Patents

Literature

94results about How to "Good anti-occlusion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite sliding material

InactiveUS20030008169A1Avoid mechanical strengthImprove sintering performanceShaftsBearing componentsSteel platesCopper alloy

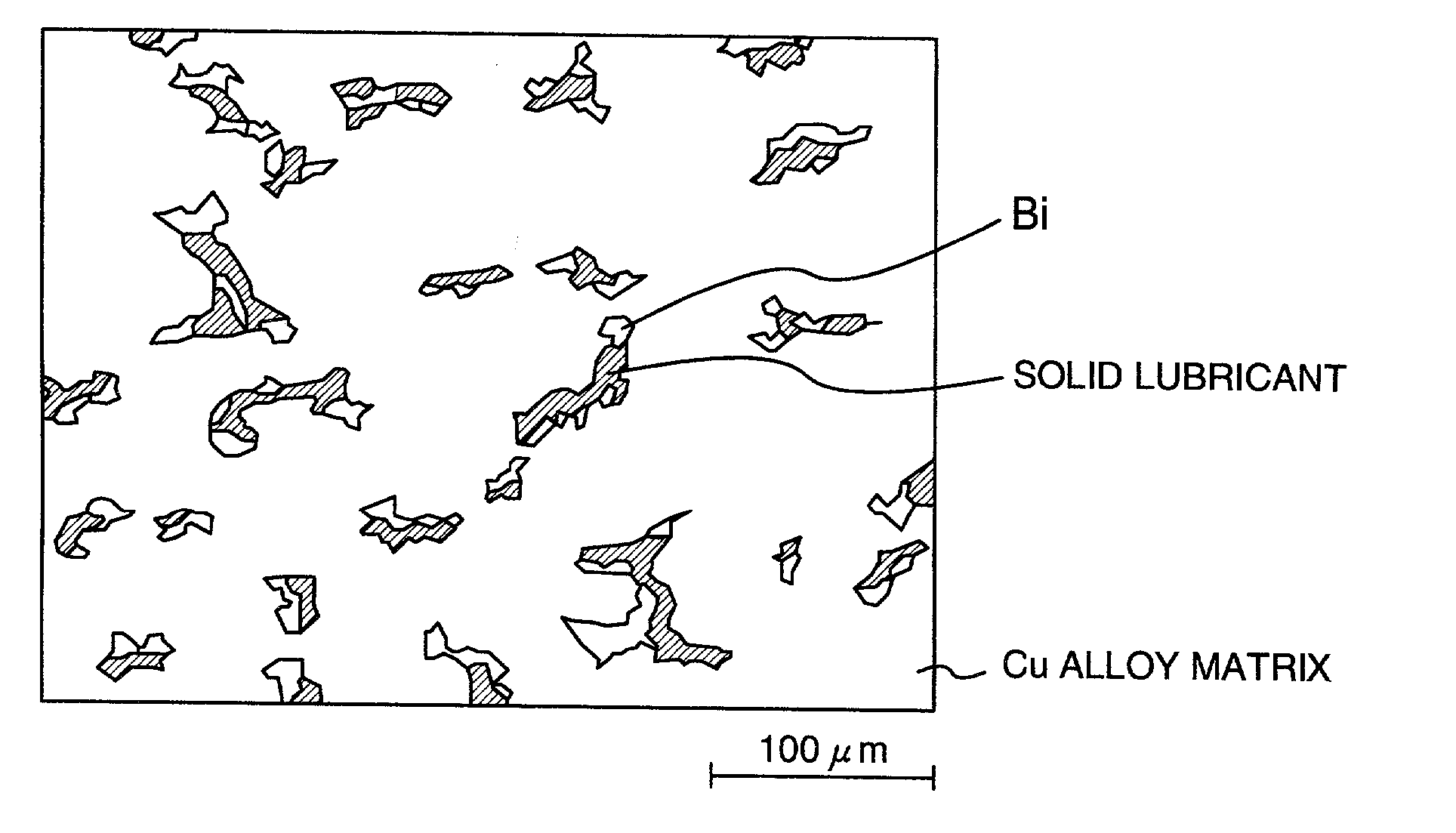

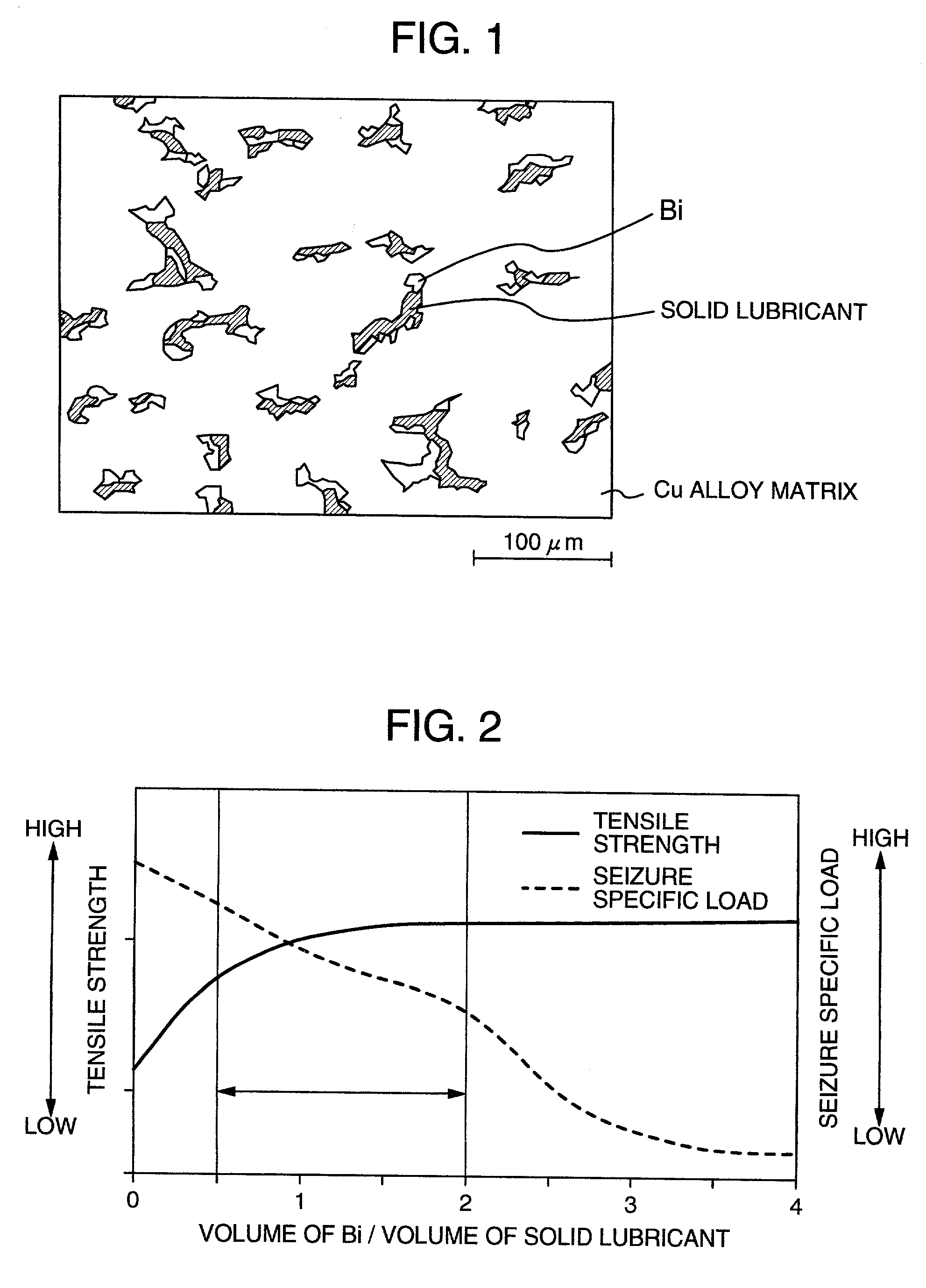

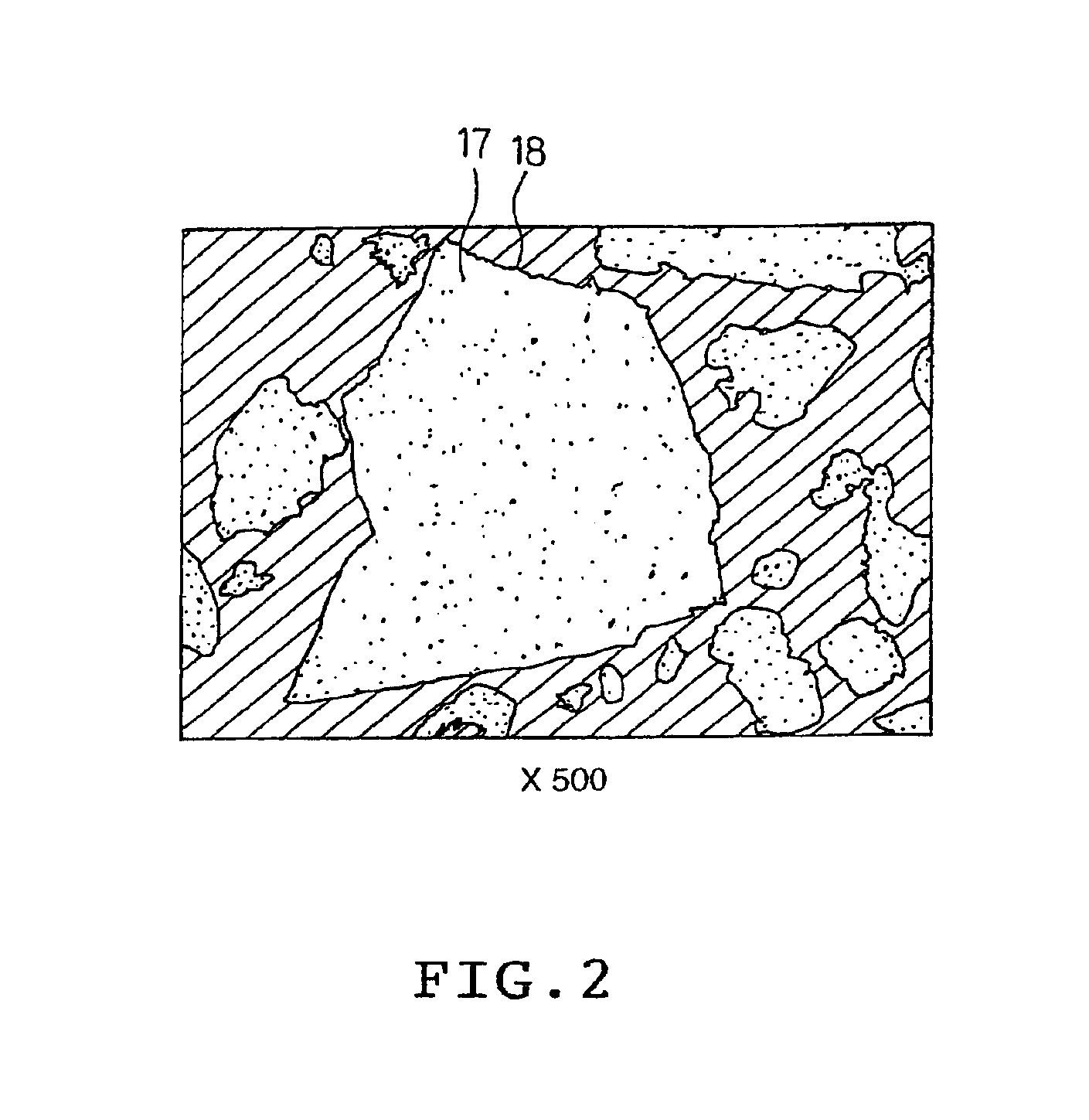

Disclosed is a composite sliding material having a steel plate and a sintered copper alloy layer which is bonded to the steel plate. The copper alloy contains, 1.5 to 15 mass % Sn, 1.5 to 15 mass % Bi, 1.5 to 20 volume % of a solid lubricant, and balance of Cu and incidental impurities. The volume ratio of Bi to the solid lubricant is in a range of 0.5 to 2.0. Bi and the solid lubricant improves the copper alloy in sintering property, since Bi melts when sintering because of a low melting point resulting in improved sintering property, and the solid lubricant ensures good anti-seizure property, and deterioration of mechanical strength is prevented by virtue of a phenomenon that the solid lubricant is entrained in Bi.

Owner:DAIDO METAL CO INC

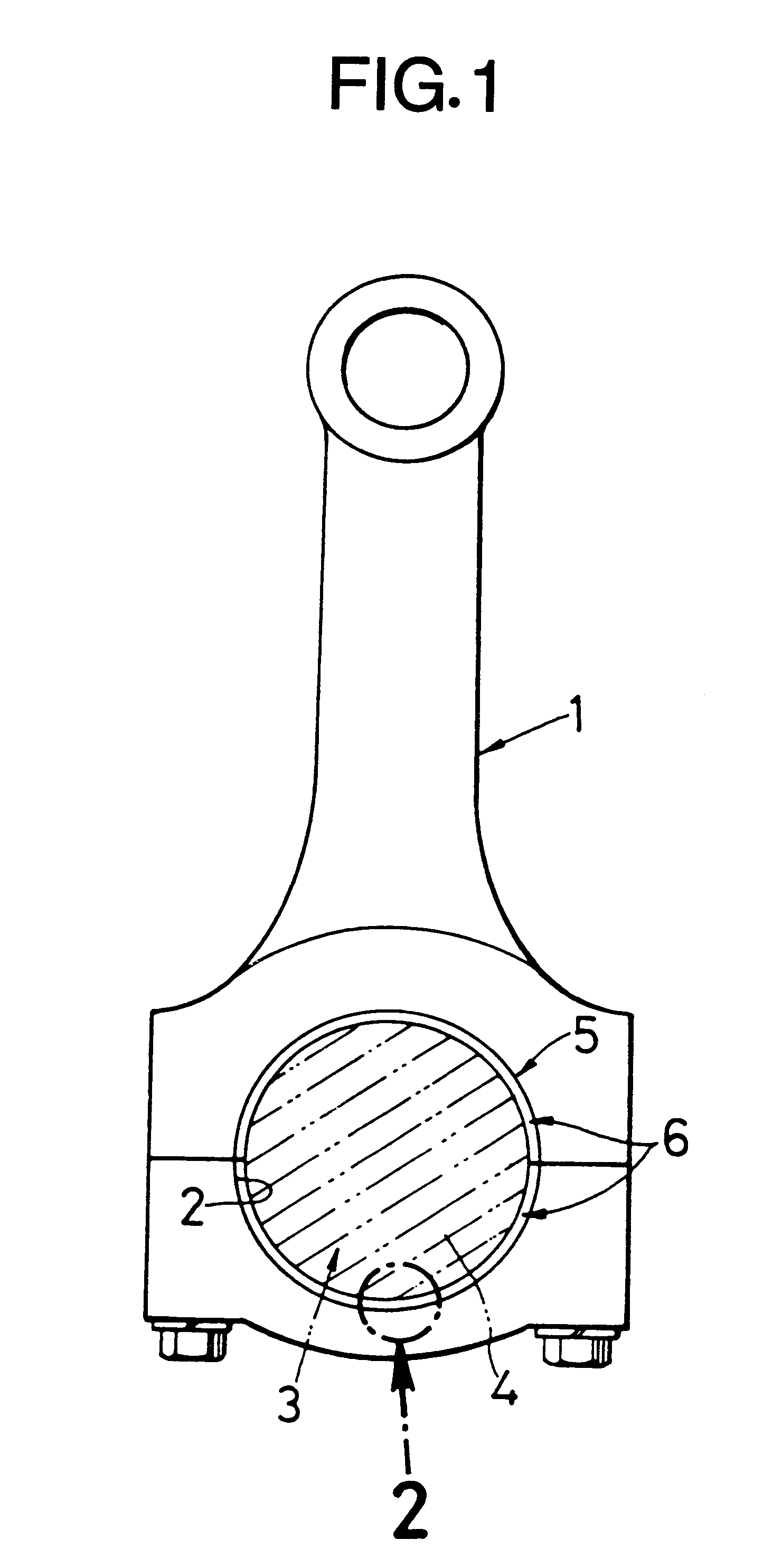

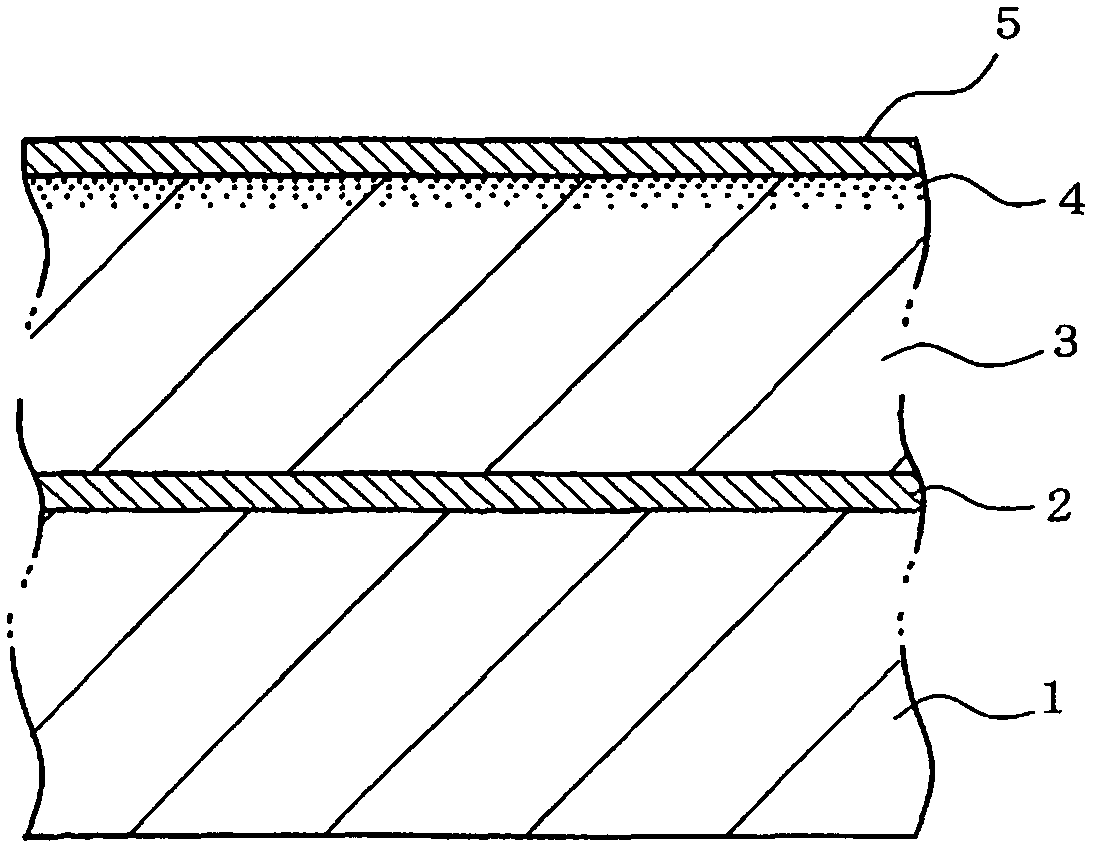

Sliding bearing

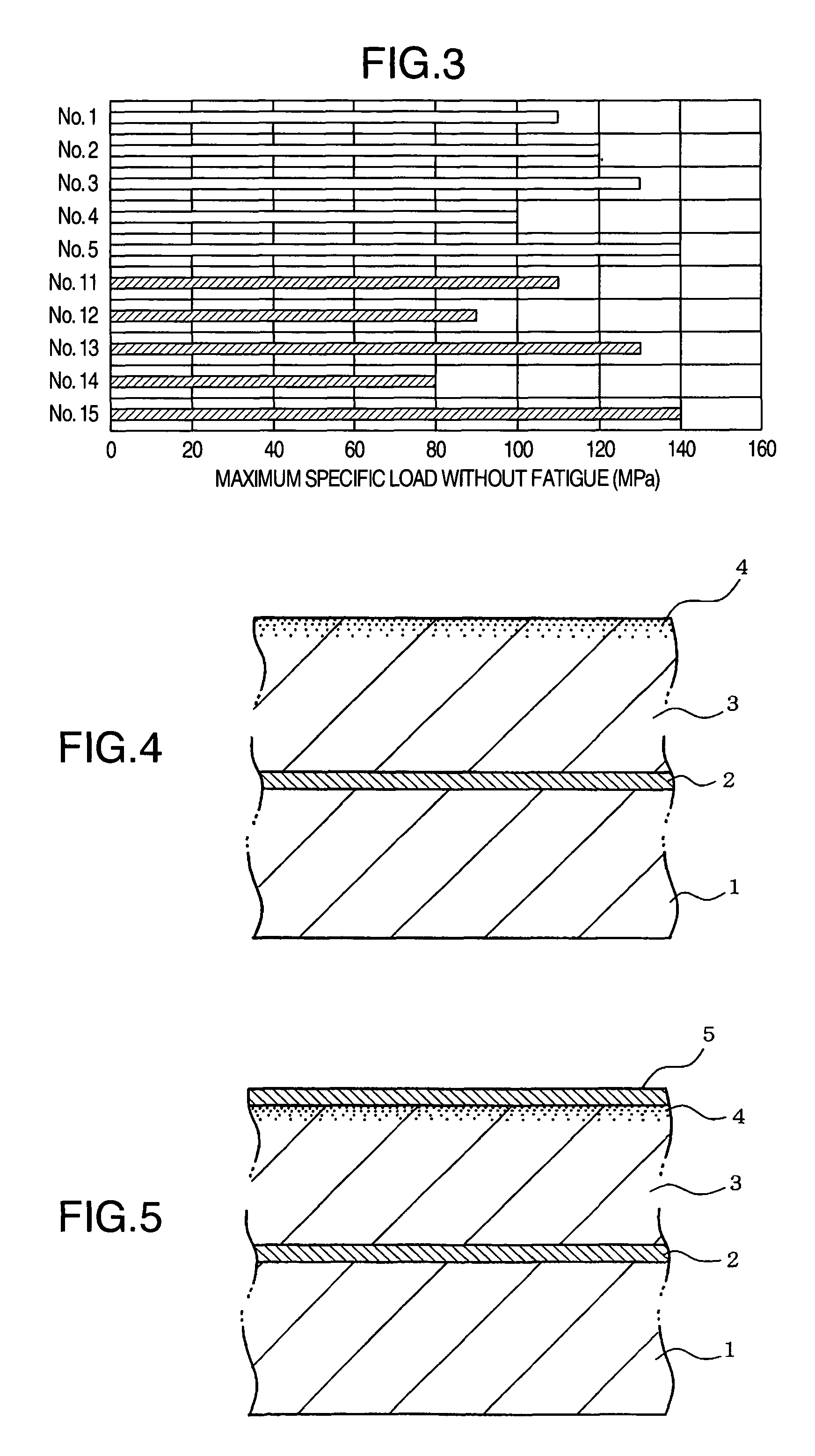

InactiveUS20060083451A1Good anti-occlusion performanceIncrease roughnessShaftsBearing componentsEngineeringAlloy

