Carbon fiber-added microcapsule shape-stabilized phase-change material and preparation method thereof

A technology of shape-setting phase change material and carbon fiber, applied in microcapsule preparation, microsphere preparation, heat exchange materials, etc. Exothermic function, enhancing mechanical strength, slowing or preventing the escape of paraffin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A microcapsule shaped phase change material added with carbon fiber, including the following components in parts by weight: 50 parts by weight of core material, 300 parts of chloroform, 0.2 parts of emulsifier, 15 parts of toluene diisocyanate, 6 parts of ethylene diamine, and 10 parts of distilled water Parts; The core material includes paraffin, polyethylene and carbon fiber powder, the weight ratio of which is 45:45:10.

[0031] The preparation method of the core material is: adding polyethylene and carbon fiber powder into the reaction kettle, heating to 100°C, adding molten paraffin dropwise, and continuing to heat up to 250°C until the polyethylene and carbon fiber powder are melted, and then starting to stir , Maintain 40min; then cool to room temperature, smash to get.

[0032] The emulsifier is OP-10 emulsifier.

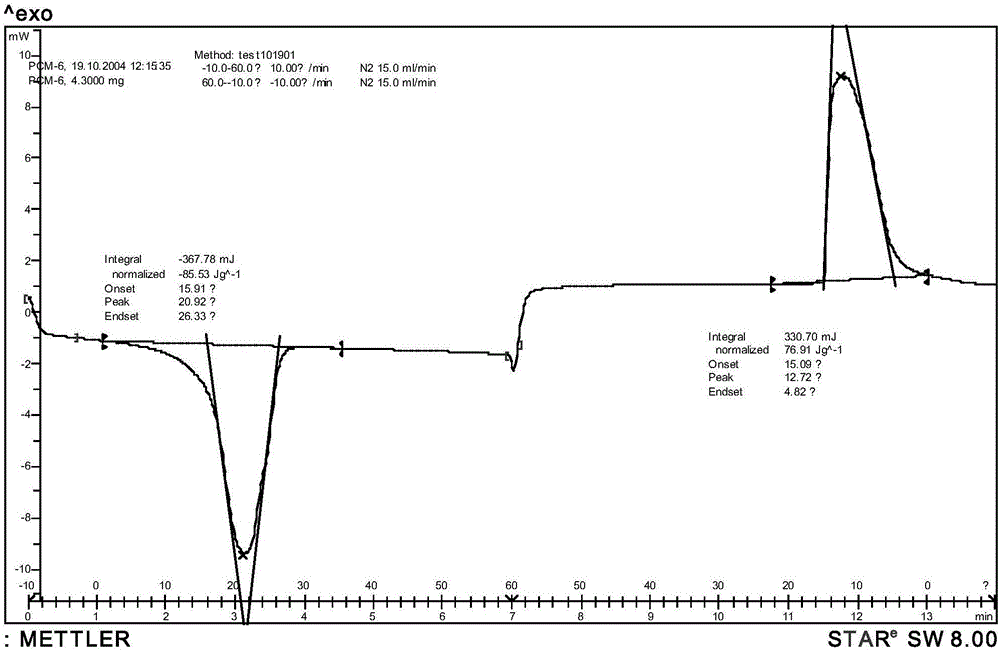

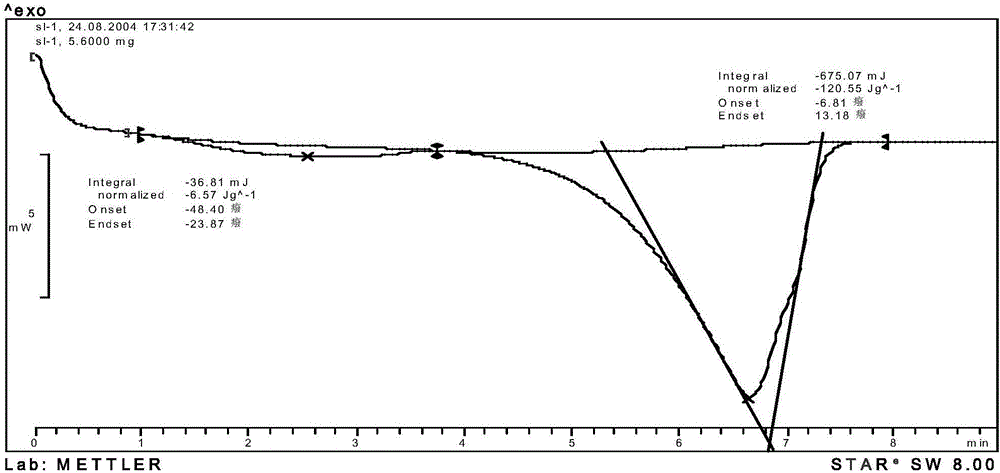

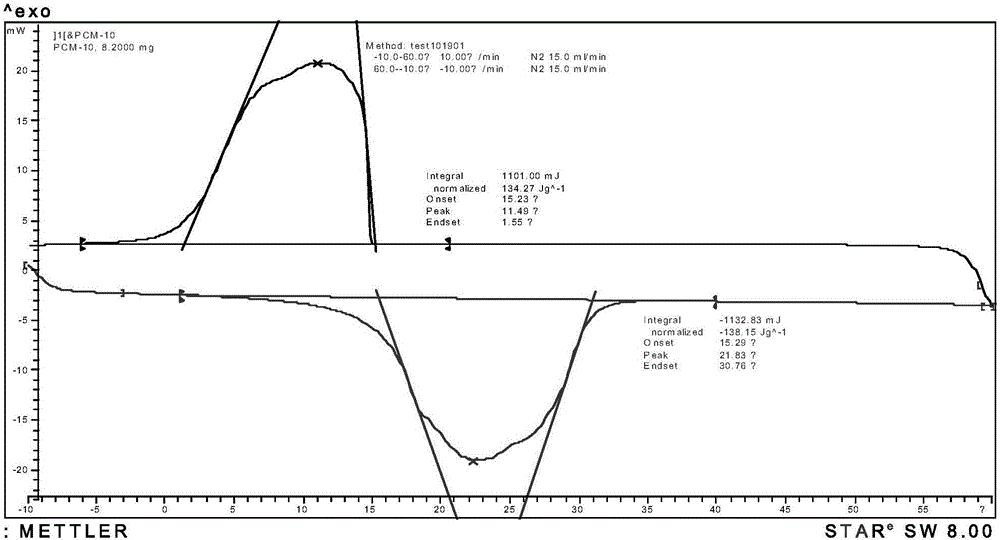

[0033] The paraffin wax is industrial paraffin wax with a melting point of 17°C.

[0034] A preparation method of carbon fiber-added microcapsule shaped pha...

Embodiment 2

[0041] A microcapsule shaped phase change material added with carbon fiber, comprising the following components in parts by weight: 100 parts of core material, 500 parts of chloroform, 0.6 parts of emulsifier, 30 parts of toluene diisocyanate, 15 parts of ethylene diamine, and 30 parts of distilled water Parts; The core material includes paraffin, polyethylene and carbon fiber powder, the weight ratio of which is 60:25:15.

