Quenching device with air taking structure and design method of air taking structure

A technology of quenching chamber and air chamber, which is applied in the field of cement production equipment, can solve the problems of low capture efficiency, low chlorine ion discharge rate, and affecting specific surface area, etc., and achieve the effect of increasing specific surface area, improving chlorine removal efficiency, and good capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

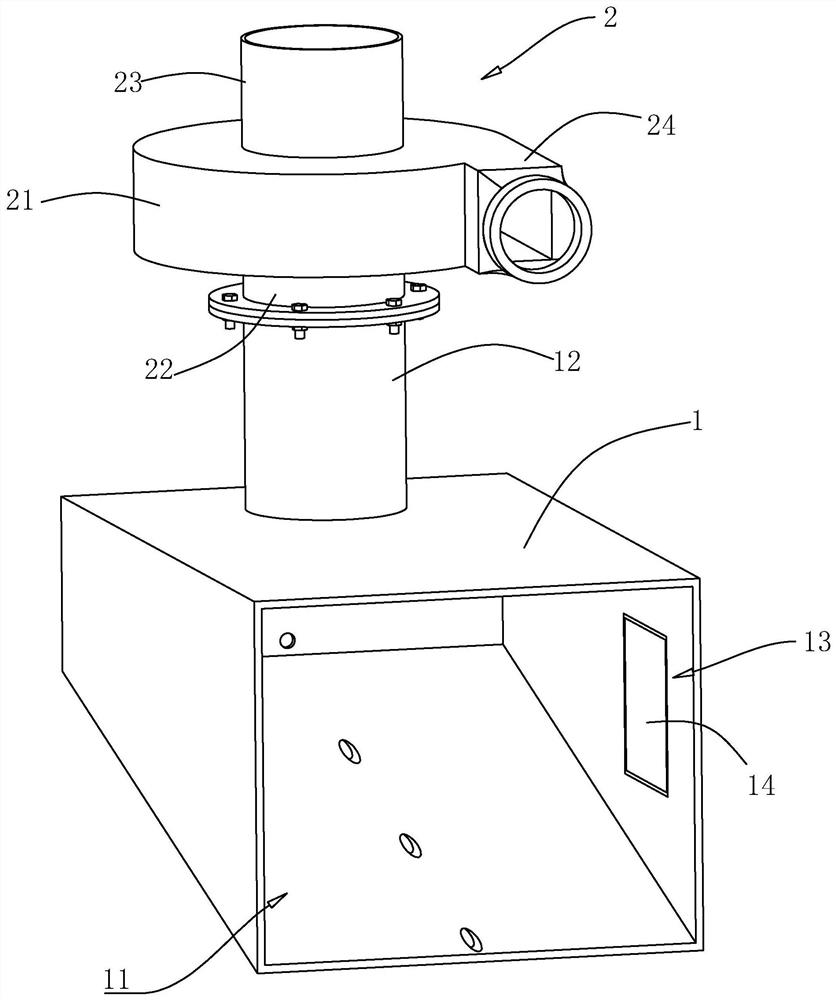

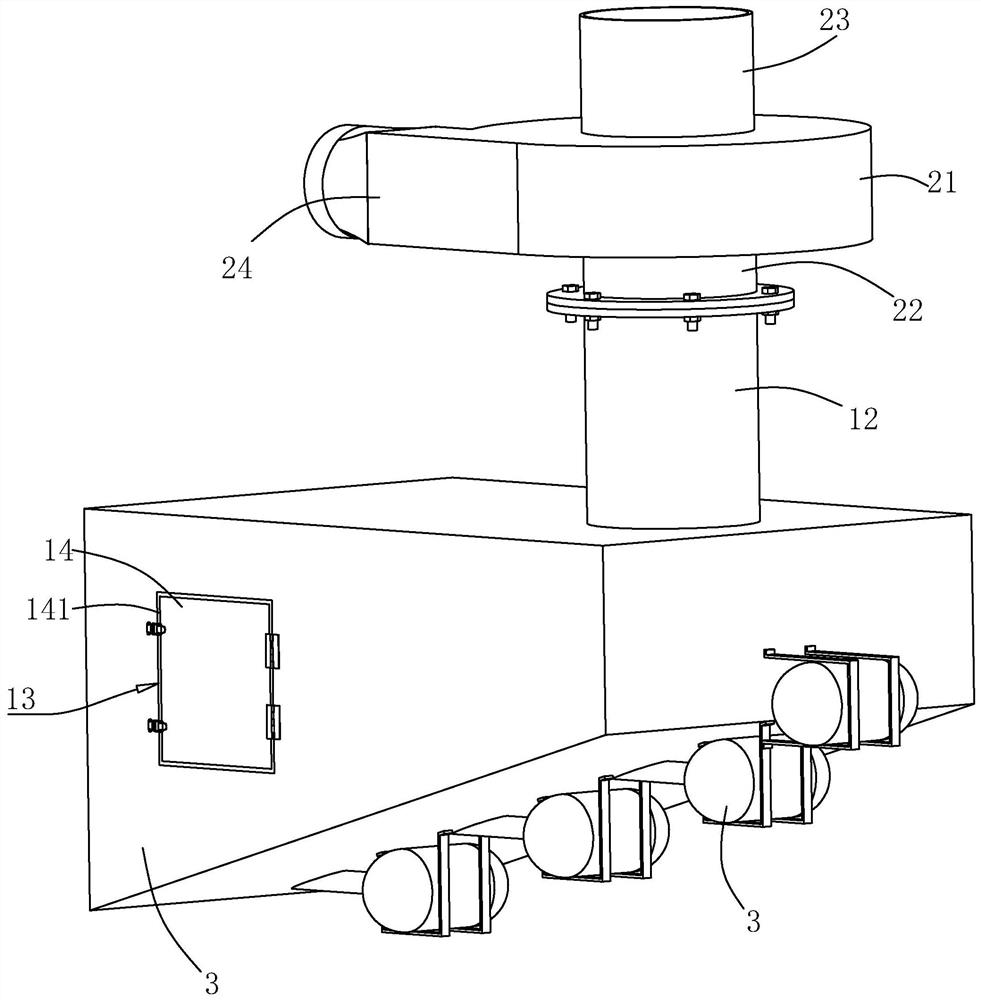

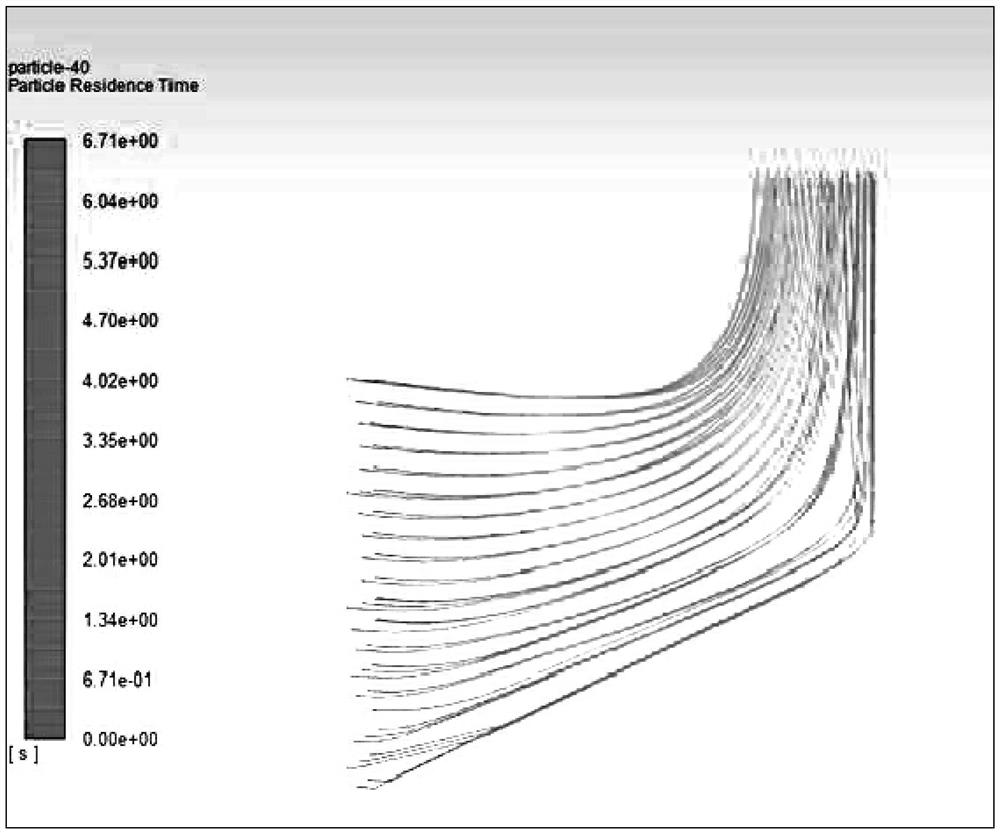

[0041] The following is attached Figure 1-7 The application is described in further detail.

[0042] The embodiment of the present application discloses a quenching device provided with an air intake structure. refer to figure 1 , the quenching device includes air intake chamber 1 and quenching chamber 2, the intake chamber 1 is connected with the smoke chamber of the brick kiln, the quenching chamber 2 is connected with the intake chamber 1, the flue gas enters the quenching chamber 2 through the intake chamber 1, and the intake chamber 1 It can capture the particles in the flue gas and reduce the escape degree of the particles, thereby improving the efficiency of removing chlorine in the flue gas. The quenching chamber 2 can cool down the flue gas so that the temperature of the discharged flue gas will not be too high and avoid high temperature Fumes are damaging to the environment. The air intake chamber 1 is made of manganese steel. The manganese steel has high strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com