A method for high-value zinc smelting intermediate materials and collaborative chlorine removal

A zinc smelting and high-value technology, applied in the field of high-value treatment technology, can solve problems such as poor activity, low bivalent copper content, and increased dechlorination costs, and achieve quick results, low operating costs, and improved copper slag. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

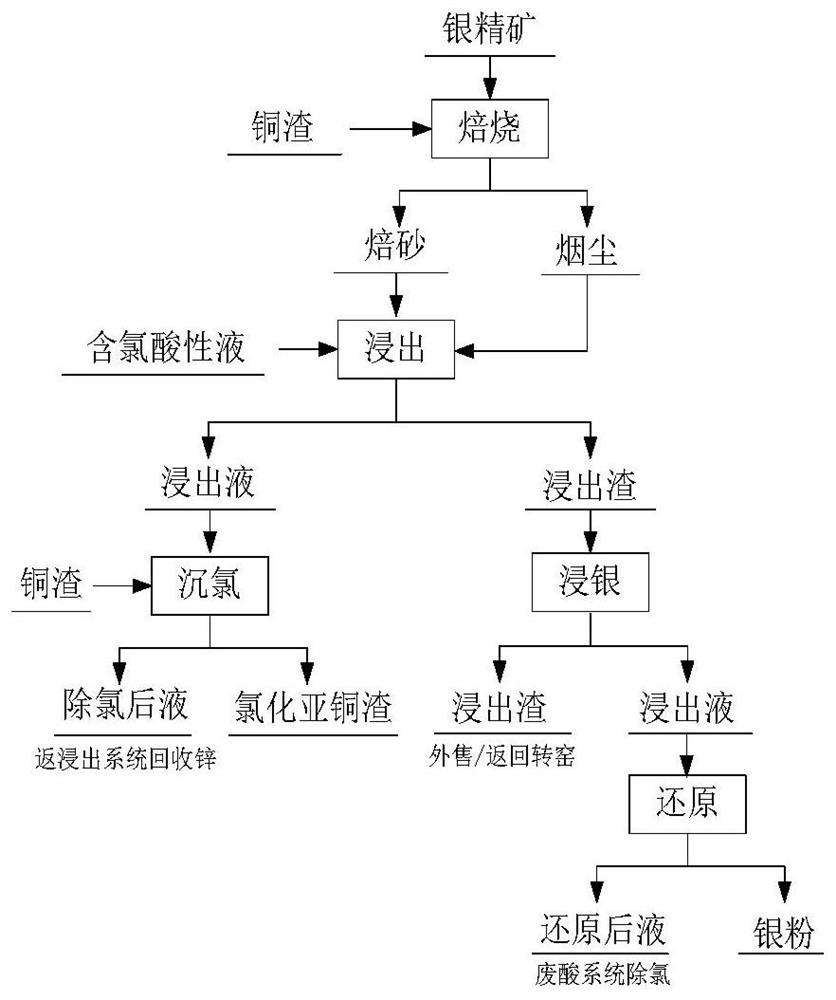

[0025] In this example, the amount of copper slag (low activity) added is 2% of the silver concentrate quality, and the mixed material of silver concentrate and copper slag contains Cu: 1.24%, Ag: 3629g / t, Pb: 2.04%, Zn: 30.86%, the dosage of sulfuric acid is 15% of the quality of silver concentrate, such as figure 1 As shown, the processing technology and effect are as follows:

[0026] (1) The mixture is roasted, roasting conditions: temperature 550 ° C, time 4h, air excess coefficient 1.2, the composition of the calcined sand and soot mixture is Cu: 1.42%, Pb: 2.31%, Zn: 34.83%, Ag : 4108.07g / t.

[0027] (2) The mixture of calcine and soot is leached out with chlorine-containing waste acid. Leaching conditions: temperature 80°C, liquid-solid ratio 10:1 (volume L / mass g), acidity 150g / L, time 1h, chlorine concentration in chlorine-containing waste acid 1.26g / L. The composition of acid leaching solution is Cu: 1.38g / L, Zn: 33.70g / L, Pb: 2.67mg / L, Ag: <0.1mg / L, Cl: 0.96g / L,...

Embodiment 2

[0032] In this example, the dosage of copper slag is 4.5% of the mass of silver concentrate, and the mixed material of silver concentrate and copper slag contains Cu: 2.32%, Ag: 3347g / t, Pb: 3.73%, Zn: 28.69%. sulfuric acid, such as figure 1 As shown, the processing technology and effect are as follows:

[0033] (1) The mixture is roasted, the roasting conditions are: temperature 600°C, time 3.5h, air excess coefficient 1.1, the composition of the calcined sand and soot mixture is Cu: 2.61%, Pb: 4.18%, Zn: 32.07%, Ag: 3748.82g / t.

[0034] (2) Leaching of calcine and soot mixture by using chlorine-containing waste acid. Leaching conditions: temperature 90°C, liquid-solid ratio 15:1 (volume L / mass g), acidity 50g / L, time 2h, chlorine concentration in chlorine-containing acidic liquid is 2.47g / L. The composition of the acid leaching solution is Cu: 1.64g / L, Zn: 20.98g / L, Pb: <0.1mg / L, Ag: <0.1mg / L, Cl: 2.04g / L, and the composition of the acid leaching residue is: Cu: 0.55%, Z...

Embodiment 3

[0039]In this example, the dosage of copper slag is 0.5% of the silver concentrate, and the mixture of silver concentrate and copper slag contains Cu: 1.04%, Ag: 3507g / t, Pb: 3.87%, Zn: 31.82%, sulfuric acid The input amount is 8% of the mass of silver concentrate, such as figure 1 As shown, the processing technology and effect are as follows:

[0040] (1) The mixture is roasted, roasting conditions: temperature 700 ° C, time 2h, air excess coefficient 1.2, the composition of the calcined sand and soot mixture is Cu: 1.17%, Pb: 4.35%, Zn: 35.65%, Ag : 3937.4g / t.

[0041] (2) Leaching of calcine and soot mixture by using chlorine-containing waste acid. Leaching conditions: temperature 90°C, liquid-solid ratio 20:1 (volume L / mass g), acidity 170g / L, time 3h, chlorine concentration in chlorine-containing acidic liquid is 0.8g / L. The composition of the acid leaching solution is Cu: 0.57g / L, Zn: 17.53g / L, Pb: <0.1mg / L, Ag: <0.1mg / L, Cl: 0.45g / L, and the composition of the acid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com