Patents

Literature

70results about How to "High contact fatigue strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High carbon chromium bearing parts surface chemical heat-treatment process

ActiveCN1804128AHigh surface hardnessIncrease compressive stressSolid state diffusion coatingFurnace typesHigh carbonIn vehicle

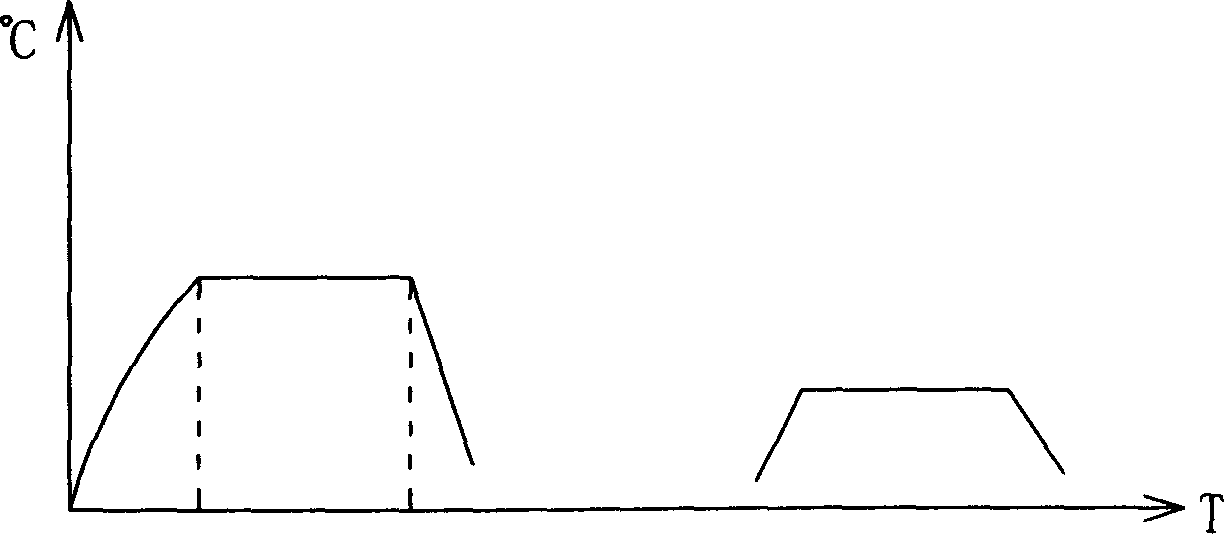

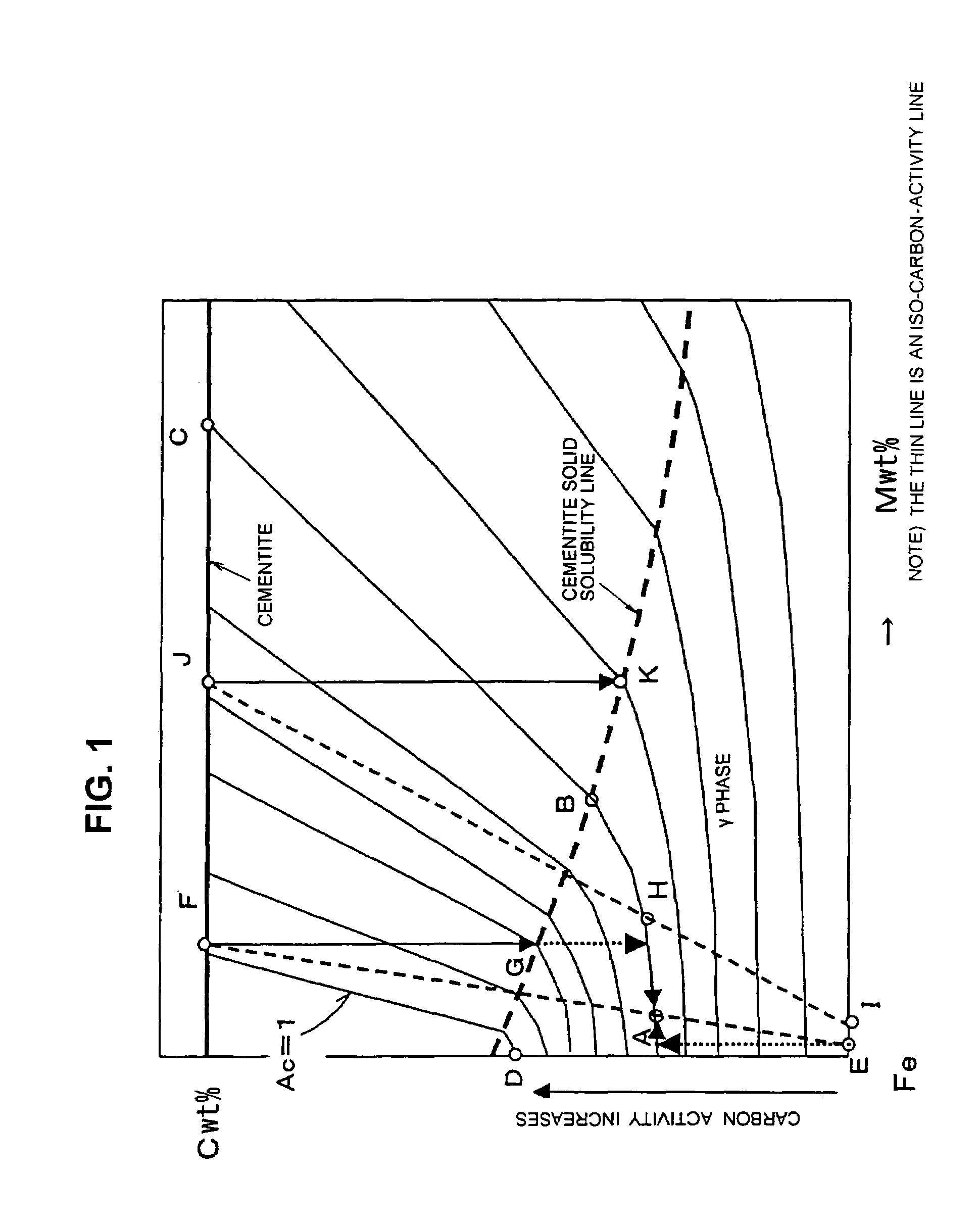

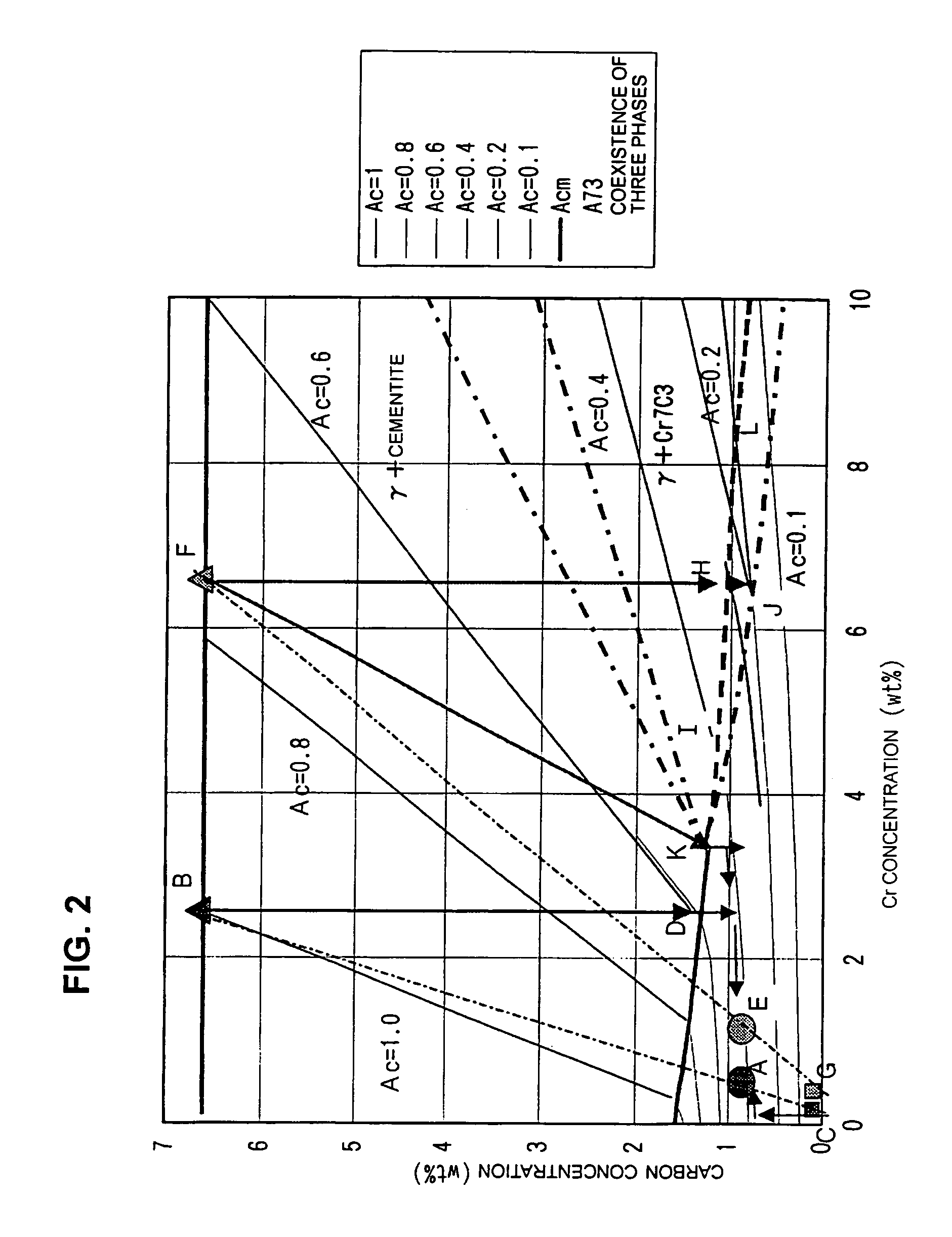

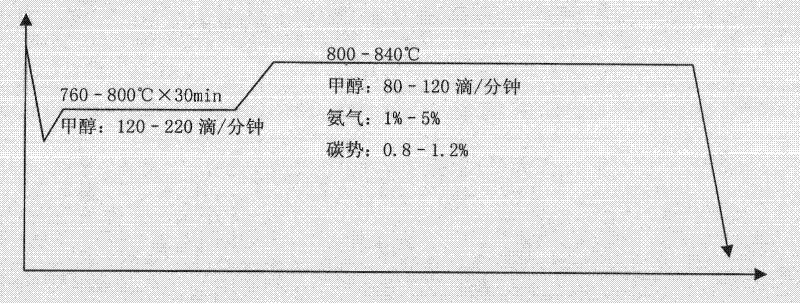

The disclosed surface chemical thermal treatment technique for a high-C-Cr bearing comprises: setting parameters, front cleaning, pre-oxidizing, heating, carbonitriding, cooling to diffuse, quenching, and tempering. This invention uses the treatment device in vehicle and motor cycle gear process to form one layer with special tissue and improve contact fatigue strength and surface hardness.

Owner:CHONGQING CHANGJIANG BEARING

Rolling elements

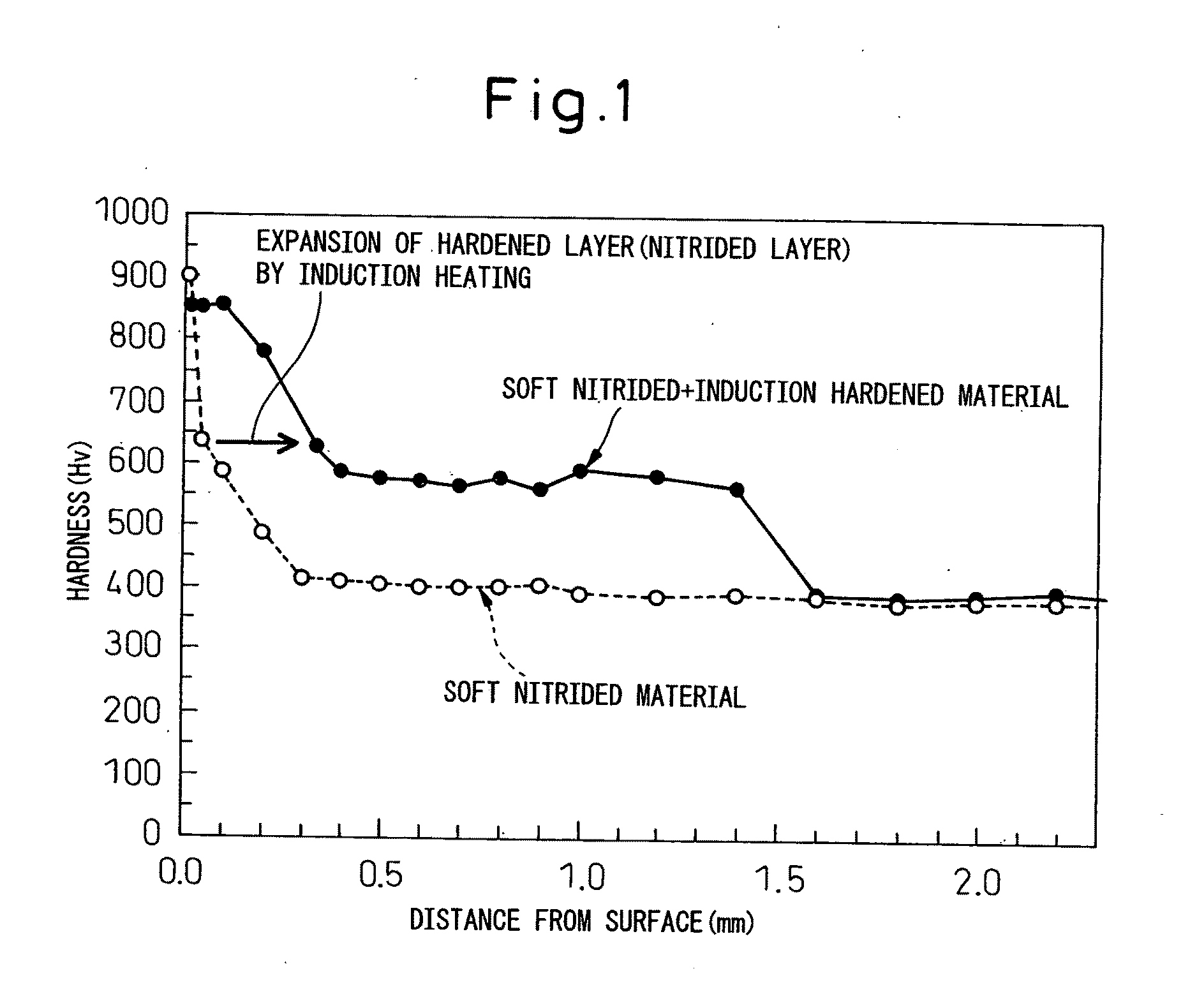

InactiveUS20050247377A1Improve the immunityHigh contact fatigue strengthSolid state diffusion coatingFurnace typesSurface layerInduction hardening

