts, and then dried and activated to obtain different dechlorination agents product. The type and amount of modified activated carbon used, the type and amount of heteropoly acid, the type and amount of nitrate, the impregnation time, activation temperature, and activation time are shown in Table 2.

[0028] Table 2

[0029]

[0030]

Embodiment 3

[0031] Embodiment 3 (product effect evaluation)

[0032] The dechlorination effect evaluation steps are as follows: (1) add the dechlorination agent prepared in Example 2 and the naphtha (chlorine content is 51.4ppm) of a certain refinery in the reaction device, stir and feed inert gas to get rid of oxygen in the reactor Finally, control the pressure to 1.0MPa, then close the reactor, the mass ratio of dechlorination agent to oil is 1:15; (2) control the temperature in the reaction device to 150°C, and keep stirring for 6h; (3) stop heating, After cooling, samples were taken to analyze the chlorine content, and the data are shown in Table 3.

[0033] table 3

[0034]

[0035] Note: JX‐5D is a commercially available dechlorination agent

[0036] It can be seen from the data in the table that the dechlorination agents II, III, VII, and IX of the present invention can reduce the organic chlorine content in the oil to below 1.0ppm, and the dechlorination effect is obviously b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com