Simple preparation method for metallographic phase sample of silicon wafer

A technology for metallographic sample preparation and silicon wafers, which is applied in semiconductor and photovoltaic production technology and research fields, can solve the problems of inability to take out thin samples completely, long curing time, warping of silicon wafers, etc., to achieve all-round observation and implementation cost The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

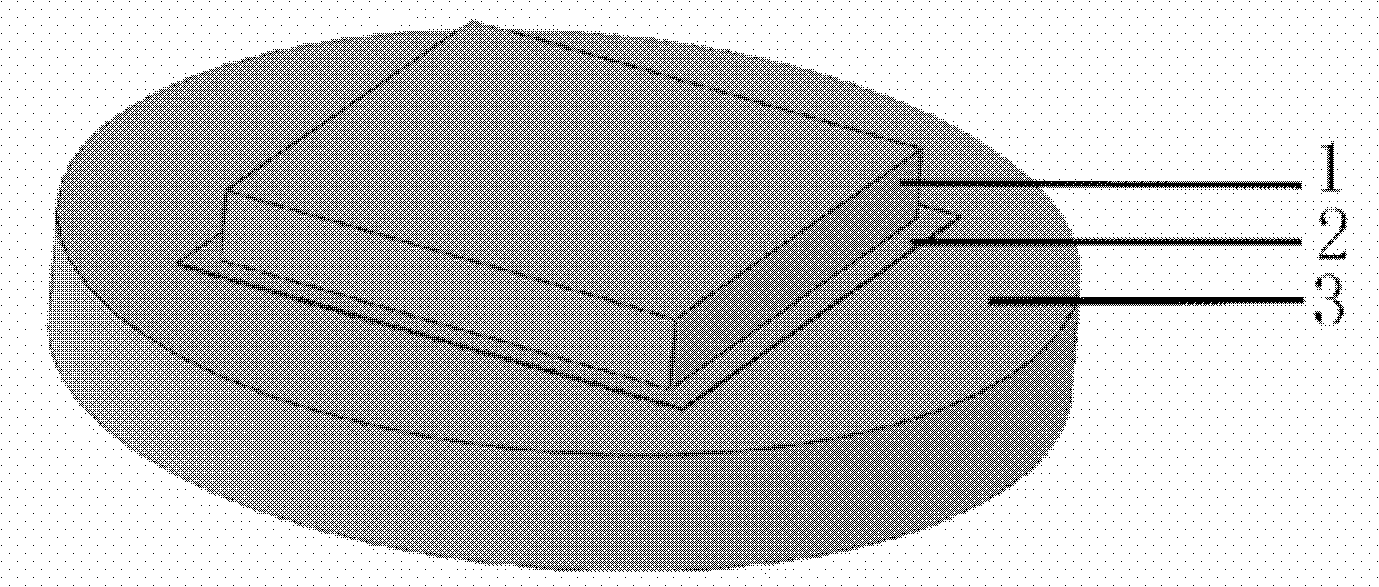

[0026] A kind of simple and easy preparation method of silicon chip metallographic sample, it comprises the steps:

[0027] (1) Select a flat stainless steel, hard alloy or ceramic cylinder (diameter 40mm, height 10mm) as the carrier plate of the silicon wafer;

[0028] (2) Put the solid hot melt adhesive on the surface of the carrier board, the dosage is 0.3 ~ 0.5g, the dosage is enough to adhere to the silicon wafer, and the carrier board is heated until the hot melt adhesive melts into a liquid thin layer (according to the hot melt adhesive characteristics, generally heated to 70 ~ 100 ℃, about 2 minutes to melt);

[0029] (3) After the hot melt adhesive is melted, place the silicon wafer (thickness below 250 μm) flat on the upper surface of the carrier and cover it on the hot melt adhesive, and use another flat pressing block (generally weighing 50 to 100 g) to evenly Apply pressure on the silicon wafer to make the thin silicon wafer closely adhere to the surface of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com