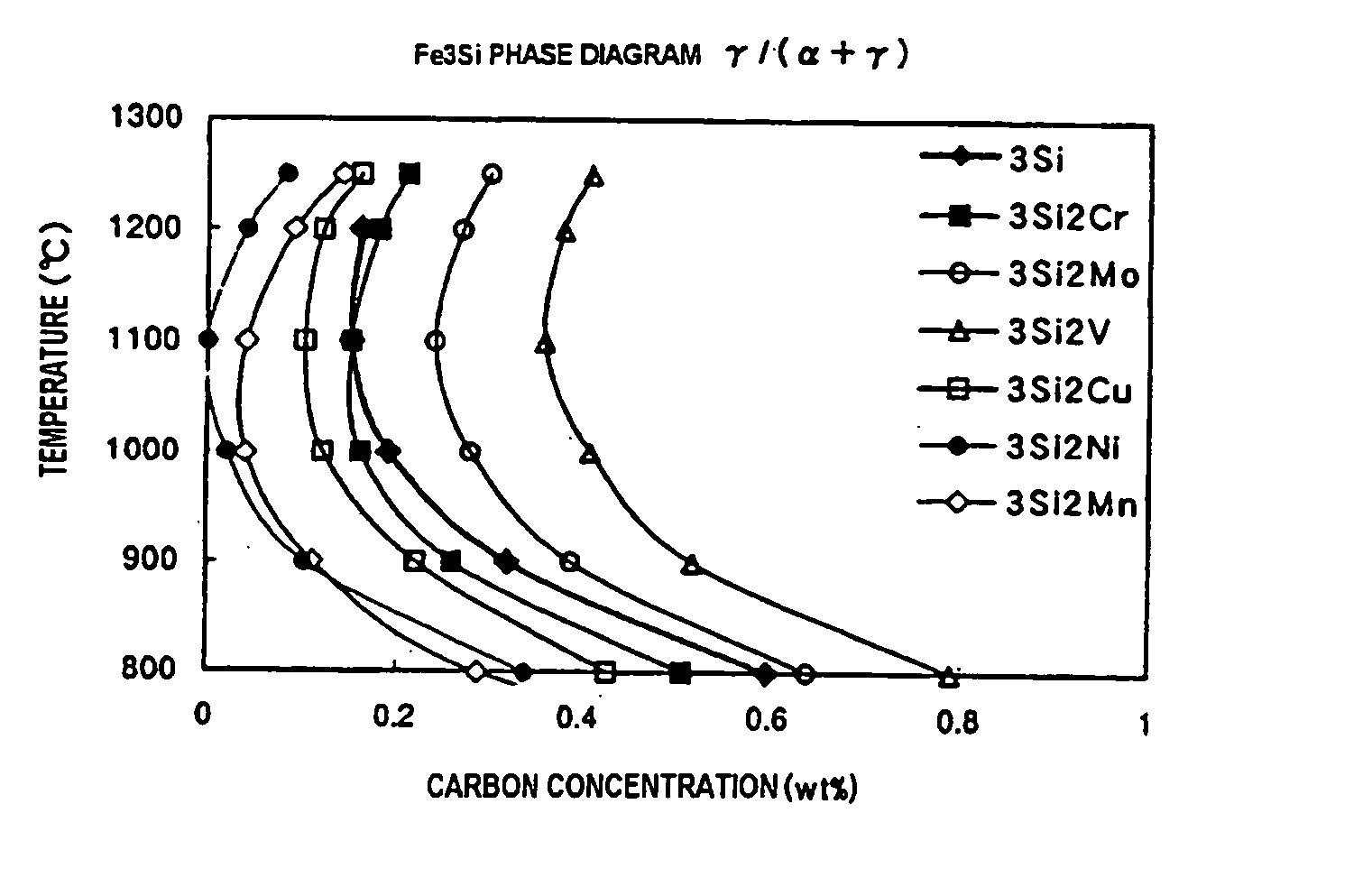

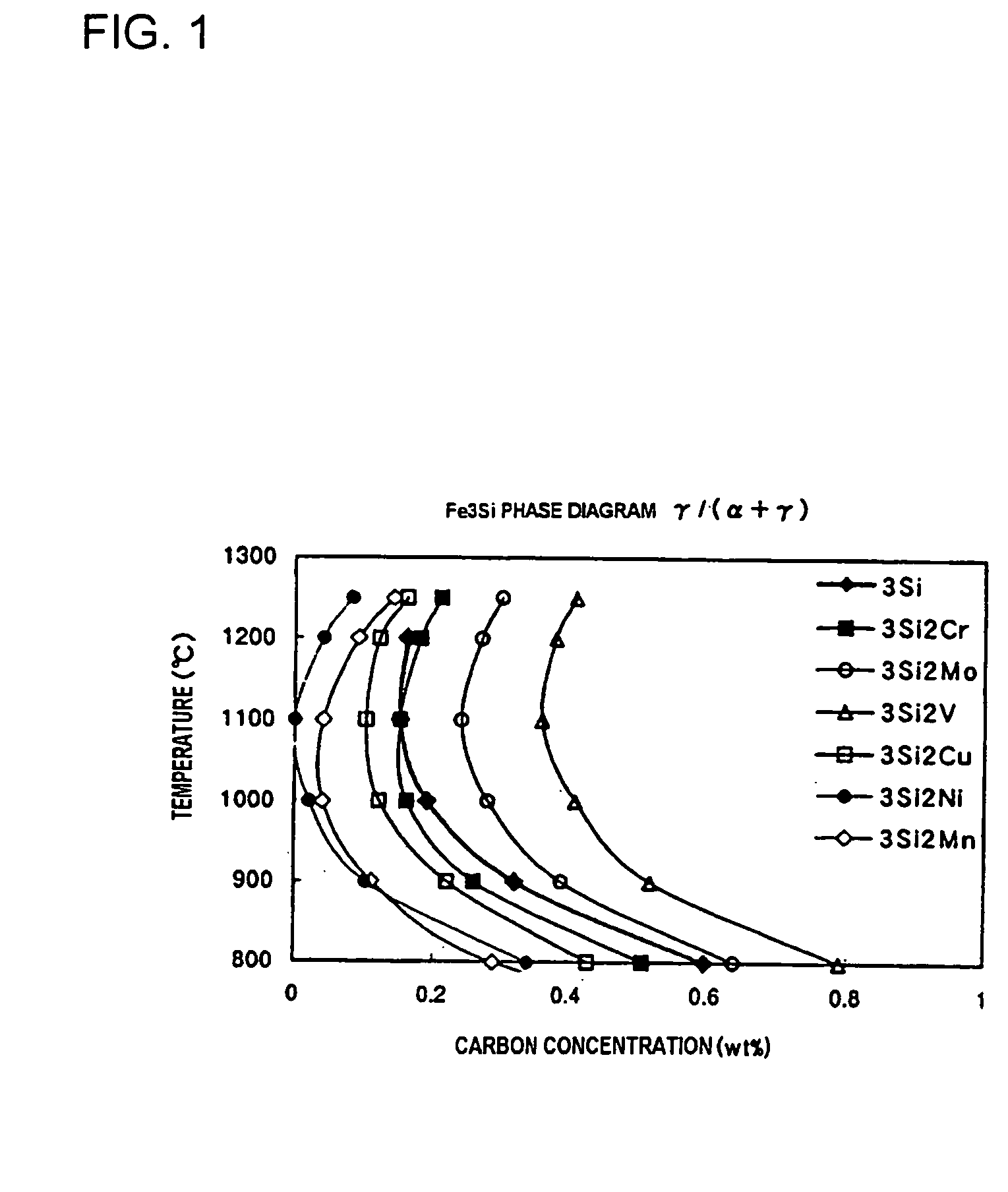

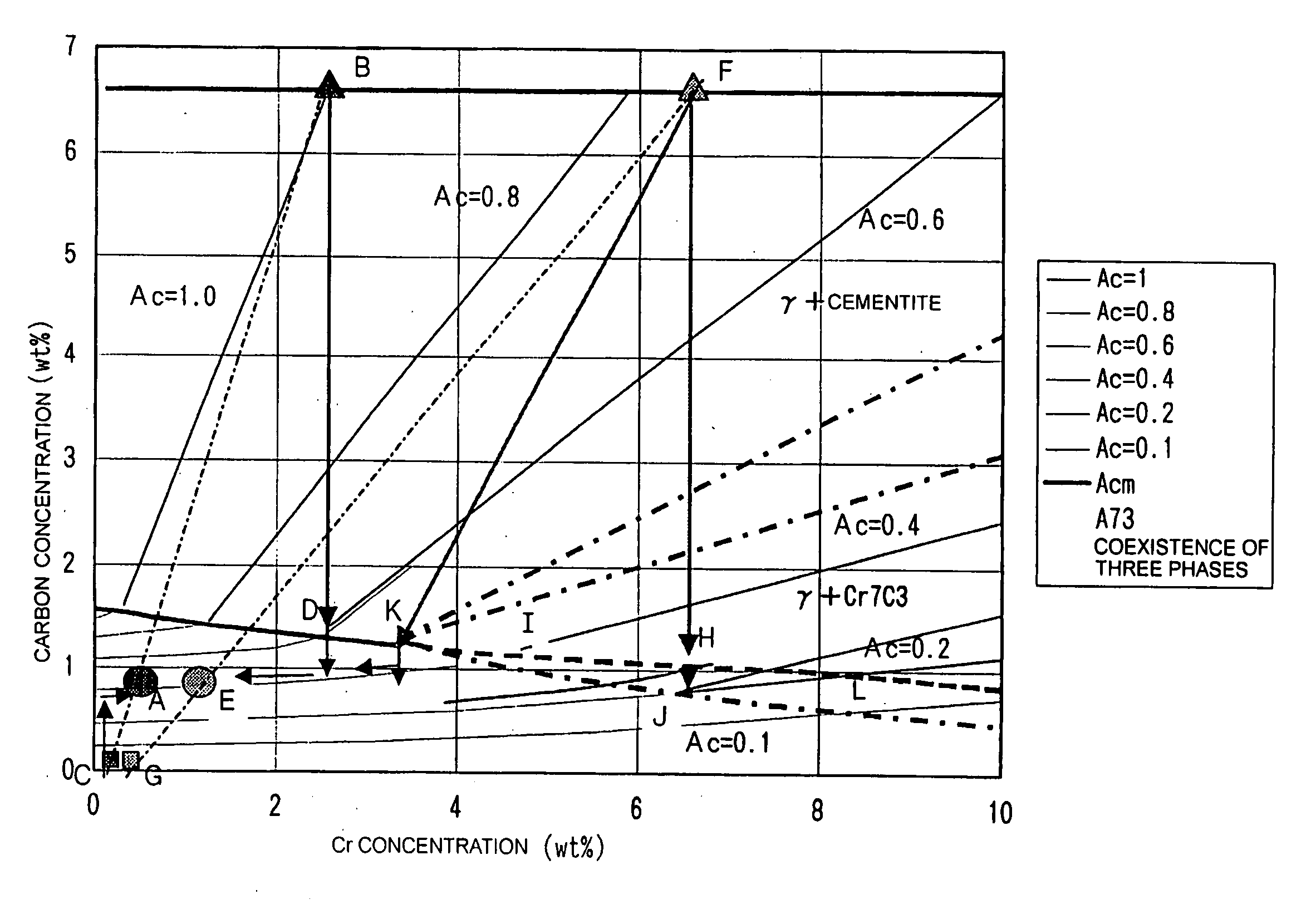

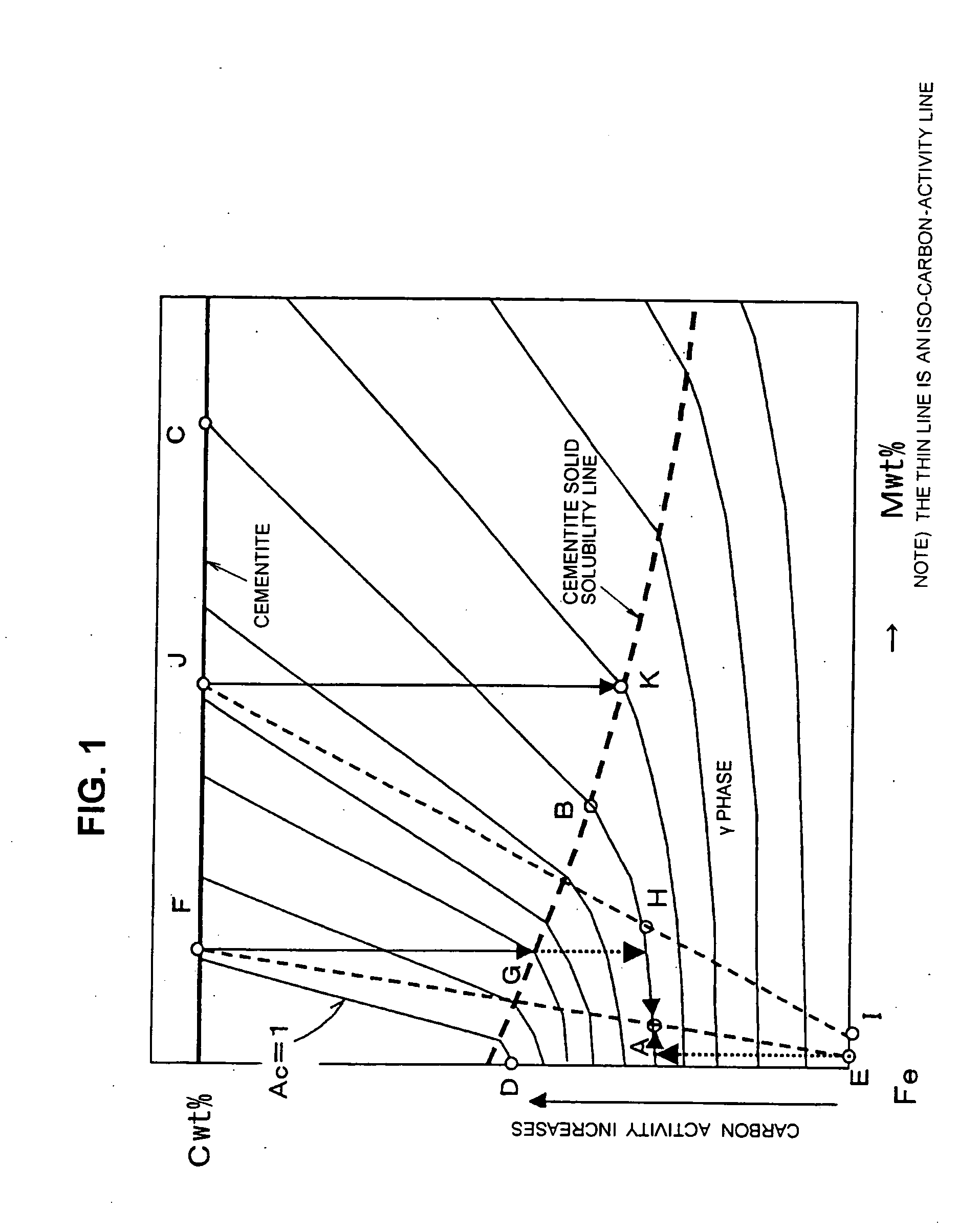

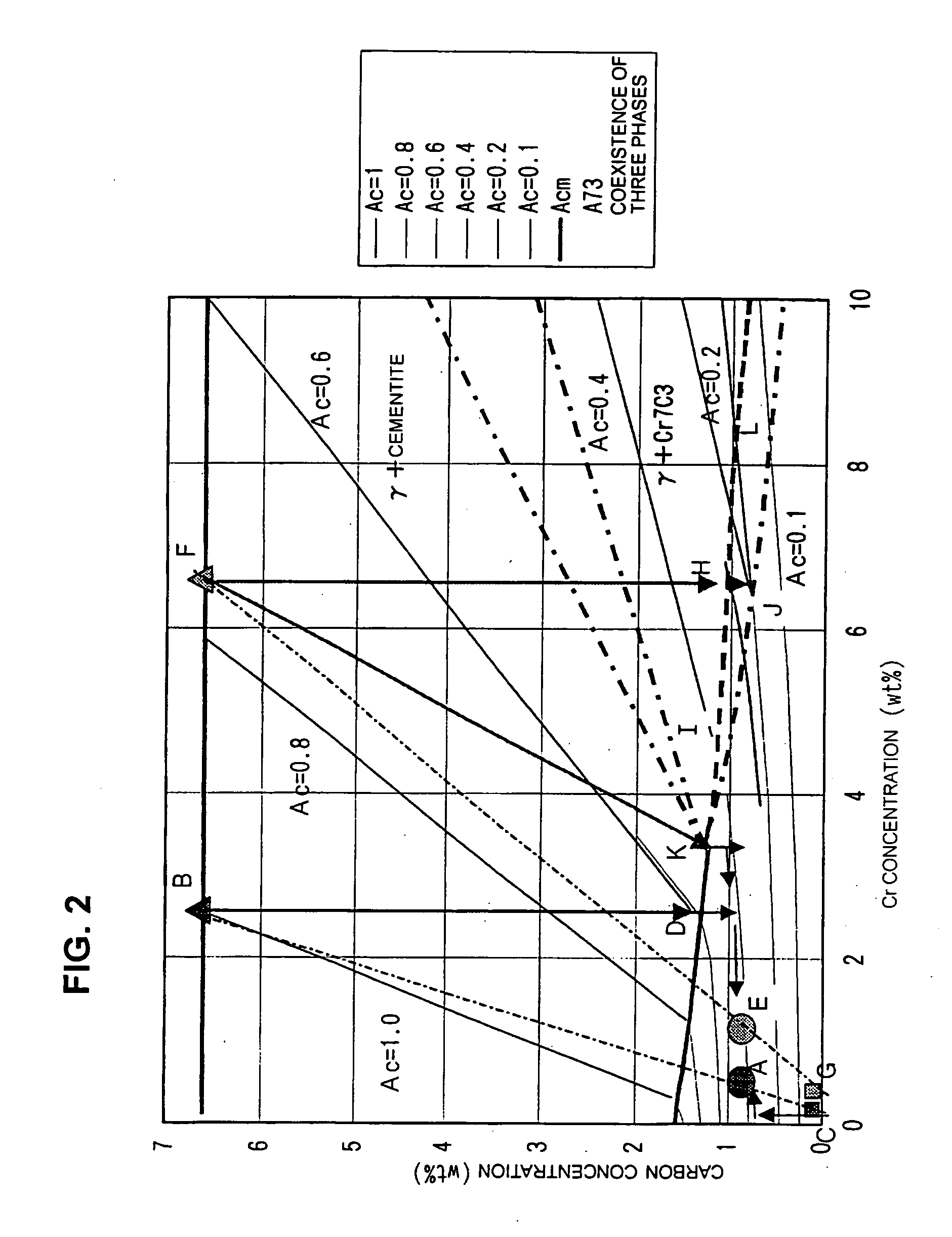

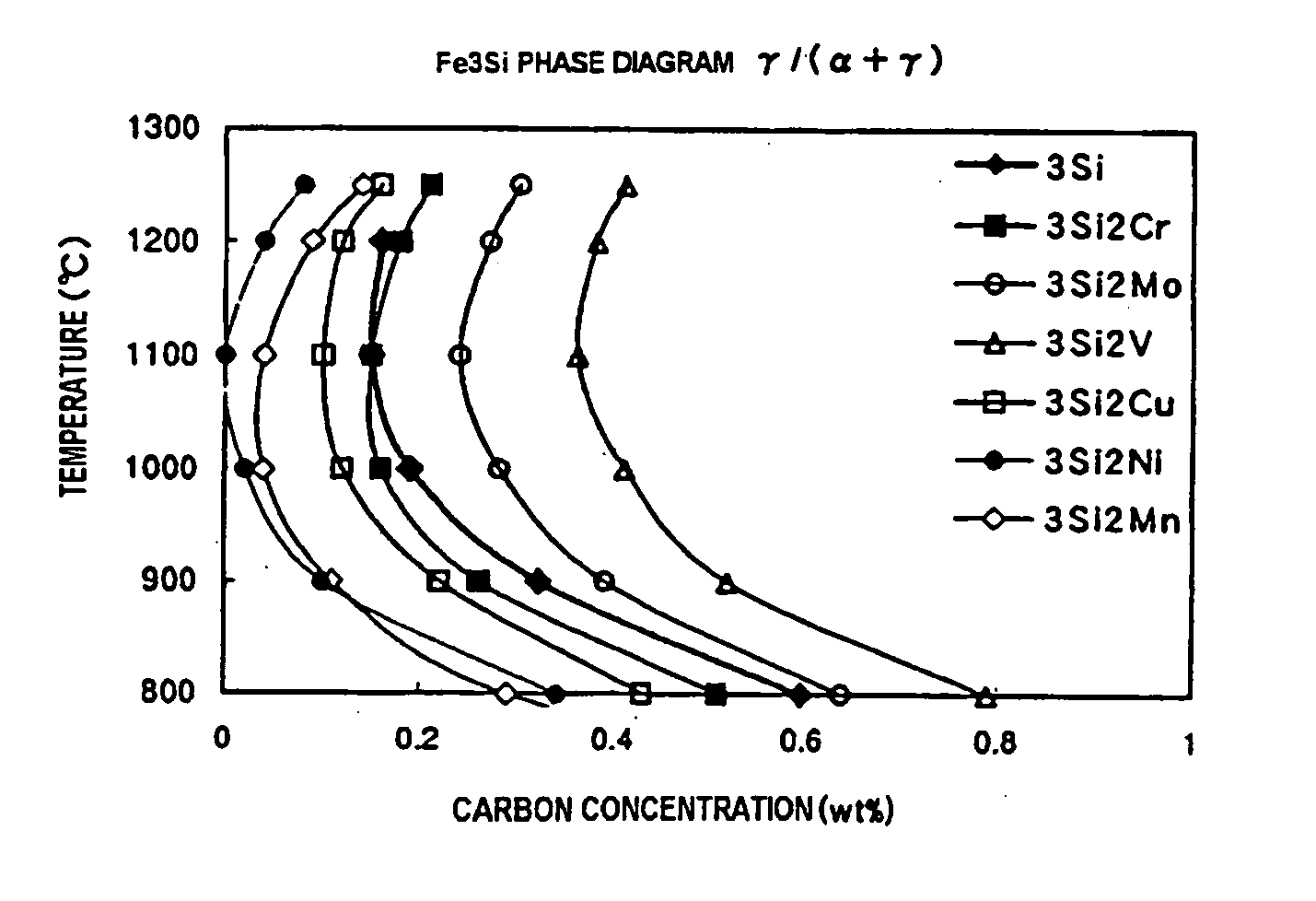

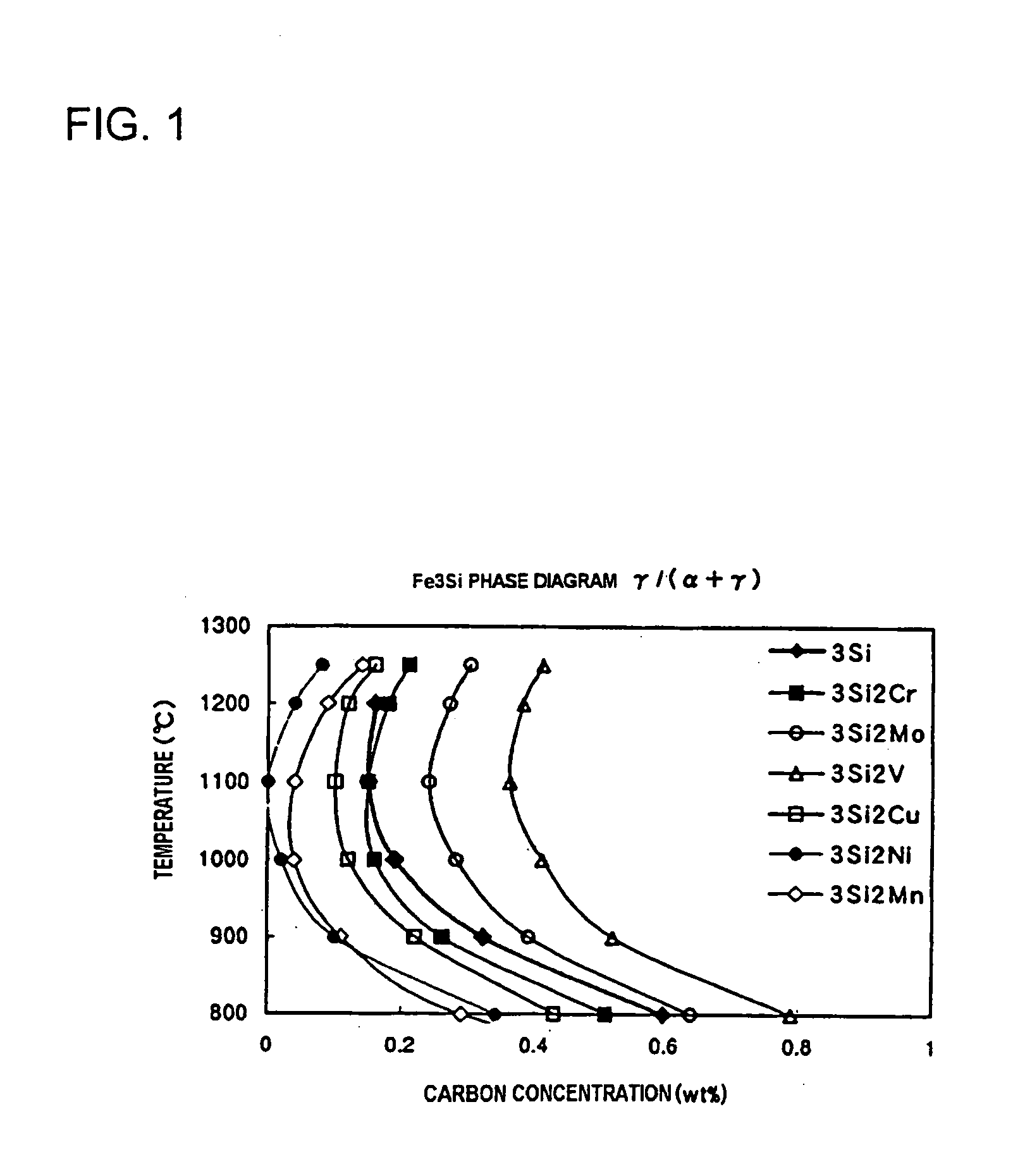

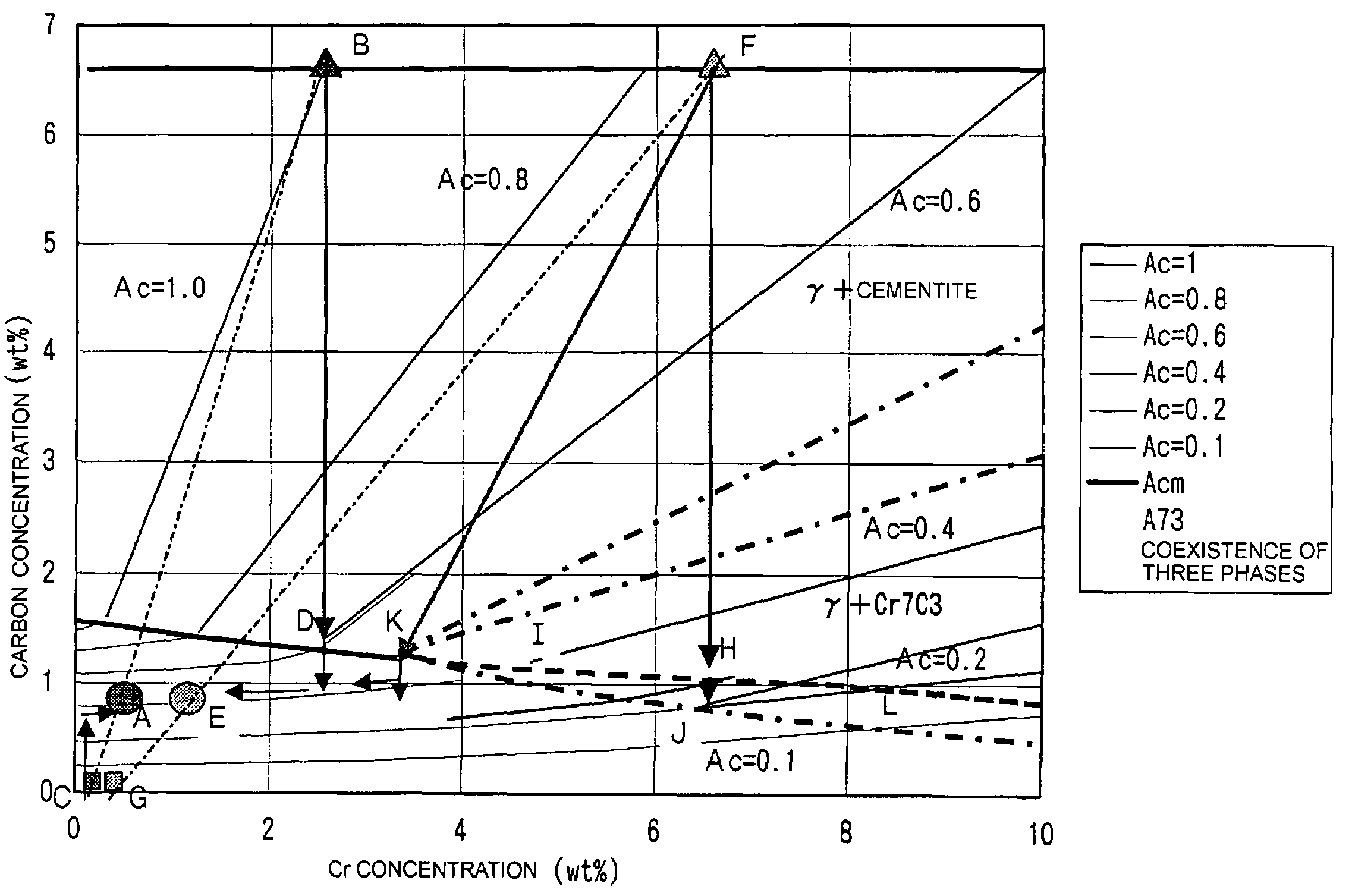

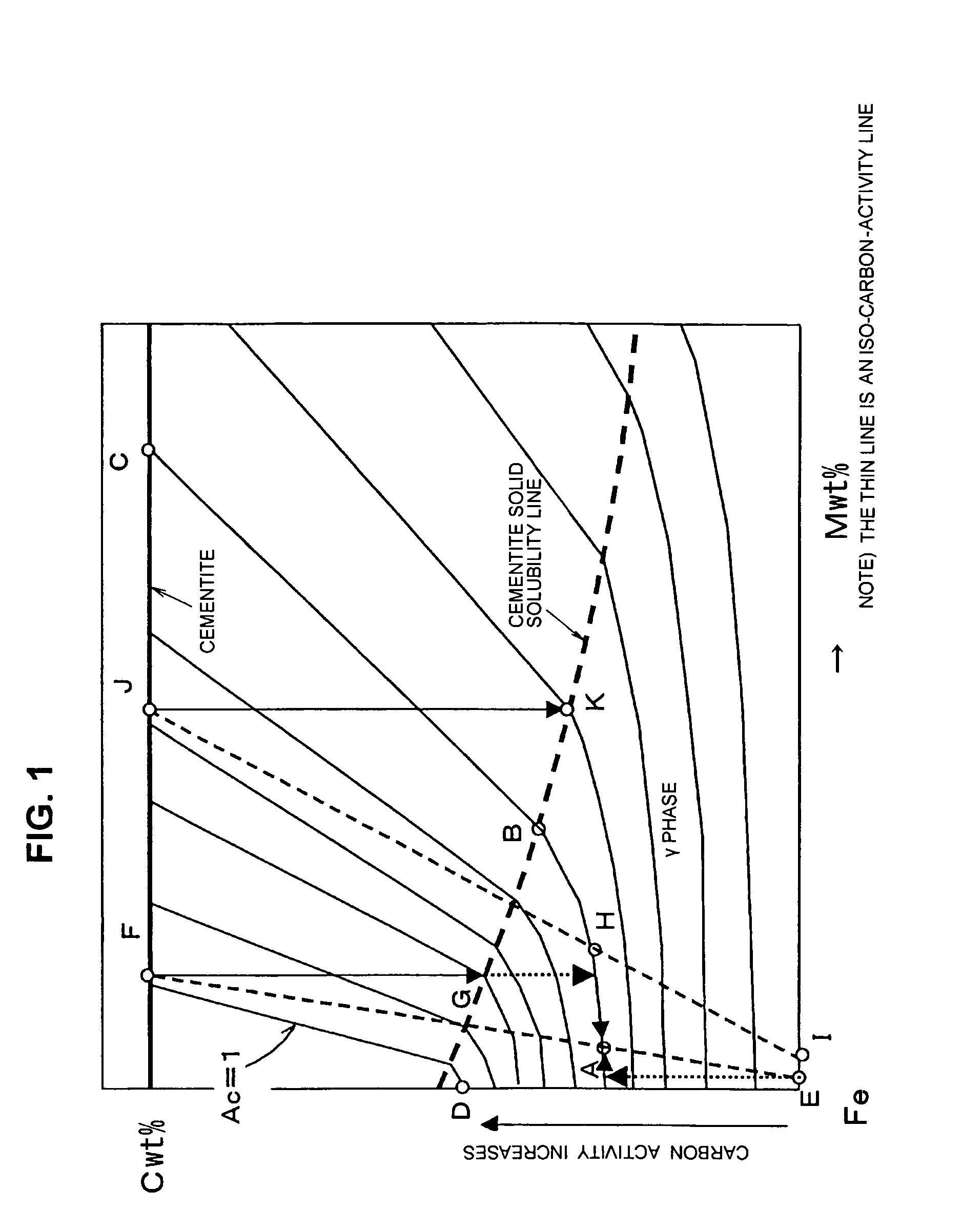

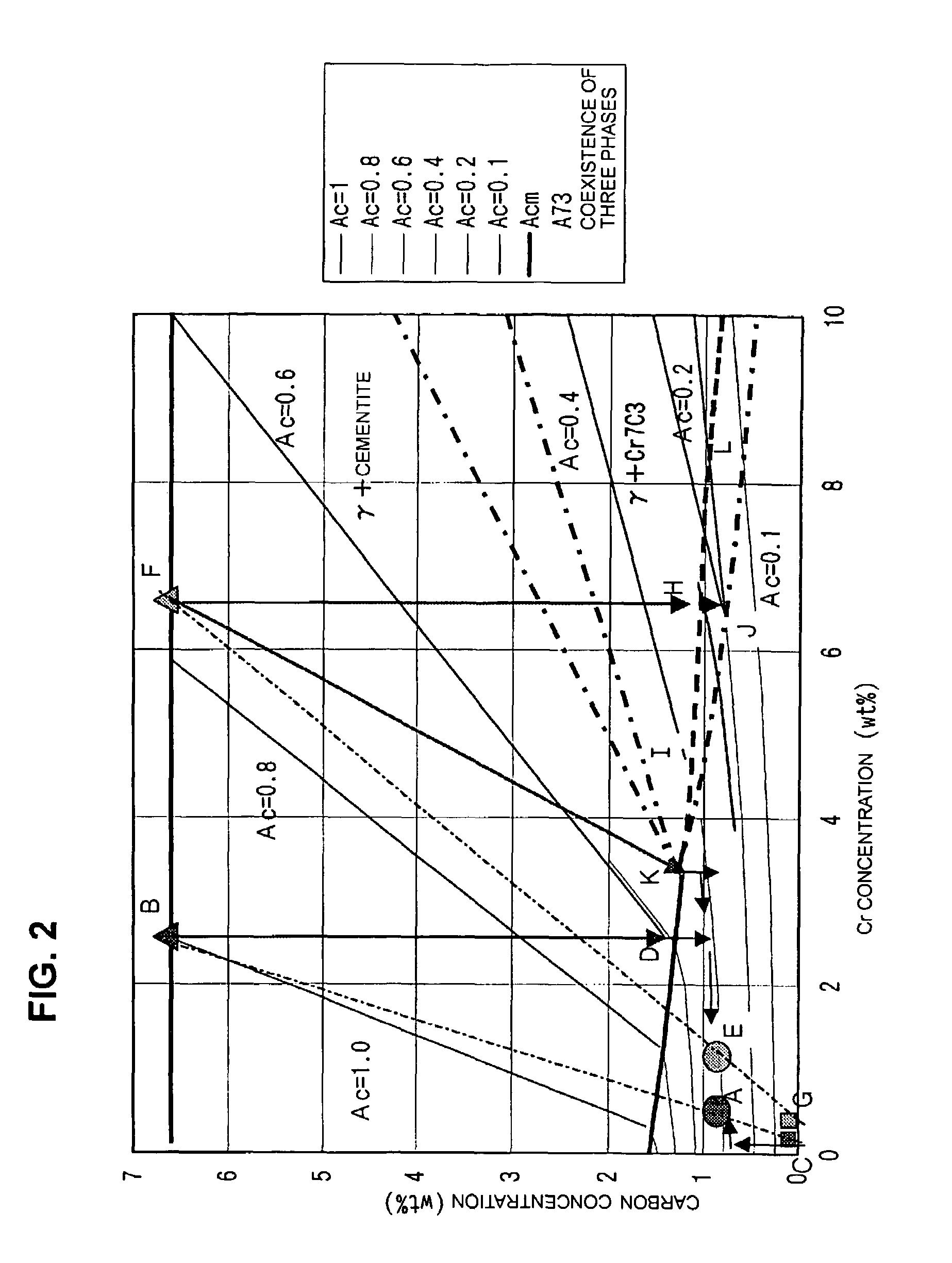

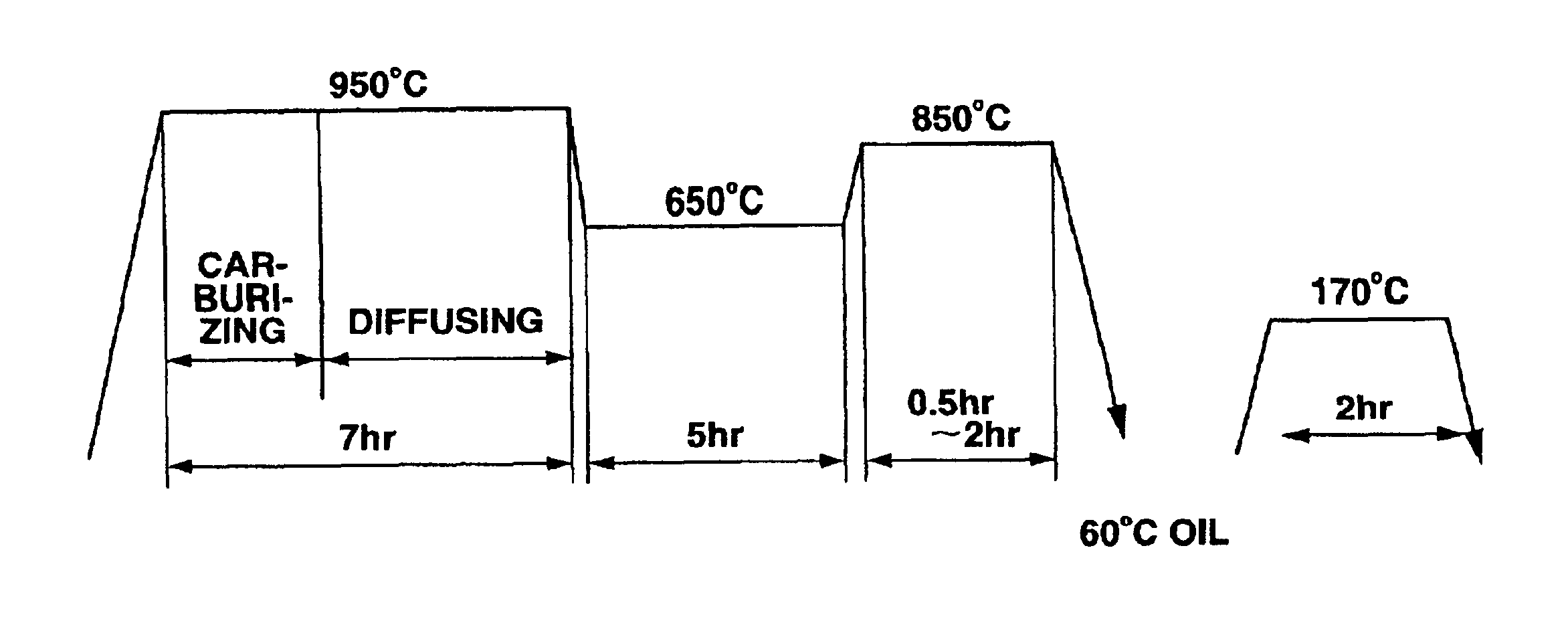

The pitting resistance of a gear is increased by hardening its tooth flanks through application of carburizing / quenching, bright hardening and induction hardening to a steel material capable of providing significantly improved softening resistance in tempering at a low temperature of 300 to 350° C. To this end, the steel material prepared so as to satisfy the relationship described by: 5≦4.3×Si (wt %)+7.3×Al (wt %)+3.1×V (wt %)+1.5×Mo (wt %)+1.2×Cr (wt %)×(0.45÷C (wt %)) is carburized such that the carbon concentration of its carburized surface layer is adjusted to 0.6 to 0.9 wt %; and the steel material is subjected to quenching and tempering at 300° C. or less subsequently to the carburization process, or alternatively the steel material is once cooled after the carburization process and then subjected to treatments of re-heating hardening and tempering at 300° C. or less so that a hardness of HRC 58 or more is ensured by the tempering process at 300° C.

Owner:KOMATSU LTD

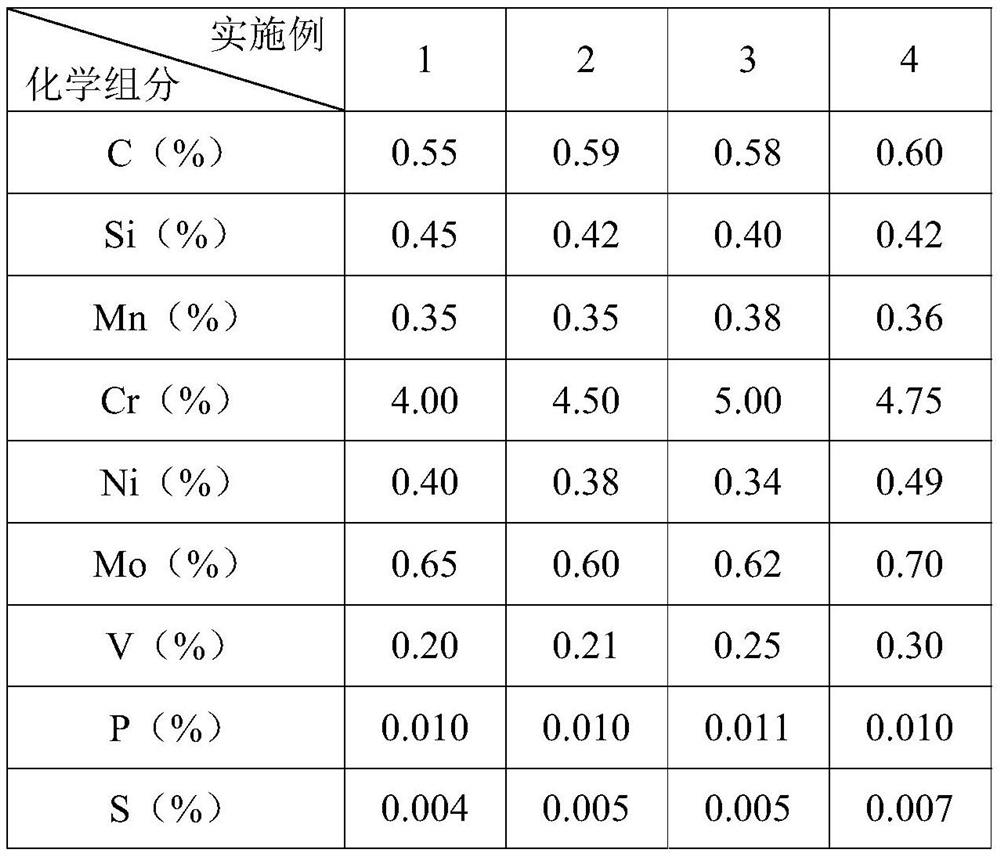

