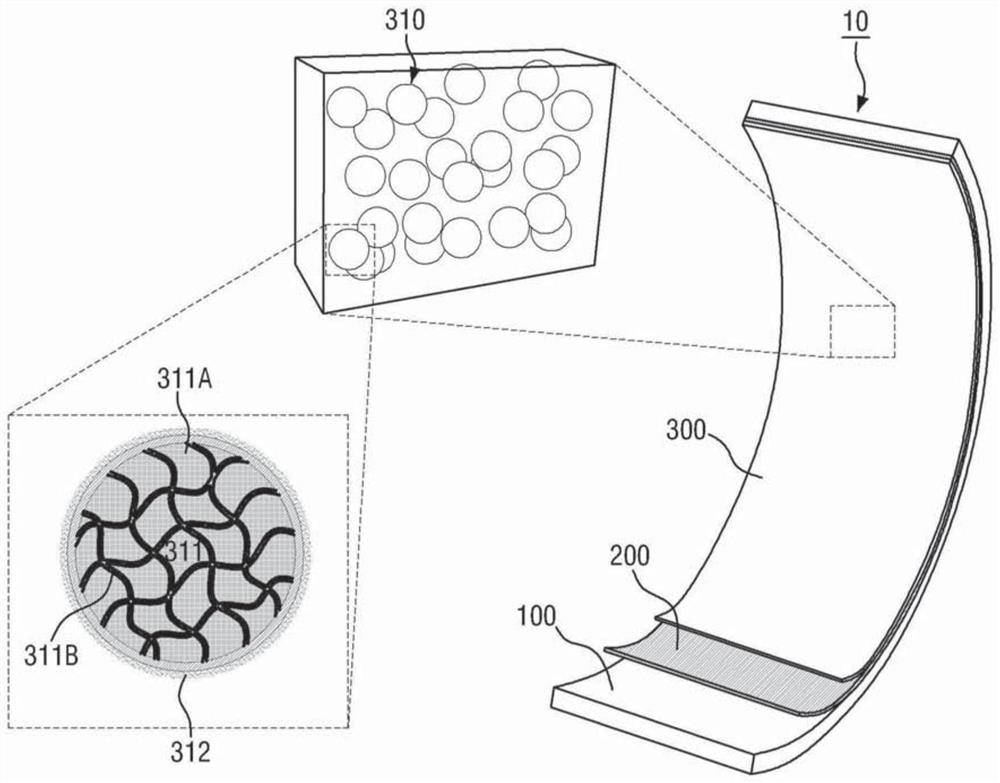

Method for manufacturing oil gel capsules and method for manufacturing contact part for vehicle, including oil gel capsules

An oil gel and capsule technology, applied in mechanical equipment, bearing components, petroleum industry, etc., can solve problems such as application limitations, and achieve the effect of improving anti-seizure performance and improving friction resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] An NMP solution (first organic solution) including 10 wt% of oil gel capsules was prepared by adding 10 g of oil powder to 90 g of NMP solvent. After preparing the first organic solution, the oil gel capsules were uniformly redispersed in the NMP solvent using a blender. After preparing an NMP solution (second organic solution) including 50 wt% of polyamideimide and additives (including lubricant), by mixing 50 g of the first organic solution and 50 g of the second organic solution, a covering mixed solution was prepared . After the surface of the bearing alloy is coated with the covering mixed solution and dried at 150°C-200°C for 30 minutes, a covering layer with a thickness of about 10 μm is prepared by drying the surface of the bearing alloy at 210°C-240°C for 15 minutes (Example 1 by Figure 16 and 17 Indicated by sample 1 in ).

Embodiment 2

[0074] A coating having a thickness of about 20 μm was prepared by coating the surface of the bearing alloy twice with the covering mixed solution in Example 1 (Example 2 by Figure 16 and 17 Indicated by sample 2 in ).

Embodiment 3

[0076] A coating with a thickness of about 30 μm was prepared by coating the surface of the bearing alloy three times with the covering mixed solution in Example 1 (Example 3 by Figure 16 and 17 Indicated by sample 3 in).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com