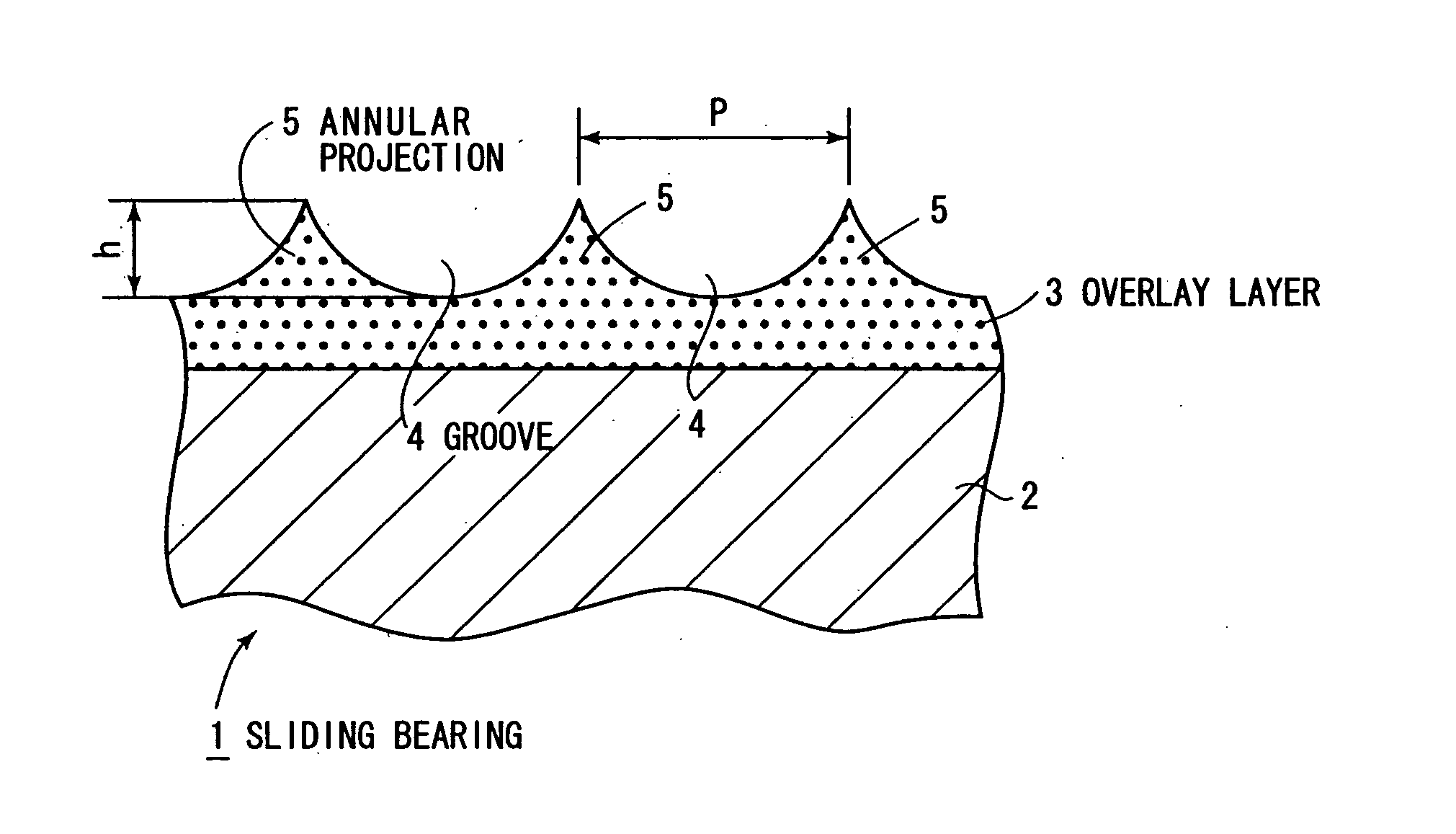

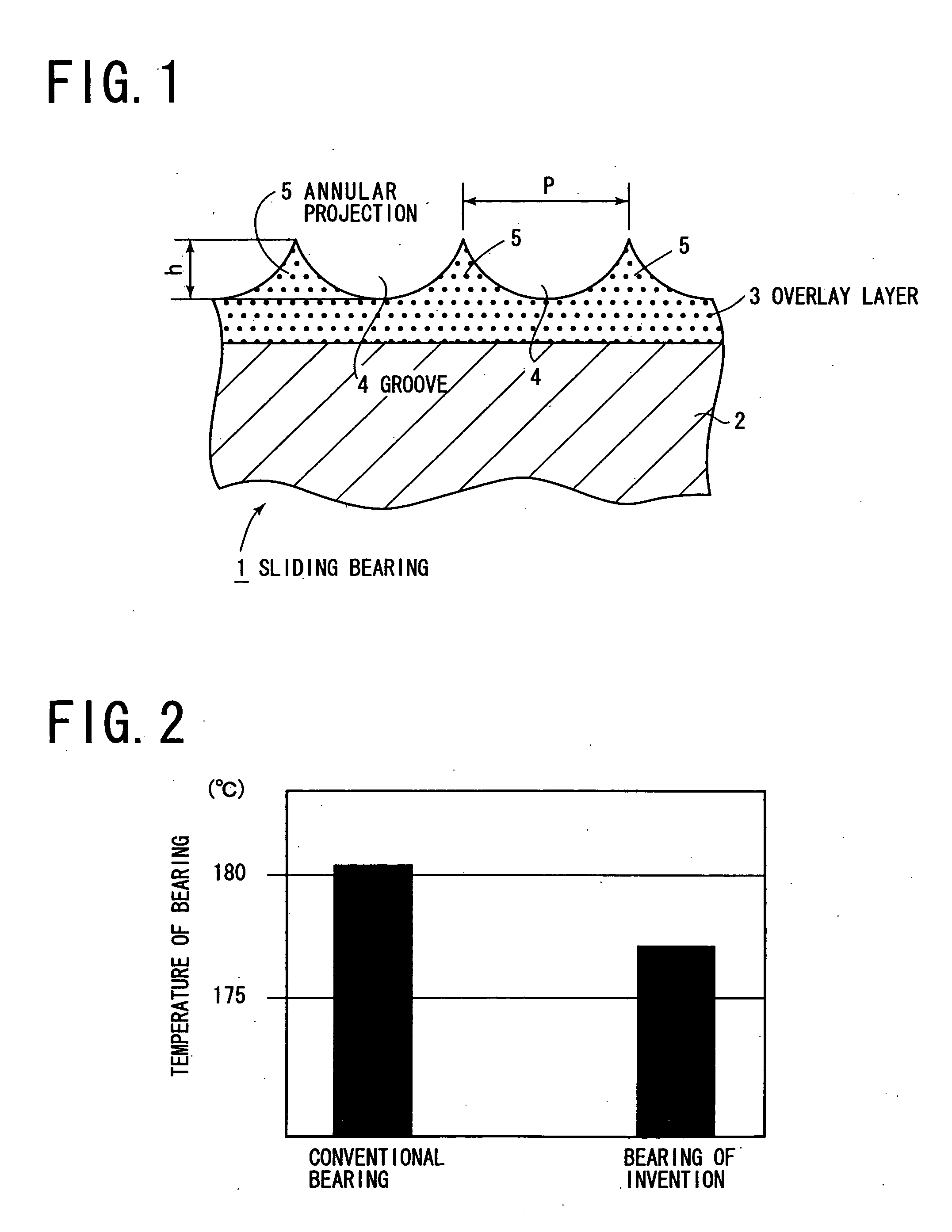

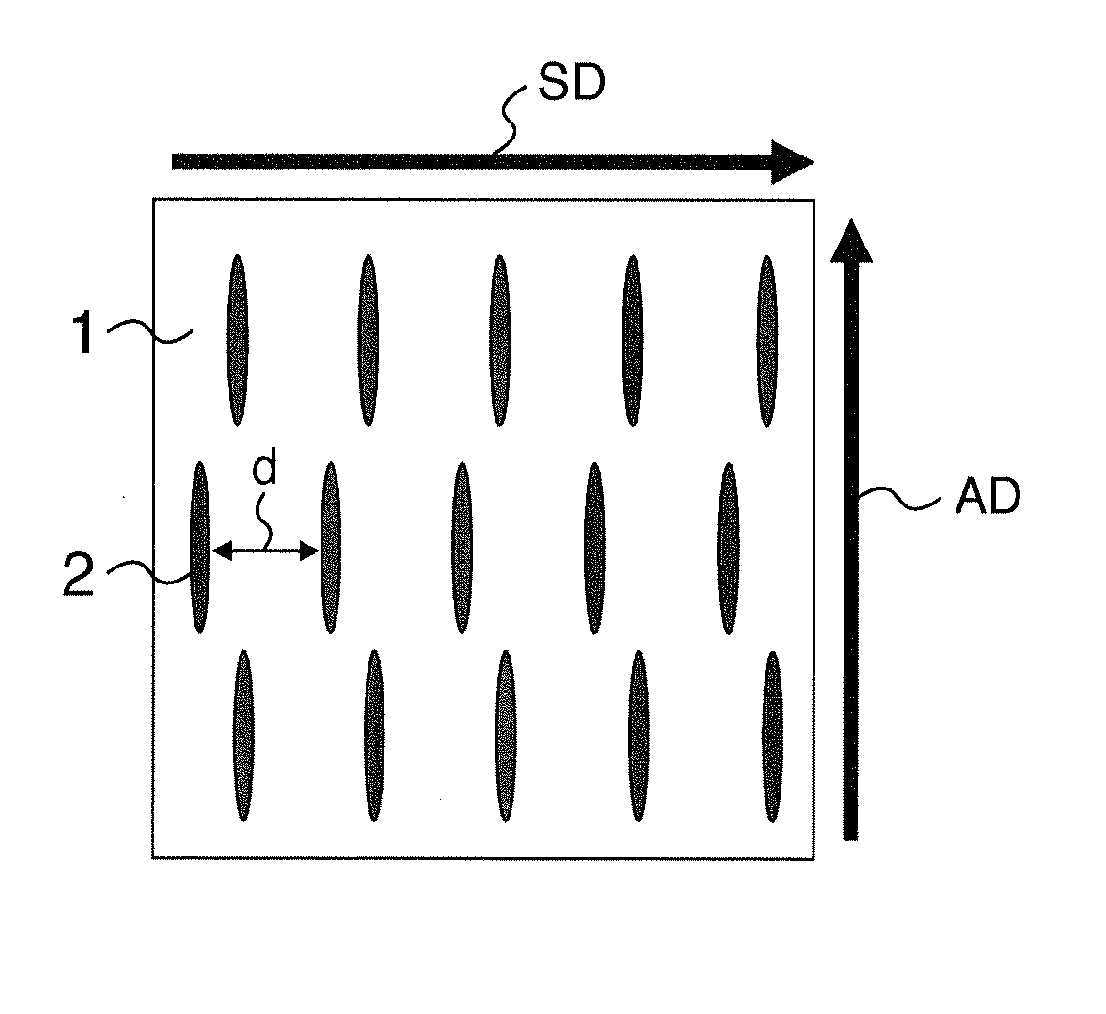

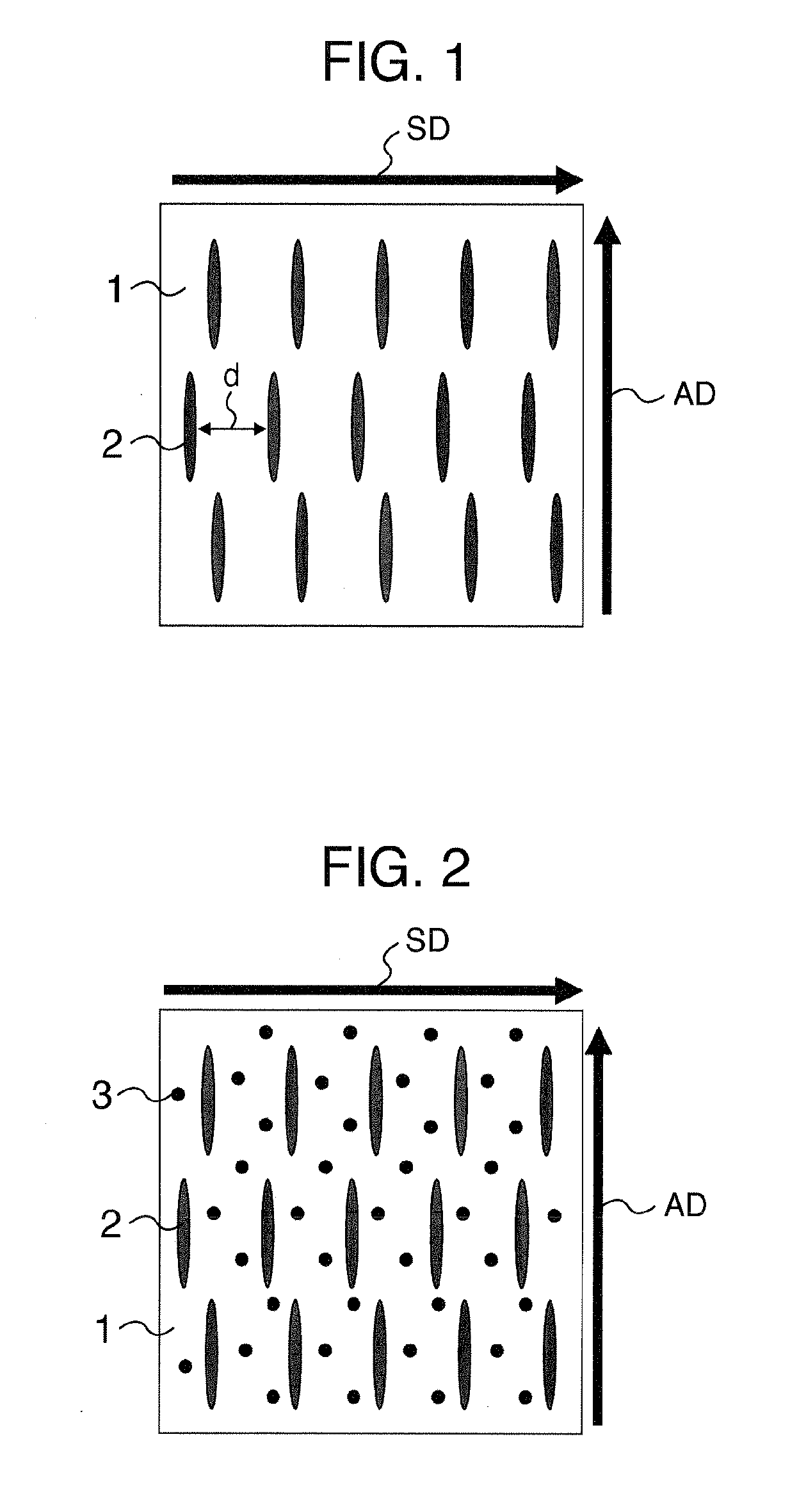

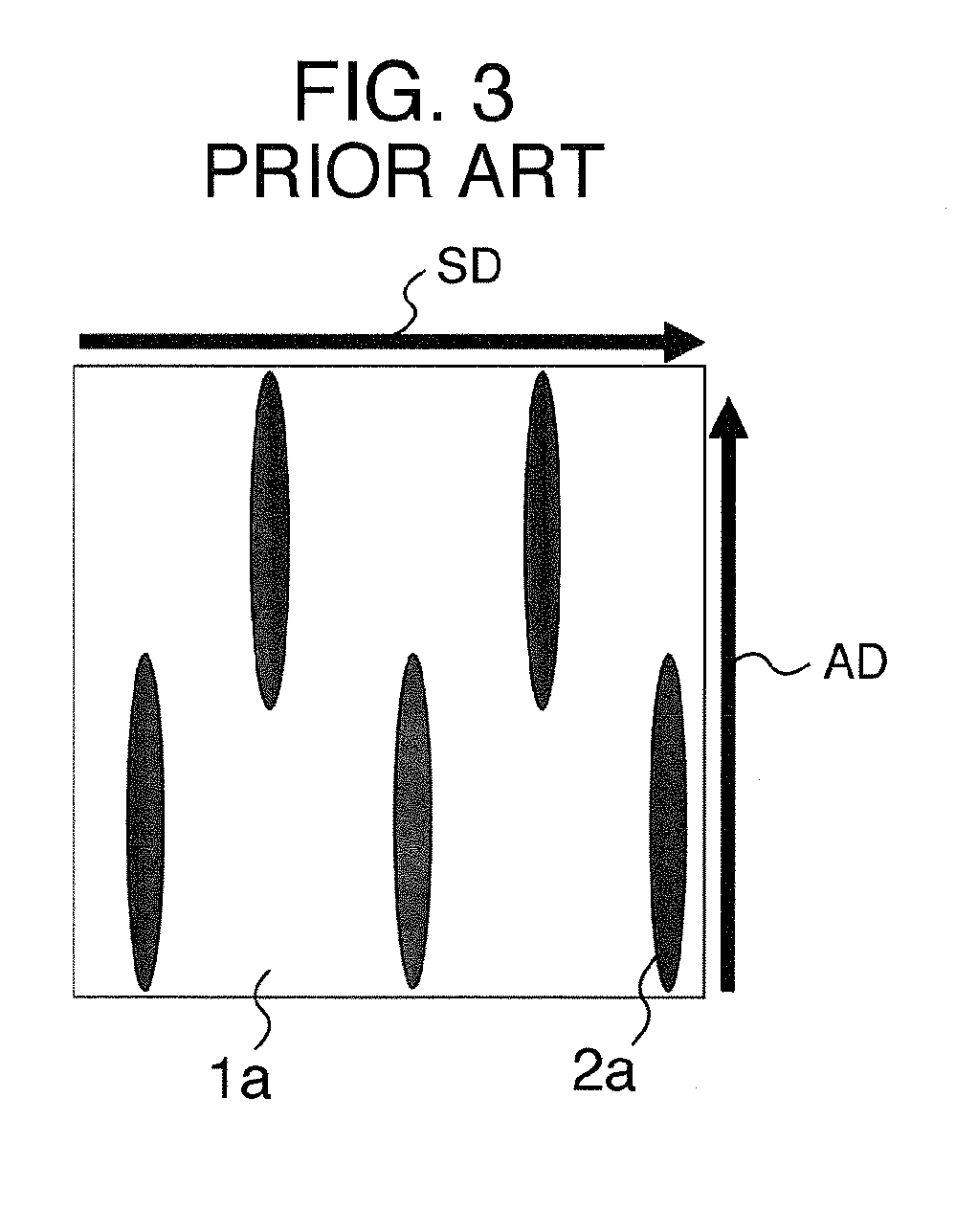

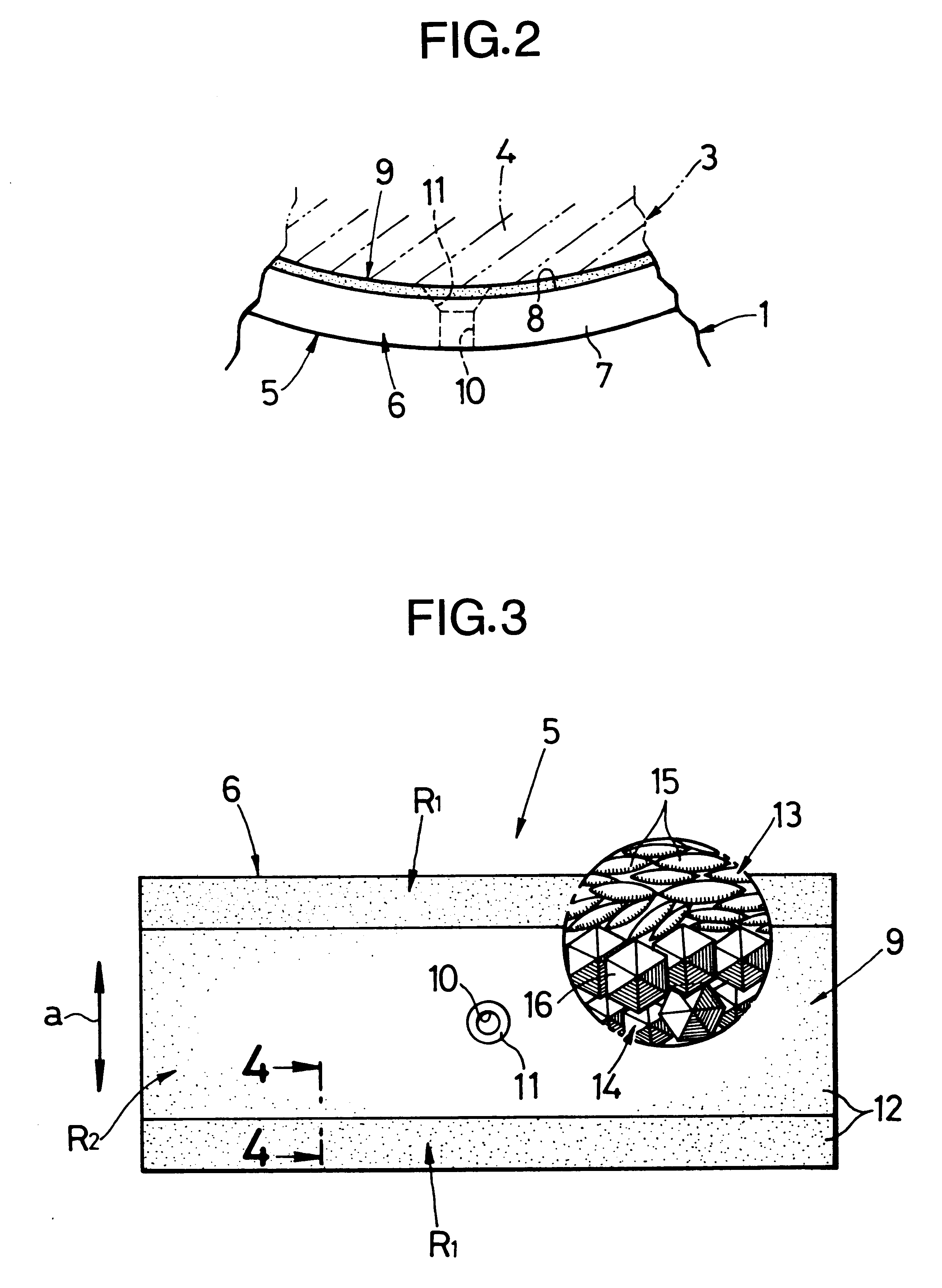

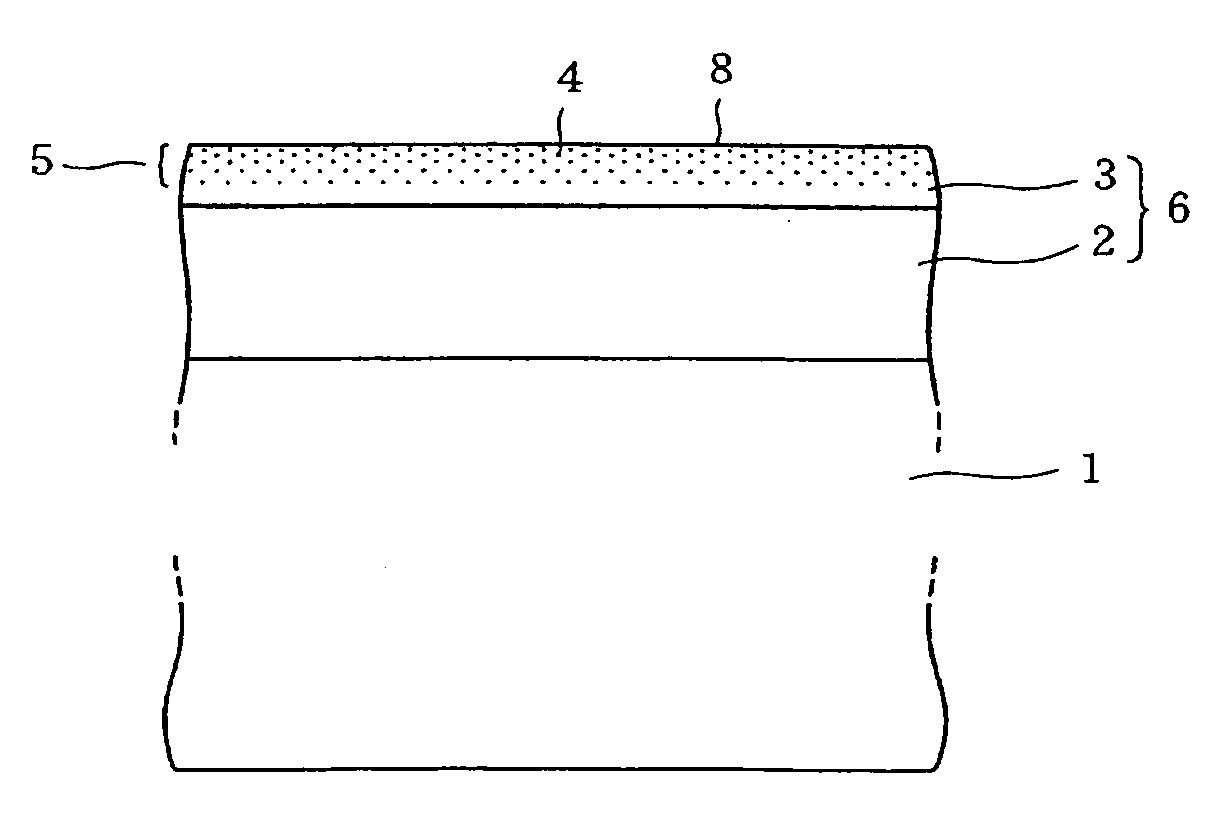

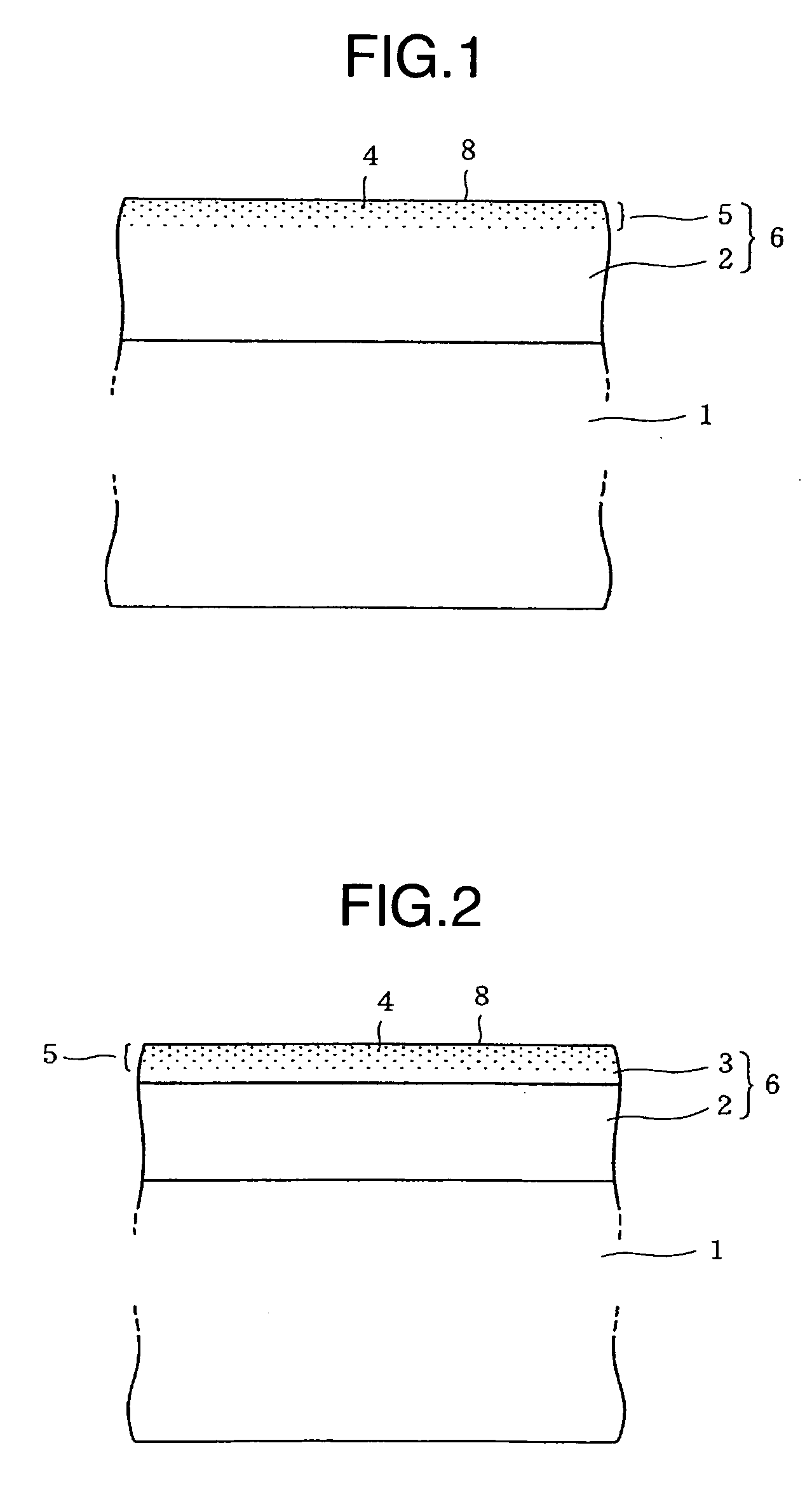

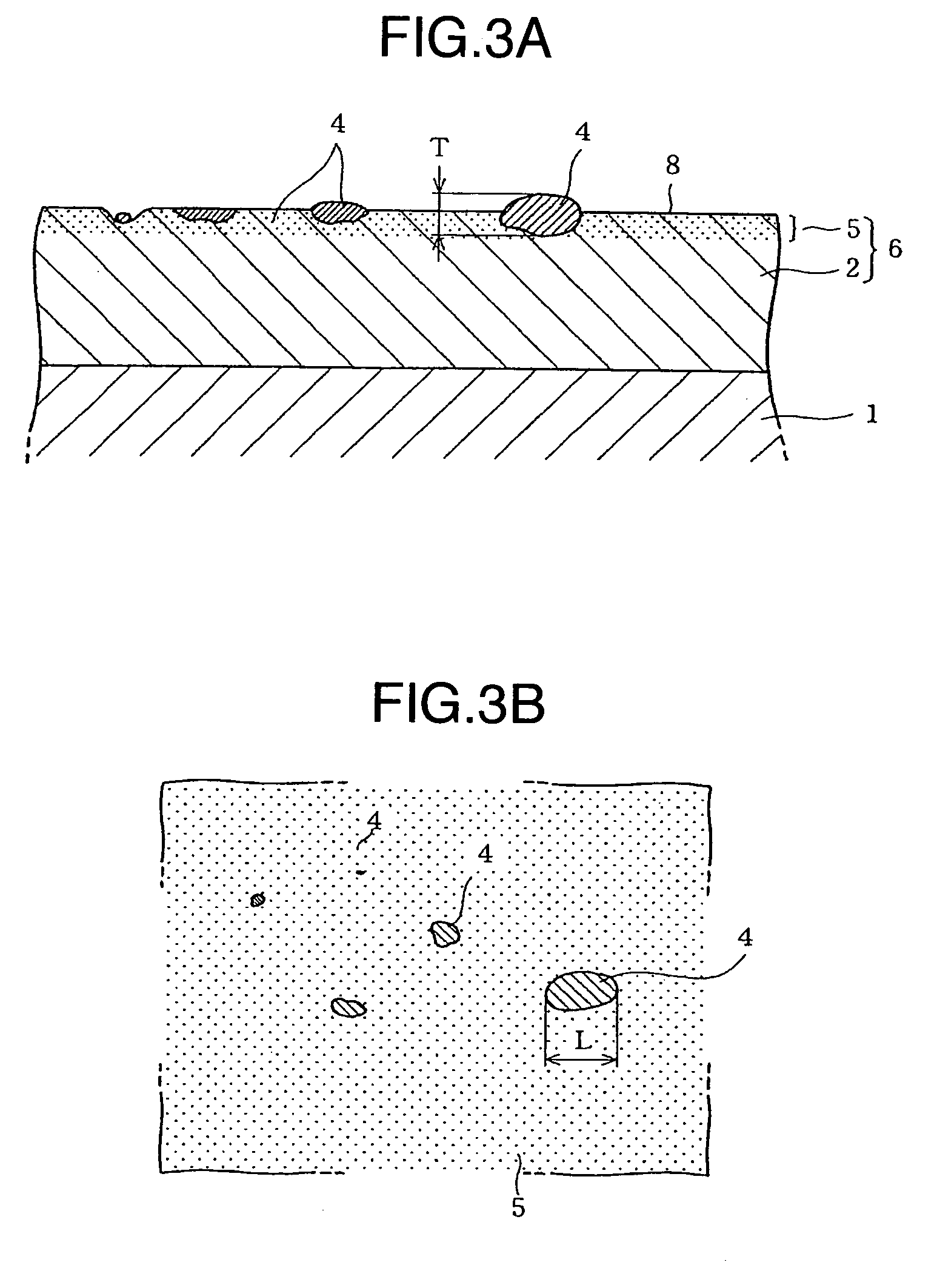

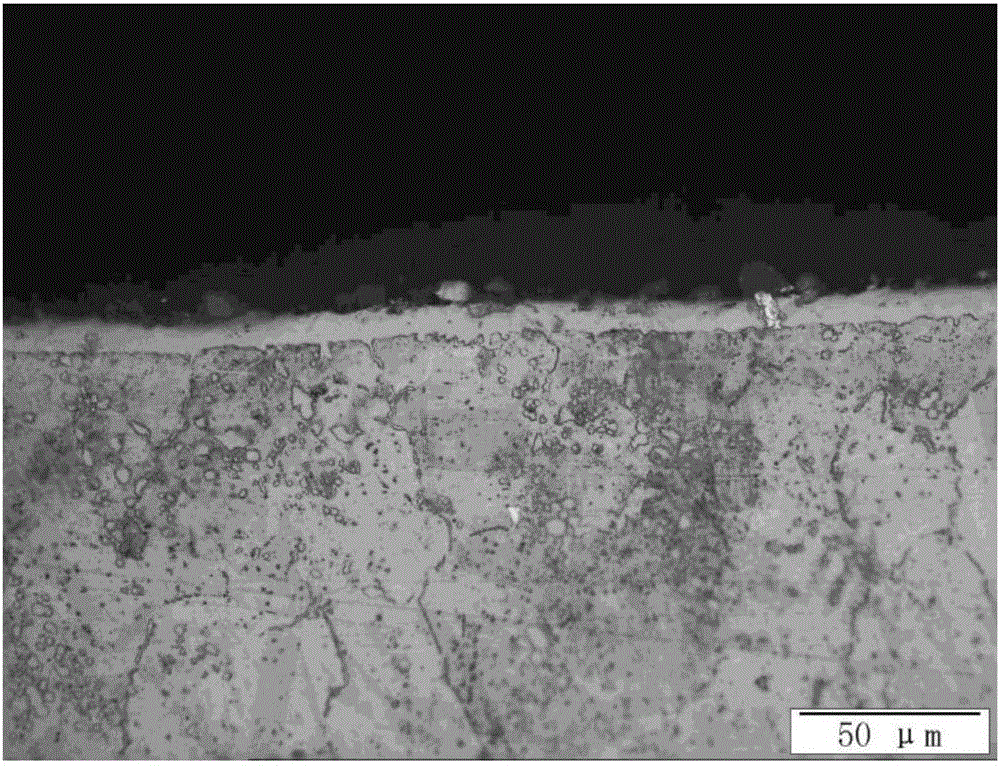

An overlay layer 3 comprising MoS2 as a solid lubricant and PAI resin as a binder resin is formed on a flattened surface of a bearing alloy layer 2, and a helical groove 4 and annular projections 5 are formed as an uneven configuration in and on the surface of the overlay layer. In accordance with the invention, a regular uneven configuration is formed on the surface of the overlay layer to allow a lubricant oil to be secured in recesses of the uneven configuration, allowing a seizure resistance to be improved. The bearing alloy layer is machined to have a flat surface having a fine roughness on its surface which represents a boundary with an overlay layer, whereby individual convex areas of the overlay layer are evenly subject to a plastic deformation, allowing the fitting property response of the sliding bearing to be improved.