Alloy steel for gear wheel and preparation method thereof

InactiveCN101191181AInternal oxidation tendencyHigh contact fatigue strengthPortable liftingFurnace typesGear wheelManganese

The invention discloses an alloy steel for gears. The weight percentage of the chemical compositions is that: carbon of 0.16 to 0.19 percent; silicon of less than or equal to 0.12 percent; manganese of 0.50 to 0.60 percent; chromium of 1.75 to 1.90 percent; nickel of 1.75 to 1.90 percent; phosphorus of less than or equal to 0.020 percent; sulfur of less than or equal to 0.015; copper of less than or equal to 0.20 percent; aluminum of 0.015 to 0.040 percent; molybdenum of 0.15 to 0.35 percent; tin of less than or equal to 0.020 percent; [oxygen] of less than or equal to 0.002 percent; [nitrogen] of 0.006 to 0.018 percent; [hydrogen] of less than or equal to 0.00015; stibium of less than or equal to 0.008 percent; titanium of less than or equal to 0.01 percent; calcium of less than or equal to 0.0020 percent; and the remainder is iron. The preparation method comprises hydrogen diffusion annealing procedures. The invention is made a carbonization treatment for 16 hours under the same carbonization condition, so the invention has small internal oxidation inclination; the invention has high contact fatigue strength and bending fatigue strength, and is suitable for the gears with the modulus of more than 10.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Rolling element and method of producing the same

