Method for removing chloride ions in electrolytic manganese solution

A technology of electrolyzing manganese and chloride ions, which is applied in the field of manganese hydrometallurgy, can solve the problems of large loss of manganese resources, closure of production enterprises, increase of production costs, etc., and achieve good regeneration ability, low loss, and small amount of chlorine residue removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

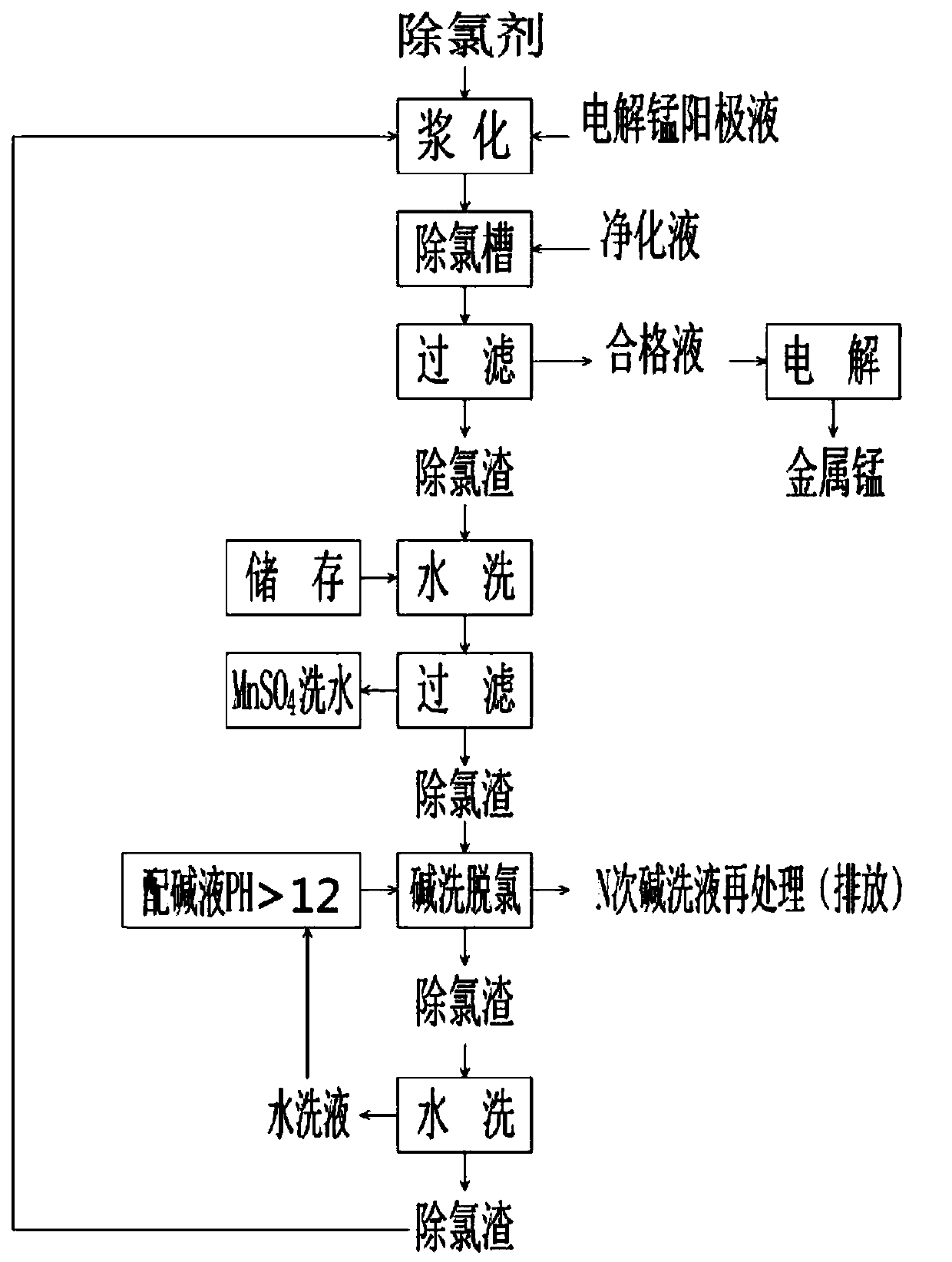

Image

Examples

Embodiment 1

[0032] Example 1, 17 grams of R-Bi 2 o 3 Add the type chlorine remover to 68g of the electrolytic manganese anode solution with a sulfuric acid content of 35g / l, start the agitator, stir for 20 minutes to make a slurry, adjust the pH value of the slurry reaction end point to 2 with dilute sulfuric acid, and add the slurry to 1000 ml In the electrolytic manganese solution to be treated with a chloride ion content of 1160 mg / L, fully stir for 60 minutes at 52°C at a stirring rate of 60 rpm, adjust the pH value at the end of the chlorine removal reaction to 4.6 with dilute sulfuric acid, and filter The chloride ion content is 87 grams per liter in the filtrate, and the removal rate of chlorine is 92.5%.

Embodiment 2

[0033] Embodiment 2, with 18 grams of R-Bi 2 o 3 Add the type chlorine remover to 90g of electrolytic manganese anode solution with a sulfuric acid content of 40g / l, start the agitator, stir for 25 minutes to make a slurry, adjust the pH value of the slurry reaction end point to 3 with dilute sulfuric acid, and add the slurry to 1000 ml In the electrolytic manganese solution to be treated with a chloride ion content of 1230 mg / L, fully stir for 45 minutes at 55°C at a stirring rate of 60 rpm, adjust the pH value of the end point of the chlorine removal reaction to 4.8 with dilute sulfuric acid, and filter The chloride ion content is 71.34 grams per liter in the filtrate, and the removal rate of chlorine is 94.2%.

Embodiment 3

[0034] Embodiment 3, with 11 grams of R-Bi 2 o 3 Add the type dechlorination agent to 66g of the electrolytic manganese anode solution with a sulfuric acid content of 30g / l, start the agitator, stir for 30 minutes to make a slurry, adjust the pH value of the slurry reaction end point to 1 with dilute sulfuric acid, and add the slurry to 1000 ml In the electrolytic manganese solution to be treated with a chloride ion content of 863 g / L, fully stir for 55 minutes at a stirring rate of 60 rpm at 51° C., adjust the pH value at the end of the chlorine removal reaction to 4.4 with dilute sulfuric acid, and the filtrate The content of chlorine ion in the medium is 100.11 g / liter, and the removal rate of chlorine is 88.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com