Owner:TAIHO INDUSTRIES CO LTD

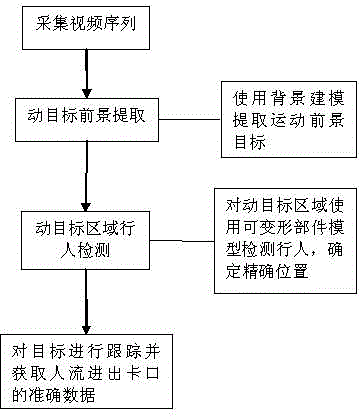

Real-time high-precision people stream counting method

InactiveCN104318263AHigh precisionGood anti-occlusion performanceCharacter and pattern recognitionFrame sequenceForeground detection

The invention provides a real-time high-precision people stream counting method, which comprises two steps of moving target foreground extraction and foreground area pedestrian detection, wherein the step of moving target foreground extraction comprises the following steps: carrying out foreground detection on an obtained video frame sequence to obtain a foreground area comprising moving targets, such as pedestrians, vehicles and the like; and the step of foreground area pedestrian detection comprises the following steps: carrying out pedestrian detection on the foreground area by utilizing an off-line training deformable component model to determine the amount and the positions of the pedestrians in the foreground area, and tracking the subsequent movement of pedestrian targets by taking a current frame detection result as start to judge and record a situation that people streams enter and leave a gate. The method extracts the foreground area which comprises a target on the basis of a background subtraction method, so that an algorithm satisfies a real-time calculation condition, the pedestrian detection based on the deformable component model guarantees the high precision of people stream counting, a real-time people stream counting method with high precision and good shielding resistance is provided, and the real-time high-precision people stream counting method exhibits high practical value and good development prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

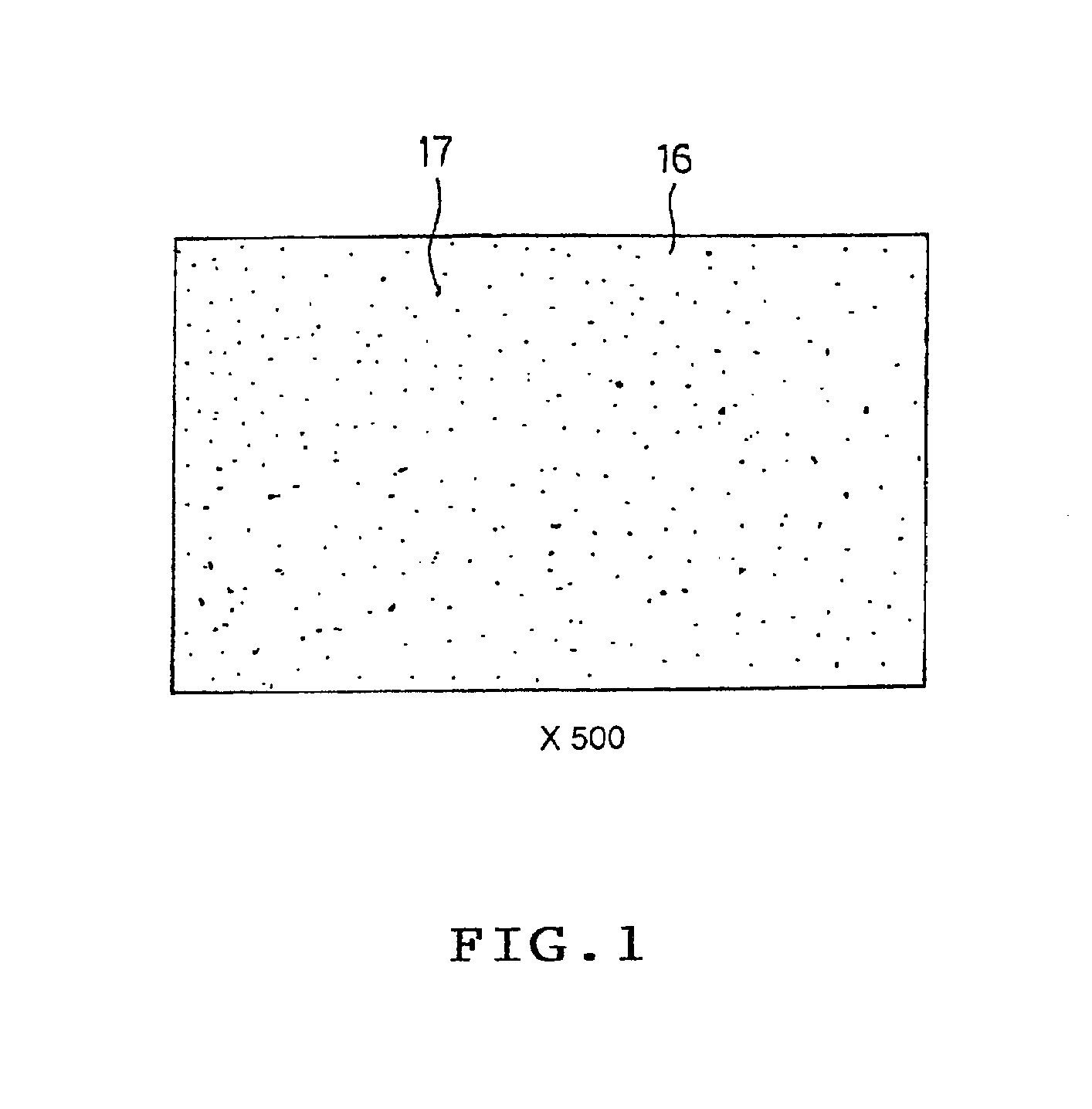

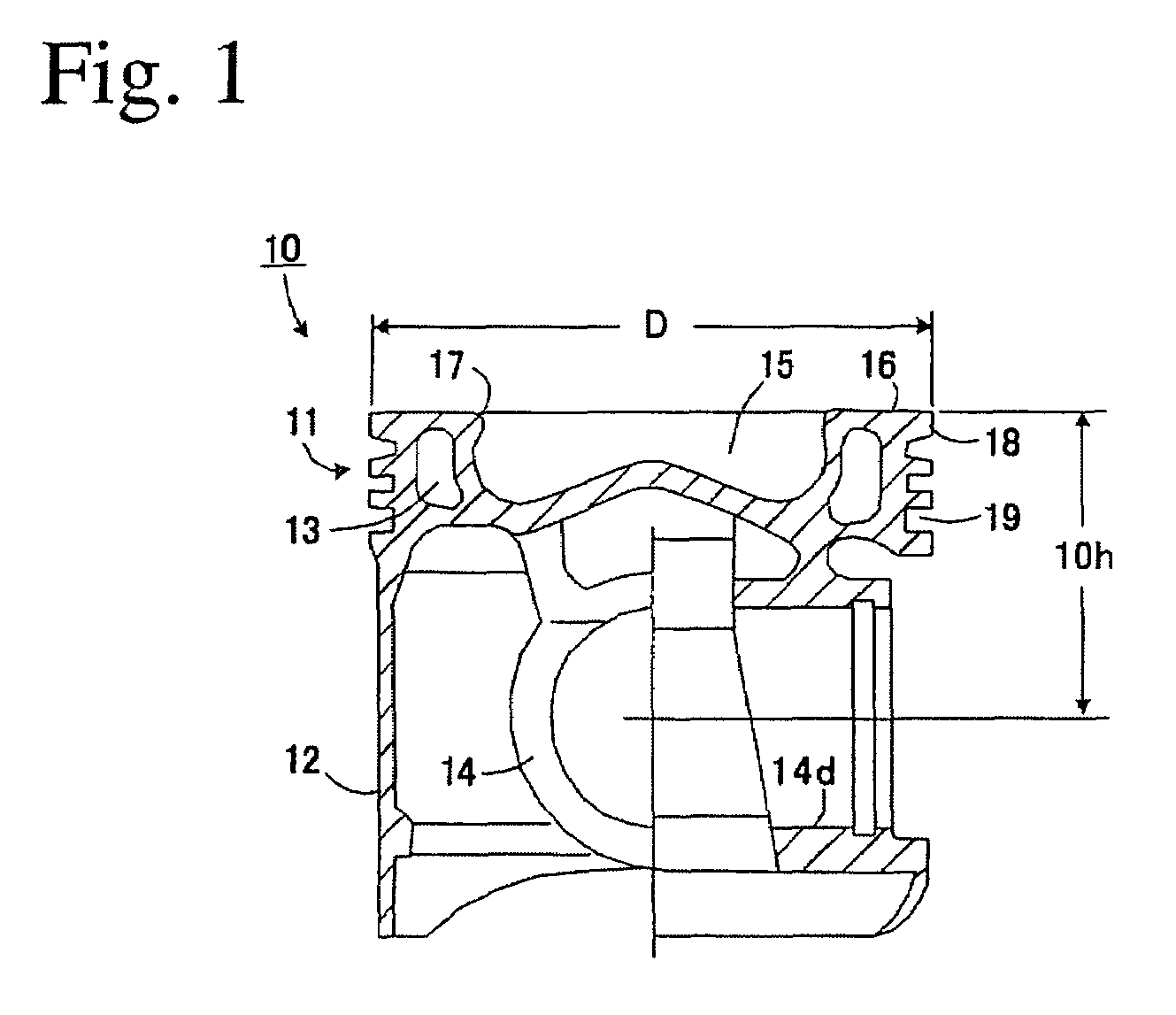

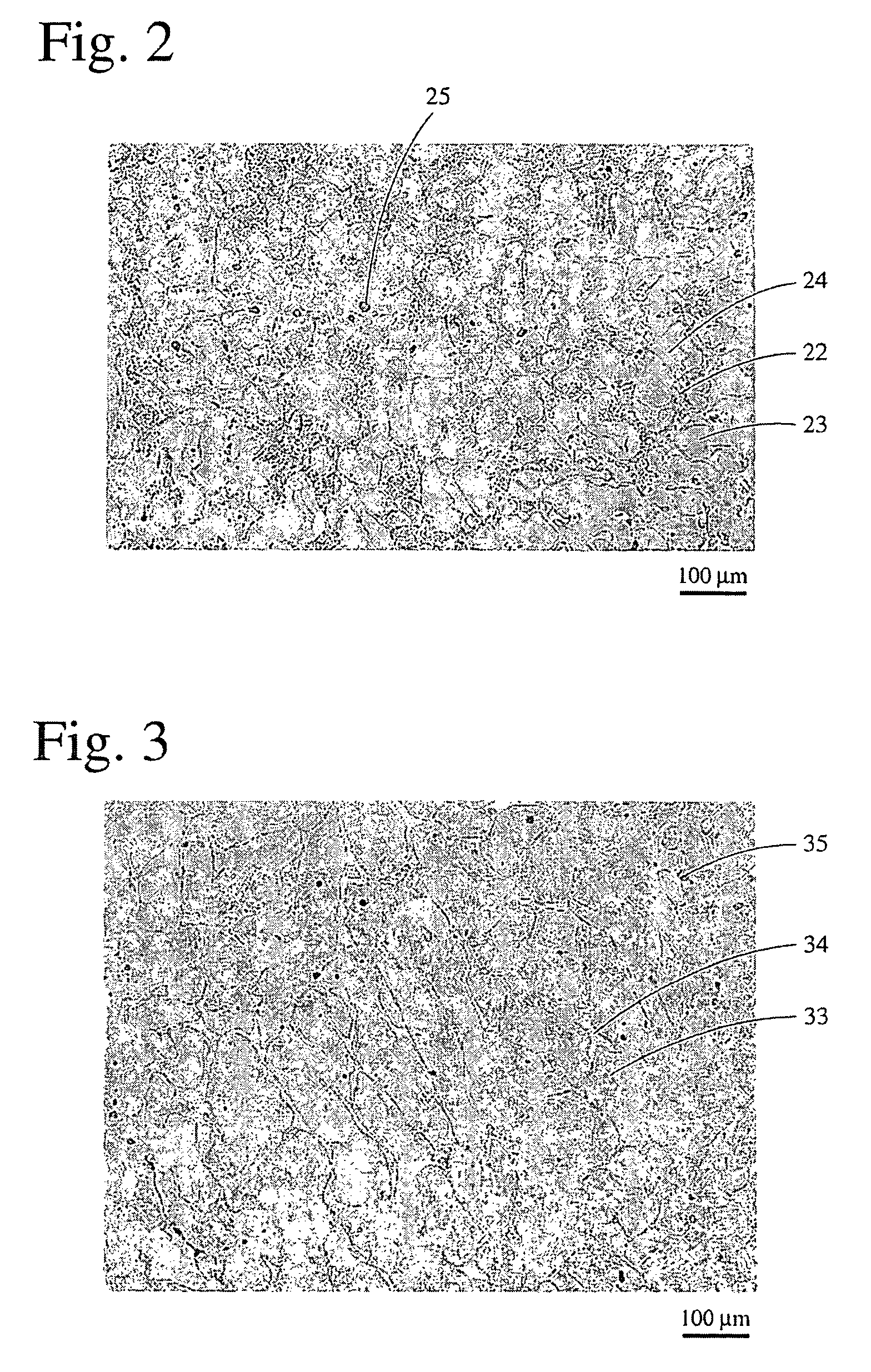

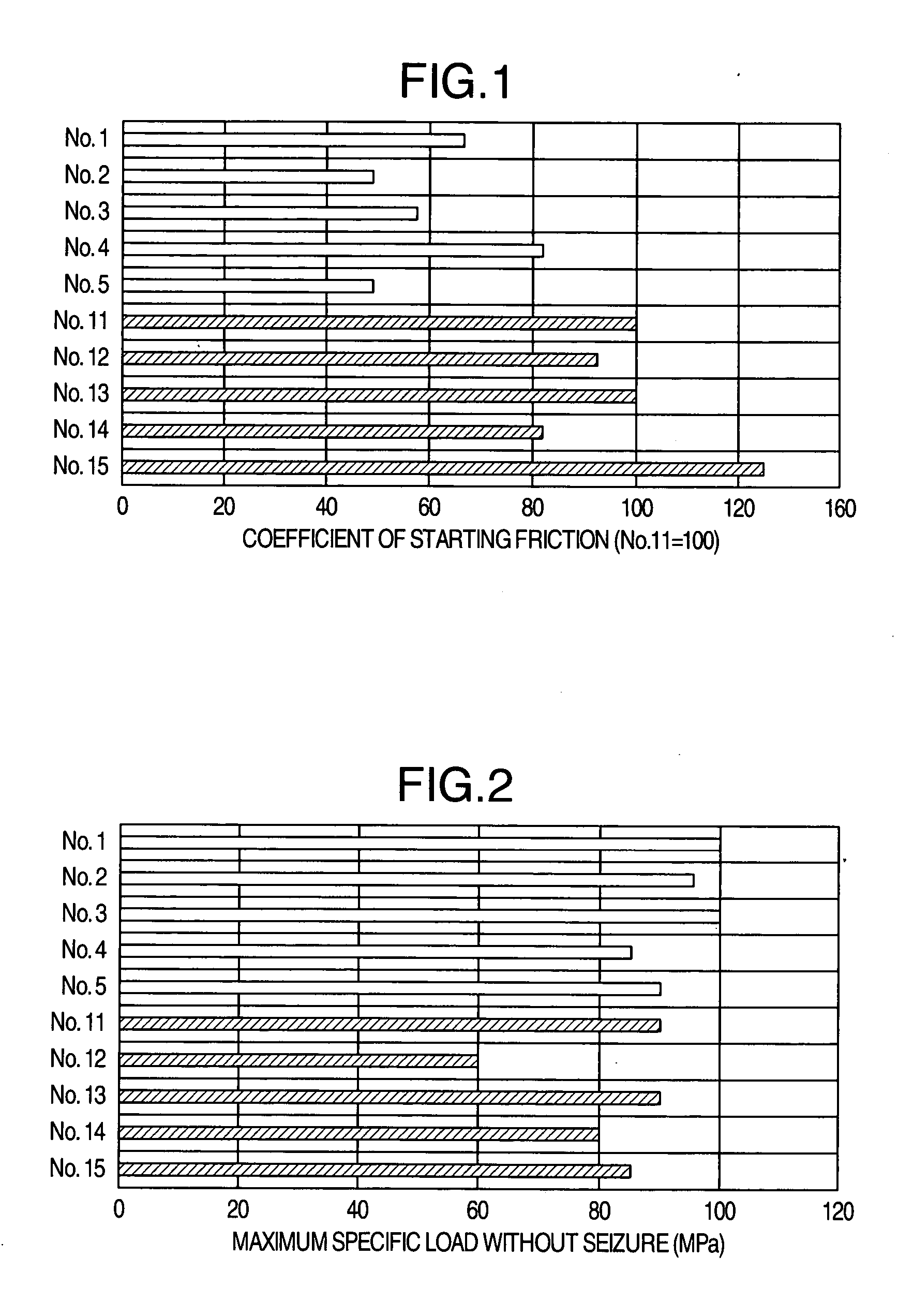

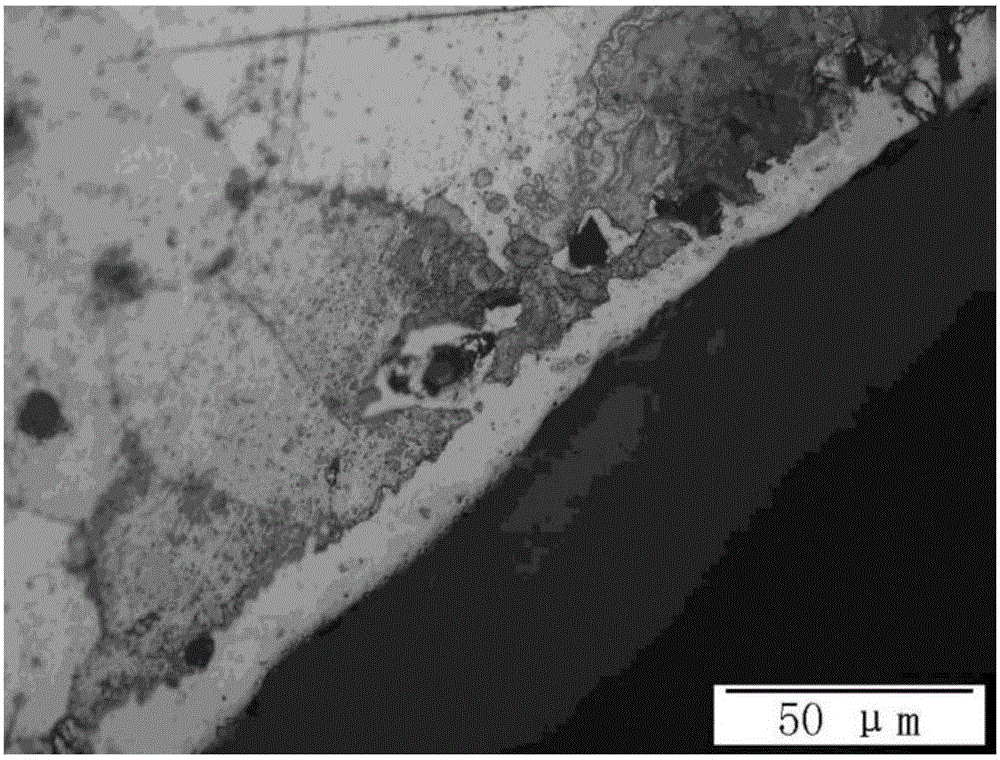

Sliding material made of copper alloy, method of producing same, sliding bearing material, and method of producing same

InactiveUS6905779B2Low production costEnhance anti-seizure propertyShaftsBearing componentsHardnessCopper alloy

A copper-based sliding material comprising sintered copper or sintered copper alloy, and 0.1 to 5 vol. % hard substance particles harder in hardness than said copper or copper alloy, said hard substance particles being substantially evenly dispersed so that, when at least one, randomly selected surface portion or sectional portion of said sintered copper or sintered copper alloy is partitioned into squares each having a side of 20 μm, at least one particle exists in each of squares not less than 80% of the whole squares. The copper-based sliding material has good anti-seizure property and superior resistance to fatigue without containing any lead.

Owner:DAIDO METAL CO LTD

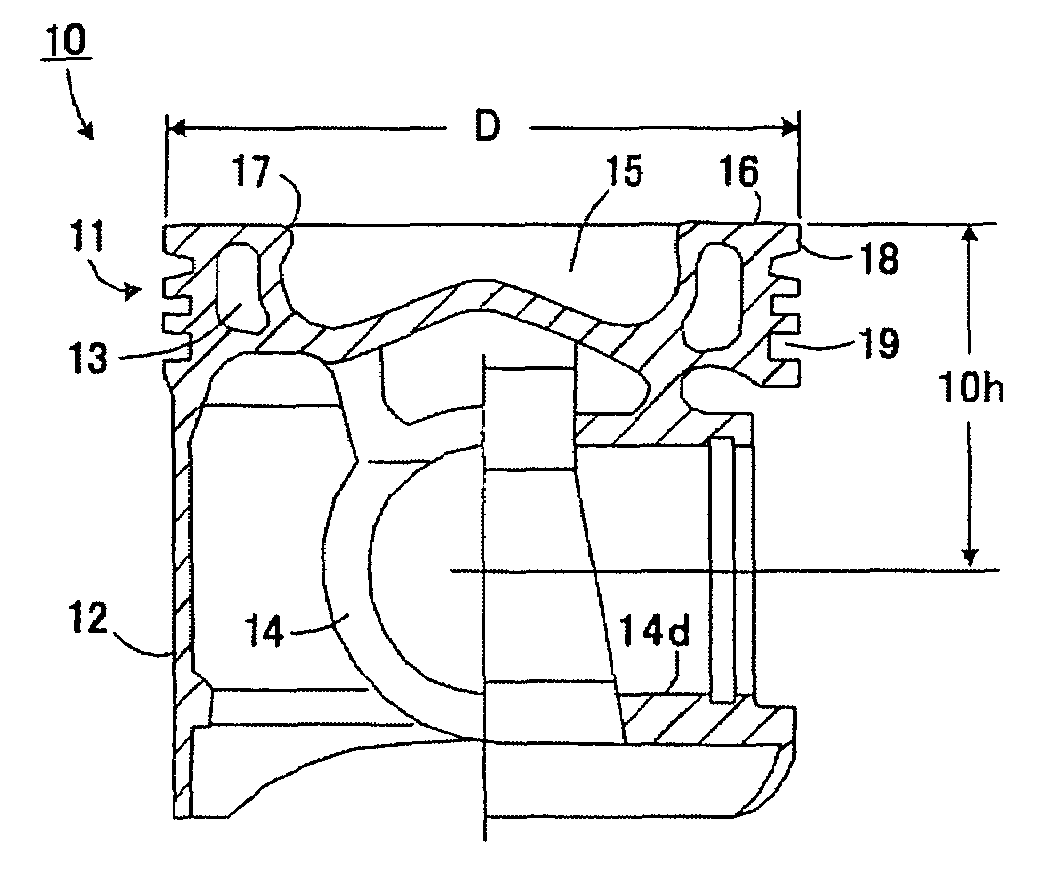

Sliding bearing used in turbocharger of internal combustion engine

ActiveUS20110211781A1Improve wearing effectDifficult to formShaftsCombustion enginesCombustionTurbocharger

Disclosed is a sliding bearing used in turbochargers of internal combustion engines. It is formed with a copper alloy containing, by mass %, 25 to 45% Zn, 0.3 to 2.0% Si, 1.5 to 6.0% Mn, and the balance being Cu and unavoidable impurities. The sliding bearing has a cylindrical shape for supporting a rotating shaft. Crystallized Mn—Si compounds are dispersed in a matrix of the copper alloy, the compounds extending in an axial direction of the rotating shaft on a sliding surface of the sliding bearing. The crystallized Mn—Si compounds have an average inter-grain distance of 20 to 80 μm. The matrix may contain precipitated Mn—Si compounds as well as the crystallized Mn—Si compounds.

Owner:DAIDO METAL CO LTD

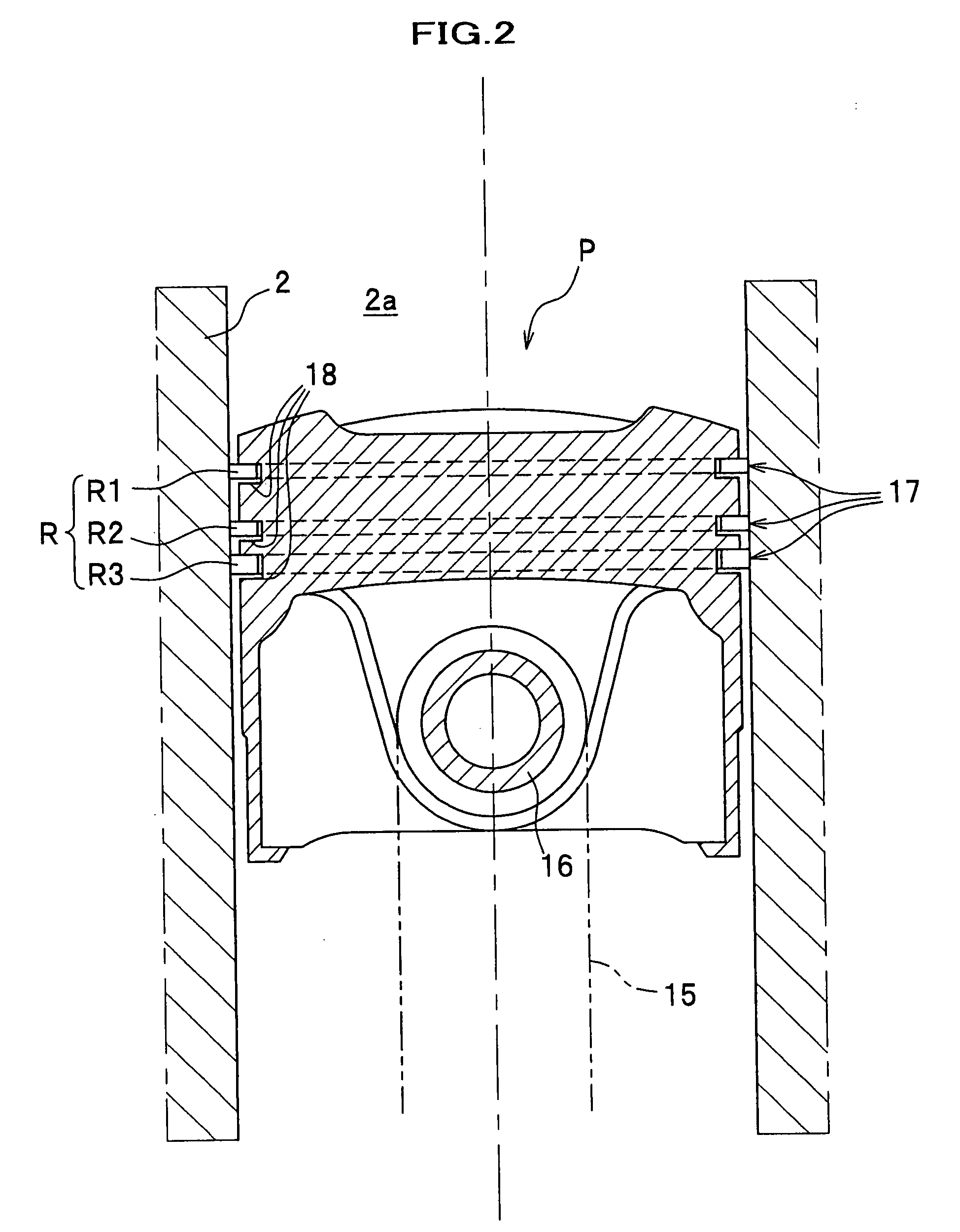

Internal engine piston and its production method

ActiveUS7503304B2Good room-temperature elongationHigh high-temperature yield strengthValve arrangementsInternal combustion piston enginesMetallurgyInternal combustion engine

An integrally cast steel piston for internal engines, the cast steel having (a) a composition comprising 0.8% or less of C, 3% or less of Si, 3% or less of Mn,0.2% or less of S, 3% or less of Ni, 6% or less of Cr, 6% or less of Cu, and 0.01-3% of Nb, the balance being substantially Fe and inevitable impurities, or (b) a composition comprising 0.1-0.8% of C, 3% or less of Si, 3% or less of Mn, 0.2% or less of S, 10% or less of Ni, 30% or less of Cr, 6 % or less of Cu, and 0.05-8% of Nb, the balance being substantially Fe and inevitable impurities, by mass.