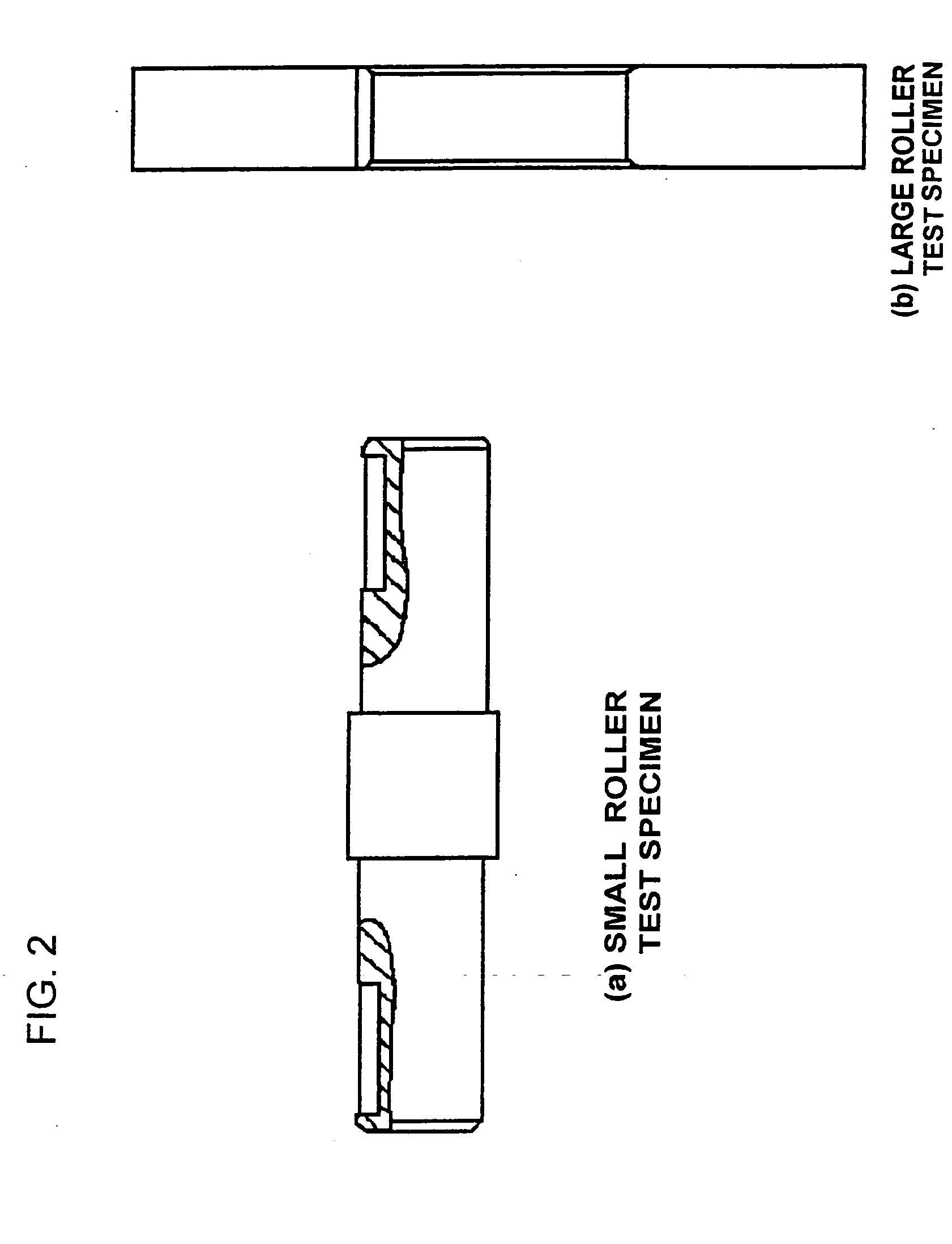

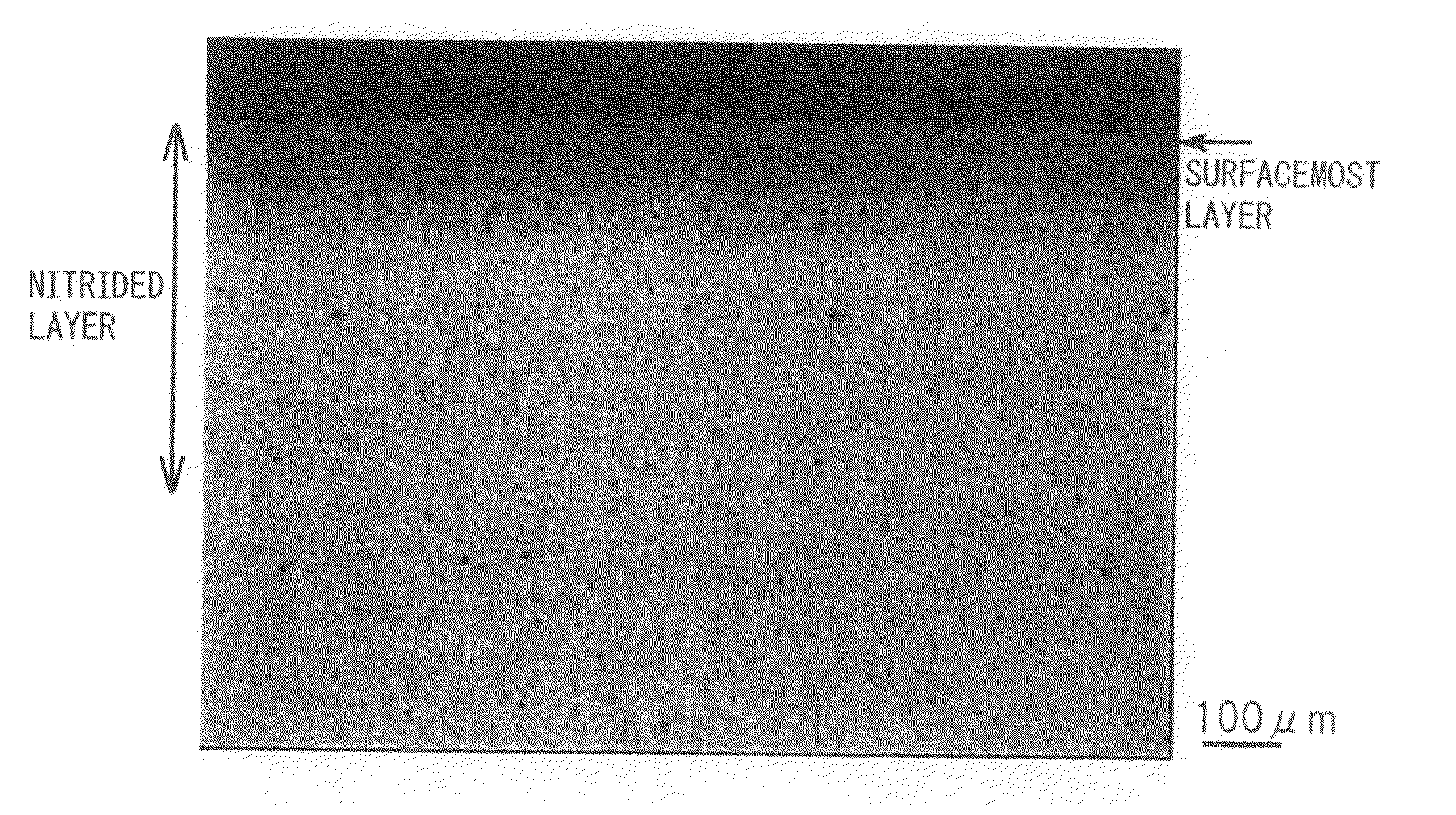

InactiveUS20060021679A1Economical efficiency can be improvedReduce carbon contentPortable liftingSolid state diffusion coatingTO-18Surface layer

There is provided an inexpensive rolling element used under high interface pressure such as induction hardened gears, the rolling element being improved in the seizure resistance of its tooth flanks and having a temper hardness of HRC 50 or more at 300° C. To this end, the rolling element is made from a steel material containing at least 0.45 to 1.5 wt % C and one or more alloy elements selected from 0.1 to 0.5 wt % V and 0.3 to 1.5 wt % Cr, and has a rolling contact surface layer having a structure tempered at low temperature in which 2 to 18% by volume cementite disperses in a martensite parent phase formed by induction heating and cooling and containing 0.25 to 0.8 wt % carbon solid-dissolving therein.

Owner:KOMATSU LTD

Rolling elements

InactiveUS20050241734A1Improve the immunityHigh contact fatigue strengthSolid state diffusion coatingFurnace typesSurface layerInduction hardening

The pitting resistance of a gear is increased by hardening its tooth flanks through application of carburizing / quenching, bright hardening and induction hardening to a steel material capable of providing significantly improved softening resistance in tempering at a low temperature of 300 to 350° C. To this end, the steel material prepared so as to satisfy the relationship described by: 5≦4.3×Si(wt %)+7.3×Al(wt %)+3.1×V(wt %)+1.5×Mo(wt %)+1.2×Cr(wt %)×(0.45÷C(wt %)) is carburized such that the carbon concentration of its carburized surface layer is adjusted to 0.6 to 0.9 wt %; and the steel material is subjected to quenching and tempering at 300° C. or less subsequently to the carburization process, or alternatively the steel material is once cooled after the carburization process and then subjected to treatments of re-heating hardening and tempering at 300° C. or less so that a hardness of HRC 58 or more is ensured by the tempering process at 300° C.

Owner:KOMATSU LTD

Isothermal forging method of straight bevel gear

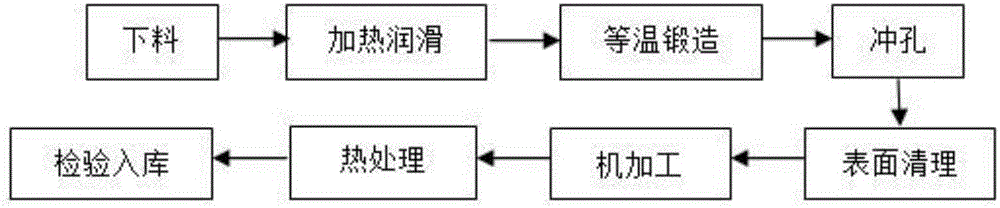

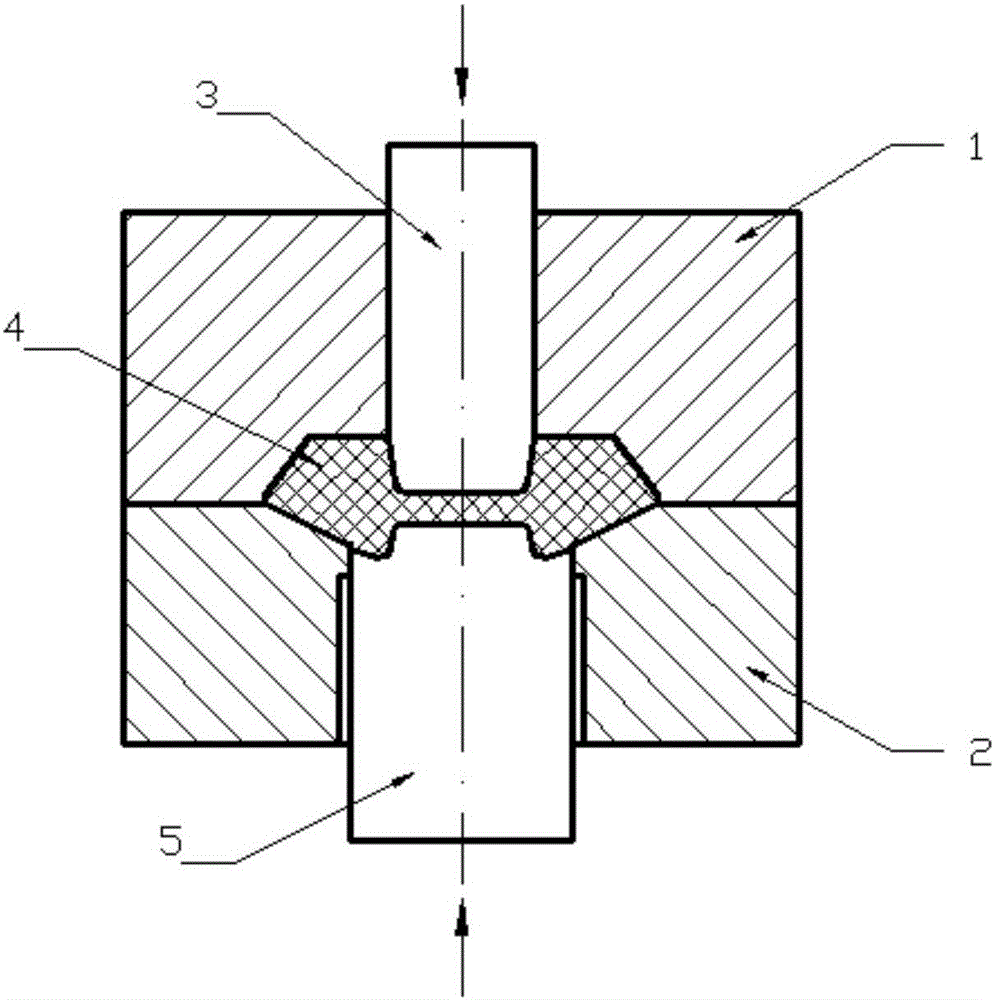

InactiveCN105921672AAvoid chillingPromote plastic flowMetal-working apparatusWheelsGear wheelBevel gear

The invention discloses an isothermal forging method of a straight bevel gear. A blank and a mold are heated to roughly consistent temperatures respectively, then the blank is placed into the mold and is subjected to forging molding in the mold at the relatively low strain rate, and the straight bevel gear is obtained through aftertreatment, wherein the relatively low strain rate is lower than 0.1 mm / s, and the mold adopts a closed mold forging structure. According to the method, firstly, the blank and the mold are heated to the equal temperature or basically equal temperatures, so that the chilling effect produced when the temperature of the mold is lower than that of the blank is avoided, and the plastic flow of the blank is improved; secondly, the mold adopts the closed mold forging structure, the blank bears three-dimensional compressive stress in the forging process, and thus molding of the blank is facilitated; thirdly, the strain rate is lower than 0.1 mm / s, accordingly, the deformation amount of the blank in unit time is small, deformation is sufficient, and molding of the blank is more facilitated.

Owner:SHANDONG UNIV +1

Case hardened gear and method of producing the same

InactiveUS7691213B2Improve the immunityHigh contact fatigue strengthPortable liftingBearing componentsTO-18Surface layer

There is provided an inexpensive rolling element used under high interface pressure such as induction hardened gears, the rolling element being improved in the seizure resistance of its tooth flanks and having a temper hardness of HRC 50 or more at 300° C. To this end, the rolling element is made from a steel material containing at least 0.45 to 1.5 wt % C and one or more alloy elements selected from 0.1 to 0.5 wt % V and 0.3 to 1.5 wt % Cr, and has a rolling contact surface layer having a structure tempered at low temperature in which 2 to 18% by volume cementite disperses in a martensite parent phase formed by induction heating and cooling and containing 0.25 to 0.8 wt % carbon solid-dissolving therein.

Owner:KOMATSU LTD

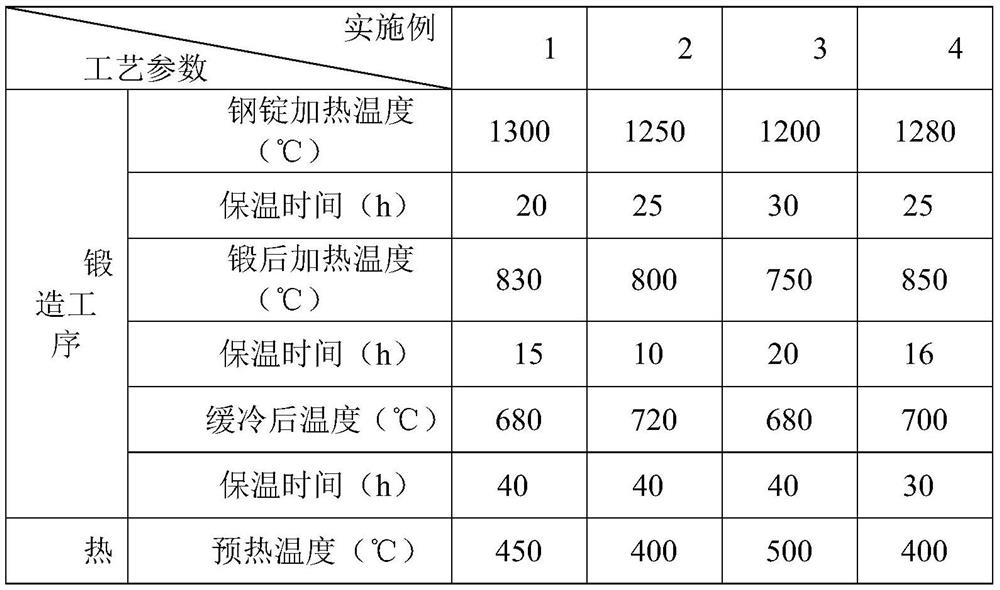

Heat treatment method for inlaid backup roll sleeve

InactiveCN105543451AImprove wear resistanceHigh contact fatigue strengthFurnace typesIncreasing energy efficiencyHardnessIngot

The invention discloses a heat treatment method for an inlaid backup roll sleeve. The heat treatment method comprises the following steps: A, smelting a steel ingot, and then forging a roll sleeve blank, followed by rough machining and flaw detection; B, performing hardening and tempering on the roll sleeve blank, heating the roughed roll sleeve, and performing tempering on the roll sleeve; C, performing semi-finish turning machining and flaw detection on the roll sleeve; D, hoisting the semi-finish turning machined roll sleeve to a power-frequency quench machining tool, carrying out overall induction heating by using a dual-power frequency power source, adopting a water quenching method; subsequently, carrying out tempering; E, detecting metallographic structures of inner and outer surfaces of the roll sleeve, and detecting residual stress and hardness of the outer surface; F, performing finish machining on the roll sleeve; and G, assembling a roll shaft, and performing finish machining on the assembled roll. The heat treatment method for the inlaid backup roll sleeve of the present invention meets the requirements in structure, hardness and residual stress aspects, and meanwhile, such properties as abrasive resistance and contact fatigue strength of the roll sleeve also are improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