[0042] The preparation method of the core material is: adding polyethylene and carbon fiber powder into the reactor, heating up to 50°C, adding melted paraffin dropwise, and continuing to heat up to 150°C until the polyethylene and carbon fiber powder are melted, and then starting to stir ,Maintain for 60min; then cool to room temperature and smash to get.

[0043] The emulsifier is OP-10 emulsifier.

[0044] The paraffin wax is industrial paraffin wax with a melting point of 17°C.

[0045] A preparation method of carbon fiber-added microcapsule shaped phase chan...

Embodiment 3

[0052] A microcapsule shaped phase change material added with carbon fiber, comprising the following components in parts by weight: 80 parts of core material, 400 parts of chloroform, 0.4 parts of emulsifier, 25 parts of toluene diisocyanate, and 10 parts of ethylene diamine; The core material includes paraffin wax, polyethylene and carbon fiber powder with a weight ratio of 70:20:10.

[0053] The preparation method of the core material is as follows: add polyethylene and carbon fiber powder into the reactor, heat up to 150°C, drop the molten paraffin, and continue to heat up to 280°C until the polyethylene and carbon fiber powder are melted, and then start to stir , Maintain for 30min; then cool down to room temperature, smash to get.

[0054] The emulsifier is OP-10 emulsifier.

[0055] The paraffin wax is industrial paraffin wax with a melting point of 17°C.

[0056] A preparation method of carbon fiber-added microcapsule shaped phase change material, including the following steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com