Owner:HITACHI METALS LTD +1

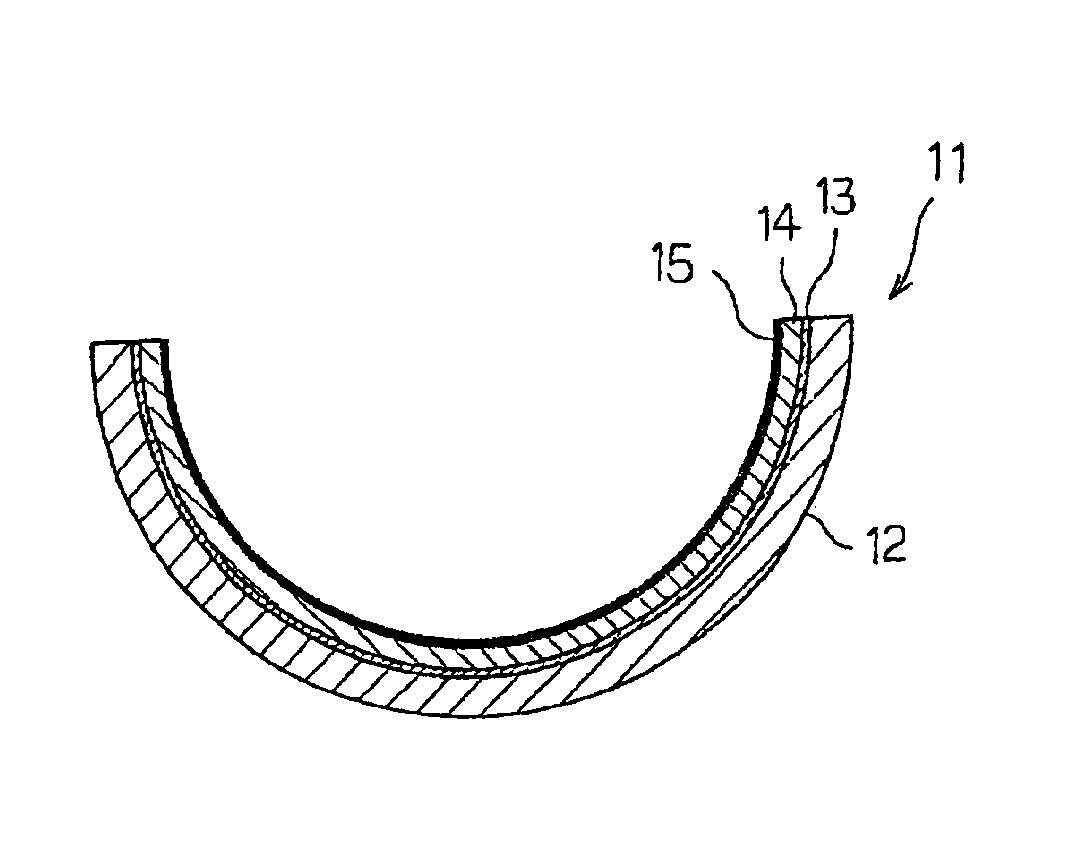

Plain bearing

InactiveCN1388872AImprove adaptabilityGood anti-occlusion performanceShaftsBearing componentsHeat resistanceAlloy

An object of the present invention is to provide a sliding bearing having an excellent initial conformability and seizure resistance as well as desired durability and heat resistance required particularly for high speed engine. The present invention provides a sliding bearing having a resin coating layer comprising a thermosetting resin being soft and having a good elongation at high temperature and a solid lubricant formed on a bearing alloy layer.

