Zinc electrolyte dechlorination method

A technology of zinc electrolyte and chlorine removal agent, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of large water volume, failure to meet environmental protection requirements, high cost, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be fully and clearly described below in conjunction with the drawings in the embodiments of the present invention.

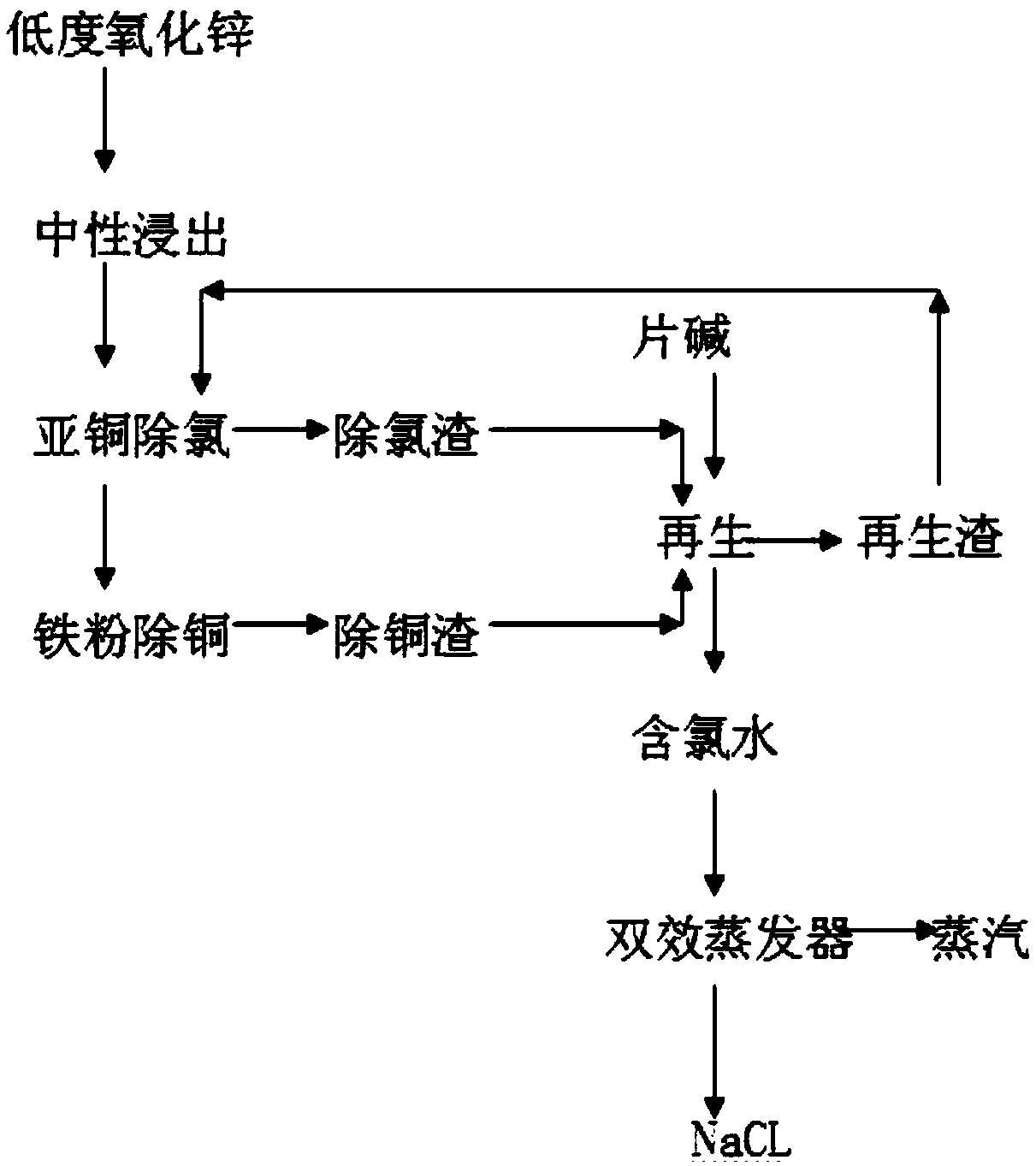

[0035] like figure 1 As shown, the invention discloses a method for removing chlorine in a zinc electrolyte, comprising the following steps:

[0036] (1) Neutrally leaching low-grade zinc oxide, then injecting the chlorine-containing leaching solution into the chlorine removal tank, starting to stir, stirring for 40-50 minutes, adding cuprous oxide and copper powder during the stirring process, and the added The amount of copper is: C 氯 ×V×1.8kg, then add industrial sulfuric acid, adjust the pH to 1.5-2.0, and obtain the dechlorination slag and dechlorination solution;

[0037] The reaction formula is: Cu+2Cl - +Cu 2+ =2CuCl, CuCl precipitation is dechlorination slag;

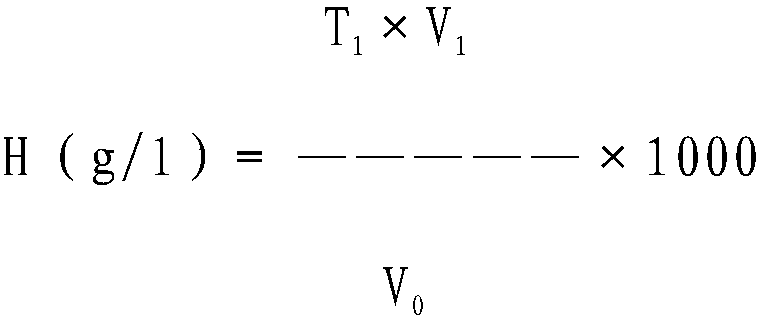

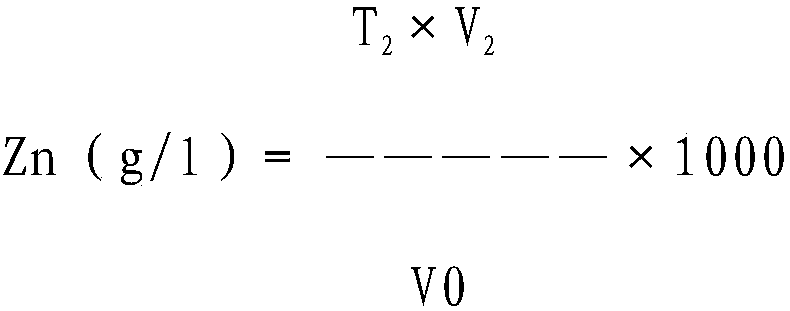

[0038] (2) React the dechlorination solution in step (1) for 30-35 minutes and perform sampling analysis. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com