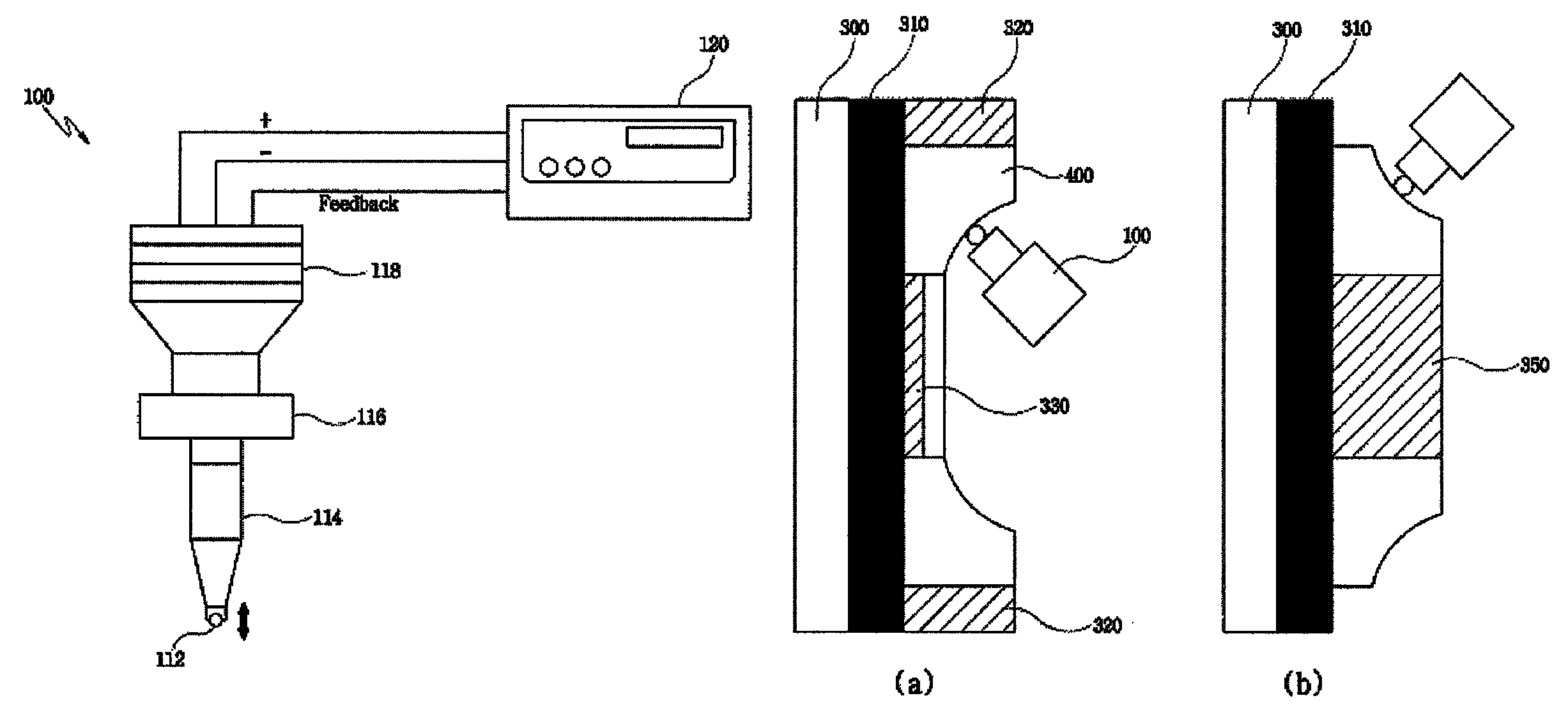

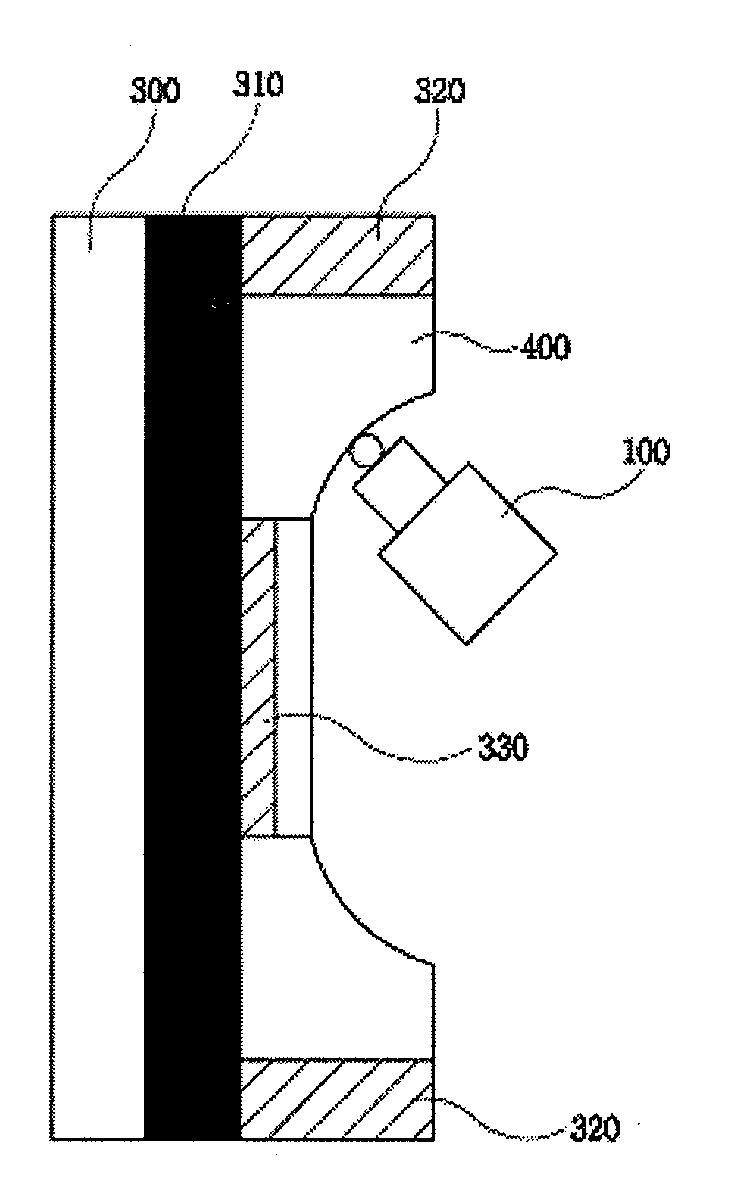

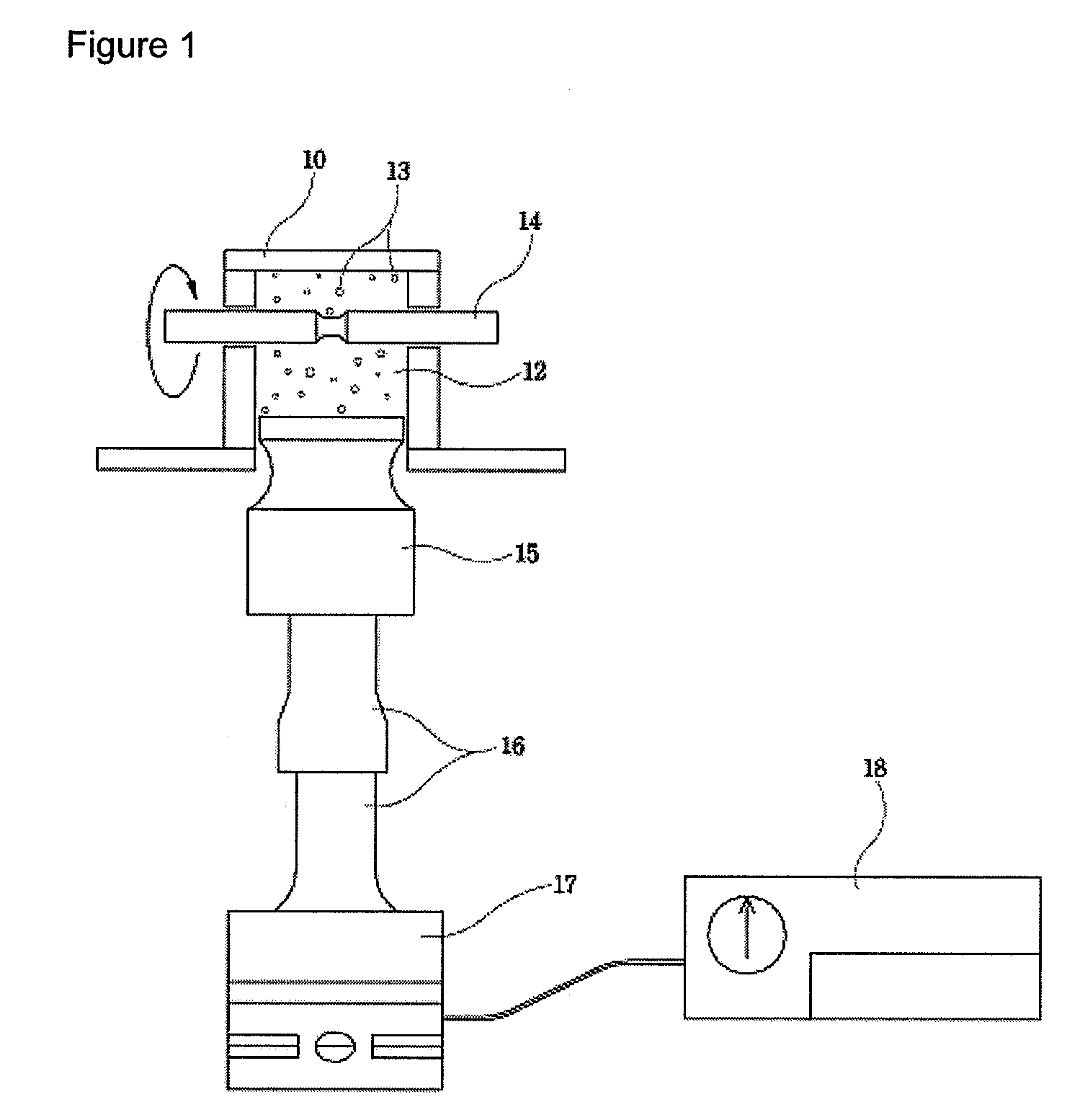

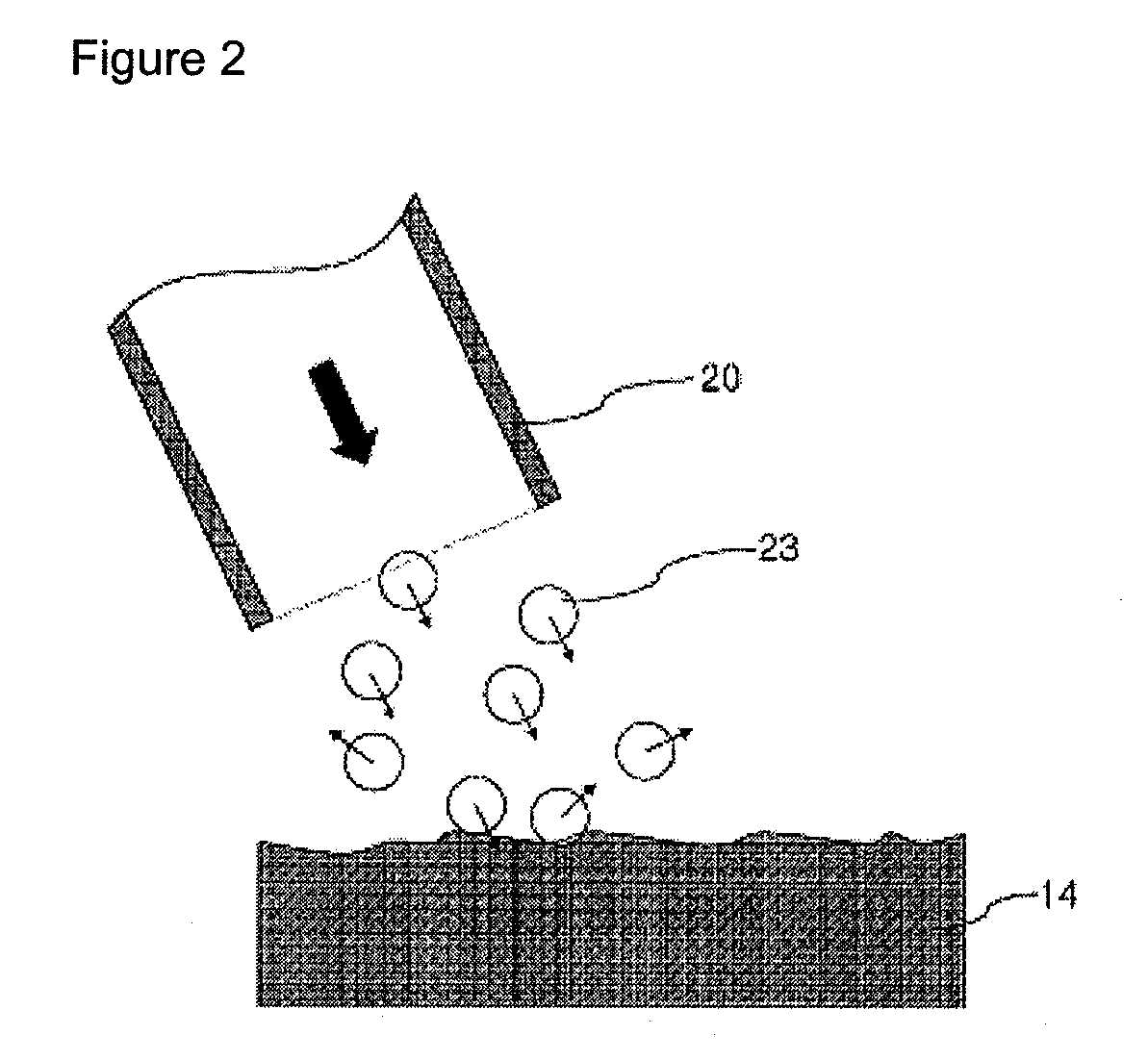

Method of making bearing using ultrasonic nano crystal surface modification technology

ActiveUS8782902B2Reduce rateImprove fatigue lifeEdge grinding machinesBearing componentsEngineeringNanocrystal

Owner:DESIGNMECHA

Rolling element and method of producing the same

InactiveUS7422643B2Improve the immunityHigh contact fatigue strengthPortable liftingSolid state diffusion coatingTO-18Surface layer

There is provided an inexpensive rolling element used under high interface pressure such as induction hardened gears, the rolling element being improved in the seizure resistance of its tooth flanks and having a temper hardness of HRC 50 or more at 300° C. To this end, the rolling element is made from a steel material containing at least 0.45 to 1.5 wt % C and one or more alloy elements selected from 0.1 to 0.5 wt % V and 0.3 to 1.5 wt % Cr, and has a rolling contact surface layer having a structure tempered at low temperature in which 2 to 18% by volume cementite disperses in a martensite parent phase formed by induction heating and cooling and containing 0.25 to 0.8 wt % carbon solid-dissolving therein.

Owner:KOMATSU LTD

High-strength toughness differential mechanism universal joint pin machining process

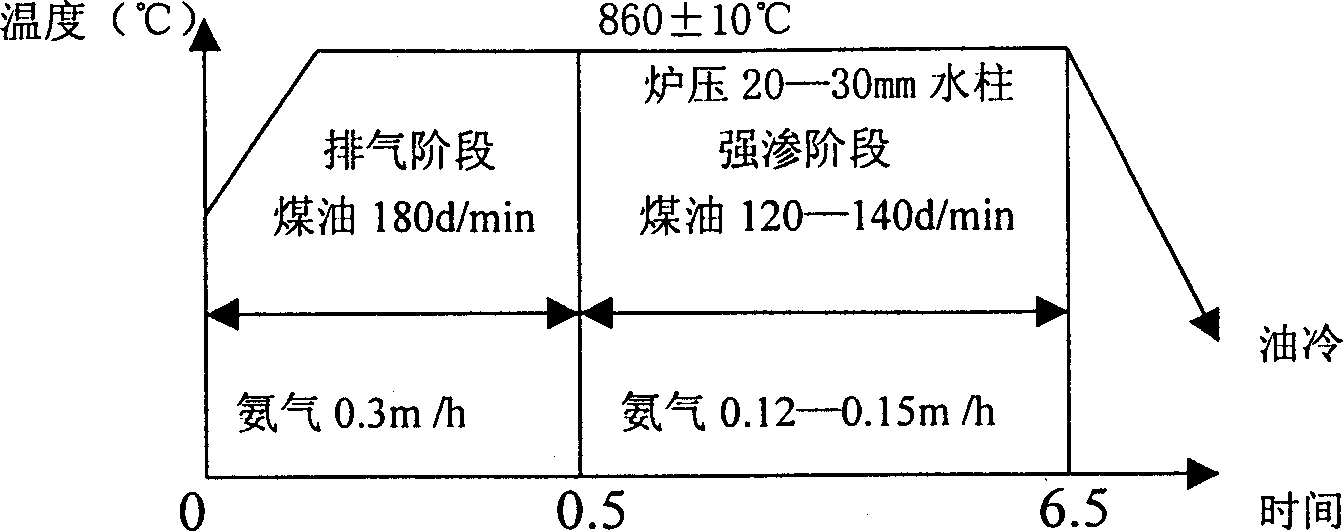

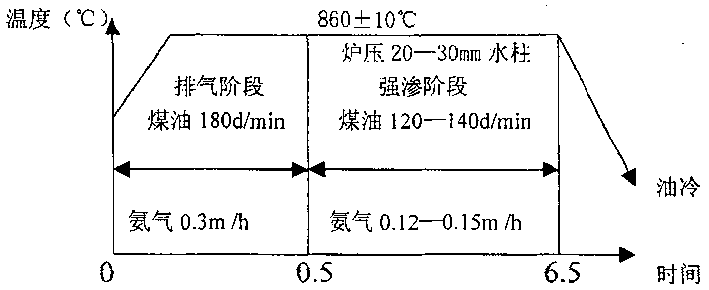

InactiveCN1456708AImprove bearing capacityReduce distortionSuperimposed coating processHigh rateKerosene

A technology for preparing the high-strength and-toughness cross axle of differential gear includes such steps as washing to remove rust and dirt, osmosizing carbon and nitrogen (including ammonia gas and osmosizing), cooling in oil, tempering, fine grinding, treating with Mn and P, electrostatic spraying, and solidifying at 150-180 deg.C. The advantages of its product are high antiwear and anticorrosion nature, no deformation and cracking, high load-bearing power, and high rate of finished products.

Owner:重汽(济南)车桥有限公司

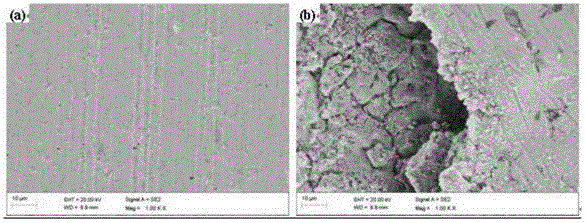

Compound reinforcement method for gear surface

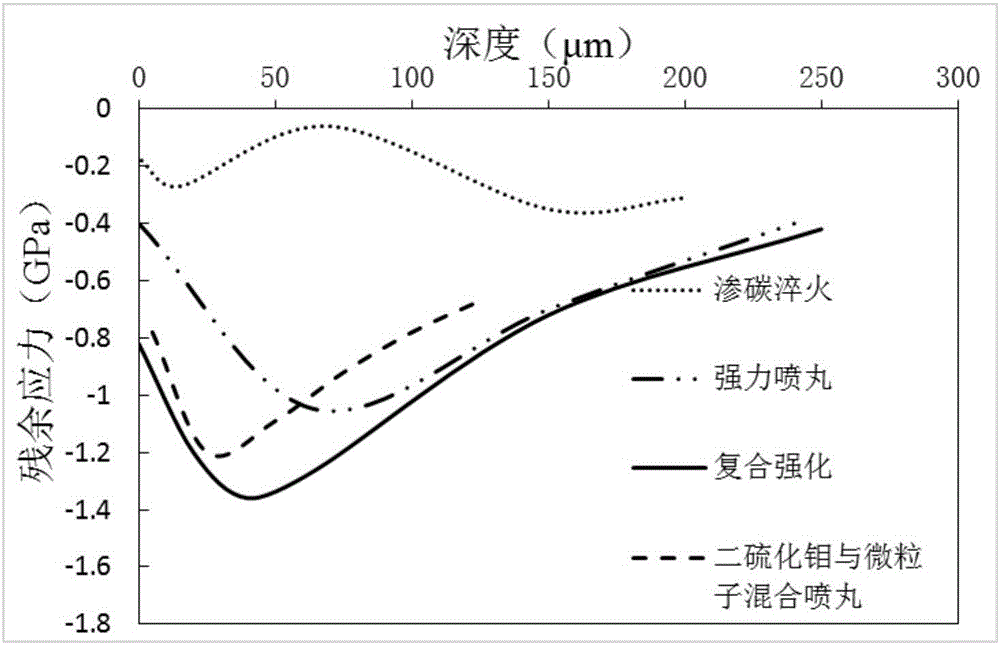

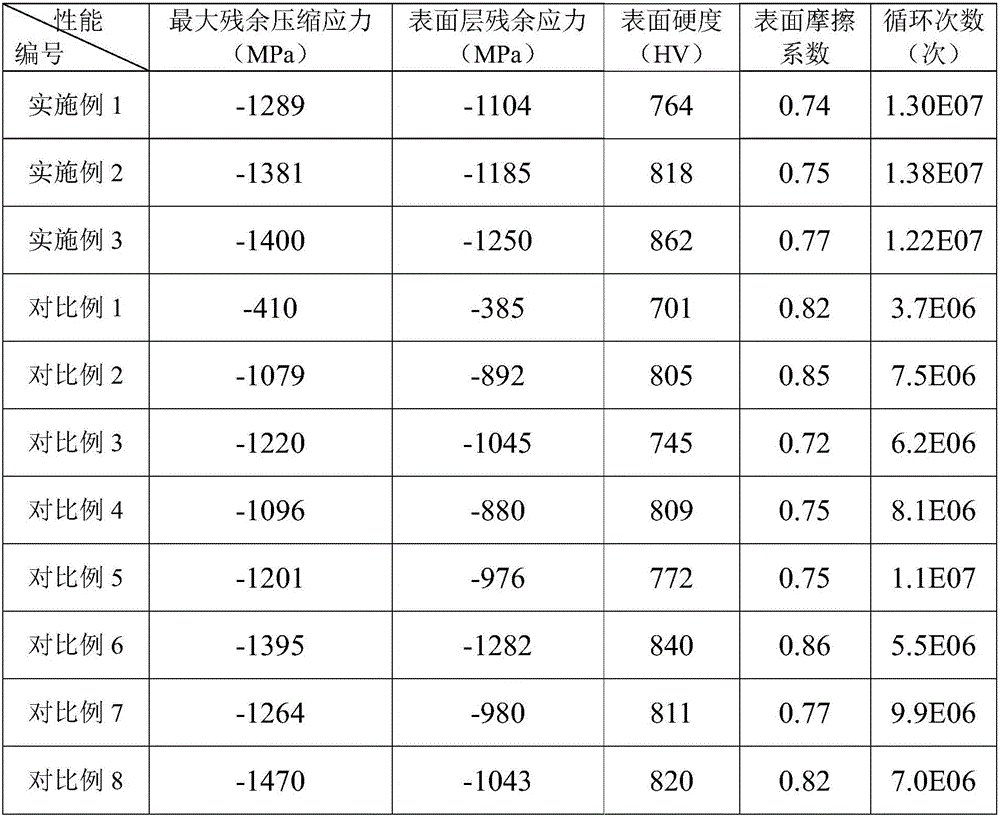

InactiveCN106826571AHigh hardnessReduce vibration and noiseAbrasive blasting machinesSurface finishHardness

The invention relates to a compound reinforcement method for a gear surface. The compound reinforcement method comprises the following steps: firstly, the gear surface is subjected to shot blasting with steel shots with particle size being 0.6-1 mm; then molybdenum disulfide is mixed with particles with particle size being 0.05-0.1 mm, the mixture is used for performing shot blasting continuously on a gear, and the gear with compound reinforced surface is obtained. By means of the coupled effect of two processes including powerful shot blasting and molybdenum disulfide and particle mixed shot blasting, amplitude of tooth surface compressive stress deeper than the stress in single surface treatment process is obtained, and tooth surface hardness is improved substantially. Meanwhile, the lubricity of the gear surface is improved, the friction coefficient of the tooth surface is reduced, the lubricating capacity and the surface smoothness are improved, and gear meshing vibration noise is reduced. The effect of prolonging both the flexible life and contact fatigue life of the gear simultaneously is realized. The method adopts simple process and flexible conditions, can realize batch production and has good application prospect.