Owner:TAIHO INDUSTRIES CO LTD

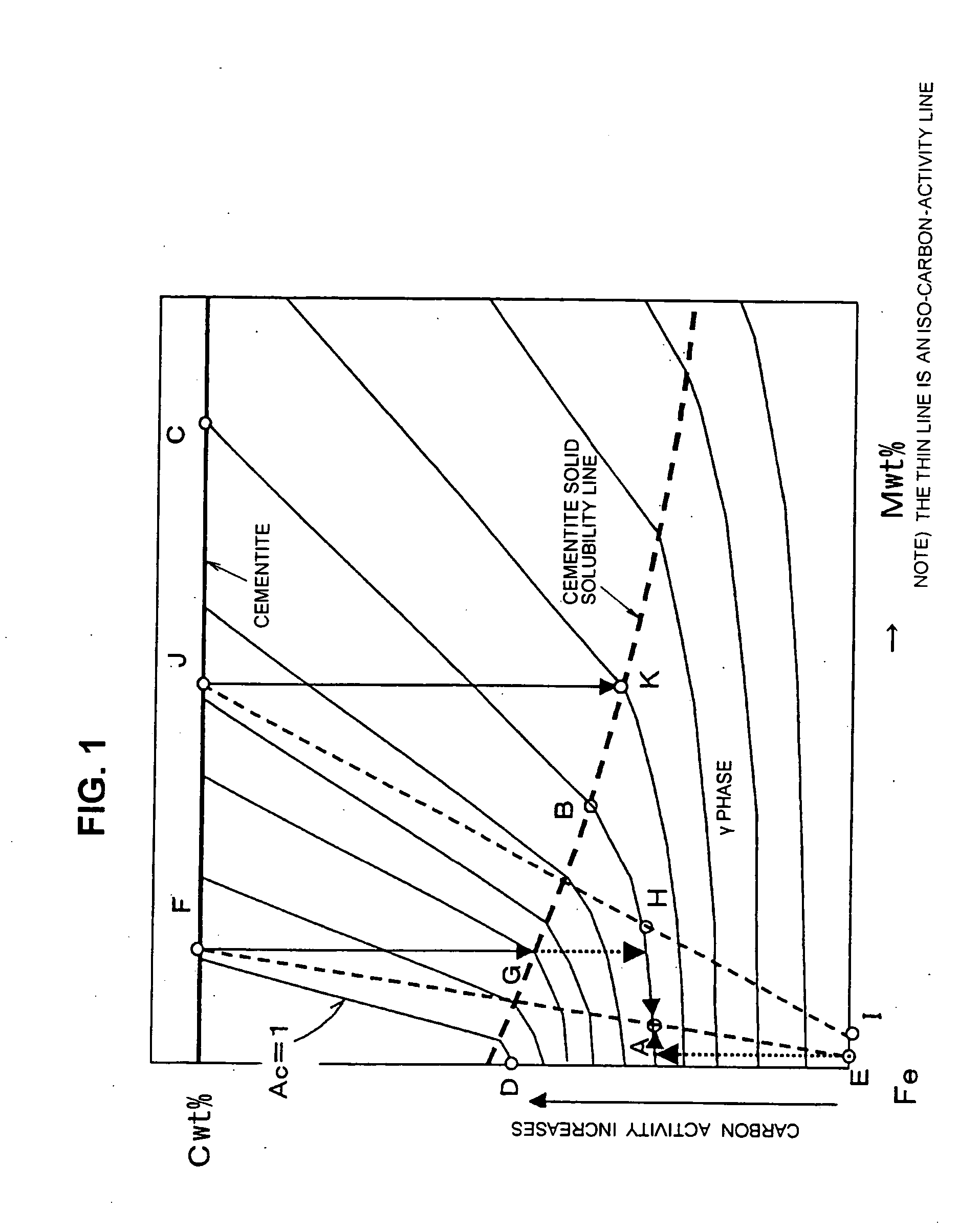

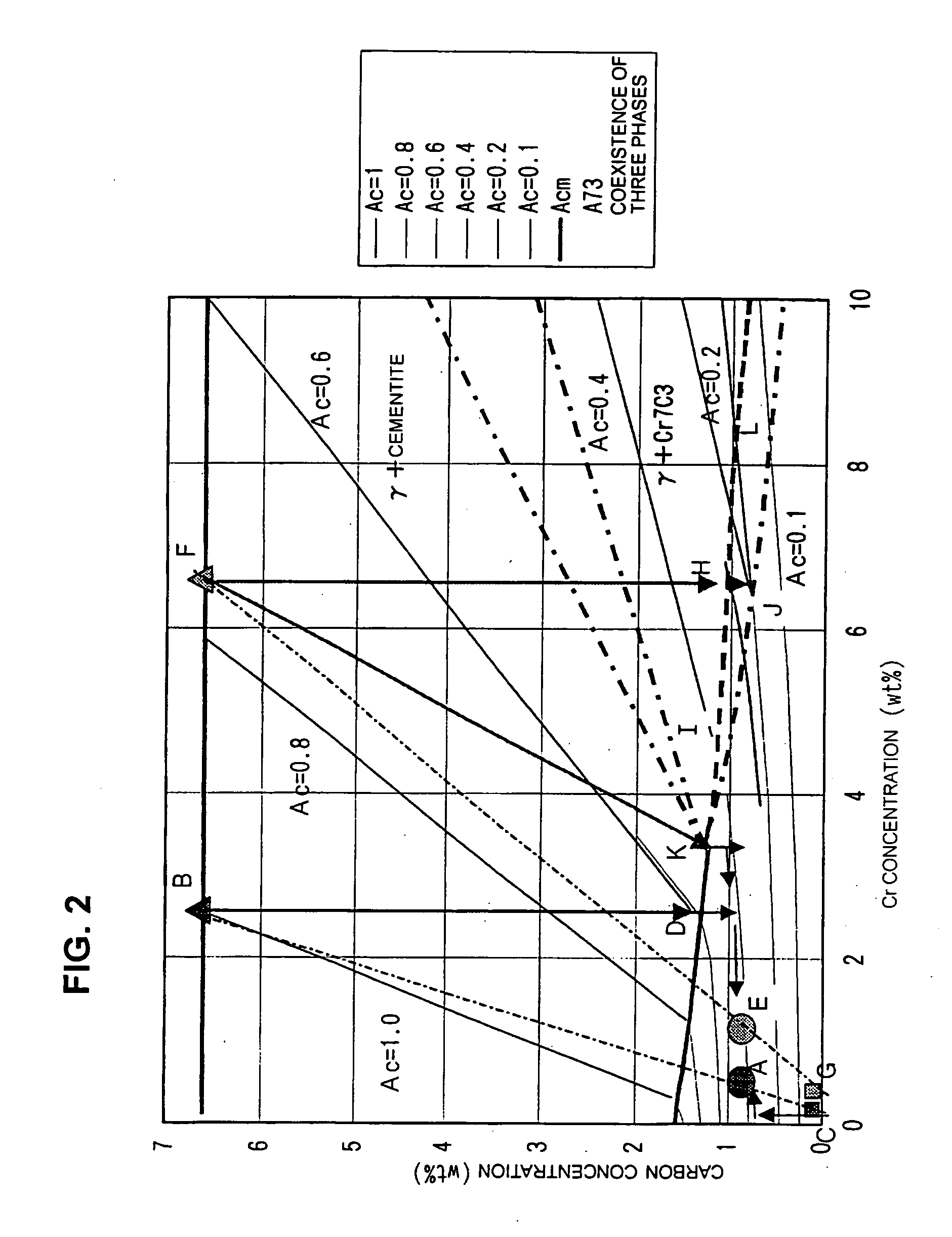

Rolling element and method of producing the same

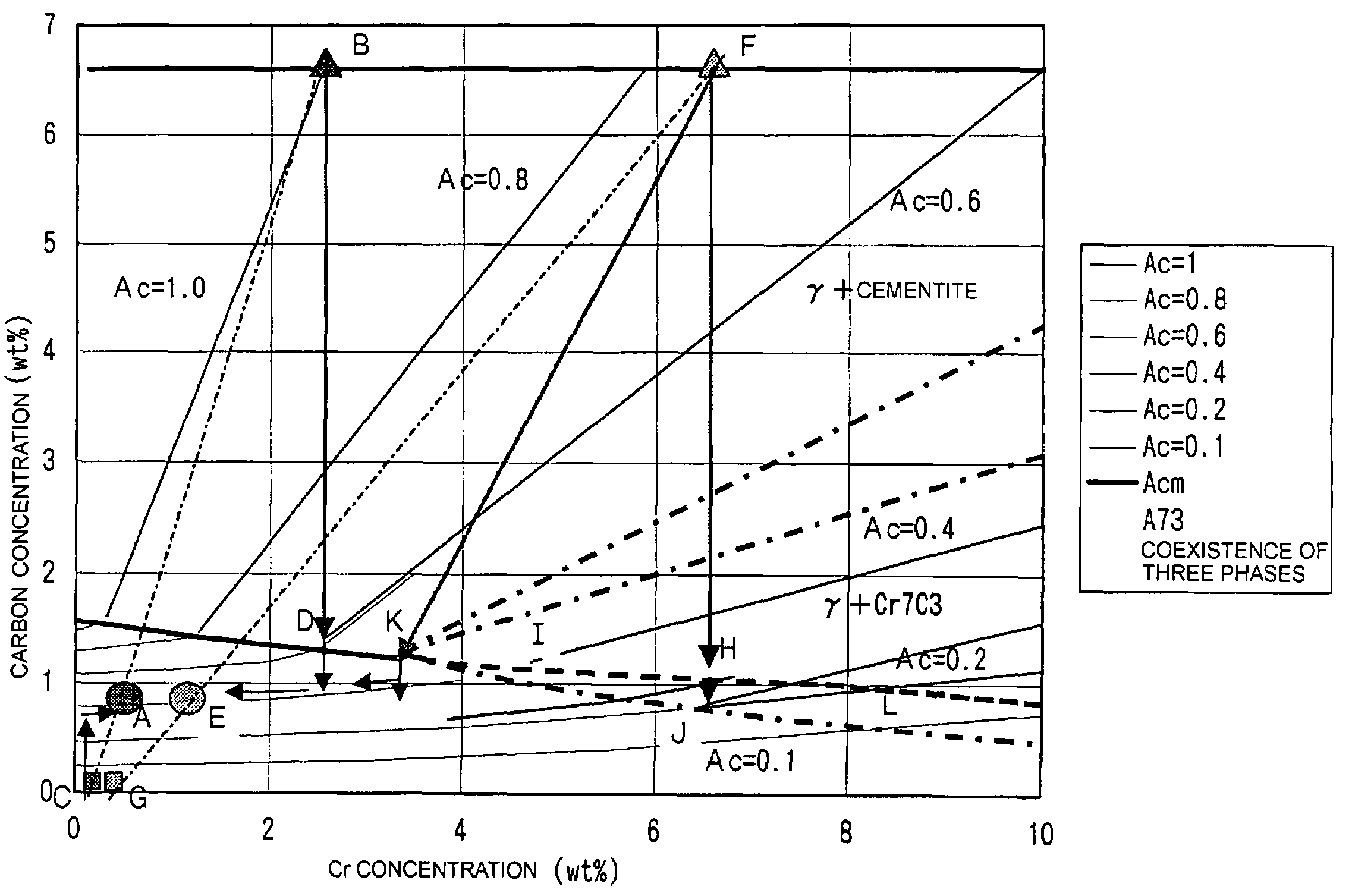

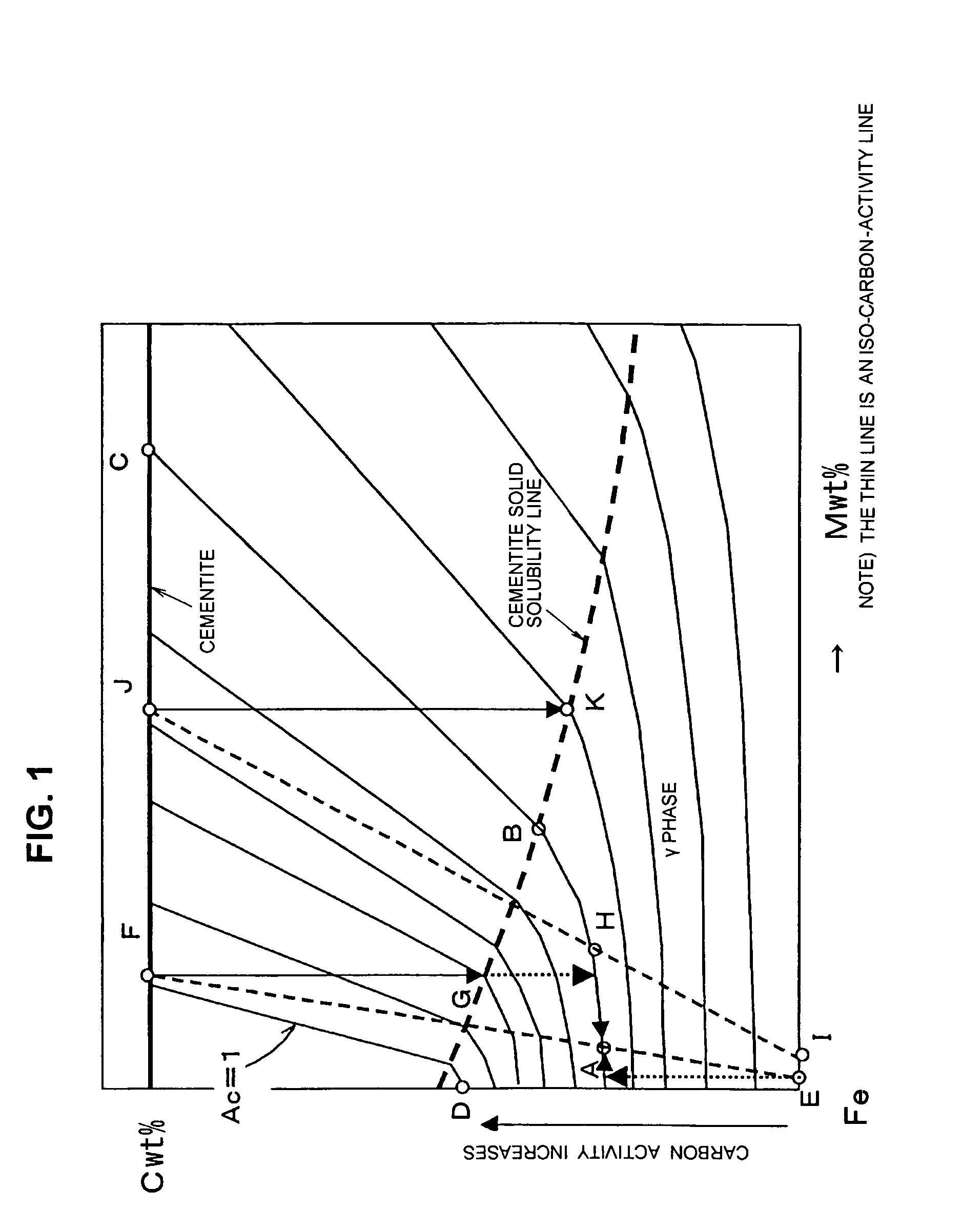

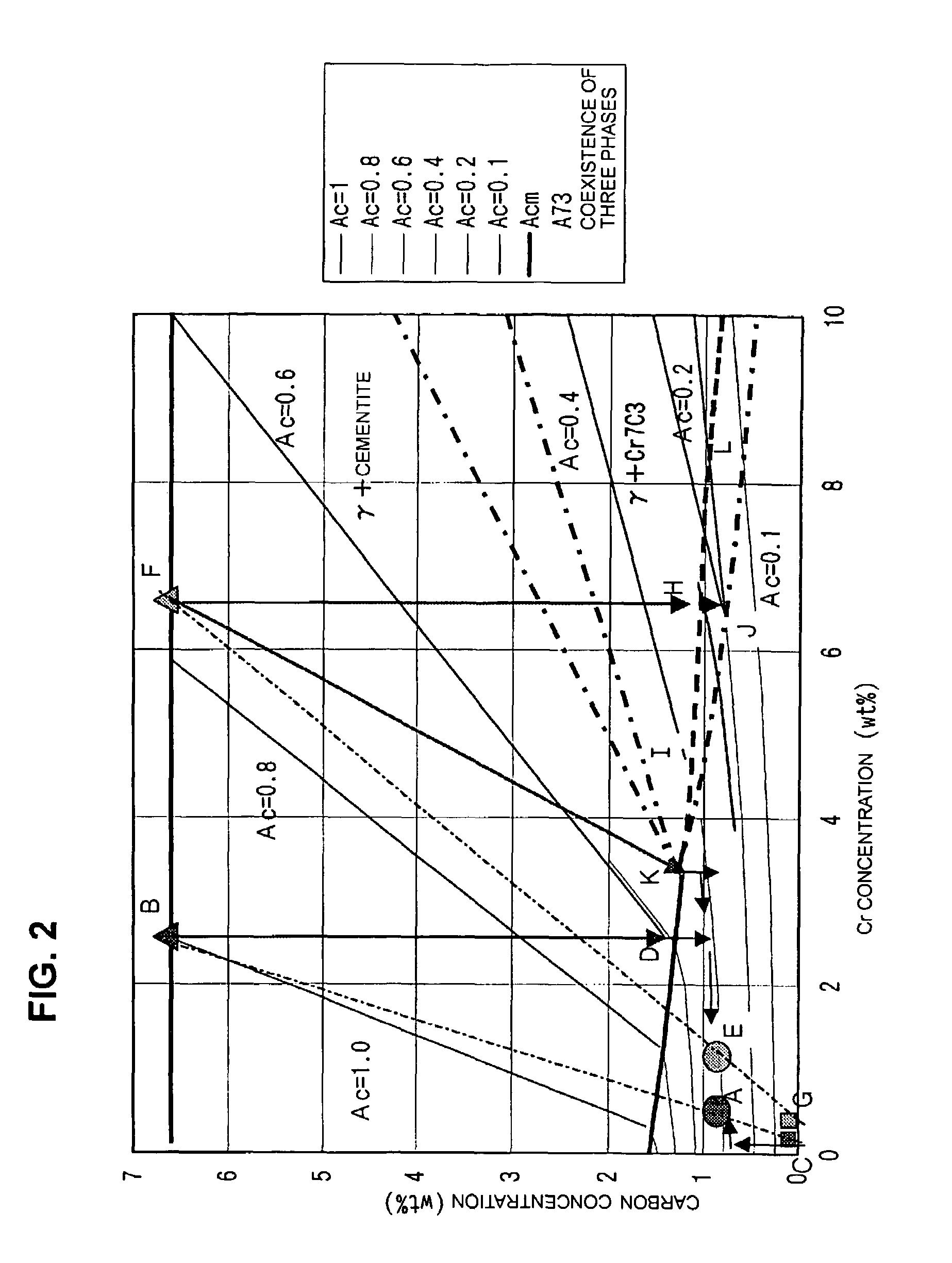

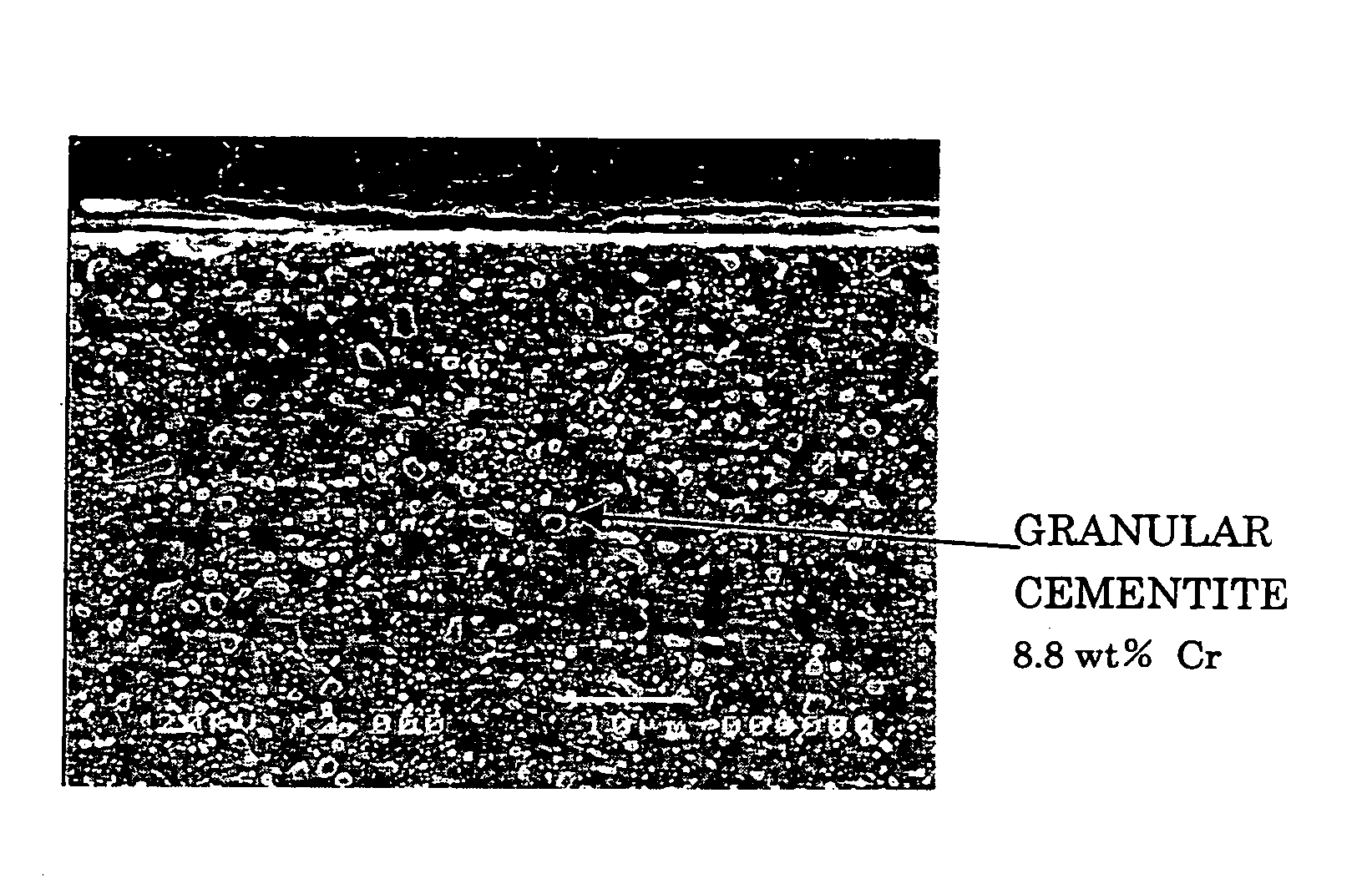

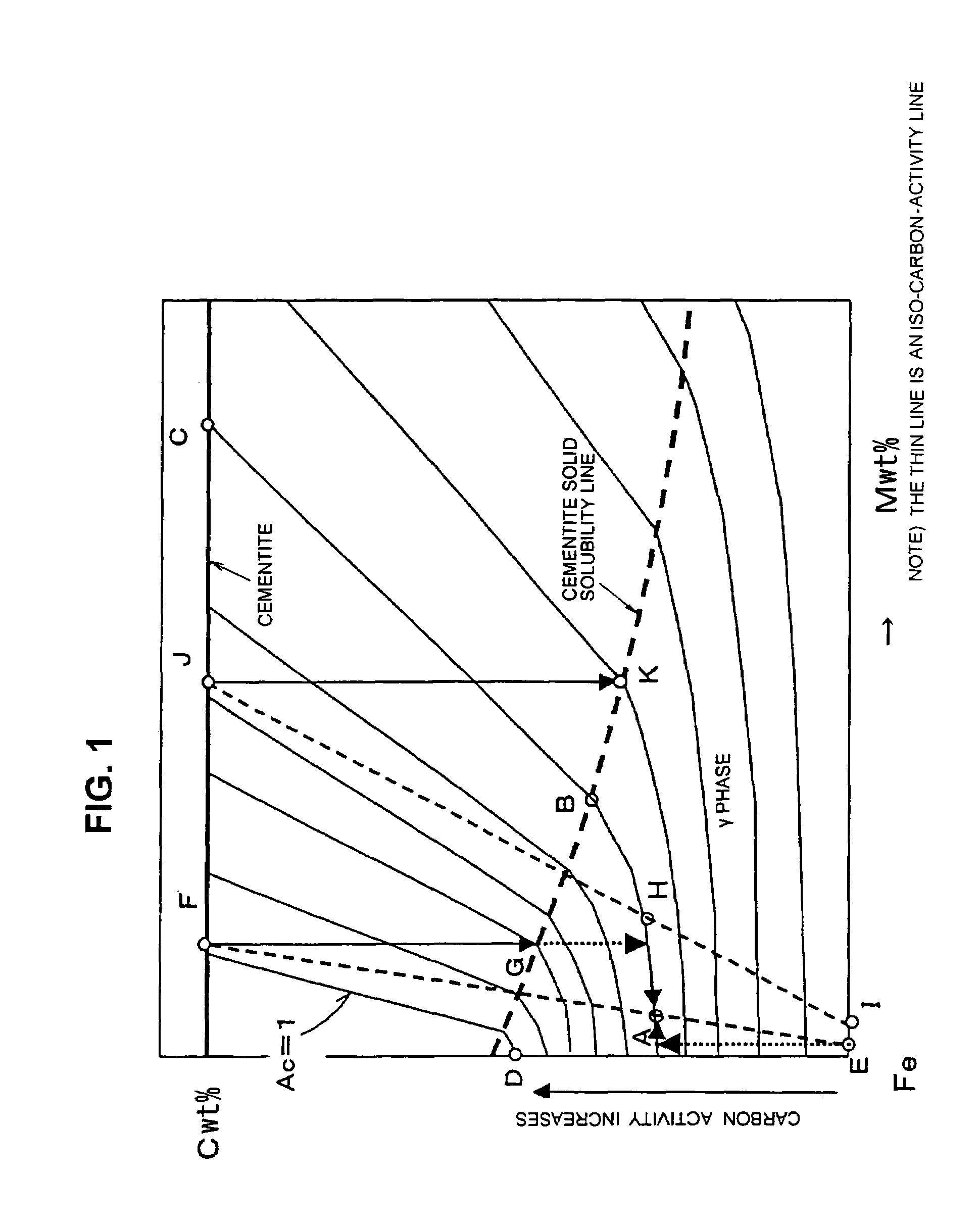

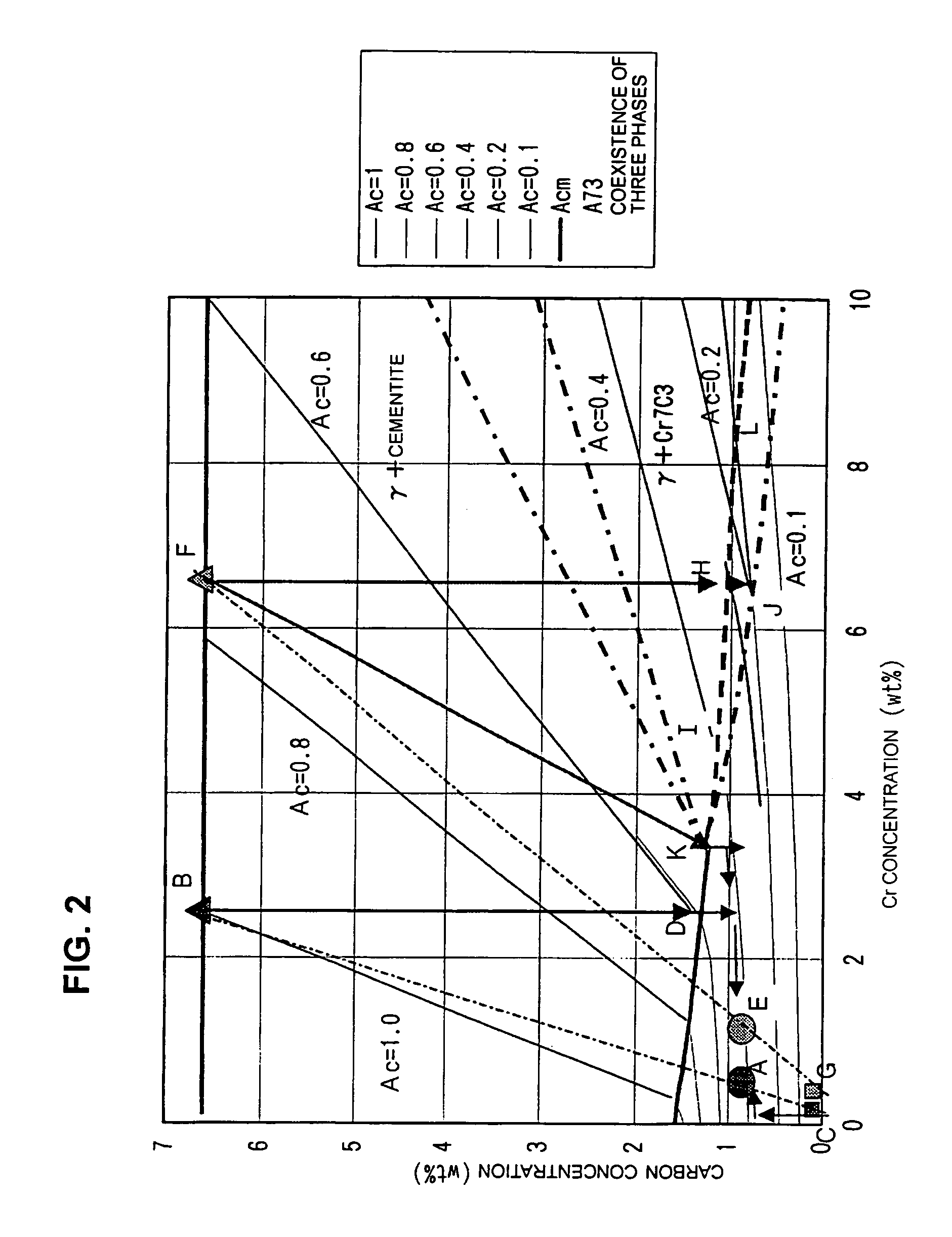

InactiveUS20060021679A1Economical efficiency can be improvedReduce carbon contentPortable liftingSolid state diffusion coatingTO-18Surface layer

There is provided an inexpensive rolling element used under high interface pressure such as induction hardened gears, the rolling element being improved in the seizure resistance of its tooth flanks and having a temper hardness of HRC 50 or more at 300° C. To this end, the rolling element is made from a steel material containing at least 0.45 to 1.5 wt % C and one or more alloy elements selected from 0.1 to 0.5 wt % V and 0.3 to 1.5 wt % Cr, and has a rolling contact surface layer having a structure tempered at low temperature in which 2 to 18% by volume cementite disperses in a martensite parent phase formed by induction heating and cooling and containing 0.25 to 0.8 wt % carbon solid-dissolving therein.

Owner:KOMATSU LTD

Surface wear-resistant strengthening treatment method for high-carbon cold work die steel

InactiveCN103225055AExtended service lifeDense tissueSolid state diffusion coatingHigh carbonWear resistant

The invention relates to a surface wear-resistant processing technology for a high-carbon cold work die steel, and particularly relates to a preparation method for vanadium-carbon-boron wear-resistant layer of the high-carbon cold work die steel. According to the method, a salt bath formed by mixing borax and BCl2+NaCl+KCl according to a certain proportion is used as a carrier; V2O5, Al and the metal yttrium are added in the salt bath; and the above materials are permeated for 6 hours at a temperature of 1,040-1,060 DEG C. The thickness of the vanadium-carbon-boron wear-resistant layer prepared by the method is 12-15 [mu]m; the hardness is HV2,900-3,3300; the vanadium-carbon-boron wear-resistant layer is compact in microstructure, and has good bonding strength with a matrix, excellent wear resistance, seizure resistance and anti-stripping capacity; and the wear-resistant layer is stable in quality. The high-carbon cold work die steel is directly subjected to quenching (or normalizing) and tempering for 8-10 hours at a temperature of 200-250 DEG C after the vanadium-carbon-boron penetrating treatment, so that toughness of the matrix is not reduced; and service life of the die is increased by a plurality times to ten times. Besides, the method is pollution-free in treatment process and good in energy conservation, and overcomes the disadvantages of unstable quality of vanadizing layer in mixed salt bath.

Owner:WUXI SHENGYUAN METAL PRODS

Ferrum-based powder metallurgy antifriction material and preparation method thereof

The invention discloses a ferrum-based powder metallurgy antifriction material and a preparation method thereof. The material is prepared from the following raw materials in part by weight: 60 to 64 parts of iron powder, 6 to 10 parts of tin powder, 3 to 6 parts of carborundum powder, 3 to 6 parts of molybdenum dioxide powder, 4 to 7 parts of zirconium corundum powder, 10 to 14 parts of quartz sand powder, 1 to 4 parts of zirconium dioxide powder, 2 to 5 parts of cobalt powder, 2 to 5 parts of alumina powder, 2 to 5 parts of feldspar powder and 1 to 4 parts of copper powder. The preparation method comprises the following steps of preparing and mixing the raw materials, pressing for forming, sintering and cooling. The ferrum-based powder metallurgy antifriction material prepared by the method has a high friction coefficient, can quickly absorb kinetic energy and brake, is high in transmission speed and low in abrasion, is high in strength, high temperature resistant and good in thermal conductivity, and is good in anti-seizure property, corrosion resistant, and slightly influenced by grease and damp.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

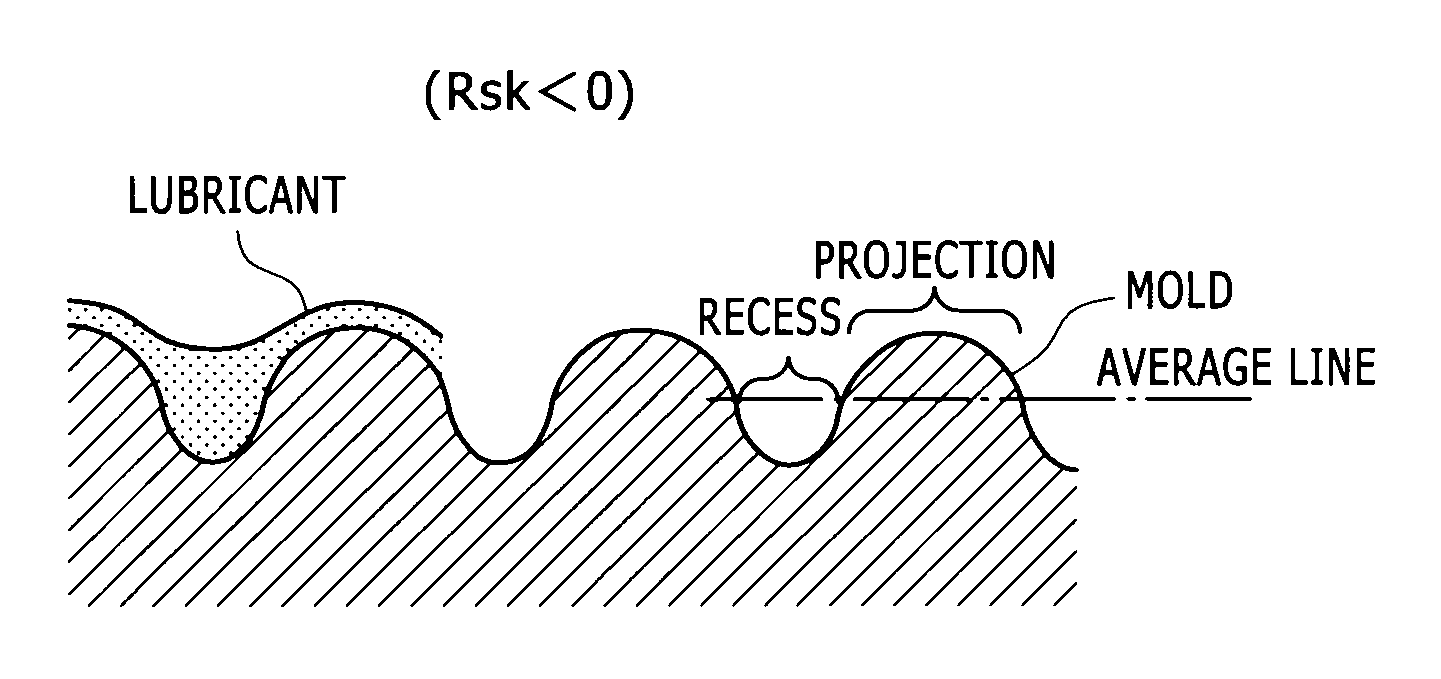

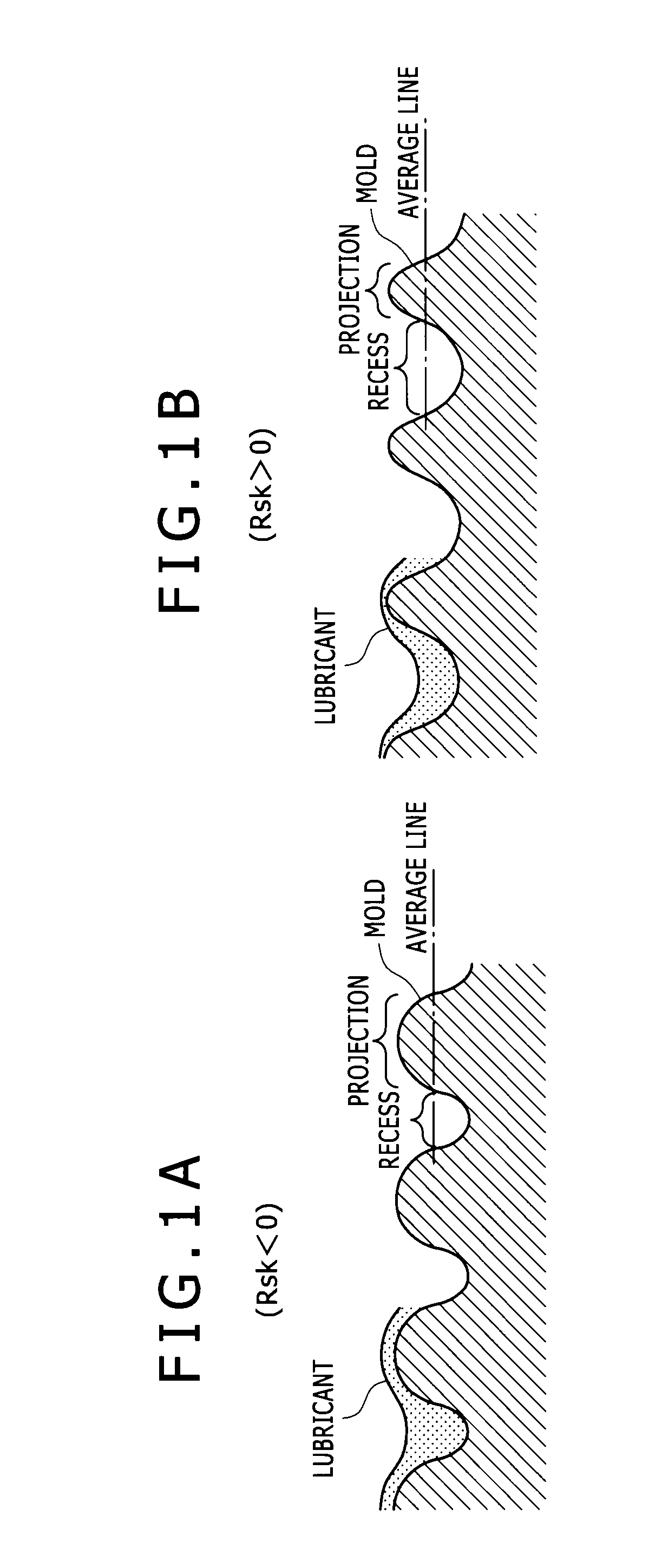

Mold for plastic forming and a method for producing the same, and method for forging aluminum material

InactiveUS20120131980A1Improve retentionGood anti-occlusion performanceCutting toolsFoundry mouldsLubricantAluminium

A mold for plastic forming having excellent seizure resistance controlled by adjusting its surface properties. In addition, a process producing the mold, that includes: roughening a surface of a base material by a shot blast method to adjust its arithmetic averaged roughness Ra: higher than 1 μm but 2 μm or lower; polishing the surface of the base material to adjust its skewness Rsk to 0 or lower while retaining Ra: 0.3 μm or higher; and forming a hard film on the surface of the base material where the surface of the hard film has an arithmetic averaged roughness Ra: 0.3 μm or higher but 2 μm or lower and skewness Rsk: 0 or lower. Adjusting the surface of the mold to have a non-concave-biased configuration, limits the capacity for concaves to accumulate lubricant, such that the lubricant is sufficiently deposited on the surfaces of the convexes.

Owner:KOBE STEEL LTD

Lubricating oil for refrigerator with compressor

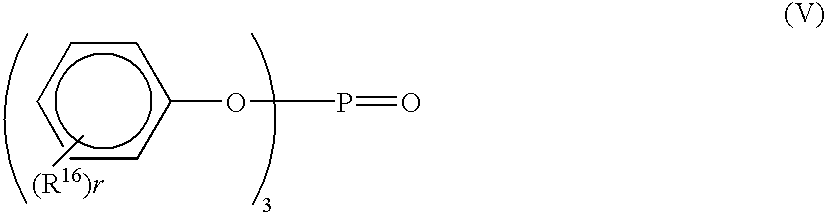

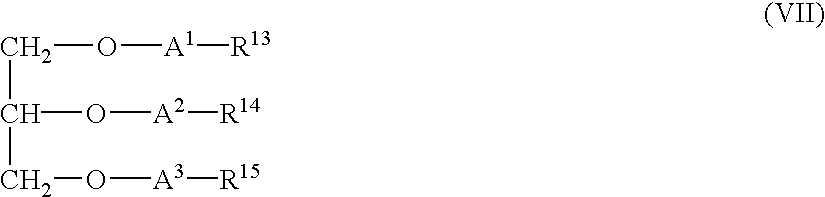

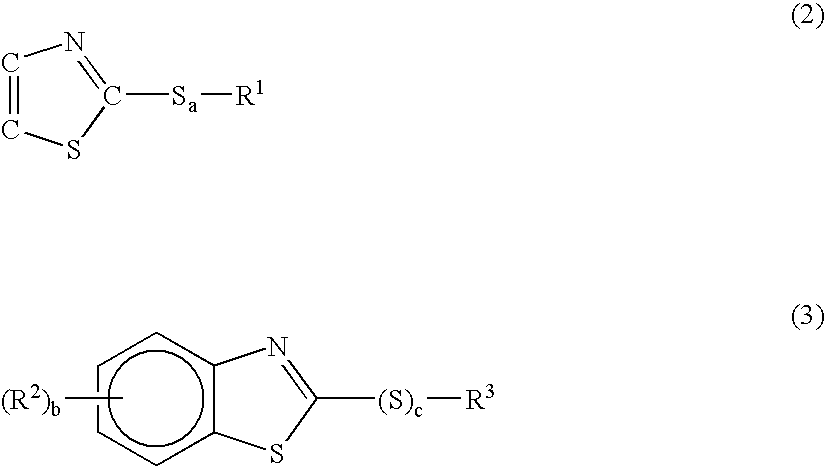

InactiveUS20030127622A1Improve compatibilityImprove the lubrication effectHeat-exchange elementsBase-materialsMethyl groupRefrigerated temperature

A lubricating oil for compression-type refrigerator includes, as a main component, a polyoxyalkyleneglycol derivative represented by the general formula: R1-[-(OR2)m-OR3]n wherein R1 is a methyl group, R2 is a propylene group, R3 is a methyl group, n is an integer of 1 and m is an integer of 12 to 80, and 1,1,1,2-tetrafluoroethane. The derivative has a kinematic viscosity of 5 to 50 cSt at 100° C.

Owner:IDEMITSU KOSAN CO LTD

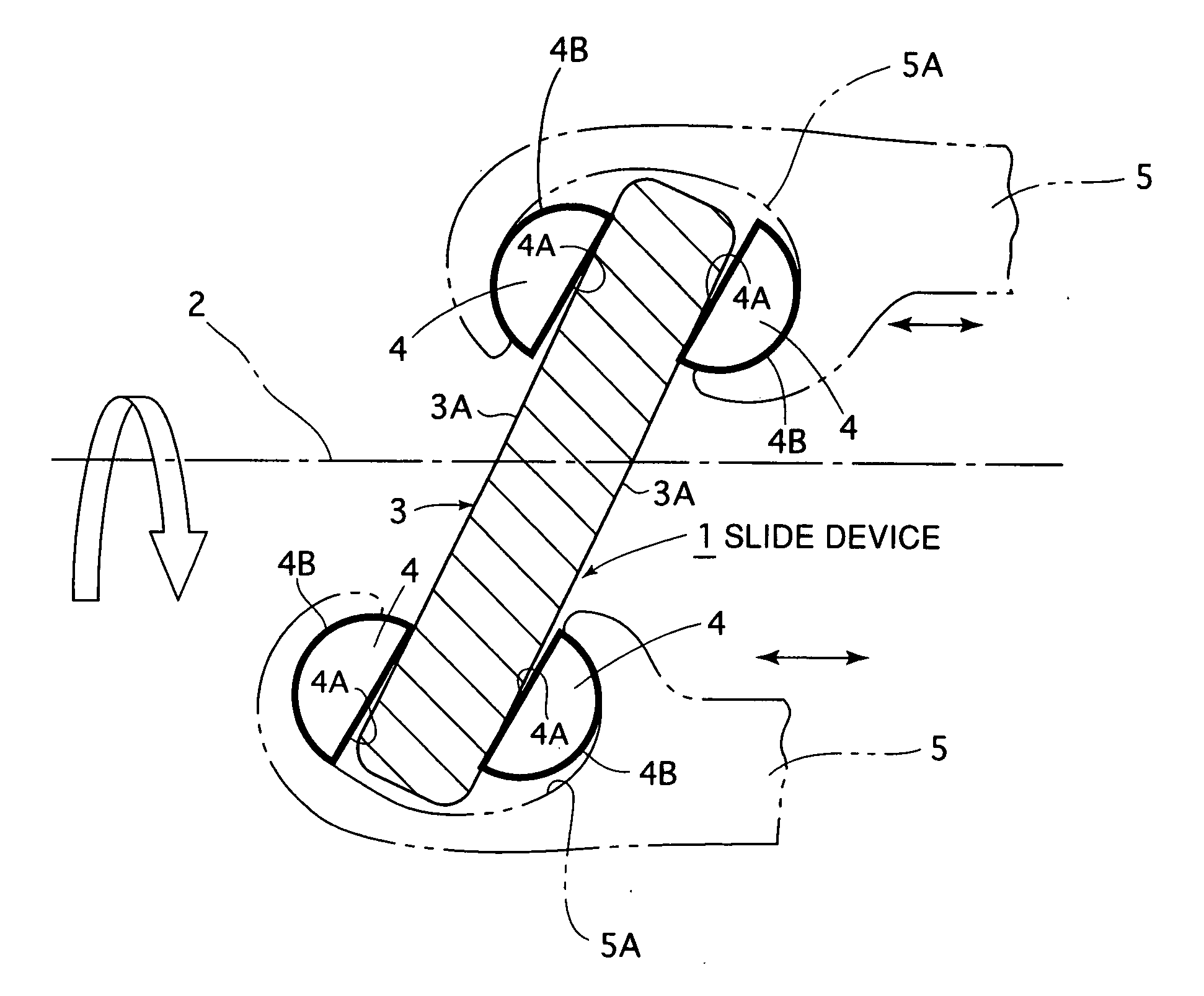

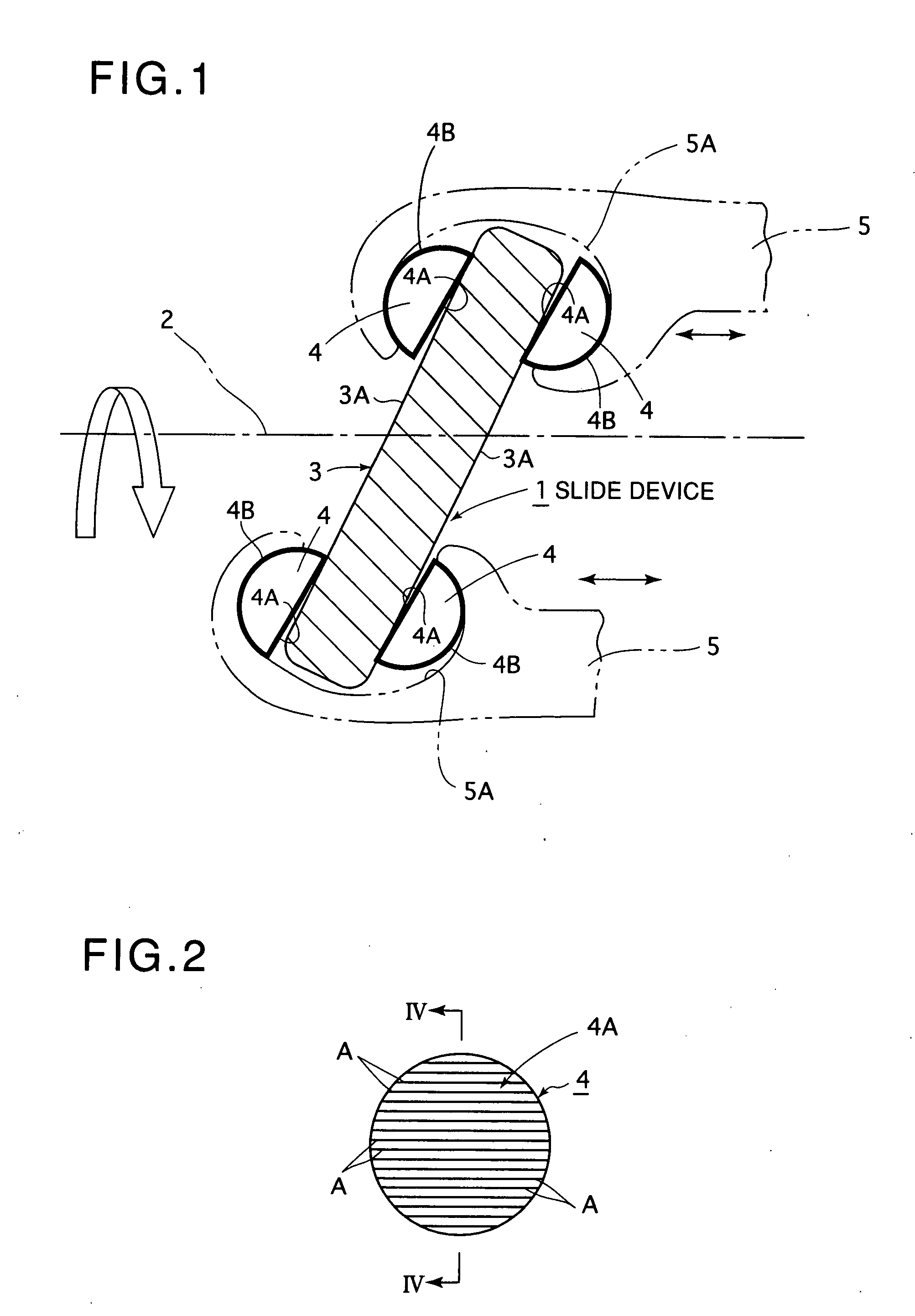

Method for manufacturing slide member

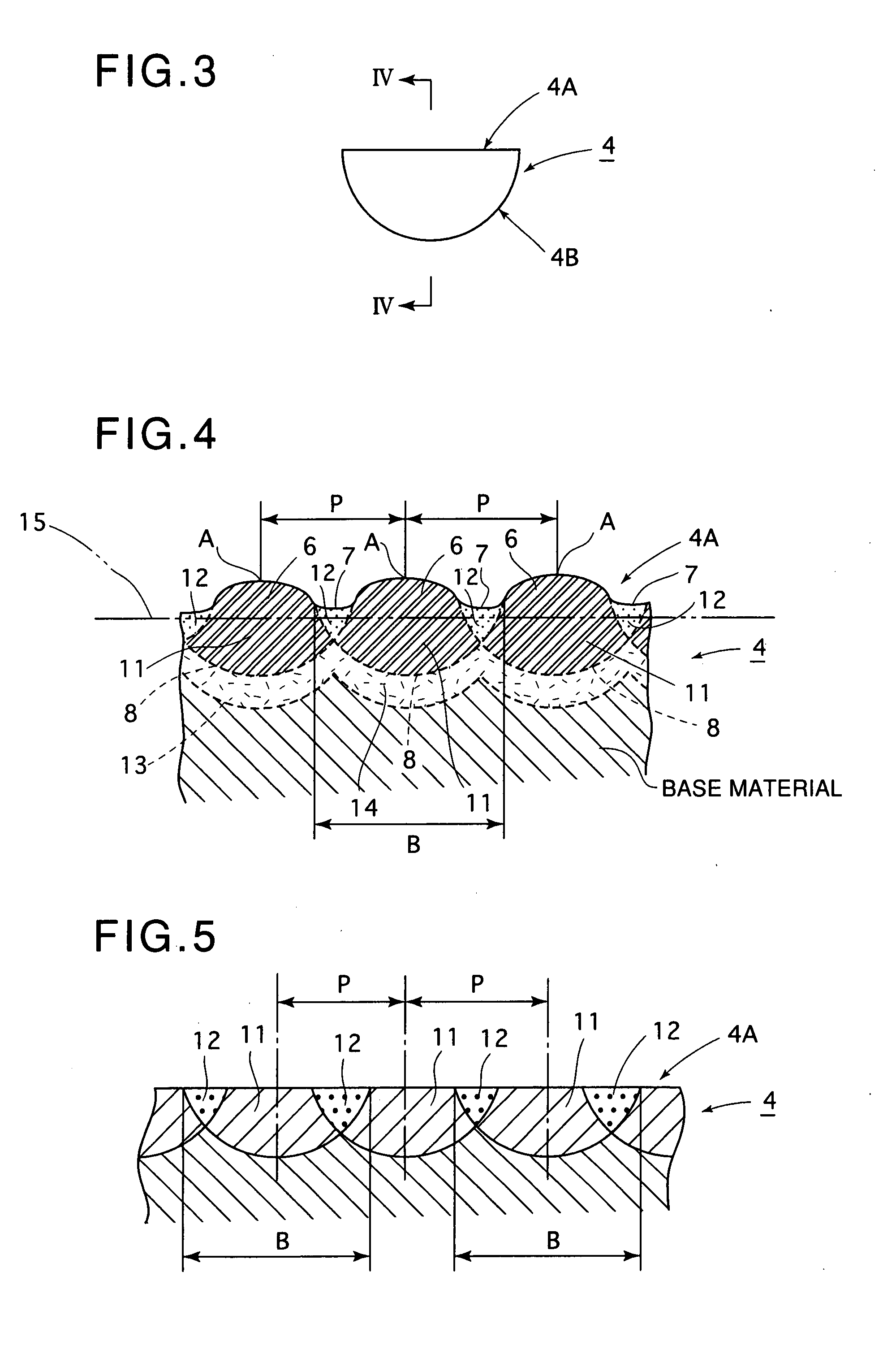

InactiveUS20090205754A1Improved seizure resistanceGood anti-occlusion performanceFurnace typesHeat treatment process controlEngineeringHardness

A sliding surface 4A of a shoe 4 undergoes laser radiation in a shape of a large number of parallel lines to form a large number of swollen portions 6 and to form concave portions 7 in adjacent positions thereof. The swollen portions 6 and the inner side thereof become direct hardening portions 11 with high hardness and the concave portions 7 and the inner side thereof become double hardening portions 12, which are lower in hardness than the swollen portions 6.After the laser hardening, the sliding surface 4A undergoes wrapping up to a position of an imaginary line 15 to delete relief to form a flat and smooth plane. Thereafter the sliding surface 4A undergoes buffing.Thereby, portions with low hardness are chipped off more largely than portions with high hardness to form a large number of minute irregularities on the sliding surface 4A (see FIG. 6).A large number of minute irregularities is formed uniformly on the sliding surface 4A of the shoe 4 and lubrication oil will be introduced thereinto. Therefore, a shoe 4 excellent in seizing resistant property can be provided.

