High-strength toughness differential mechanism universal joint pin machining process

A processing technology and differential technology, applied in the field of heat treatment, can solve the problems of the cross shaft being seized, the verticality of the cross shaft being difficult to correct, and the high heat treatment rejection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

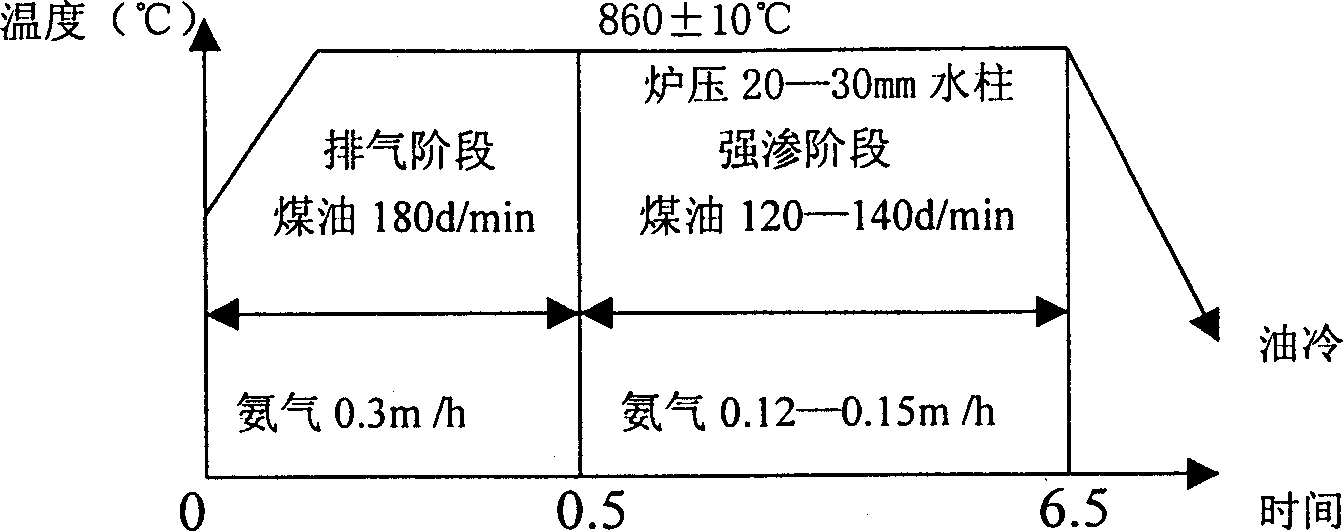

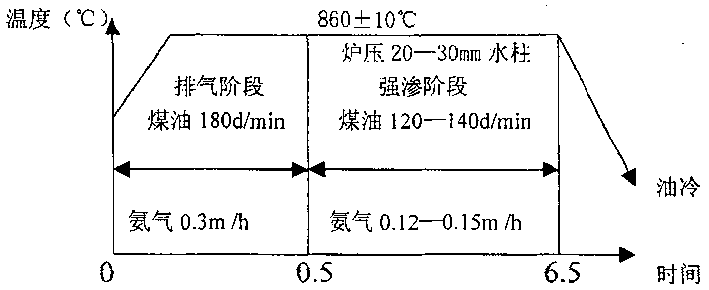

[0014] Embodiment: As shown in the attached figure, the shaft diameter of the cross shaft of the differential gear is Ф24mm, the design requires that the depth of the seepage layer is 0.8-1.1mm, the depth of the hard layer is 0.4-0.7mm, and the hardness is HRC59-63. Adopt this method: ① First, clean the cross shaft of the differential gear to make the surface free from rust and dirt; put it into the quenching rack; In the exhaust stage, the kerosene intake is 180d / min, the nitrogen intake is 0.3m / h, the furnace temperature rises to 860°C, and the exhaust stage is 0.5h; enter the strong infiltration stage, the furnace pressure is 26mm water column, and the kerosene intake The flow rate is 130d / min, the intake of ammonia gas is 0.13m / h, the furnace temperature is kept at 860°C, and the infiltration stage is 6.5h, so that the infiltration layer meets the process requirements; ③Cool with 20# engine oil to make the workpiece not easily deformed and Cracking; ④ Tempering, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com