Owner:HEBEI UNIV OF TECH

Steel for machine structure use for surface hardening and steel part for machine structure use

InactiveUS20110041959A1High contact fatigue strengthSolid state diffusion coatingIncreasing energy efficiencyMetallurgyMaterials science

Steel for machine structure use for surface hardening containing, by mass %, C: 0.3 to 0.6%, Si: 0.02 to 2.0%, Mn: 1.5% to 3.0%, W: 0.0025 to 0.5%, Al: 0.001 to 0.5%, N: 0.003 to 0.02%, S: 0.0001 to 0.025%, P: 0.0001 to 0.03%, and O: 0.0001 to 0.0050%, having an Mn / S of 70 to 30000, and having a balance of substantially Fe and unavoidable impurities.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Coating material and coating with high contact fatigue strength based on 304 stainless steel base material

InactiveCN104862698AHigh contact fatigue strengthSimple preparation processMetallic material coating processesIron powderUltimate tensile strength

The invention discloses a coating material and coating with high contact fatigue strength based on a 304 stainless steel base material. The coating material comprises the following components in percentage by weight: 3-15% of Ni powder, 5-15% of Cr powder, 4-18% of Si powder, 20-40% of Mn powder, 0.1-2% of La2O3 powder, 0-3% of C powder, and the balance of reduced iron powder. The coating material is prepared through the following steps: mixing the powder, adding ball milling mediums and mixed powder into a ball milling pot for ball milling, and then performing vacuum drying and processing at 120 DEG C for 1 h so as to obtain the coating material. The coating is prepared through the following steps: grinding the surface of the 304 stainless steel base material level, paving the coating material on the surface of the 304 stainless steel base material, and performing fusion covering by using complete laser heat treatment equipment so as to obtain the coating with high contact fatigue strength. The coating material and the coating, disclosed by the invention, are higher in contact fatigue strength, simple in preparation technology, and low in building cost, and can be produced in batches.

Owner:GUIZHOU UNIV

Method of making bearing using ultrasonic NANO crystal surface modification technology

ActiveUS20100024218A1Reduce coefficient of frictionReduce wear rateBearing componentsNanotechnologyEngineeringNanocrystal

Owner:DESIGNMECHA

Alloy material for high wear-resistant cold rolls and preparation method thereof

The invention discloses an alloy material for high wear-resistant cold rolls and a preparation method thereof. The alloy material comprises the following chemical elements in percentage by mass: 0.8-0.9% of carbon, 2.1-2.3% of tungsten, 1.2-1.5% of molybdenum, 2.2-2.4% of vanadium, 2.1-2.5% of chromium, 0.05-0.10% of niobium, 0.15-0.20% of lanthanum, 0.05-0.10% of neodymium, 0.4-0.6% of Mn, 0.03-0.05% of Co, not more than 0.030% of P, not more than 0.030% of S and the balance of ferrum. The alloy disclosed by the invention not only has high hardness and wear resistance, but also has good toughness and can resist cracking and stripping caused by bending stress, torsion stress and shearing stress, meanwhile, the alloy has high contact fatigue strength and high breaking tenacity and thermal shock strength, thereby being suitable for making cold rolls. The refining agent disclosed by the invention is applied to casting production, the porosity in a casting is reduced by 1-2 degrees, and oxide inclusions are reduced by about 2 grades.

Owner:马鞍山市方圆材料工程股份有限公司

Steel ball special for large-sized offshore wind turbine generator bearing and manufacturing process of steel ball

ActiveCN102865301AIncrease the secondary stable tempering technologyAdd NDTFinal product manufactureBearing componentsSteel ballQuenching

The invention relates to a steel ball special for a large-sized offshore wind turbine generator bearing and a manufacturing process of the steel ball. The roundness of the steel ball is less than or equal to 0.8 mum, the hardness is 59-64 HRC, the single-grain hardness grain difference is less than or equal to 0.8 HRC, the batch hardness difference is less than or equal to 1.2 HRC, the core hardness is 54-60 HRC, the retained austenite is 8-13 percent, the metallographic structure is 2-3 grade, the surface roughness is less than or equal to 0.8 mum, and the crush load and the compression ratio of the steel ball are 1.2 times greater than international crush load and compression ratio. By selecting raw materials, adopting hot extrusion continuous forming during ball billet forming, adopting a water soluble quenching agent to perform multi-stage quenching during thermal treatment, increasing a secondary stable tempering technology, increasing various technologies such as eddy current nondestructive flaw detection in a process flow, the steel ball has the characteristics of good high contact fatigue strength, high wear resistance, high elastic limit, proper hardness, high impact toughness, good dimensional stability and the like.

Owner:JIANGSU LIXING GENERAL STEEL BALL

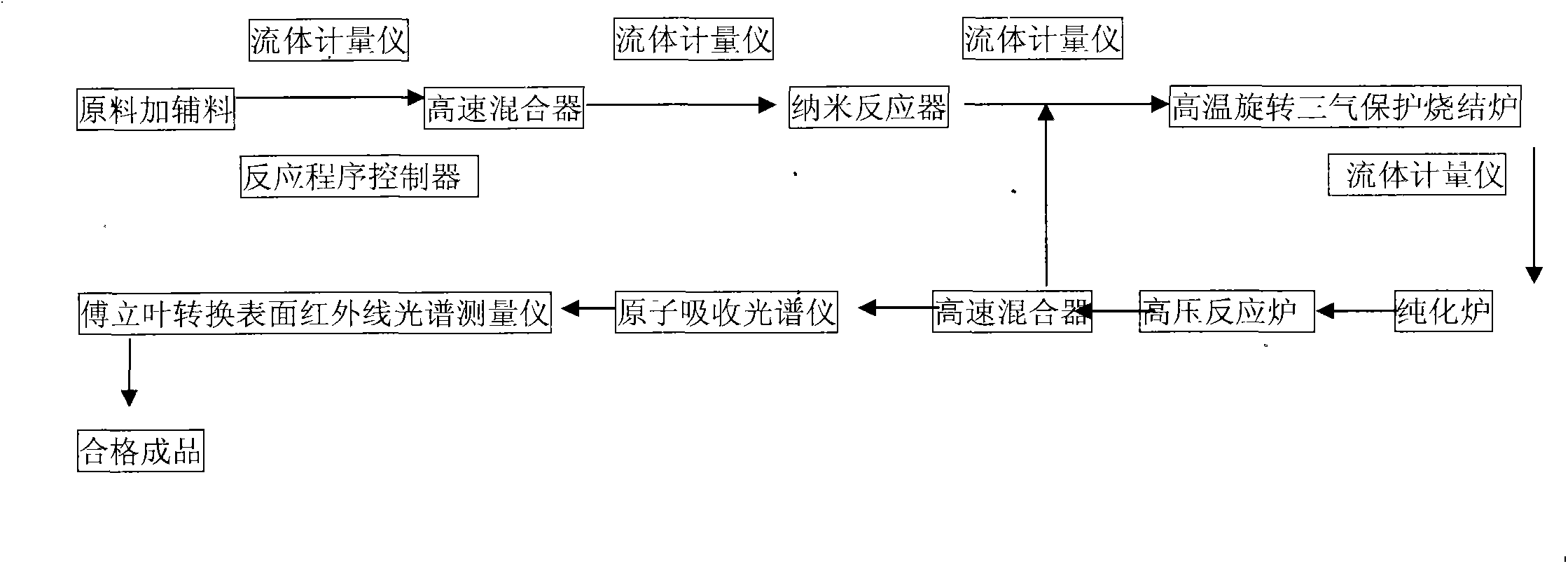

Nanoscale metal ceramization lubricant additive and preparation method therefor

InactiveCN103396862ARetain plasticityBoth super hard and super wear-resistantAdditivesChemical structurePhosphate

The invention provides a nanoscale ceramic metallization lubricant additive and a preparation method therefor, and aims to provide a nanoscale ceramic metal lubricant extreme pressure-antiwear additive which can improve the friction pair antiwear property and has self-lubricating functions. The invention is realized through the following technical scheme: quantification of raw materials is carried out according to the formula of the lubricant additive; nano ceramic powder is added into the raw materials; the above mixture is placed in a reactor wherein a coupling reaction is carried out under the atmosphere of hydrogen, nitrogen and helium; a coupling agent is added and the mixture is subjected to a coupling reaction to form ceramic primer gel with chemical covalent bonds, and one end of the coupling agent is a silicon-oxygen connection structure-Si[OEt]3 and the other end of the coupling agent is a chemical structure with molybdenum phosphate and boron nitride primer functional groups; the gel is added into a reactor through a metering pump, and is subjected to pressurization and carbon dioxide supercutical fluid solvent exchange, and the liquefied gel is converted into gasified gel; the gasified gel is then placed in a reactor atmosphere protection sintering furnace and sintered; the sintered ceramic coupling objects are placed in a stirring mixer and mixed with a surfactant additive, a dispersant, and a basic oil solvent to obtain finished products.

Owner:韩炳德

Thermal treatment method for reducing secondary gear ring nitrogenized deformation

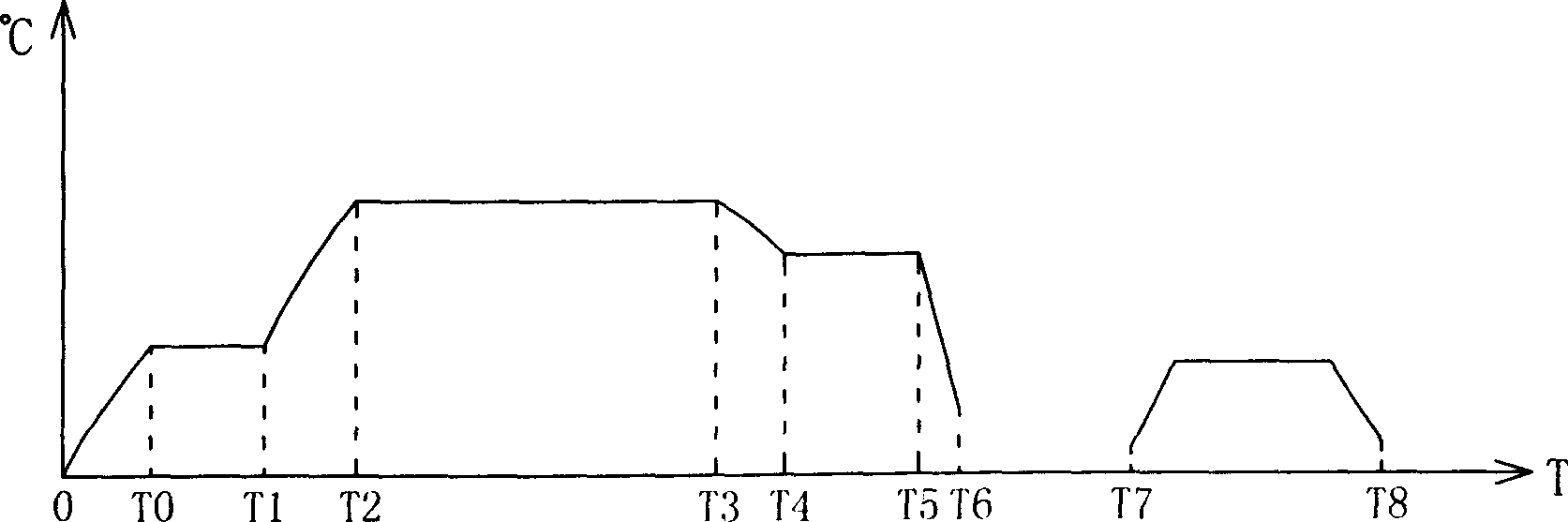

ActiveCN104032115AReduce distortionImprove mechanical propertiesSolid state diffusion coatingFurnace typesGear grindingNitrogen

The invention provides a thermal treatment method for reducing secondary gear ring nitrogenized deformation. The method comprises the following steps: (a) tempering after a secondary gear ring is roughly processed; (b) tempering; (c) processing by a gear milling machine, and destressing at high temperature; (d) processing by a gear grinding machine, and performing gas nitrogenization, wherein the gas nitrogenization comprises the following steps: uniformly fixing and supporting a plurality of cylindrical clamps in a gear ring groove; flushing a gear ring in a bell type gas nitrogenation oven, heating, and introducing 8-12m<3> / h nitrogen for 3-5 hours; heating to 400-500 DEG C, introducing 4-8m<3> / h ammonia, and insulating for 0.2-0.8 hours; heating to 500-550 DEG C, controlling the flow rate of ammonia to be 10-15m<3>, and penetrating for 60-65 hours, wherein Kn is 6; turning to diffuse, controlling the flow rate of ammonia at 4-6m<3> / h, and diffusing for 30-32 hours, wherein Kn is 2; cooling along with the oven, introducing 8-12m<3> / h nitrogen while cooling; moving the heating mantle when the temperature is reduced to 400-500 DEG C; discharging parts from the oven when the temperature is reduced to lower than 90 DEG C. The thermal treatment method has the characteristics that the deformation is small, a high-hardness high-wearing nitride layer can be obtained on the surface, the contact fatigue strength can be improved, the drawing performance and accurate requirement can be fulfilled, the product quality can be improved, and the like.

Owner:HANGZHOU ADVANCE GEARBOX GRP

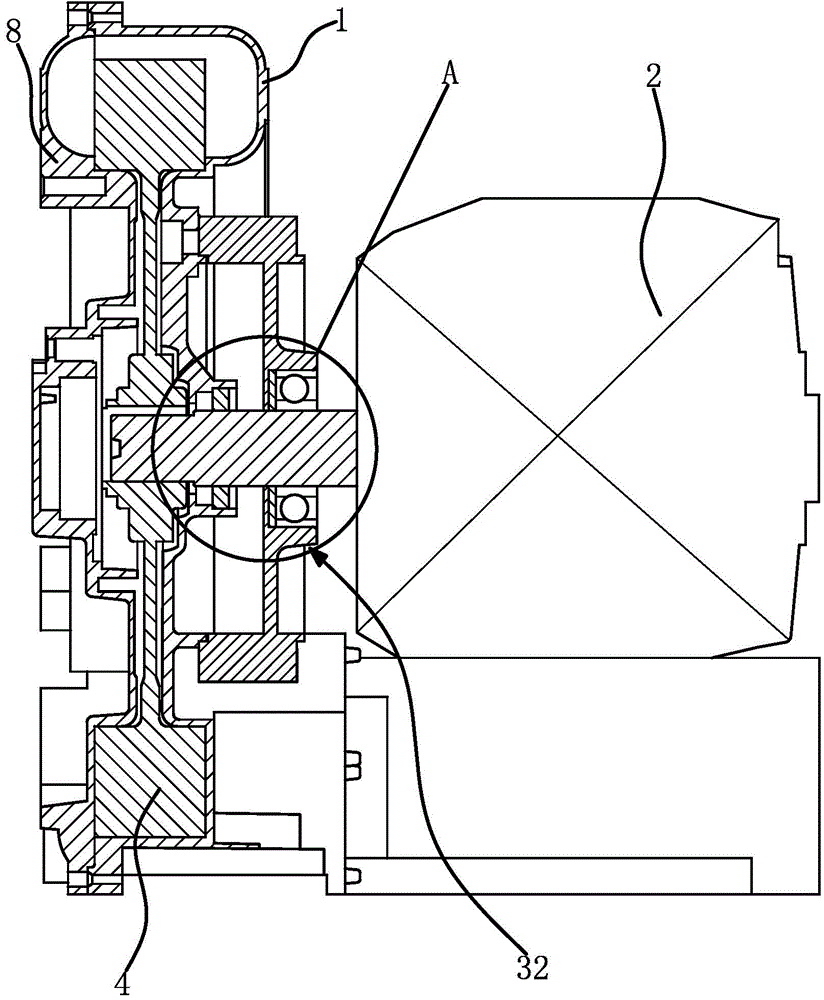

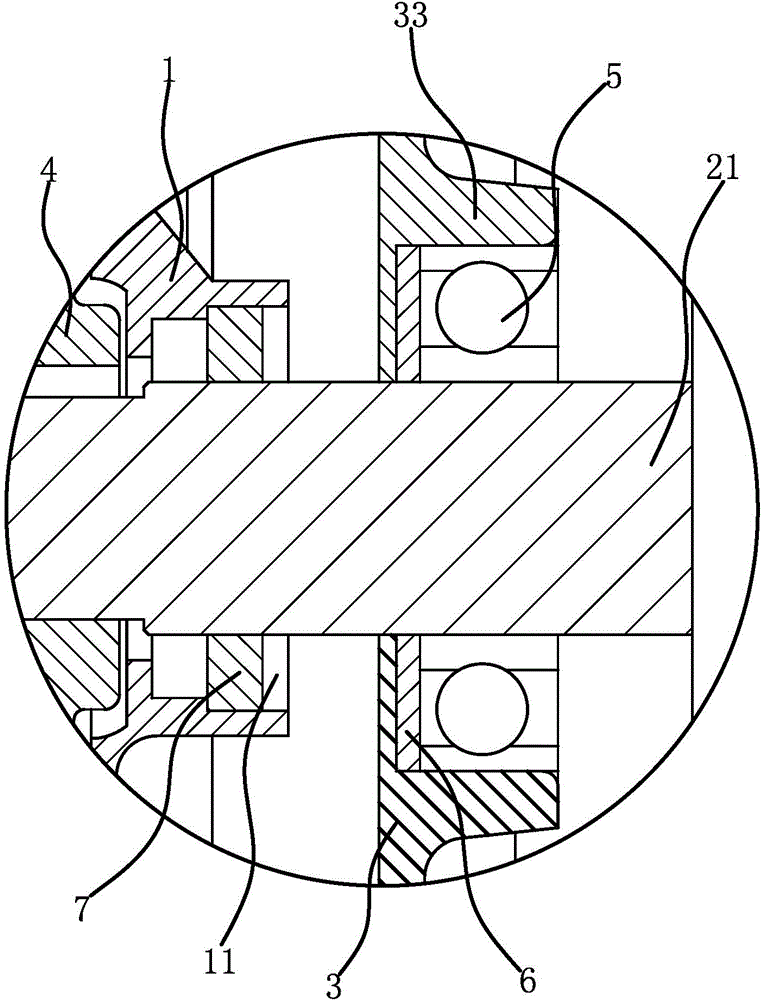

Long-service-life high-temperature-resistant textile motor bearing

PendingCN111797361AExtended service lifeExtend your lifeShaftsBearing componentsFriction torqueElectric machinery

The invention discloses a long-service-life high-temperature-resistant textile motor bearing, and belongs to the technical field of high-precision special bearing manufacturing. The long-service-lifehigh-temperature-resistant textile motor bearing is improved in the four aspects of technical design, manufacturing process, bearing lubricating grease selection and bearing manufacturing material, the service life of the improved bearing can be obviously prolonged, and the improved bearing is wear-resistant and high-temperature-resistant. According to the long-service-life high-temperature-resistant textile motor bearing, the working clearance Gr of the bearing is scientifically designed; the mounting clearance and the change clearance of inner and outer rings caused by temperature change areconsidered; and the problems that when the maximum rolling body load of a bearing raceway bearing region is increased during working operation, friction torque and temperature rise are increased dueto clearance change caused by elastic deformation and the bearing adhesion or damage due to fatigue occur too early are mainly solved, so that the service life of the bearing is greatly prolonged.

Owner:山高智能装备(山东)有限公司

Manufacturing method of equal-hardness Cr5 supporting roller

The invention discloses a manufacturing method of an equal-hardness Cr5 supporting roller. The method comprises the following steps: 1) preparing steel raw materials according to chemical components and weight percentage contents in a Cr5 supporting roller material, and preparing a steel ingot according to a smelting procedure production process; 2) preparing a roller blank from the steel ingot according to a forging procedure production process; 3) conducting heat treatment on the roller blank; and 4) machining and detecting the roller blank to obtain the equal-hardness forged steel supporting roller. According to the manufacturing method, the problems that hardness, abrasion resistance and contact fatigue of a conventional forged steel supporting roller are rapidly reduced in the middle and later periods of use are solved, and the comprehensive use period and the service life of the supporting roller are prolonged.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

High-boron alloy steel material for roller and preparation method thereof

The invention relates to a high-boron alloy steel material for a roller. The high-boron alloy steel material contains the following chemical elements in percentage by weight: 0.8-0.9% of carbon, 2.5-3% of tungsten, 0.15-0.25% of molybdenum, 0.5-0.8% of vanadium, 2.1-2.4% of chromium, 0.05-0.10% of niobium, 0.06-0.10% of cerium, 0.02-0.05% of praseodymium, 0.3-0.5% of titanium, 0.1-0.15 of cobalt, 0.3-0.5% of nickel, 0.5-0.8% of B, not more than 0.030% of P, not more than 0.030% of S and the balance of iron. The alloy steel provided by the invention has high hardness and wear resistance, as well as relatively good toughness, high heat intensity and high contact fatigue strength, and can also be used for developing a composite steel roller with high content of W and V, light segregation and good wear resistance, so as to meet the requirements of a hot continuous rolling technology, reduce the roller changing frequency in rolling, greatly improve the operation rate of a rolling machine, reduce the production cost and improve economic benefits.