Owner:TAIHO INDUSTRIES CO LTD

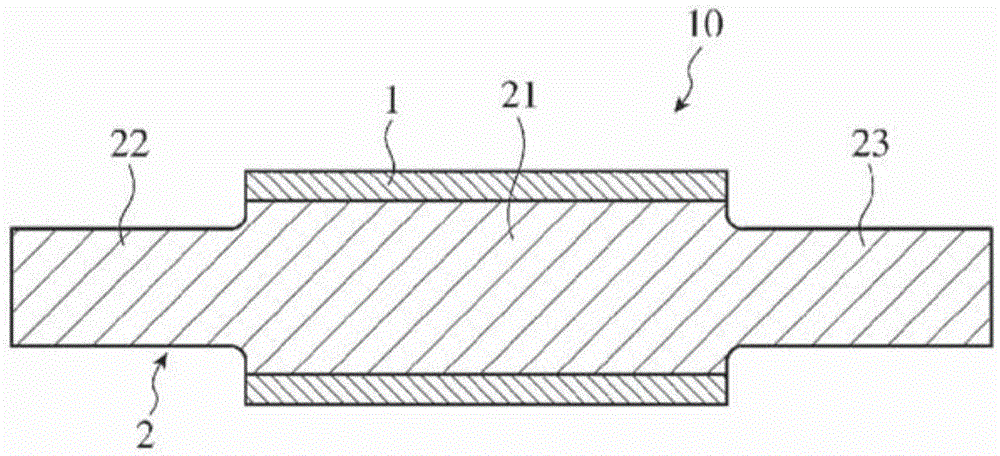

Manufacturing method for aluminum alloy-steel double metal material used for sliding bearing of multilayer structure

ActiveCN105316532AReduce labor costsCompact processMetal rolling arrangementsManganeseMaterials science

The invention relates to a manufacturing method for an aluminum alloy-steel double metal material used for a sliding bearing of a multilayer structure. A steel plate with the two faces being roughened and an aluminum tin silicon-aluminum manganese copper alloy plate brushed up are rolled in a composite mode at one time, and an aluminum tin silicon-aluminum manganese copper-steel double metal sliding bearing material panel with the required aggregate thickness is obtained; monotectic alloy of which possible solidification segregation of a low melting point phase is severer than solidification segregation under the earth gravitational field in deposition alloy is prohibited. All technological processes of smelting and rolling are integrated to a production line, and the technological processes are compact. A product has super wear resistance and corrosion resistance, good occlusion-proof performance and carrying ability and high fatigue strength, and the fatigue strength reaches 100 MPa to 120 MPa; the processing method has high application and popularization value and is extremely suitable for being used in middle-speed or high-speed or middle-load main bearings and connecting rod bearings.

Owner:SHANGHAI HEWEI IND

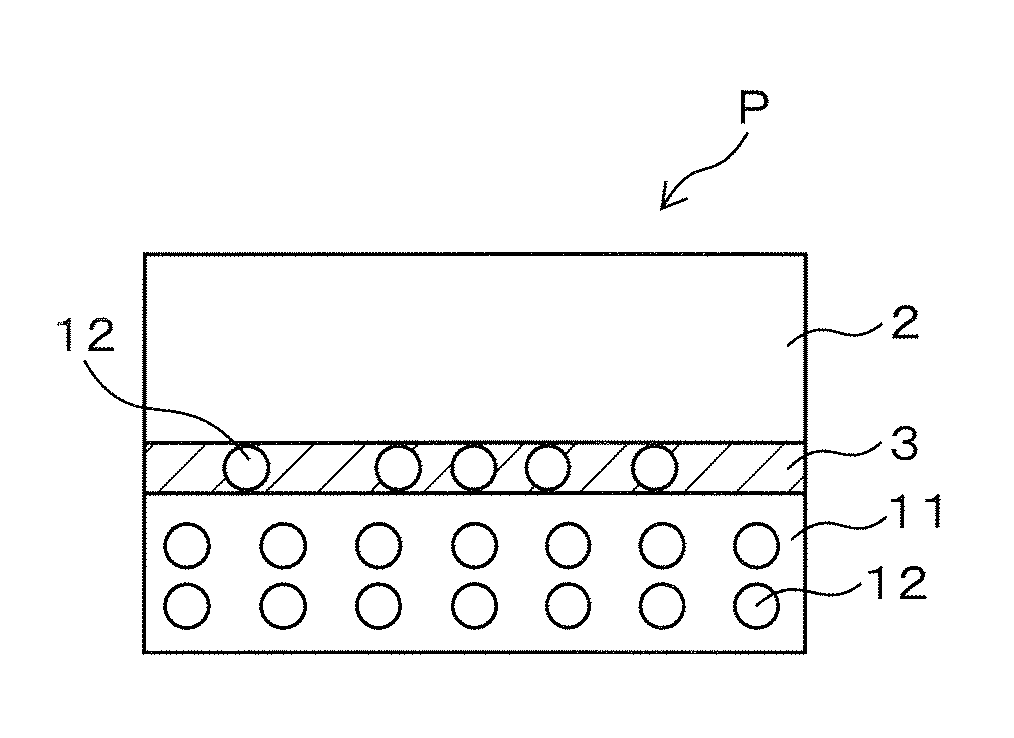

Bearing material coated slide member and method for manufacturing the same

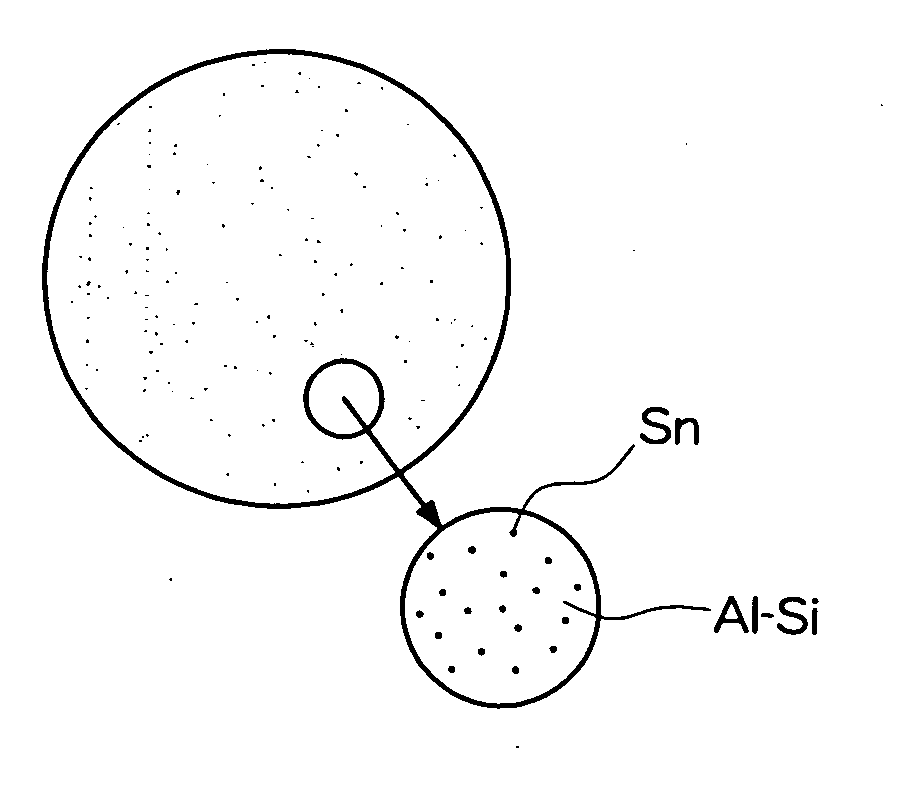

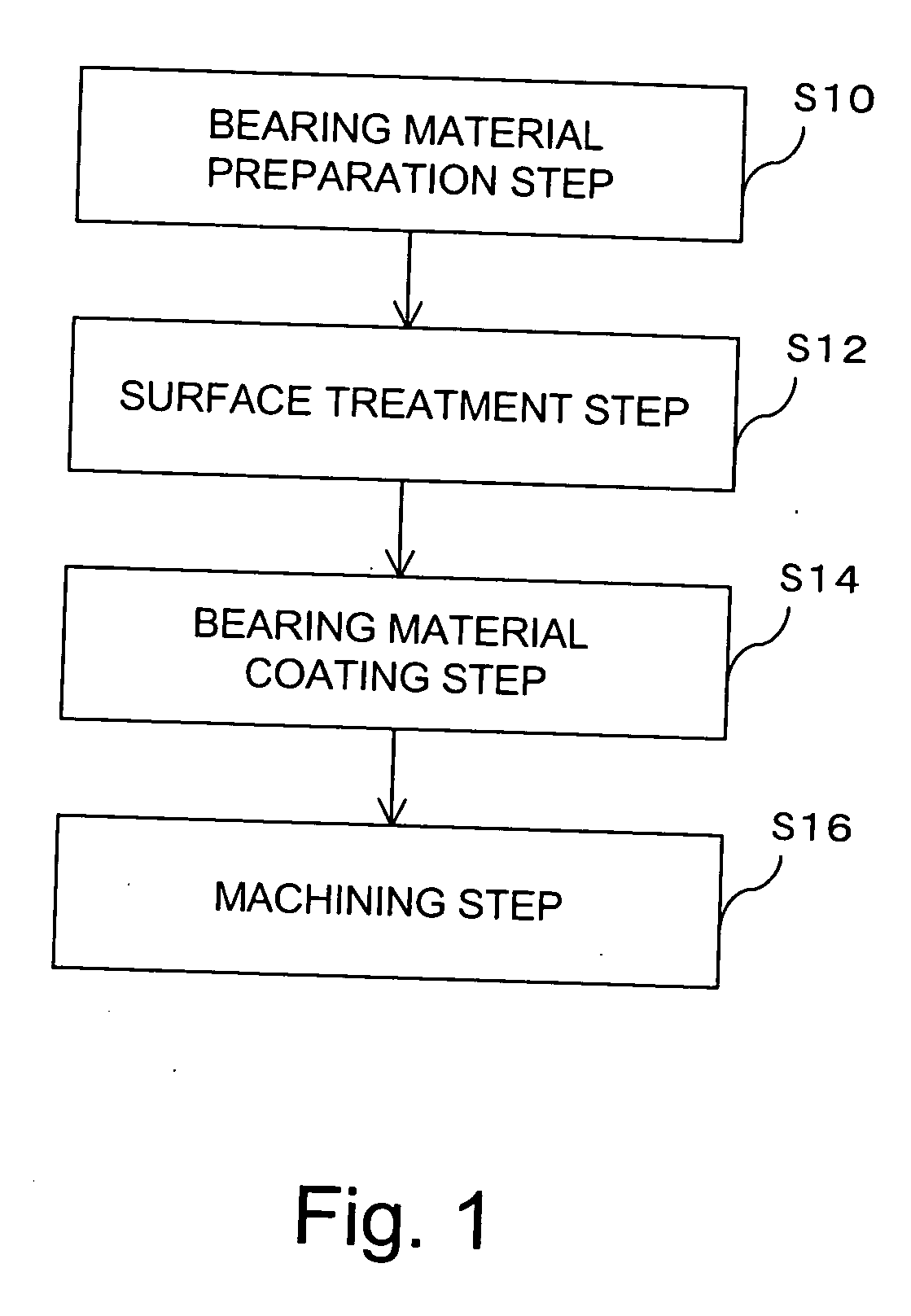

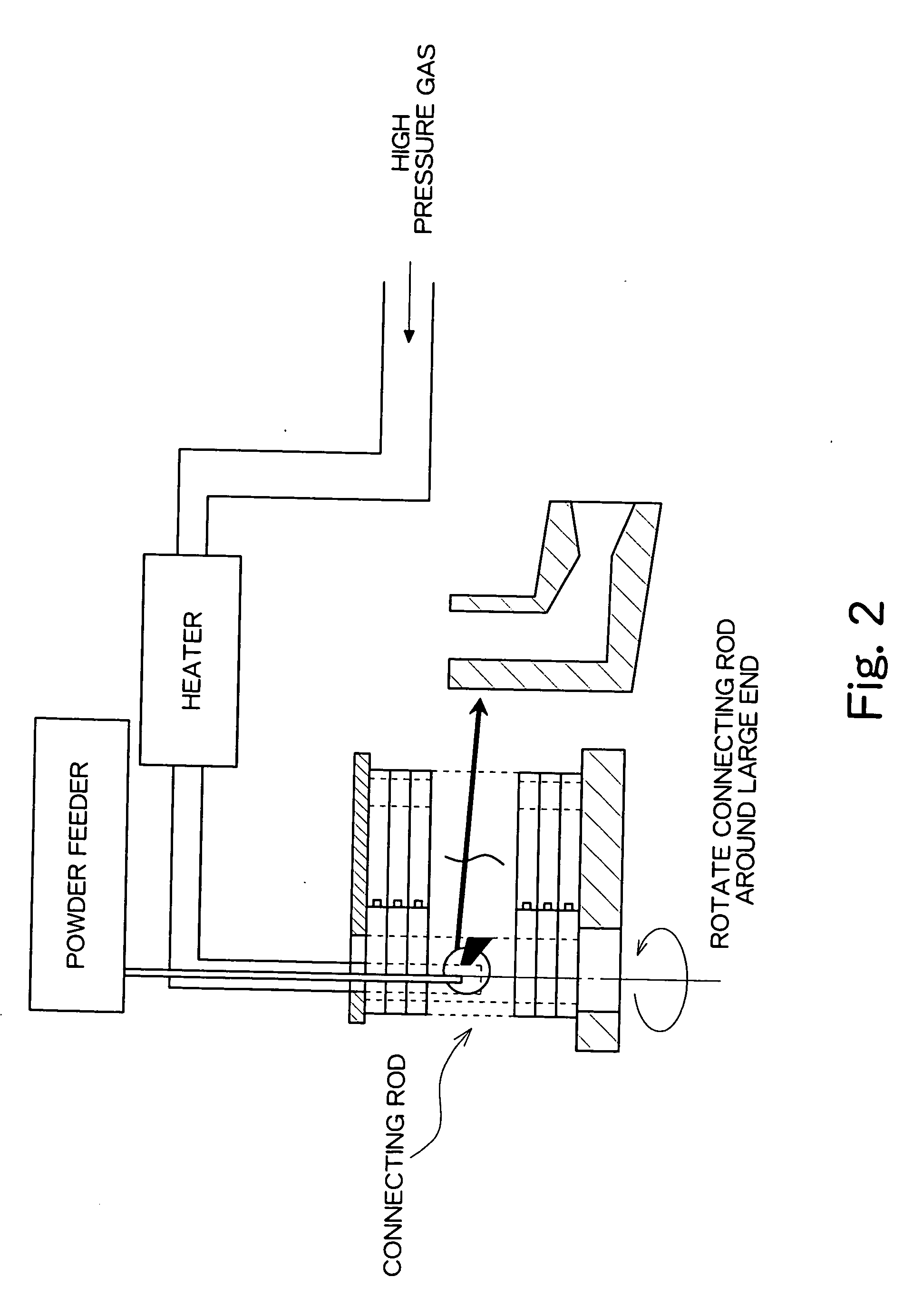

InactiveUS20070009756A1Good anti-occlusion performanceConnecting rod bearingsLiquid surface applicatorsAlloySolid phases

The present invention provides a bearing material coated slide member manufactured by coating a bearing material on a sliding surface of a slide member, and a method for manufacturing the same, in which the bearing material is composed of an Sn containing alloy powder, and is forced to impact on the sliding surface while being maintained in a solid phase, to thereby form a bearing material coated layer.

Owner:TOYOTA JIDOSHA KK

Hot-rolling composite roll produced by cetrifugal casting

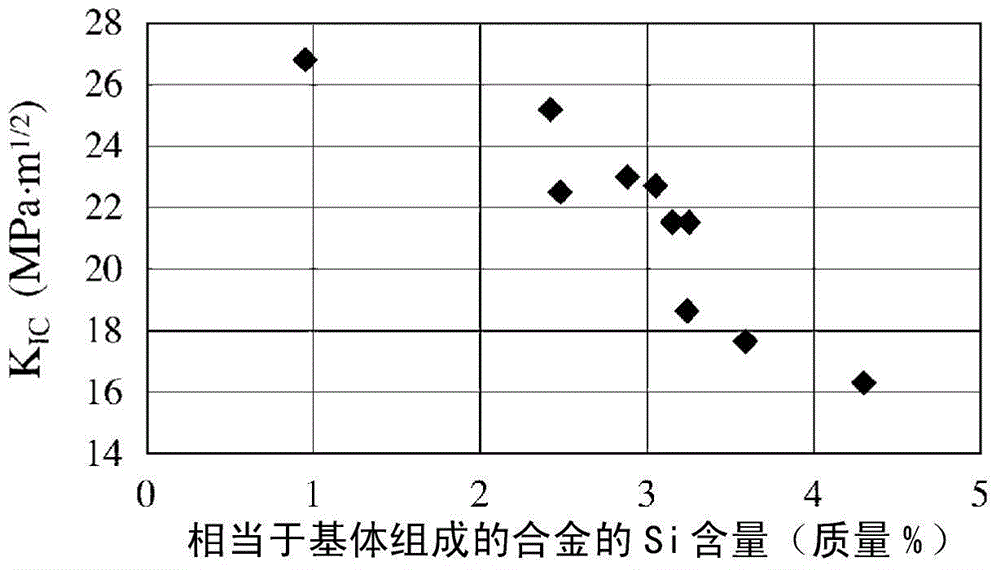

ActiveCN105121044AImprove wear resistanceGood anti-occlusion performanceFurnace typesRollsChemical compositionGraphite

A centrifugally cast hot-rolling composite roll comprising (a) an outer layer made of cast iron having a chemical composition comprising by mass 2.5-3.5% of C, 1.3-2.4% of Si, 0.2-1.5% of Mn, 3.5-5.0% of Ni, 0.8-1.5% of Cr, 2.5-5.0% of Mo, 1.8-4.0% of V, and 0.2-1.5% of Nb, the balance being Fe and inevitable impurities, a mass ratio of Nb / V being 0.1-0.7, and a mass ratio of Mo / V being 0.7-2.5, and meeting the condition of 2.5 ‰¤ V + 1.2 Nb ‰¤ 5.5, and having a structure comprising 0.3-10% by area of a graphite phase; (b) a shaft portion made of ductile cast iron in which the area ratio of ferrite is 35% or less; and (c) an intermediate cast iron layer.

Owner:PROTERIAL LTD

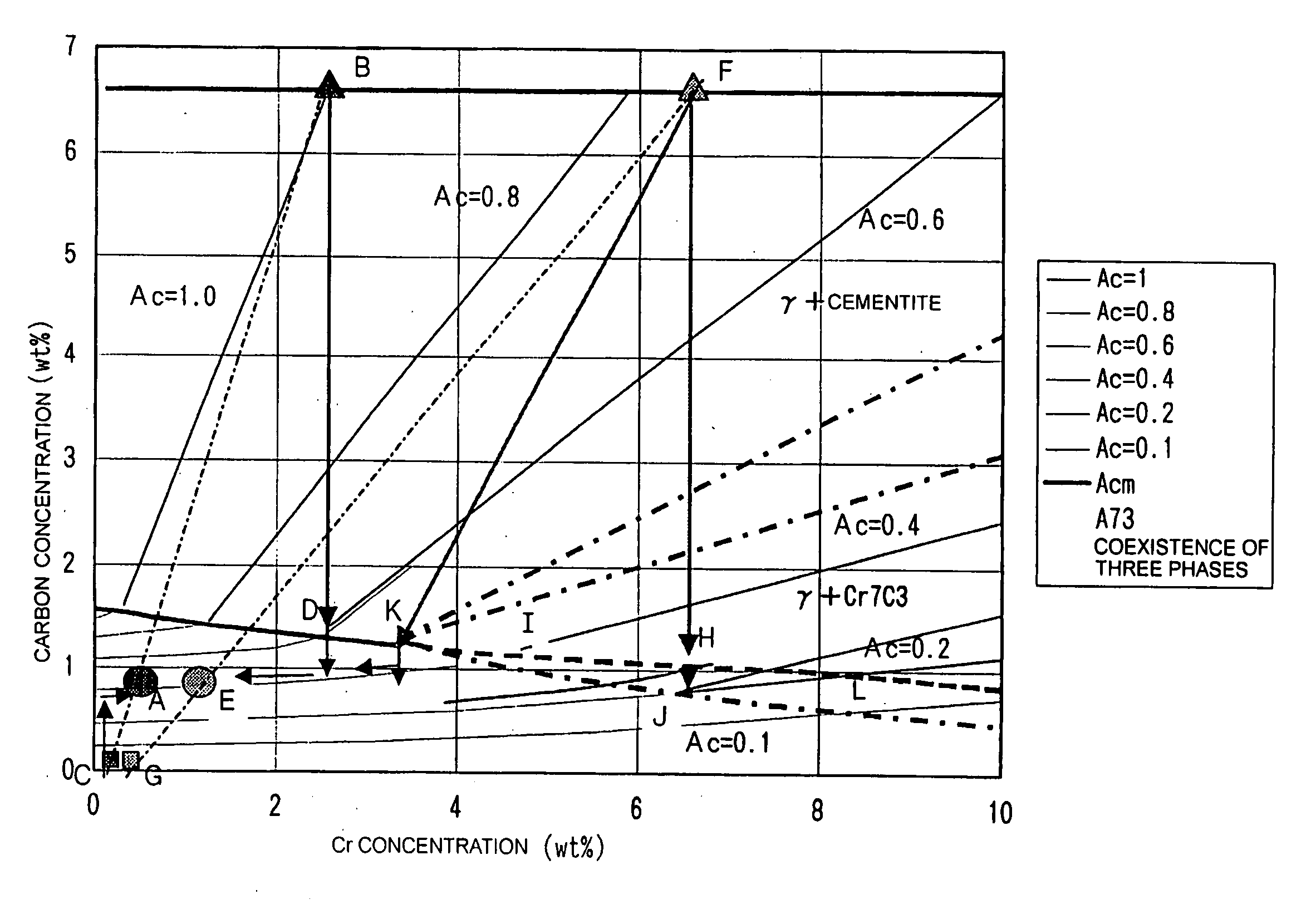

Case hardened gear and method of producing the same

InactiveUS7691213B2Improve the immunityHigh contact fatigue strengthPortable liftingBearing componentsTO-18Surface layer

There is provided an inexpensive rolling element used under high interface pressure such as induction hardened gears, the rolling element being improved in the seizure resistance of its tooth flanks and having a temper hardness of HRC 50 or more at 300° C. To this end, the rolling element is made from a steel material containing at least 0.45 to 1.5 wt % C and one or more alloy elements selected from 0.1 to 0.5 wt % V and 0.3 to 1.5 wt % Cr, and has a rolling contact surface layer having a structure tempered at low temperature in which 2 to 18% by volume cementite disperses in a martensite parent phase formed by induction heating and cooling and containing 0.25 to 0.8 wt % carbon solid-dissolving therein.

Owner:KOMATSU LTD

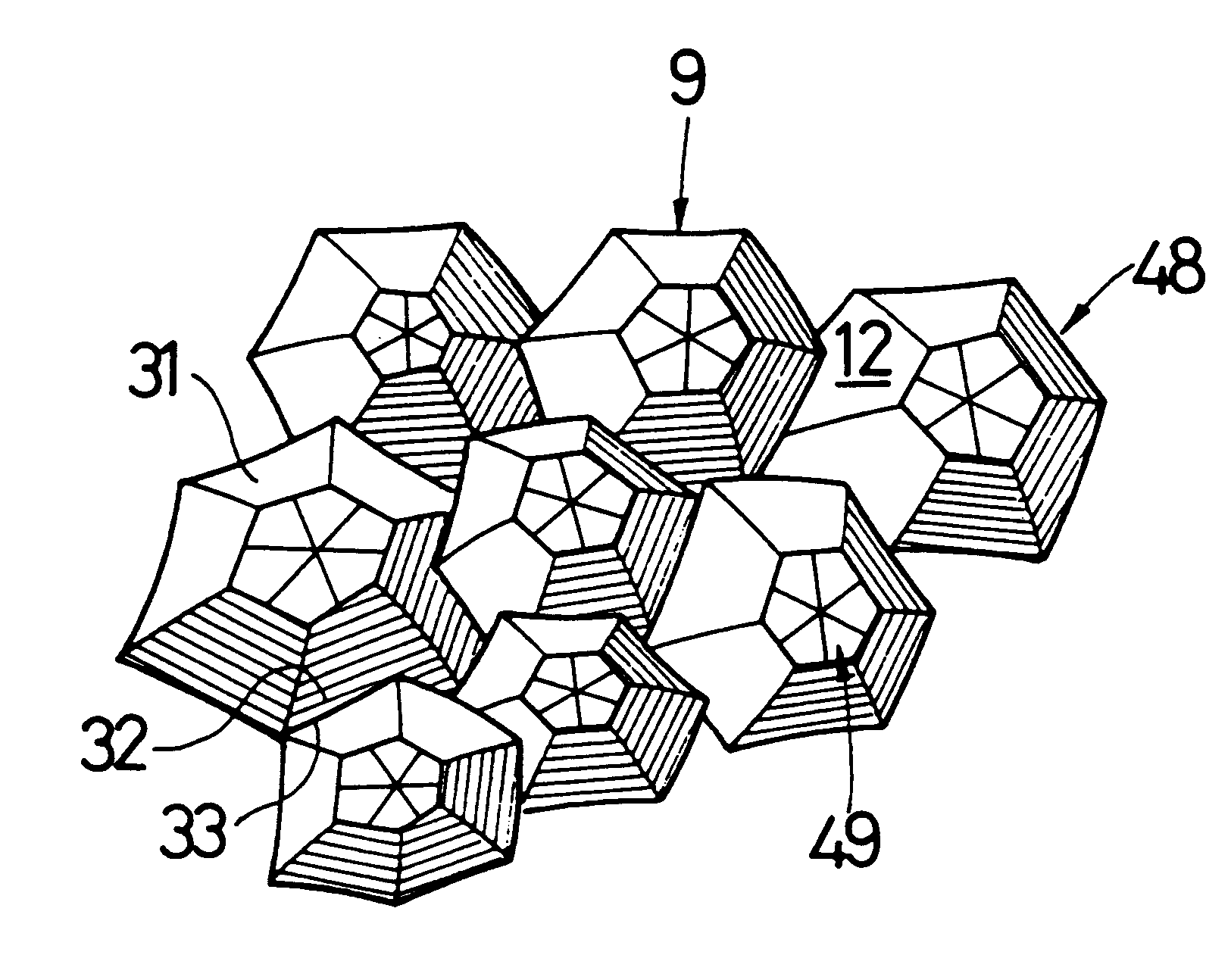

Slide surface construction and process for producing the same

InactiveUS6235413B1High hardnessIntricate aspectConnecting rod bearingsShaftsSurface constructionMetal

A slide surface construction is formed of a large number of truncated hexagonal pyramid-shaped metal crystals in a slide surface, with the area rate A of said truncated hexagonal pyramid-shaped metal crystals being in a range of 40%<=A<=100%. A top face of each of the truncated hexagonal pyramid-shaped metal crystals has a plurality of flat face portions, with a step provided between adjacent ones of the flat face portions. Each of the truncated hexagonal pyramid-shaped metal crystals is a (hhh) oriented metal crystal which has a body-centered cubic structure and whose (hhh) plane (by Miller indices) is oriented toward the slide surface.

