Method and apparatus for removing fluorine from wet-method phosphoric acid through air blowing method

A technology of wet-process phosphoric acid and blowing method, which is applied in the fields of chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., and can solve the problems of high required components and complex operation, etc., and achieve high yield, high yield, and economic benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

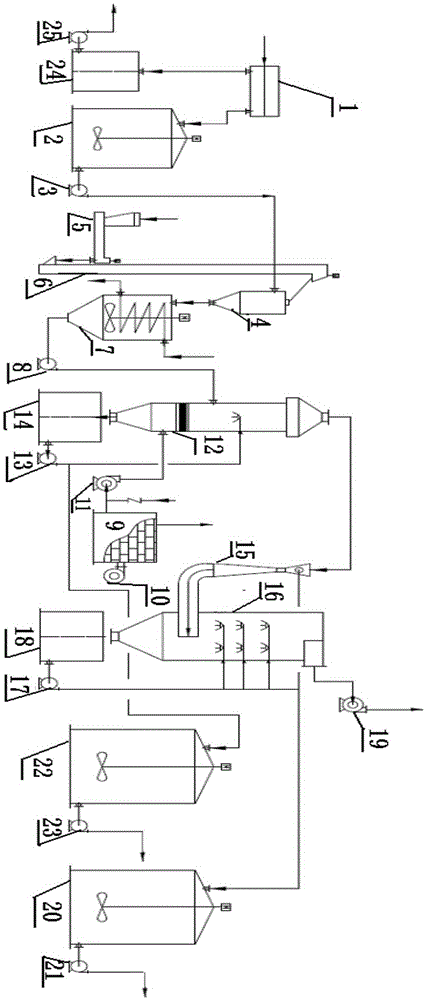

[0041] Fluorine-containing wet-process phosphoric acid (P 2 o 5 The mass fraction is 42.5% to 47.8%) after being treated by the screw discharge sedimentation centrifuge (1), the dense phase is collected by the filter residue collection tank (24) and then sent to the upstream filtration process by the filter residue pump (25), and the purified fluorine-containing The wet-process phosphoric acid is collected by the phosphoric acid storage tank (2) and sent to the pre-mixer (4) by the phosphoric acid feed pump (3). The diatomite with a particle size of 80 to 100 mesh is sent to the pre-mixer (4) (SiO 2 : The molar ratio of F in phosphoric acid is 1.35:1). The mixed material enters the heating tank (7) and is heated by steam and further mixed, then sent to the defluorination device (12) by the second phosphoric acid feeding pump (8), and countercurrently flows with the hot air at 205-215°C from the hot air blower (11) The contact is fully reacted, and the gas velocity of the li...

Embodiment 2

[0043] Fluorine-containing wet-process phosphoric acid (P 2 o 5 The mass fraction is 42.5% to 47.8%) after being treated by the screw discharge sedimentation centrifuge (1), the dense phase is collected by the filter residue collection tank (24) and then sent to the upstream filtration process by the filter residue pump (25), and the purified fluorine-containing The wet-process phosphoric acid is collected by the phosphoric acid storage tank (2) and sent to the pre-mixer (4) by the phosphoric acid feed pump (3). The diatomite with a particle size of 135 to 150 mesh is sent to the pre-mixer (4) (SiO 2 : The molar ratio of F in phosphoric acid is 2:1). The mixed material enters the heating tank (7) and is heated by steam and further mixed, then sent to the defluorination device (12) by the second phosphoric acid feeding pump (8), and countercurrently flows with the hot air at 305-315°C from the hot air blower (11) The contact is fully reacted, and the gas velocity of the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com