Owner:马鞍山市方圆材料工程股份有限公司

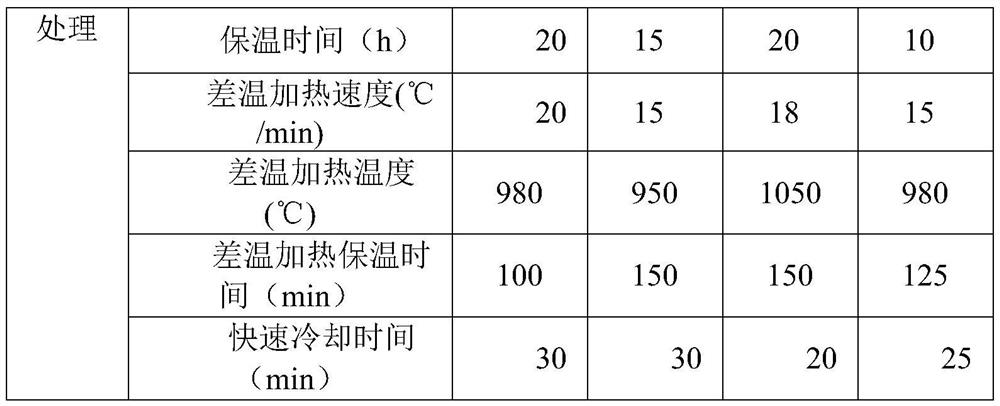

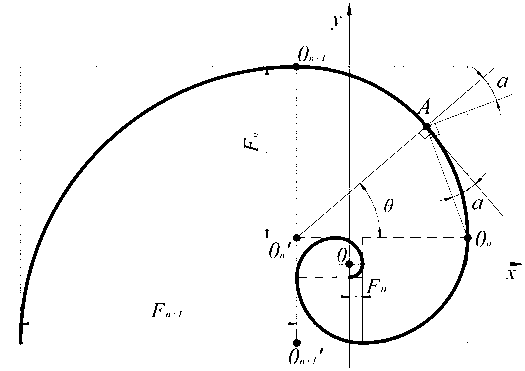

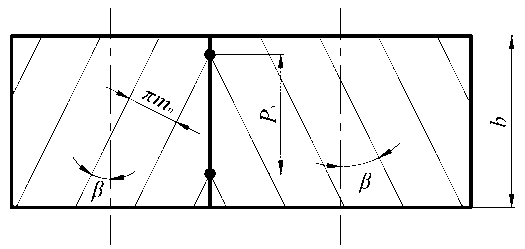

Helical gear with Fibonacci helix tooth form

InactiveCN103267106AIncrease the radius of curvatureHigh contact fatigue strengthPortable liftingGearing elementsEngineeringPressure angle

The invention discloses a helical gear with a Fibonacci helix tooth form. The tooth form of an end face of the helical gear from a root circle to an addendum circle is the Fibonacci helix tooth form, namely a section with a pressure angle a=17-28 degrees is the Fibonacci helix. Compared with an involute tooth form with the identical pitch diameter, the Fibonacci helix tooth form has large radius of curvature, so that contact stress can be reduced effectively, contact fatigue strength of the gear is improved, the service life of the gear is prolonged, and gear load-bearing capacity is improved. Compared with an involute tooth form with the identical radius of curvature, the pitch radius of the Fibonacci helix tooth form is smaller, so that the gear size is small, the weight is small, the rotational inertia is small when the gear rotates at high speed, the noise is low, operation is stable, and the high-speed requirement of the gear can be well met. According to the Fibonacci helix tooth form, the tooth width is limited, overlapping ratio of the Fibonacci helix tooth form can be improved, and continuous meshing conditions of the gear are guaranteed. Meanwhile, meshing contact area is increased, and gear load-bearing capacity is improved.

Owner:ZHEJIANG UNIV +1

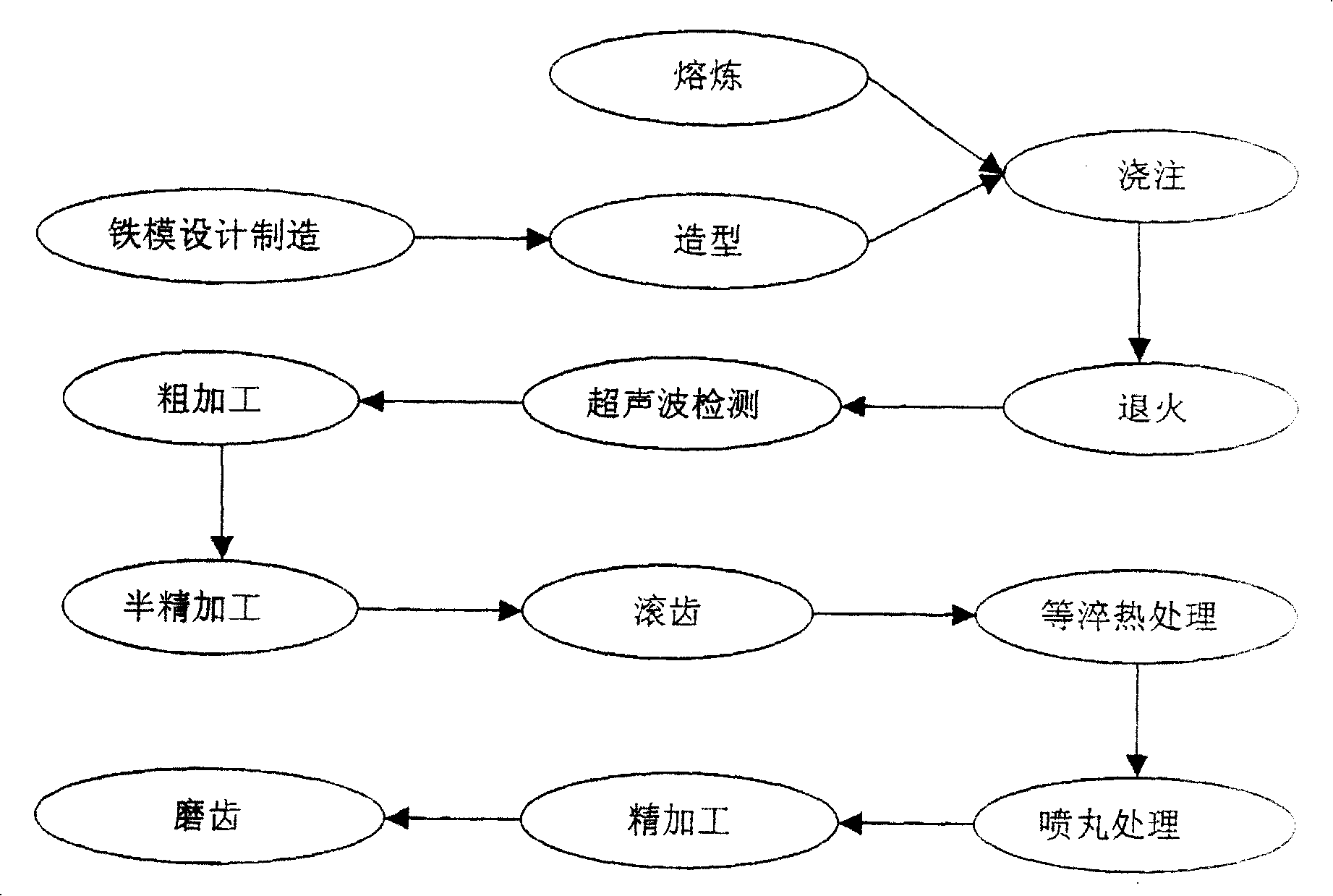

Art for manufacturing Austempered Ductile iron gear for diesel engine

A technology for manufacturing the gear with modular 'austenite plus residual bainite' iron and used for the diesel engine includes such steps as making iron mould, making sand mould, smelting in electric furnace, nodulizing, pouring, annealing, ultrasonic inspection, primary machining, semi-fine machining, hobbing gear, iso-quenching, blasting pills, fine machining, grinding teeth, marking, washing, and applying antirust oil. It has high mechanical performance and strength.

Owner:FAW GROUP

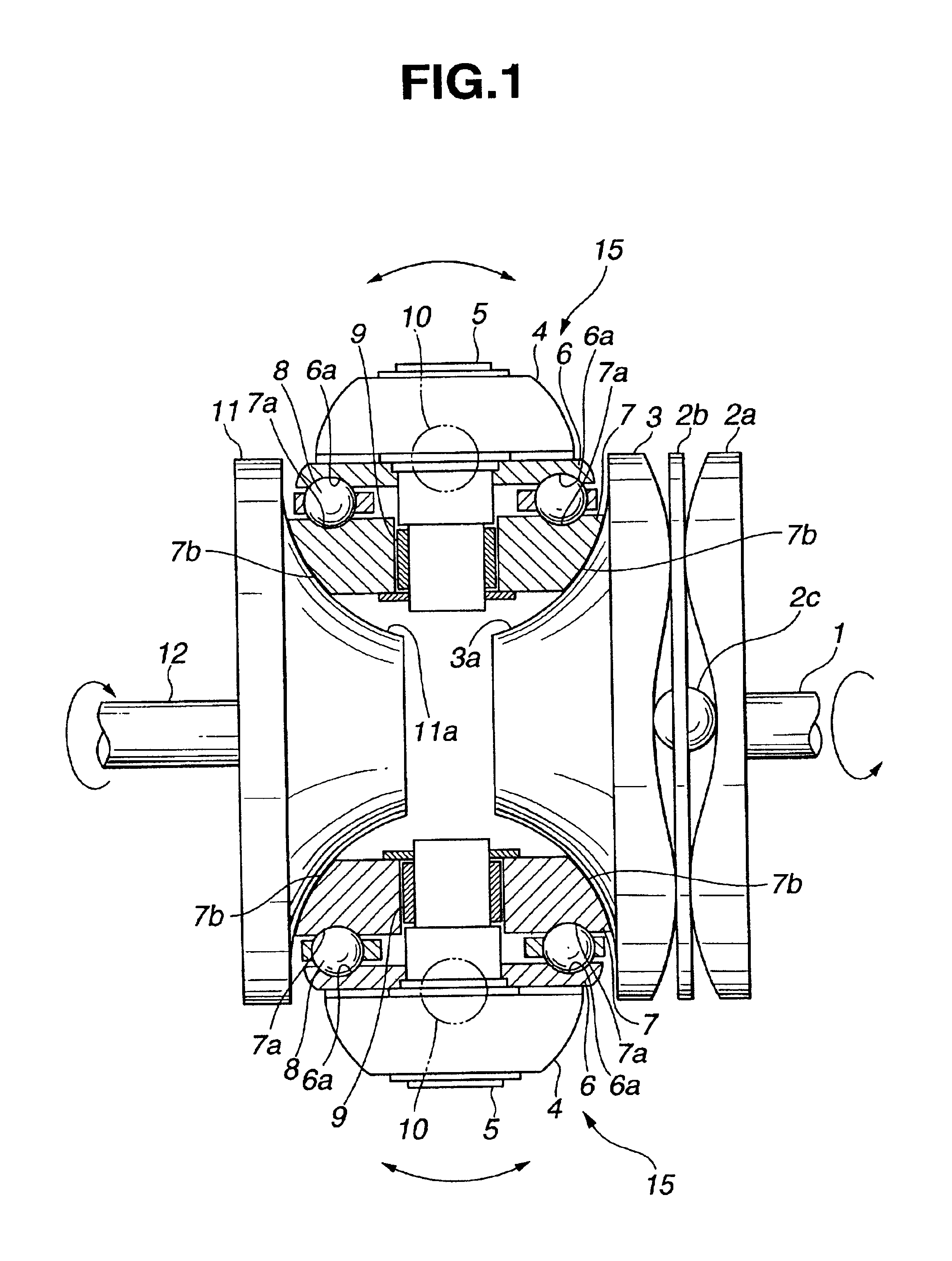

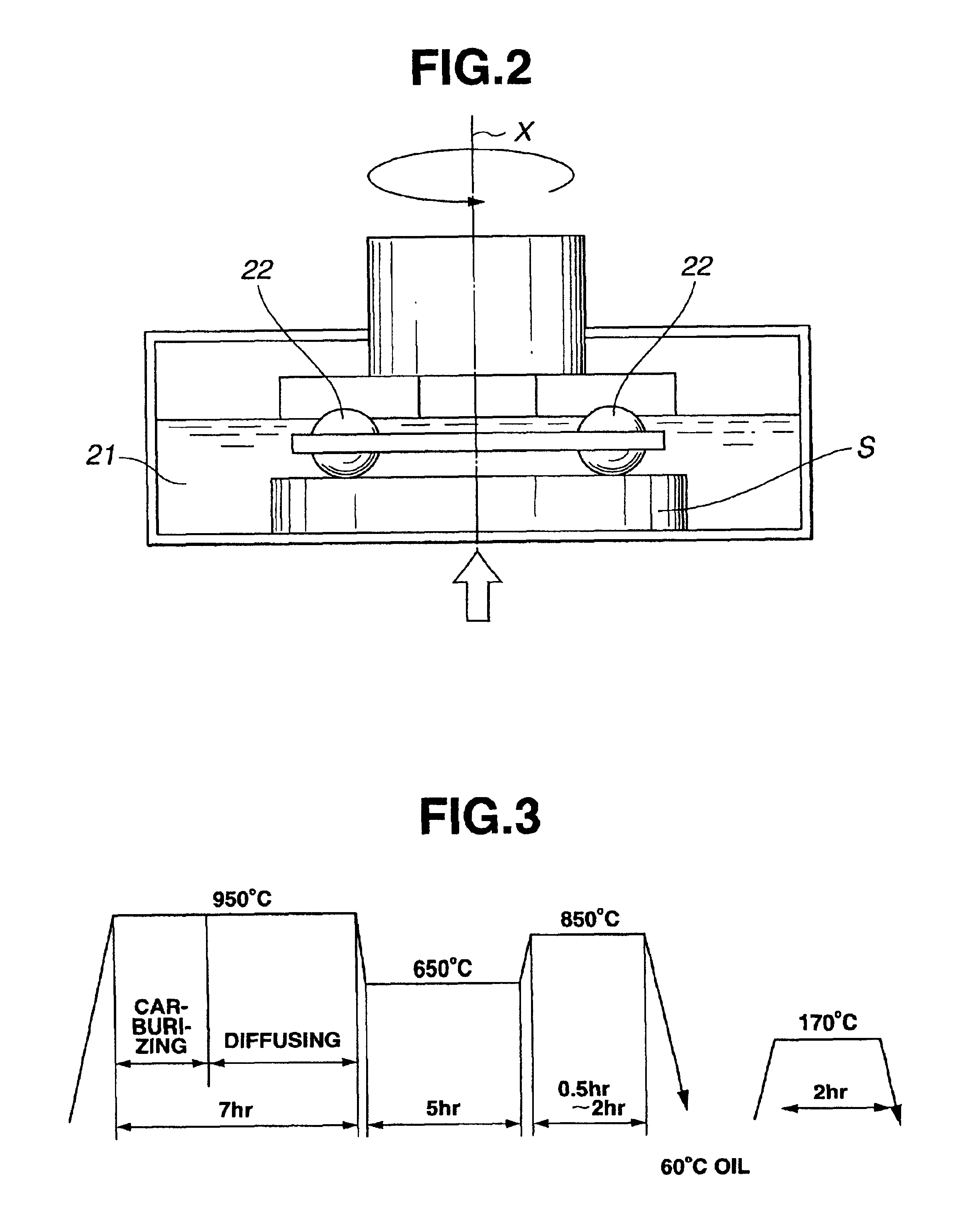

Rolling element for a continuously variable transmission (CVT), a CVT using the rolling element and a method for producing the rolling element

InactiveUS6858096B2Increase capacityReduced dimensionSolid state diffusion coatingFurnace typesSurface layerMaterials science

A rolling element for a continuously variable transmission, including a plurality of rolling members having rolling contact portions that come into rolling contact with each other via lubricating oil. At least one of the rolling contact portions includes an outer surface layer having a surface microhardness of not less than Hv 750, a surface residual compressive stress of not less than 1000 MPa and a residual austenite content of not more than 10% by volume.