Owner:HONDA MOTOR CO LTD

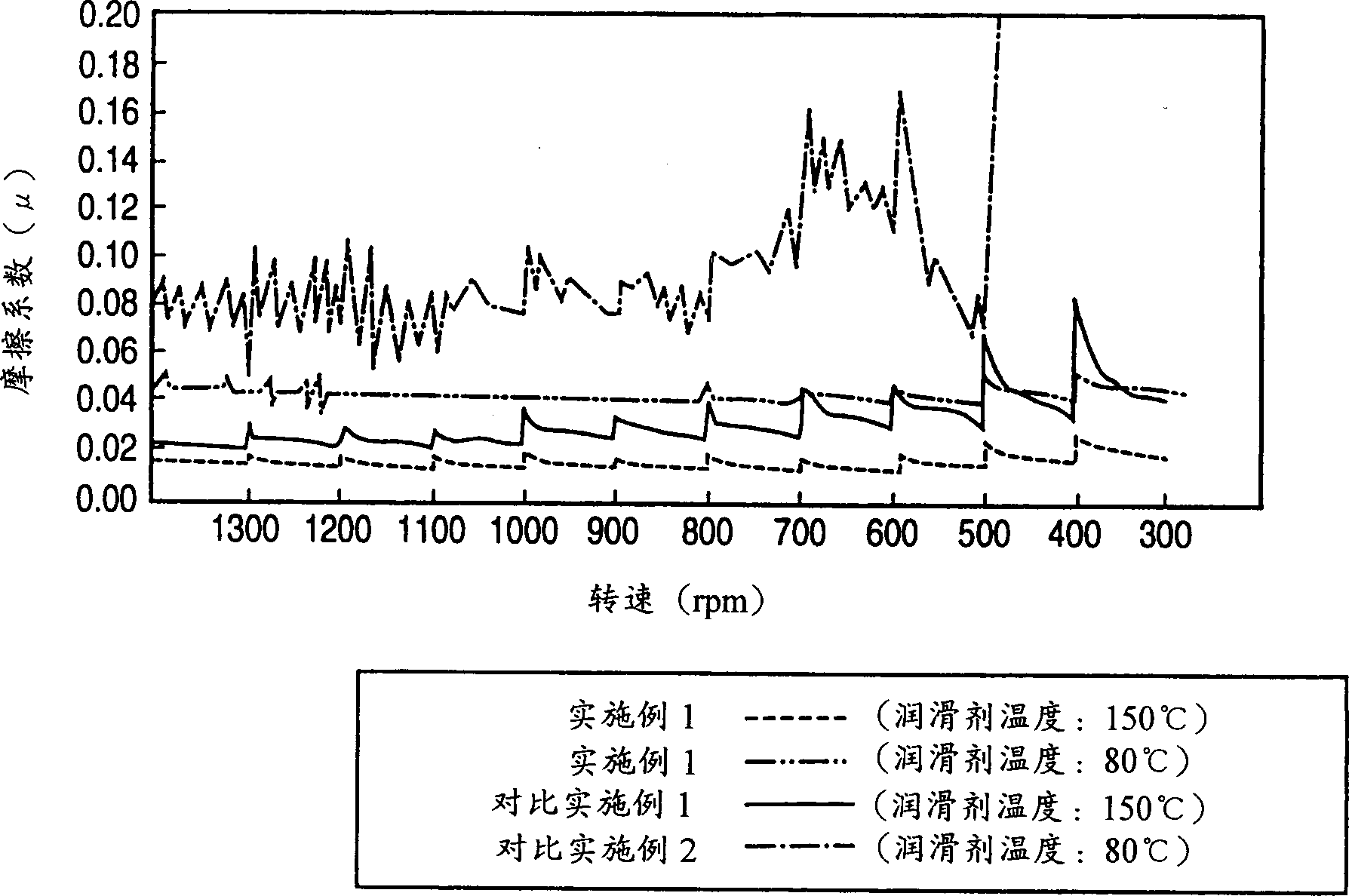

Plain bearing for internal combustion engines

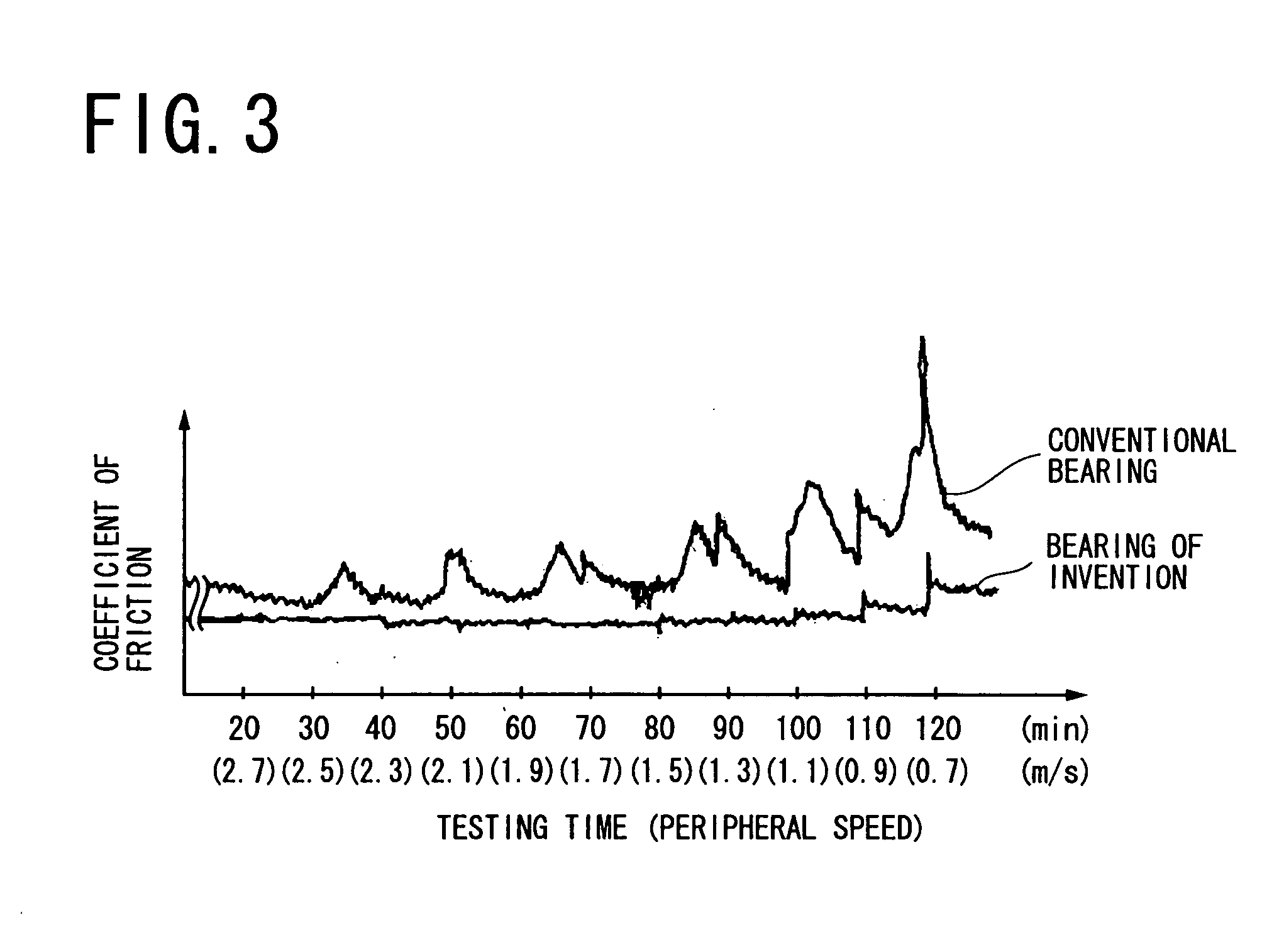

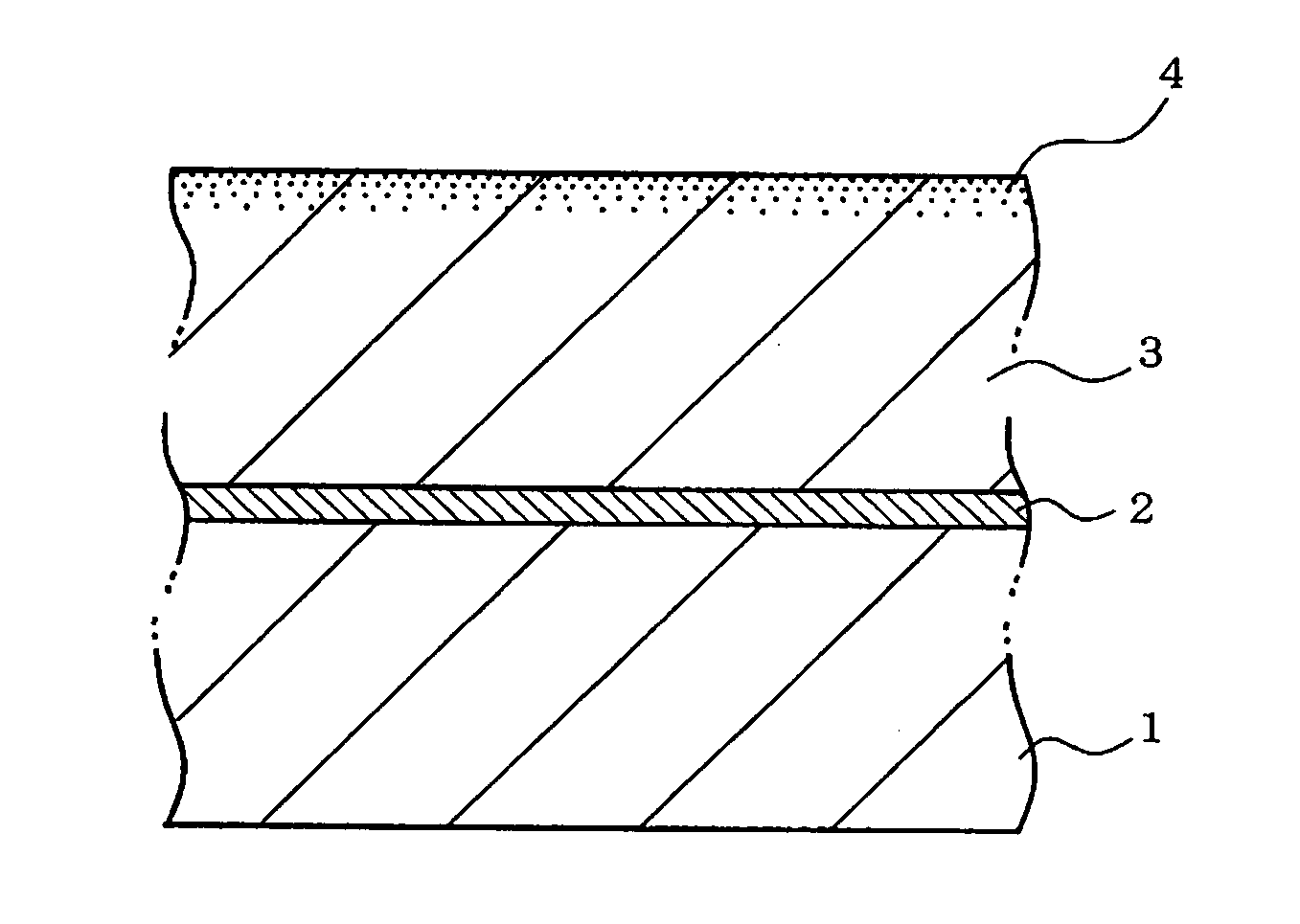

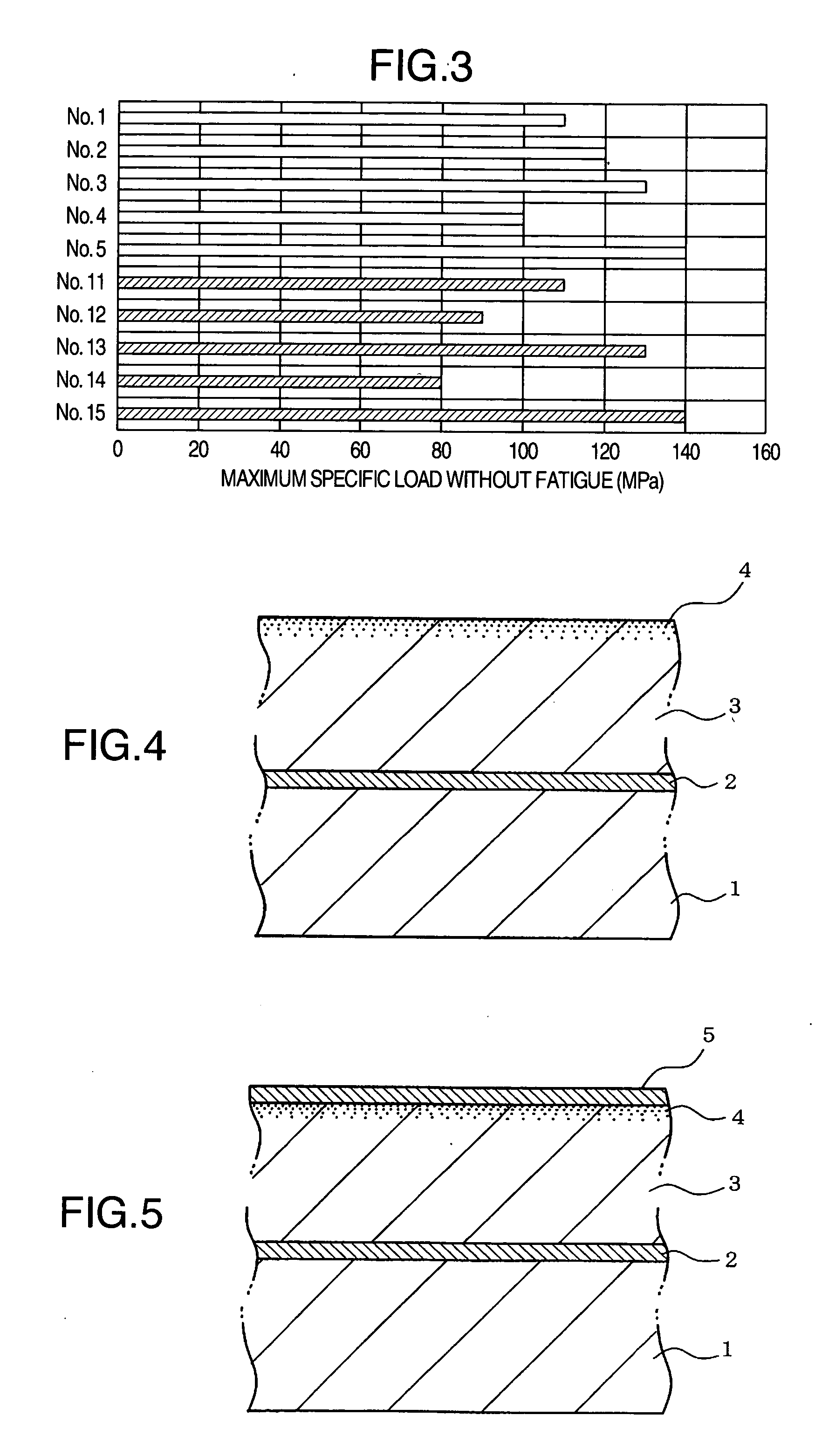

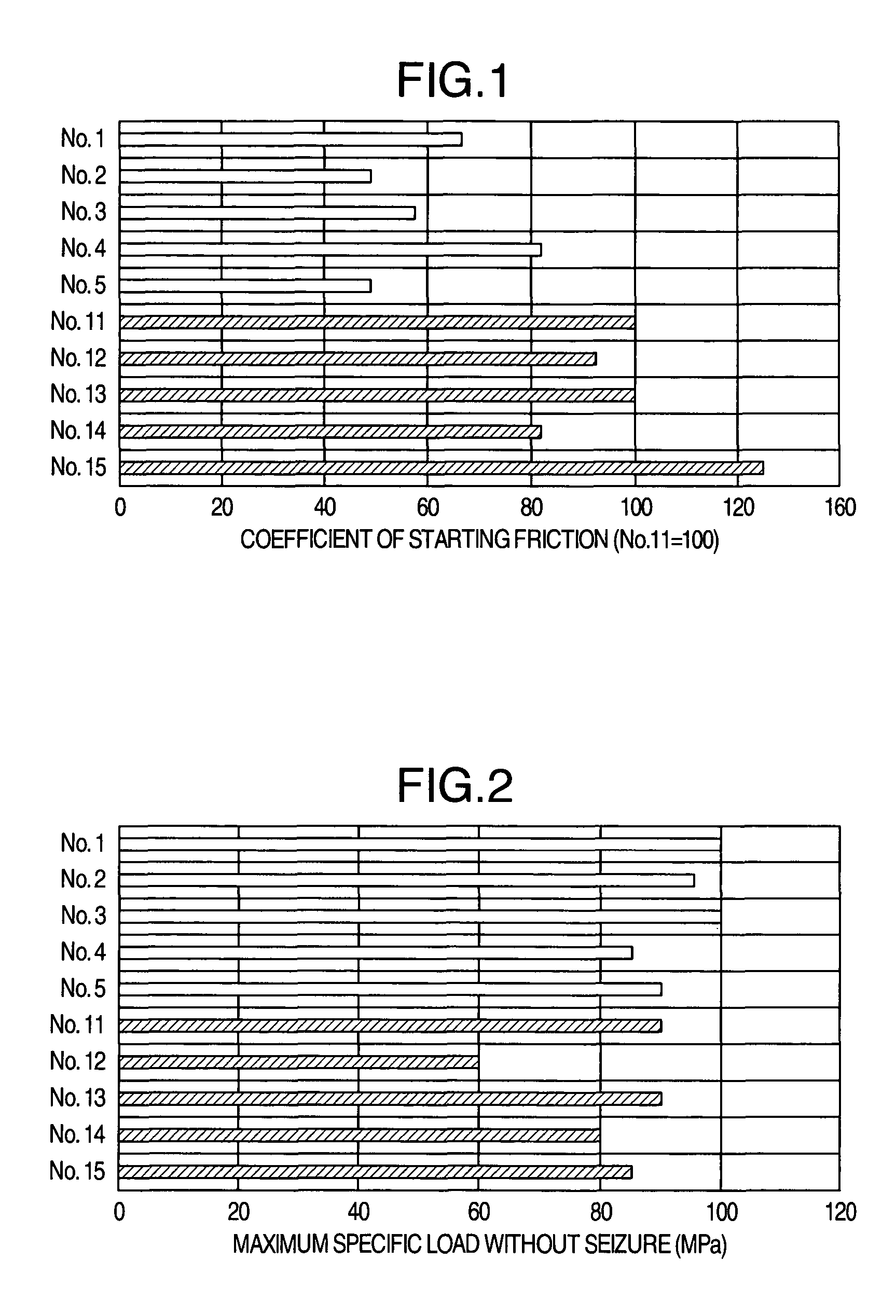

ActiveUS20050180669A1Reduce coefficient of frictionImprove fatigue resistanceCrankshaft bearingsShaftsCombustionSurface layer

Disclosed is a plain bearing for internal combustion engines, in which a back metal layer is lined with a bearing alloy layer made of an aluminum-base bearing alloy which has a Vickers hardness (Hv) of from not less than 40 to not more than 160. The bearing alloy layer includes a lubricative surface layer which has a thickness of not more than 10 μm and contains a solid lubricant. The maximum concentration of an element contained in the solid lubricant is not less than 5 mass %.

Owner:DAIDO METAL CO LTD +1

Slide bearing for internal combustion engines

InactiveUS20070031651A1Reduce frictionHigh bonding strengthShaftsBearing componentsCombustionInternal combustion engine

A slide bearing for internal combustion engines, comprising a slide layer including a lubricant outer layer in which a solid lubricant is contained, and wherein the lubricant outer layer contains an element which is contained in the solid lubricant, at a maximum concentration of not less than 5 mass % in the lubricant outer layer, and at least a solid lubricant gathered particle is formed on a surface of the lubricant outer layer, the solid lubricant gathered particle being a particle of the solid lubricant formed by gathering a plurality of primary particles, the solid lubricant gathered particle having a long side of not less than 20 μm but less than 100 μm in terms of surface visual field of the lubricant outer layer.

Owner:DAIDO METAL CO LTD

Slurry chromium impregnation permeating agent slurry and chromium impregnation layer preparing method

InactiveCN106282913AImprove thermal stabilityLow friction factorSolid state diffusion coatingSurface corrosionTemperature resistance

The invention belongs to the technical field of metal impregnation, and particularly relates to a slurry chromium impregnation permeating agent slurry and chromium impregnation layer preparing method. The method is used for preparing a permeating layer capable of improving surface corrosion resistance, wear resistance and high-temperature resistance performance of a metal material product. The method comprises the steps that a protecting sleeve is used for the non-permeating-layer portion of a cleaned part for protecting, and therefore the portion cannot be coated with permeating agent slurry; the portion, required to be subject to chromium impregnation, of the part is evenly coated with the permeating agent slurry, and the thickness of a coating layer ranges form 1.5 mm to 2.0 mm; after the coating layer is dried, the part is subject to chromium impregnation in a vacuum tank under the protection atmosphere protection, in the chromium impregnation process, the heat preservation temperature ranges from 1040 DEG C to 1090 DEG C, the heat preservation time ranges from 5 h to 10 h, furnace cooling to the temperature below 300 DEG C is carried out, and during furnace cooling, the pressure is 0.5 to 1.0 time of the standard atmospheric pressure. Metallurgical bonding is achieved, it is ensured that the coating can be tightly combined with a base body and is not prone to falling off, the depth of the prepared chromium impregnation layer ranges from 0.005 mm to 0.020 mm, and the chromium impregnation surface shows the silver gray.

Owner:AECC AVIATION POWER CO LTD

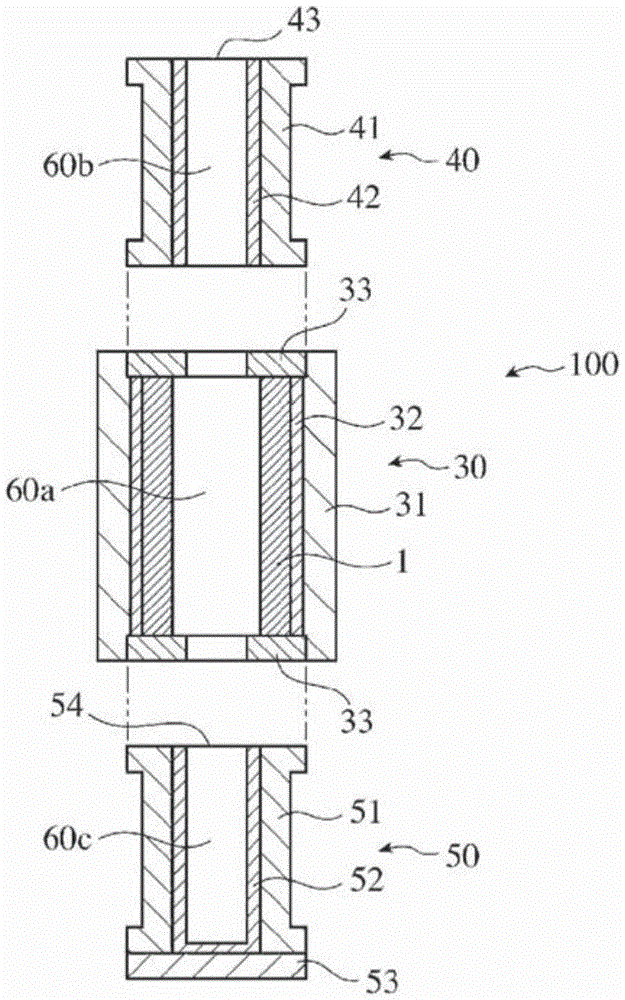

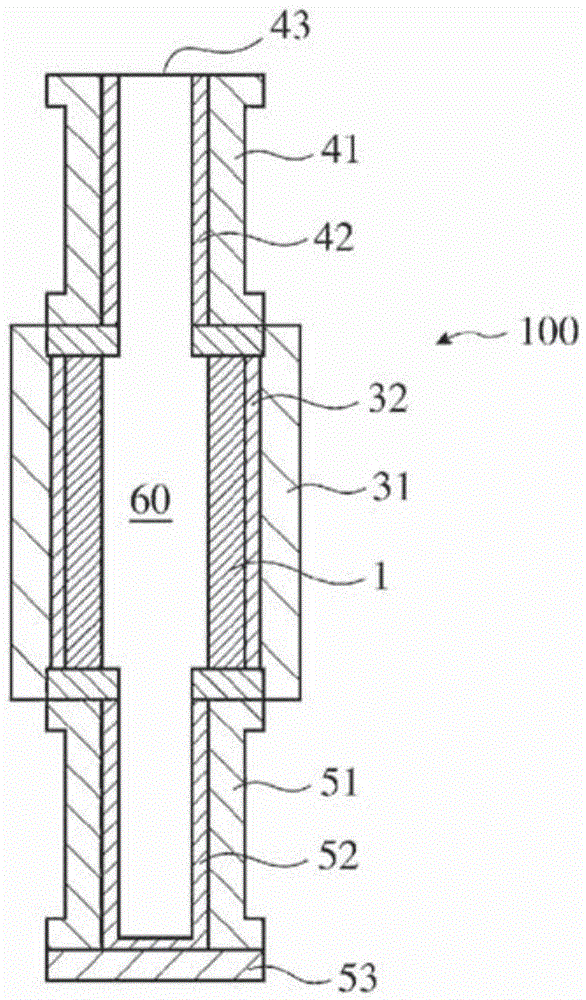

Centrifugally cast composite roll for hot rolling

ActiveCN105579156AImproved seizure resistanceExcellent abrasion resistanceRollsMetal rolling arrangementsBorideChemical composition

Provided is a centrifugally cast composite roll for hot rolling in which: an outer layer (1) that is formed by centrifugal casting and an inner layer (2) comprising a ductile cast iron are integrated by welding; the outer layer has a chemical composition that includes, by mass, 1-3% of C, 0.4-3% of Si, 0.3-3% of Mn, 1-5% of Ni, 2-7% of Cr, 3-8% of Mo, 3-7% of V, 0.01-0.12% of B, and a remainder of Fe and unavoidable impurities; the relationship that is represented by Cr / (Mo + 0.5W) < -2 / 3[C - 0.2(V + 1.19Nb)] + 11 / 6 (wherein W = 0 and Nb = 0 when W and Nb are not included) is satisfied; and 1-15% of an MC carbide, 0.5-20% of a charcoal boride, and 0.5-20% of an Mo-based carbide by area ratio are included therein.

Owner:PROTERIAL LTD

Rolling element and method of producing the same

InactiveUS7422643B2Improve the immunityHigh contact fatigue strengthPortable liftingSolid state diffusion coatingTO-18Surface layer

There is provided an inexpensive rolling element used under high interface pressure such as induction hardened gears, the rolling element being improved in the seizure resistance of its tooth flanks and having a temper hardness of HRC 50 or more at 300° C. To this end, the rolling element is made from a steel material containing at least 0.45 to 1.5 wt % C and one or more alloy elements selected from 0.1 to 0.5 wt % V and 0.3 to 1.5 wt % Cr, and has a rolling contact surface layer having a structure tempered at low temperature in which 2 to 18% by volume cementite disperses in a martensite parent phase formed by induction heating and cooling and containing 0.25 to 0.8 wt % carbon solid-dissolving therein.

Owner:KOMATSU LTD

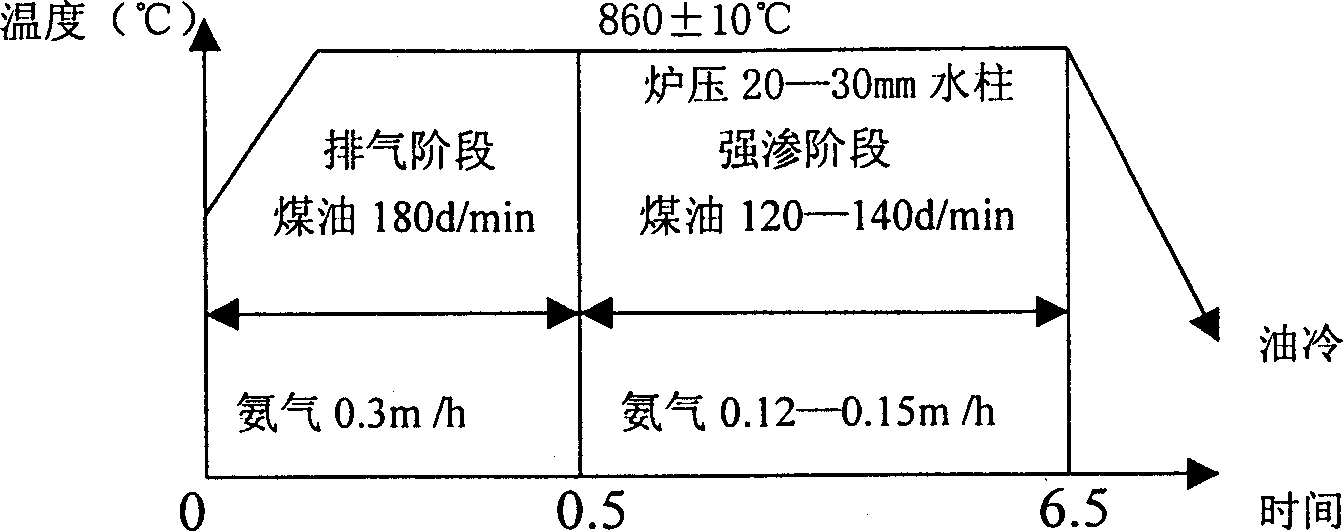

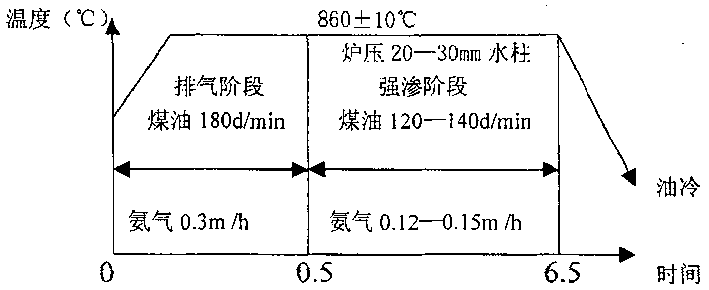

High-strength toughness differential mechanism universal joint pin machining process

InactiveCN1456708AImprove bearing capacityReduce distortionSuperimposed coating processHigh rateKerosene

A technology for preparing the high-strength and-toughness cross axle of differential gear includes such steps as washing to remove rust and dirt, osmosizing carbon and nitrogen (including ammonia gas and osmosizing), cooling in oil, tempering, fine grinding, treating with Mn and P, electrostatic spraying, and solidifying at 150-180 deg.C. The advantages of its product are high antiwear and anticorrosion nature, no deformation and cracking, high load-bearing power, and high rate of finished products.

Owner:重汽(济南)车桥有限公司

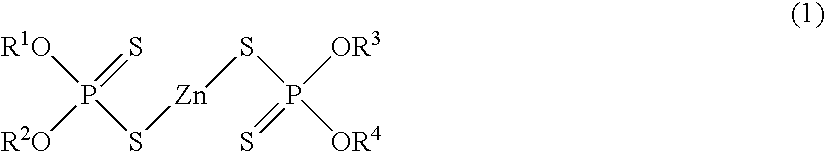

Lubricant for use in press working of a metal material and a press working method of a metal material using the same

InactiveUS20080194439A1Increase viscosityHigh propertyOrganic compound preparationAdditivesOrganozinc compoundMetallic materials

Owner:TOYOTA BOSHOKU KK

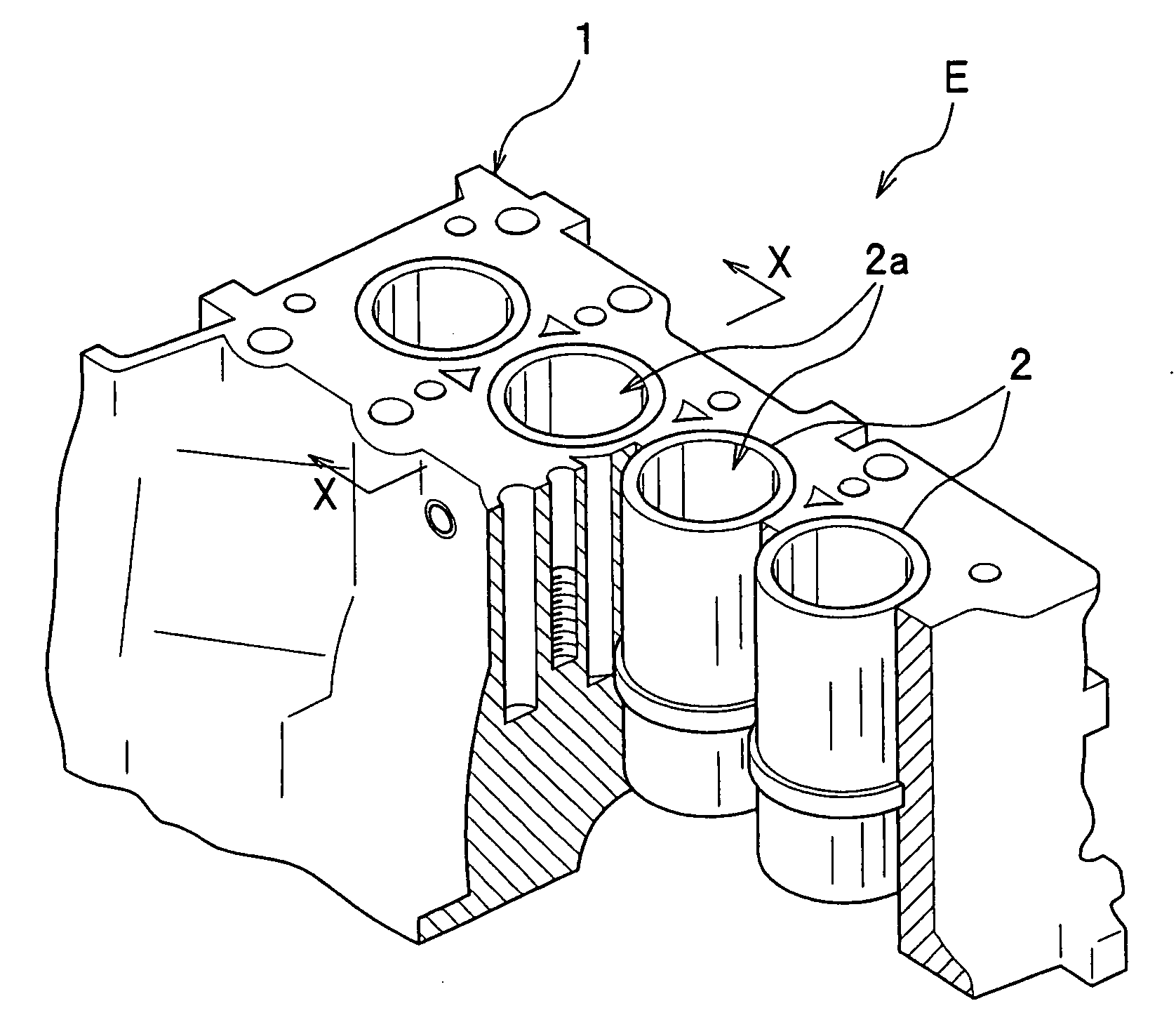

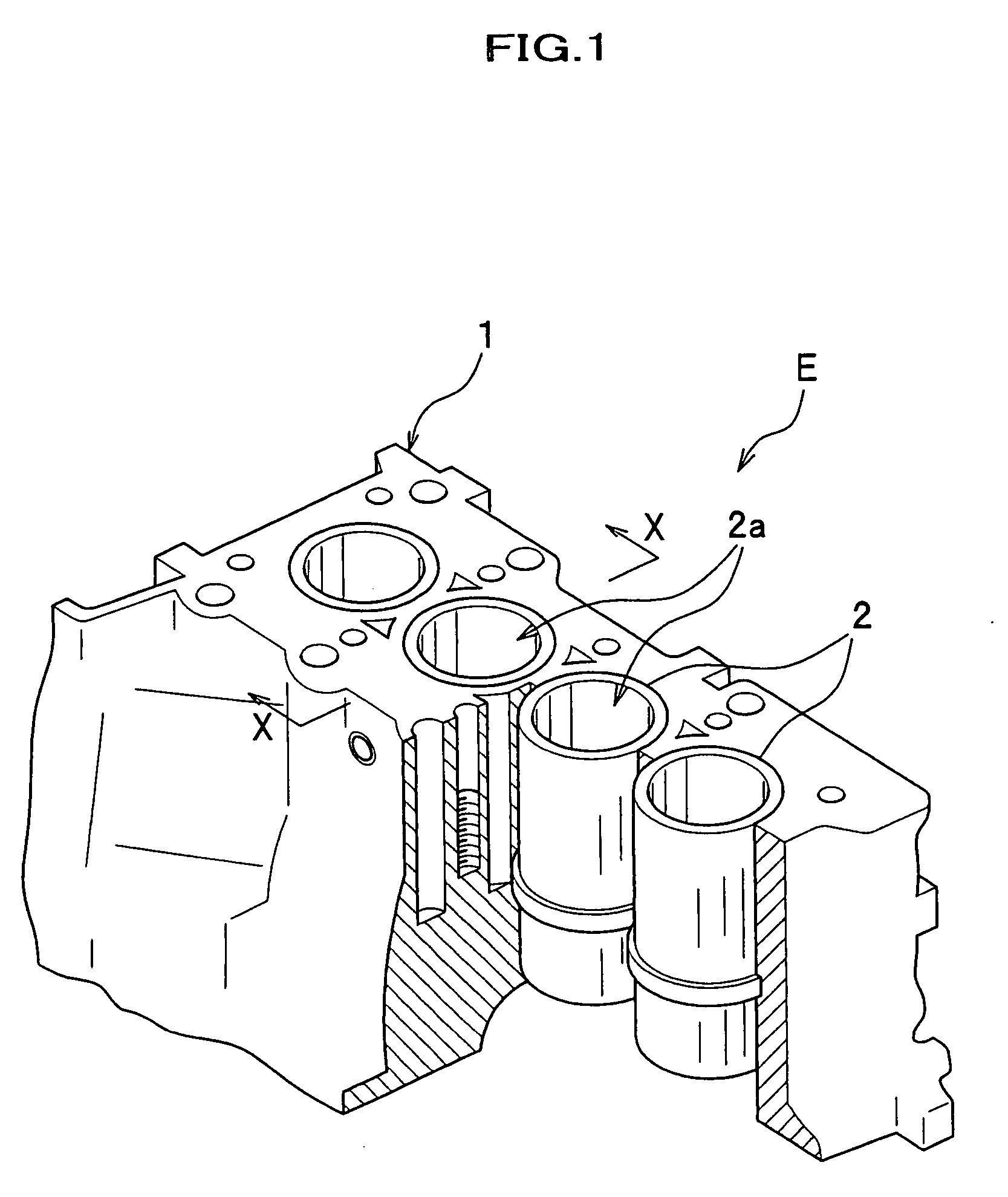

Engine

InactiveUS20080017160A1Increased strengthIncreased durabilityCasingsCylinder headsAluminum matrix compositesCylinder block

Owner:HONDA MOTOR CO LTD +1

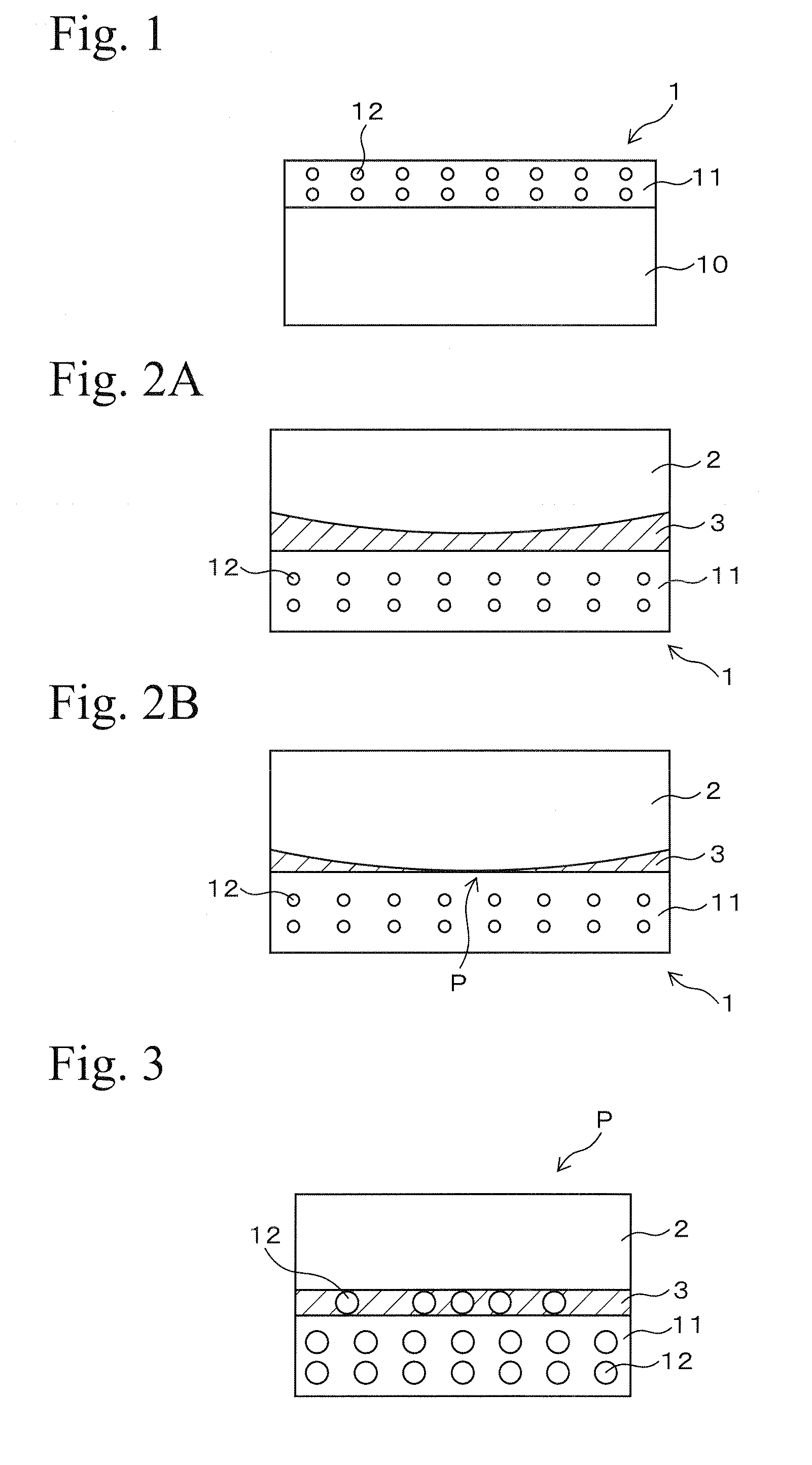

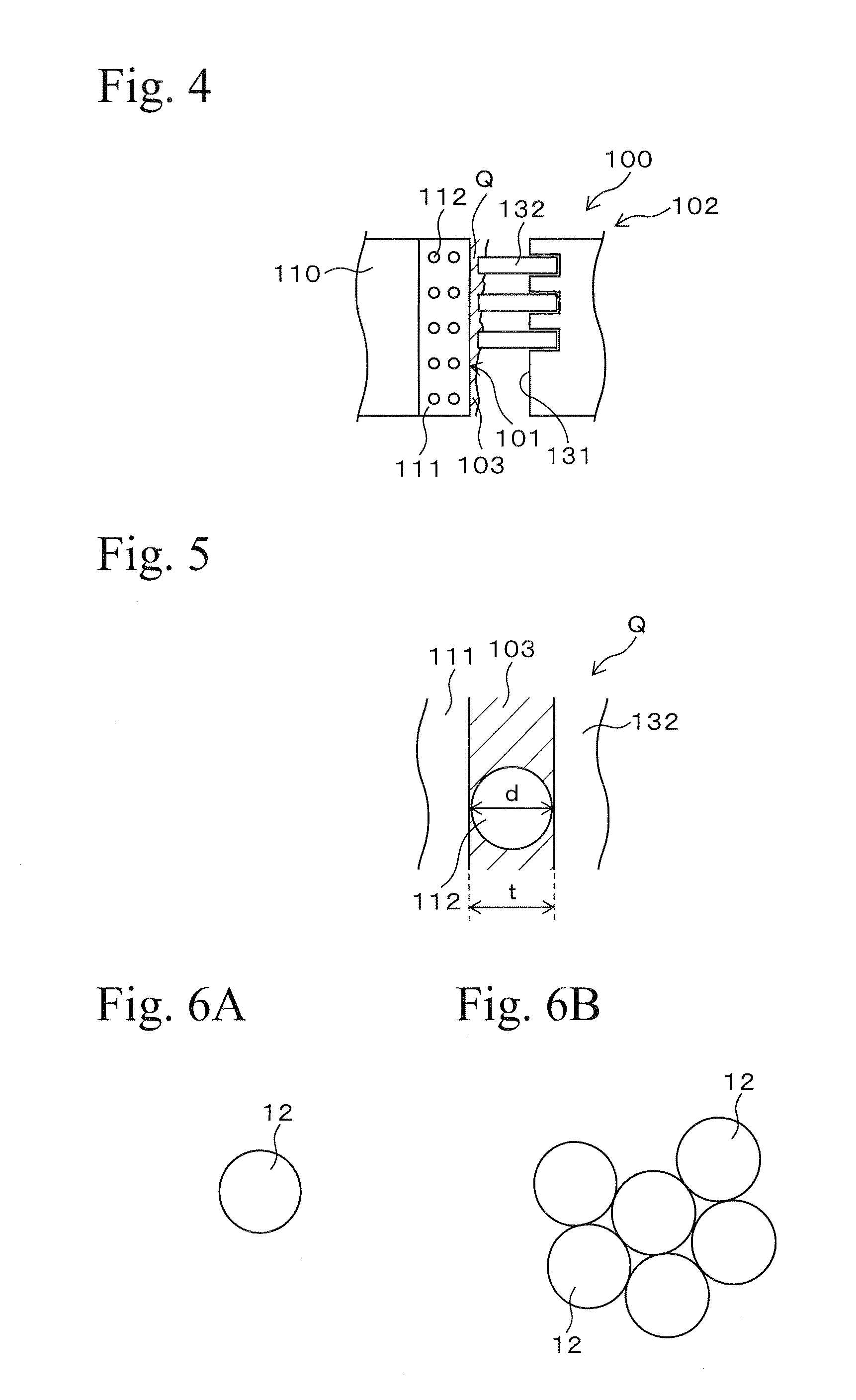

Sliding member and process for producing the same

InactiveUS20110249920A1Reduce frictionLow production costMaterial nanotechnologyVacuum evaporation coatingBall bearingStructure function

High surface pressure is applied to the sliding surfaces such that local solid contact occurs on sliding interfaces. Microscopic wear occurs on the sliding surfaces. Carbon-based molecules 12, having rollable hollow structures, are included as separate molecules or aggregates of molecules in the lubricating film 11. The molecules 12 are exposed from the lubricating film 11 by the microscopic wear. A portion of the carbon-based molecules 12 is separated from the lubricating film 11, and supplied to the sliding surfaces. The carbon-based molecules 12 having rollable hollow structures function as ball bearings on the molecular level on the sliding interfaces. When at least one separated carbon-based molecule 12 exist between the sliding interfaces, local friction can be reduced in comparison to when separated carbon-based molecule 12 does not exist.

Owner:HONDA MOTOR CO LTD

Plain bearing for internal combustion engines

ActiveUS7771120B2Reduce coefficient of frictionImproved resistance characteristicsCrankshaft bearingsShaftsSurface layerCombustion

Disclosed is a plain bearing for internal combustion engines, in which a back metal layer is lined with a bearing alloy layer made of an aluminum-base bearing alloy which has a Vickers hardness (Hv) of from not less than 40 to not more than 160. The bearing alloy layer includes a lubricative surface layer which has a thickness of not more than 10 μm and contains a solid lubricant. The maximum concentration of an element contained in the solid lubricant is not less than 5 mass %.

Owner:DAIDO METAL CO LTD +1

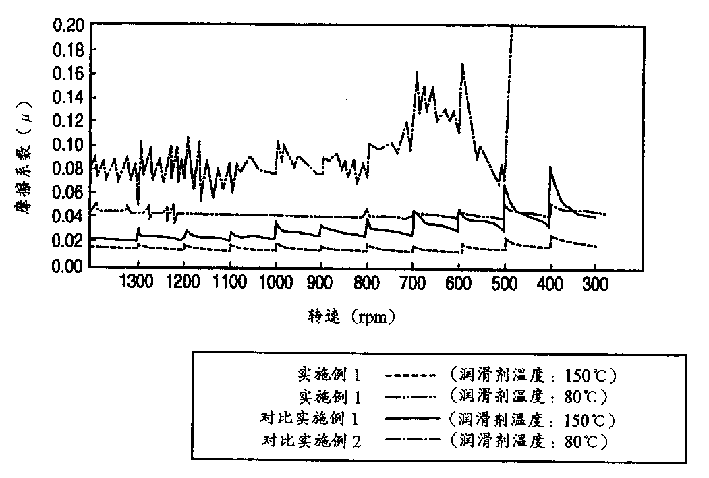

Lubricating oil composition for manual transmission

ActiveUS20070265175A1Good anti-occlusion performanceLow viscosityAdditivesSulfonateChemical composition

Owner:NIPPON OIL CORP +1

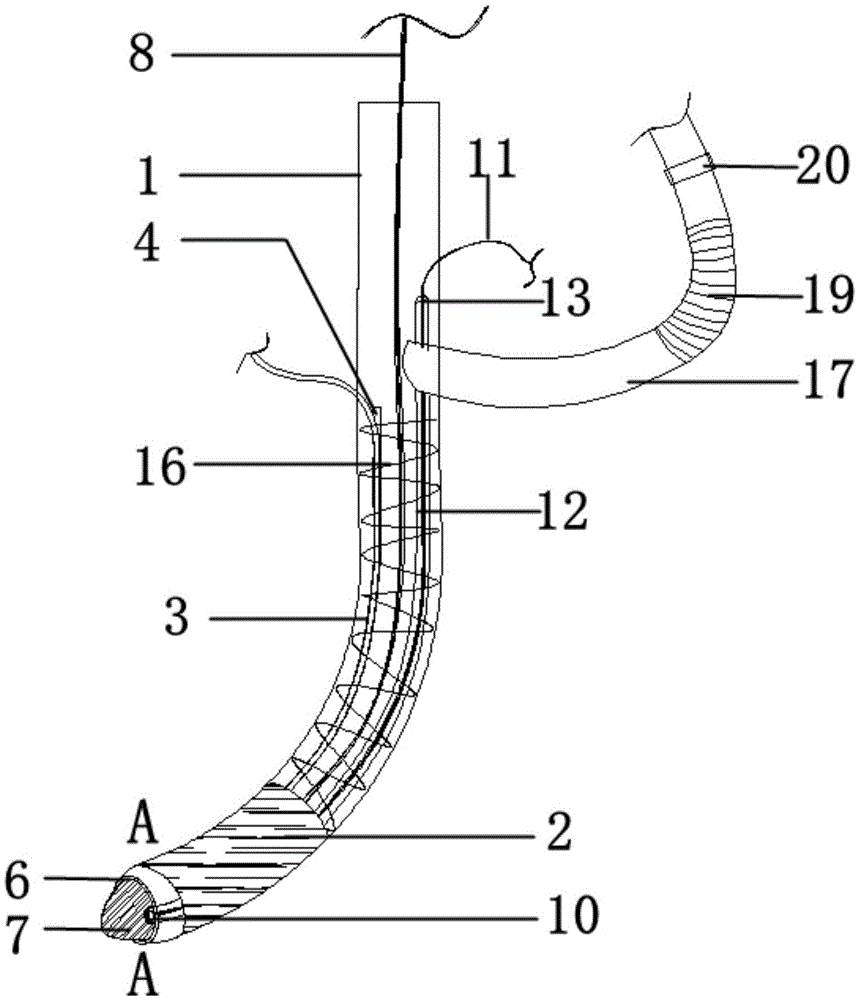

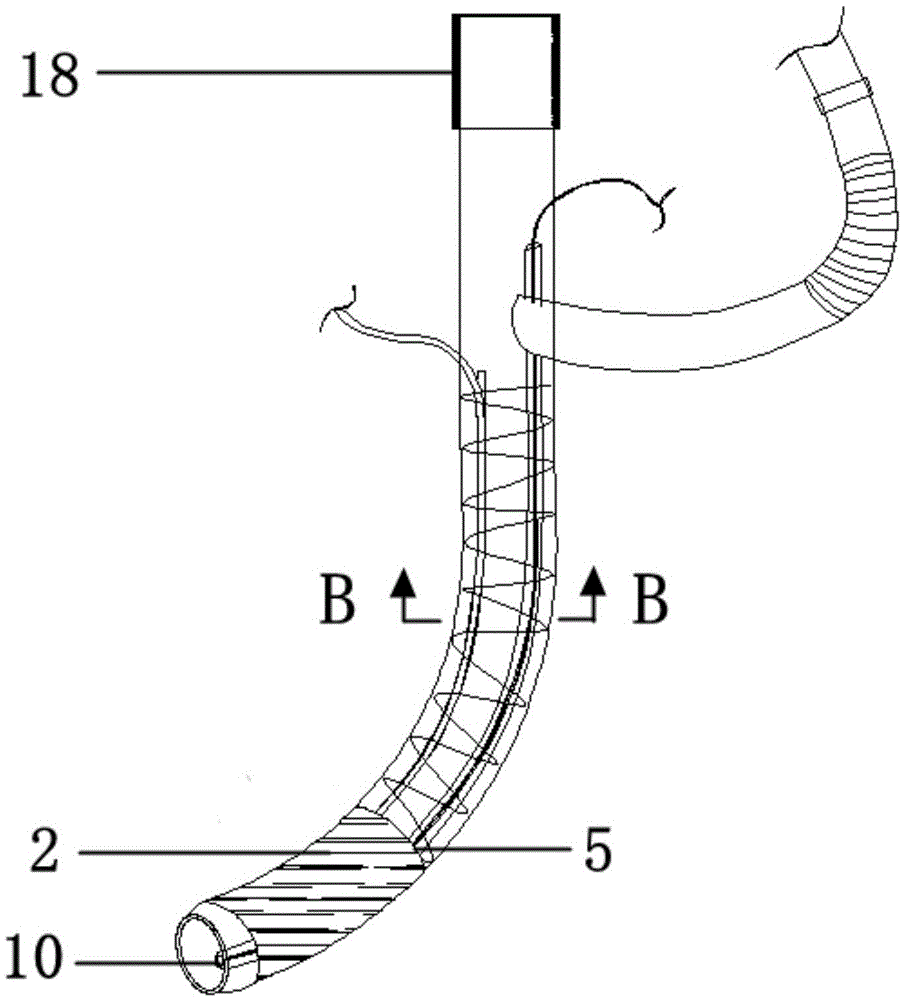

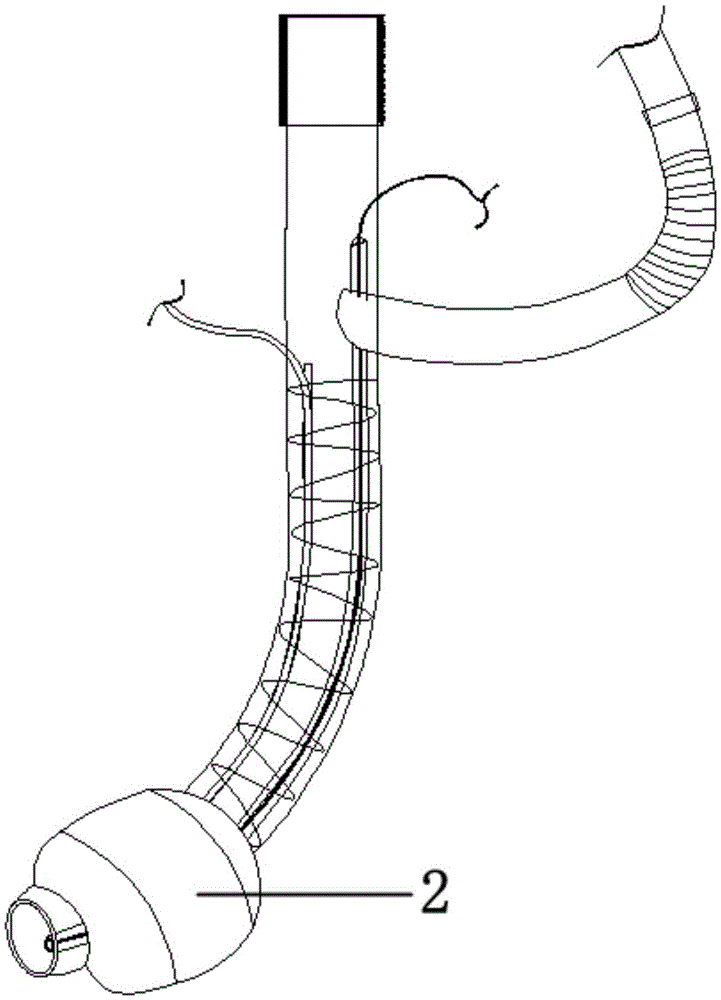

Novel trachea cannula

InactiveCN105477758AHigh reuse rateReduce the probability of frictional sheddingTracheal tubesMedical devicesSurgical operationSurgical Manipulation

The invention belongs to the field of medical equipment, and particularly relates to a novel trachea cannula. The novel trachea cannula comprises a cannula body, a balloon and a balloon inflation connecting pipe; the lower end of the balloon inflation connecting pipe is communicated with the balloon, the upper end of the balloon inflation connecting pipe is connected with a balloon inflation device, a strip-shaped groove is formed along the outer wall of the cannula body, and the balloon inflation connecting pipe is embedded in the strip-shaped groove; an annular groove is formed in the lower section of the cannula body, and the balloon is fixed in the annular groove. According to the novel trachea cannula, visual operation of the trachea cannula is achieved, and meanwhile it is guaranteed that a camera device is used repeatedly; insertion of the trachea cannula is safe, and the probability of disengagement of a gular cartilage and damage of the inner wall of a respiratory tract is reduced; collapse and bending of the trachea cannula body at the meshing part are prevented; oxygen supply is not interfered with surgical operation.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com