Owner:NISSAN MOTOR CO LTD

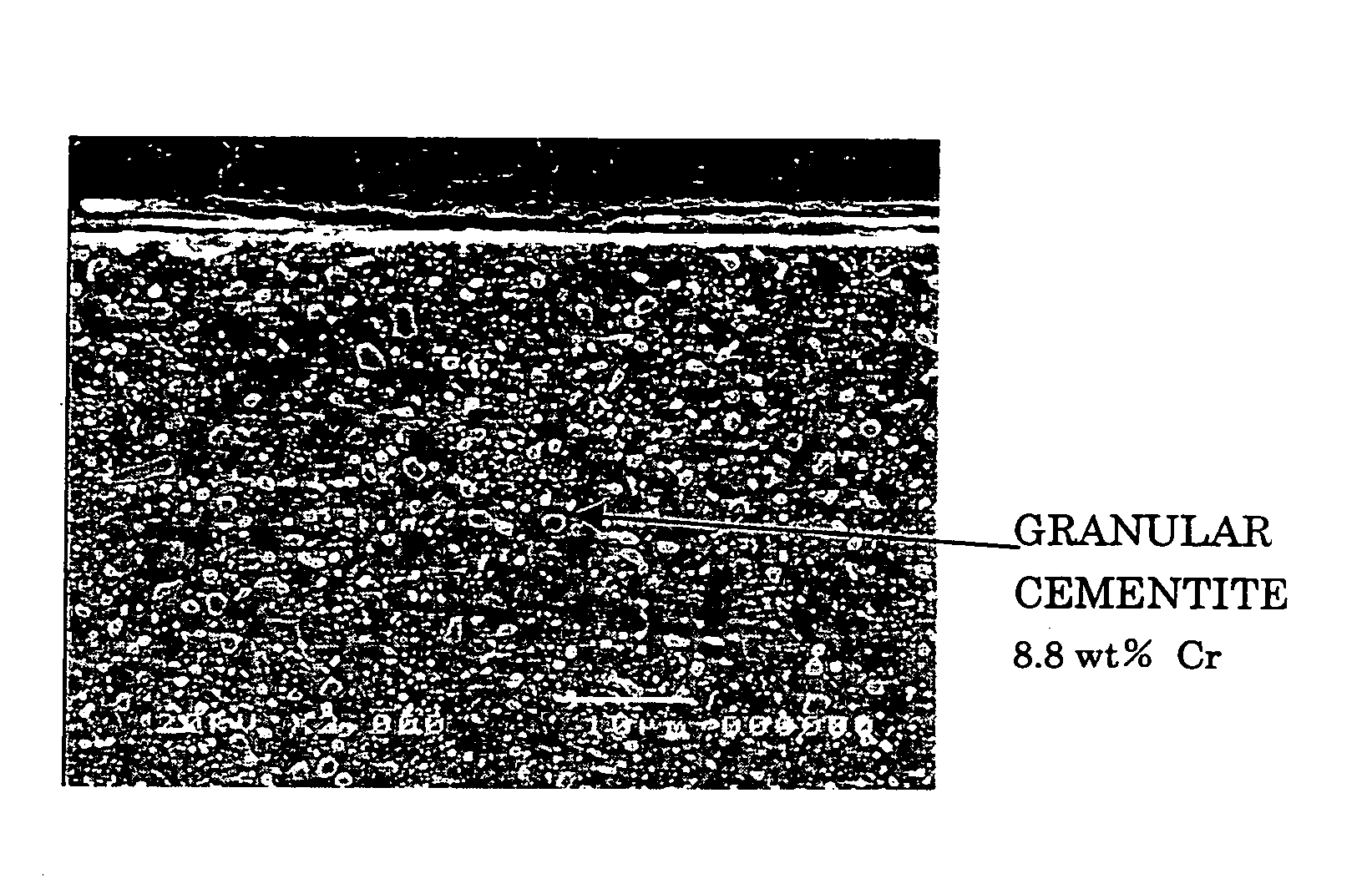

Process for strengthening nodular cast iron and finished product thereof

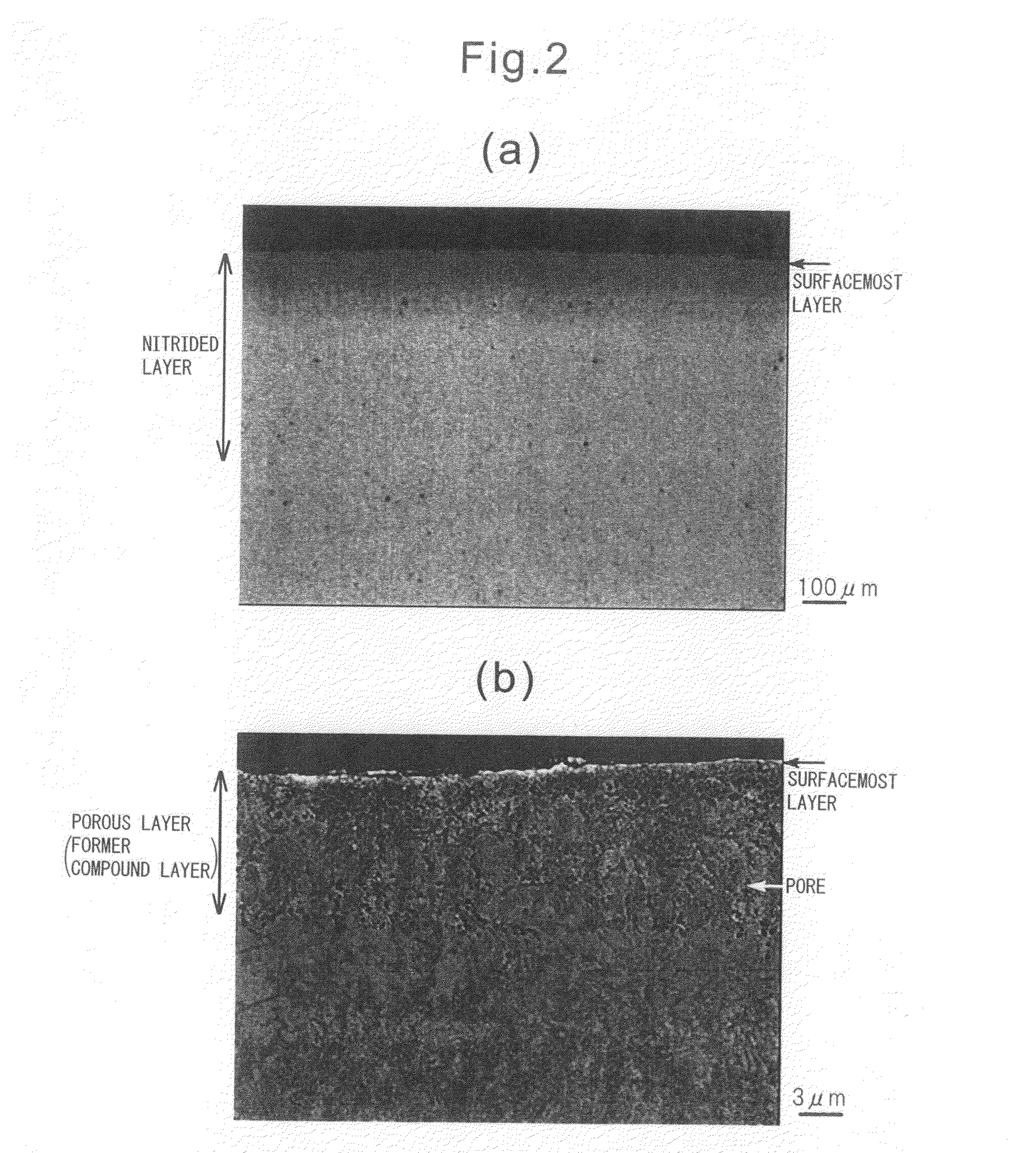

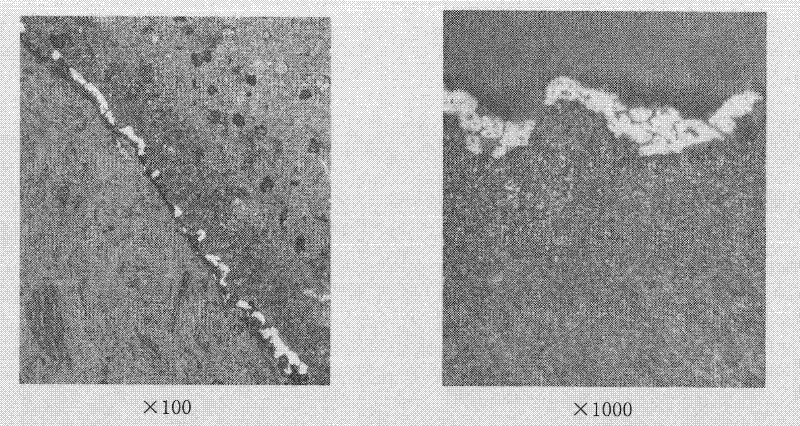

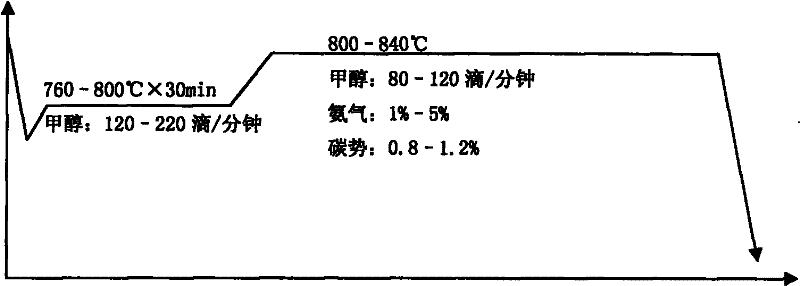

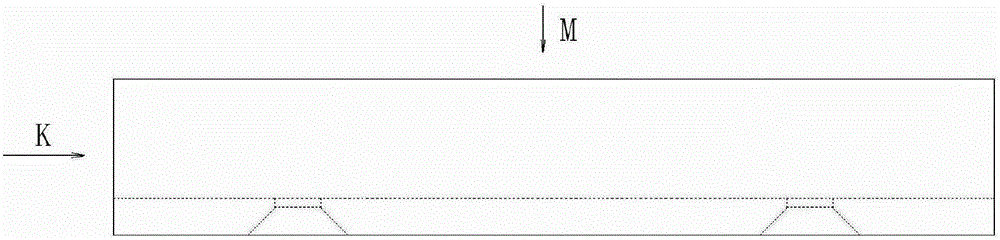

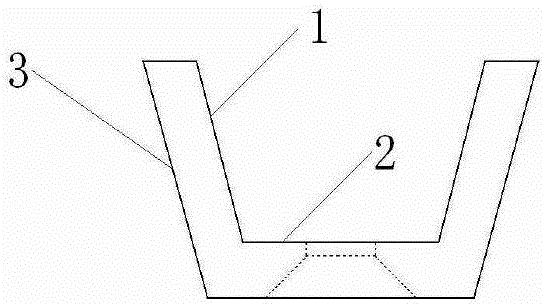

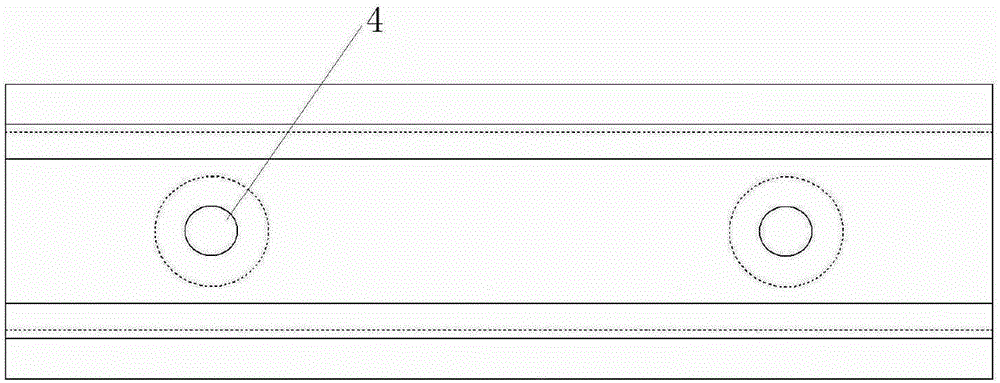

ActiveCN101851735BEasy to useEasy to processSolid state diffusion coatingFurnace typesCarbon potentialDuctile iron

The invention discloses a process for strengthening nodular cast ion and a finished product thereof. The process comprises the following steps of: putting cleaned nodular cast iron parts into a carburizing furnace; performing carbonitriding, namely adding methanol and ammonia at the temperature of between 800 and 840 DEG C, wherein the addition of the methanol is 80-120 drops / minute, the adding volume of the ammonia is 1 to 5 percent of the volume of the methanol cracked gas, the carbon potential is maintained to between 0.8 and 1.2 percent, and the processing time is 2 to 4 hours; and performing quenching to obtain a part finished product. In the carbonitriding process, the decarbonization preventing technological measure is adopted, the metallographic structure of the finished product comprises a surface layer, a sublayer and a substrate in turn, the surface layer is a granular or continuously distributed compound layer, the sublayer is hidden needle-like nitrogenous martensite, retained austenite and graphite, and the substrate is thin needle-like martensite, retained austenite and graphite. The process can improve the scratch resistance, wear resistance and contact fatigue strength, can effectively prevent full decarbonization during carbonitriding of the nodular cast ion, and has the advantages of low process difficulty and low production cost.

Owner:DONGFENG MOTOR CORP HUBEI

Carbon-carbon composite guide rail and preparation method thereof

ActiveCN103523216BReduce weightHas high temperature non-softening deformationChemical vapor deposition coatingWheel arrangementsCarbon compositesChemical vapor deposition

The invention discloses a carbon-carbon composite material guide rail for an aircraft braking wheel and a preparation method of the carbon-carbon composite material guide rail. The carbon-carbon composite material guide rail is made of a carbon-carbon composite material, and the cross section of the guide rail is U-shaped, V straight channel-shaped or V-shaped. The carbon-carbon composite material guide rail is prepared through a composite process of dipping and chemical vapor deposition, or a chemical vapor deposition method. The carbon-carbon composite material guide rail disclosed by the invention has the advantages of light weight, impossibility of softening deformation at a high temperature and the like, is used as an airplane wheel guide rail, can avoid steel guide rail corrosion, deformation, cracks and a dynamic disk clamping stagnation problem caused by guide rail deformation, and can ensure that a steel clip does not need to be arranged on a dynamic disk key groove, so that potential safety hazards of rivet fracture and steel clip falling are eliminated. The carbon-carbon composite material guide rail is used for a brake shell, and replaces a convex key on the brake shell to match with a static disk key groove, so that the problem of abnormal wear of the side surface of the static disk key groove is fundamentally solved.

Owner:XIAN AVIATION BRAKE TECH

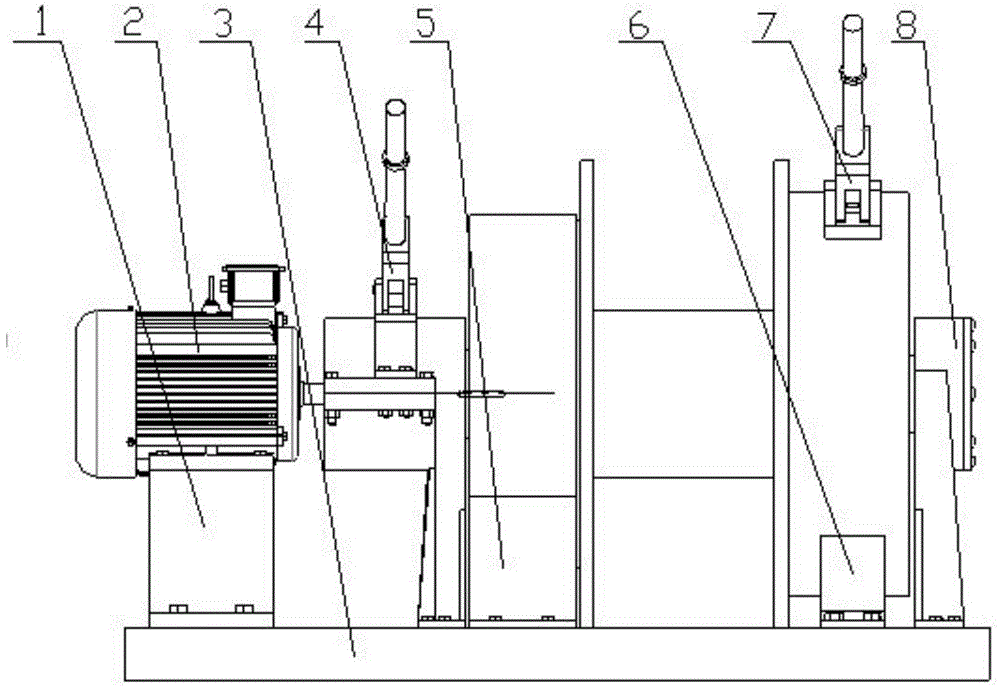

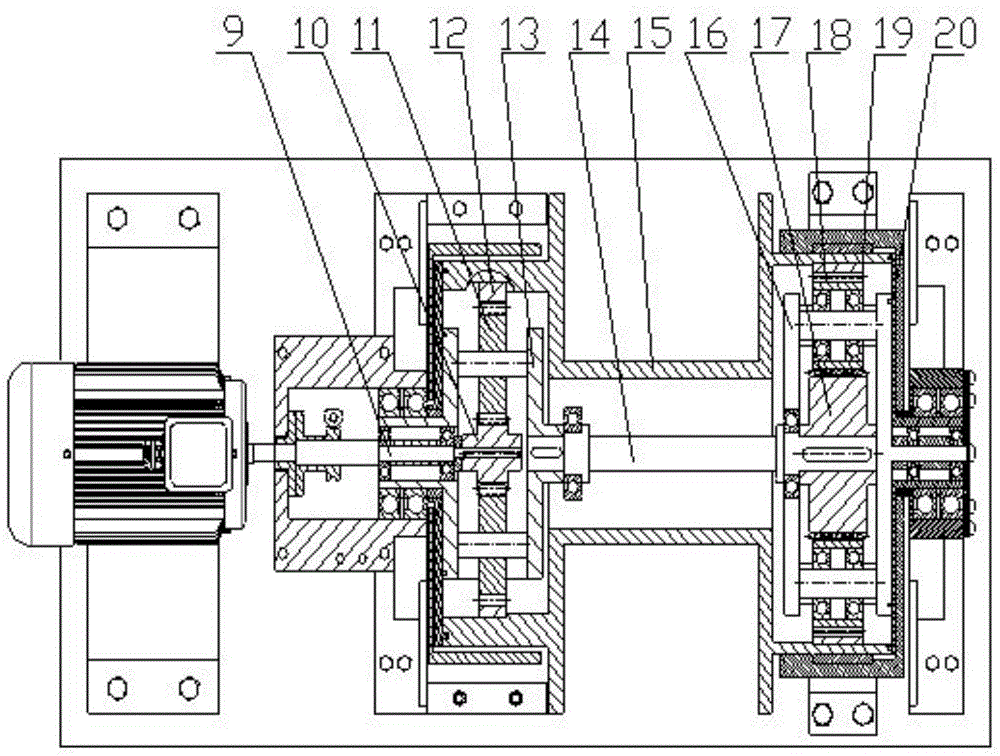

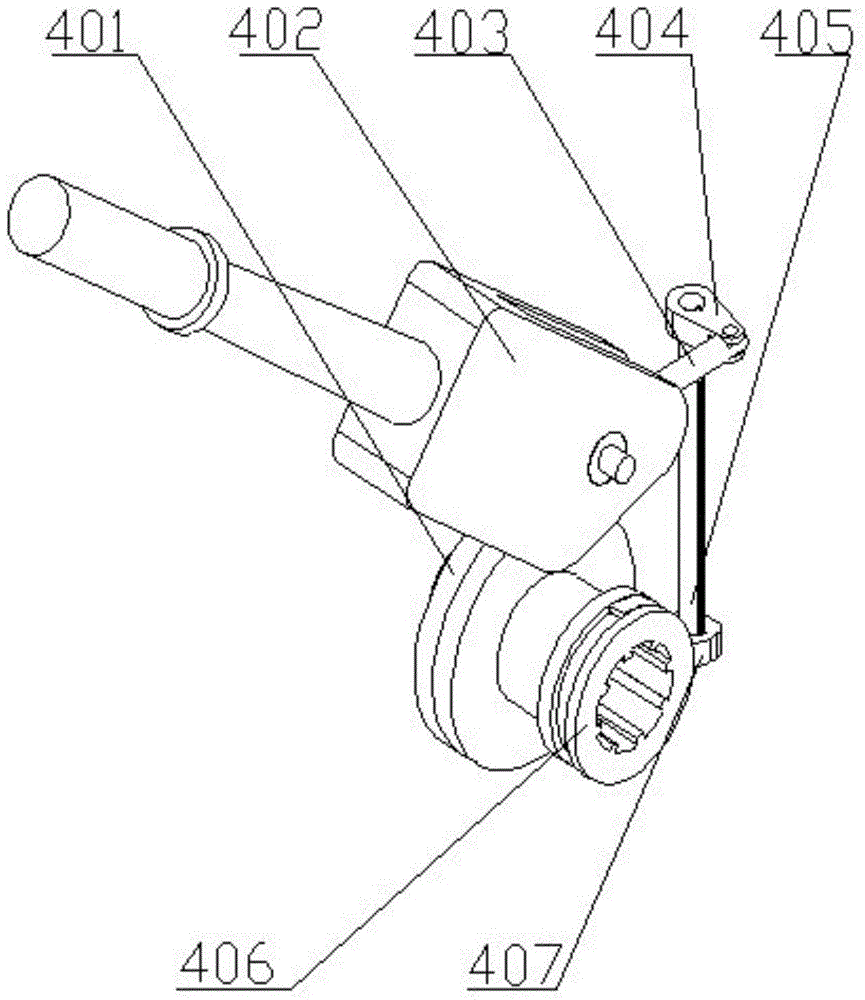

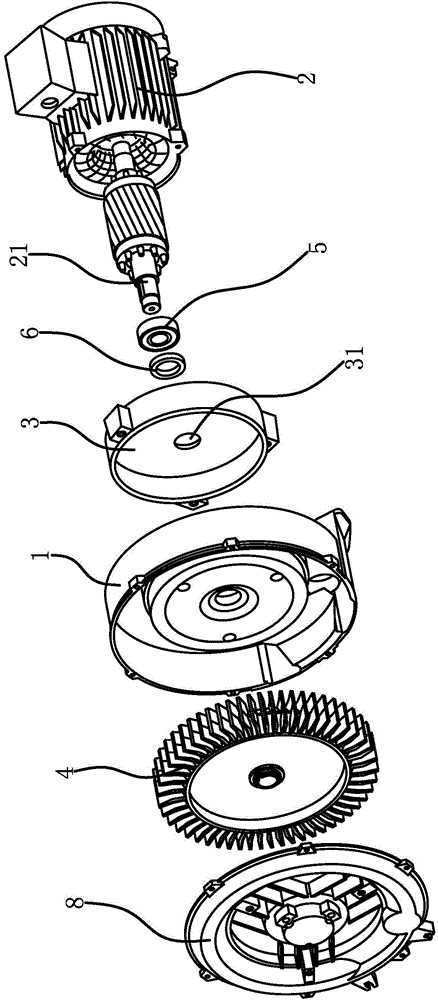

Mining dispatch winder

InactiveCN104944303AHigh bending fatigue strengthLarge transmission ratioWinding mechanismsAutomatic clutchesAgricultural engineeringWinch

The invention discloses a mining dispatch winder. The mining dispatch winder comprises a motor, a winding drum, a transmission device, a clutch, a brake and a machine base; the transmission device is a flow dividing type closed planetary transmission system and is composed of a differential stage and a closed stage, and the differential stage and the closed stage are arranged at the two ends of the winding drum respectively, so that the radiating condition is good, assembling is convenient, limitation to the modulus and the diameter of a gear is smaller, and the tooth root bending fatigue strength and the gear face contact fatigue strength are improved; the flow dividing type closed planetary transmission system is adopted, so that the transmission ratio and the winding drum output torque are improved; the clutch is a radial lever type multi-friction-plate clutch and is installed on a high-speed shaft, and the overload protection function is achieved.

Owner:ANHUI UNIV OF SCI & TECH

Alloy steel material with high fracture toughness for rolls and preparation method thereof

InactiveCN103741061AImprove wear resistanceHigh contact fatigue strengthProcess efficiency improvementHigh fractureNiobium

The invention discloses an alloy steel material with high fracture toughness for rolls. The alloy steel material comprises the following chemical elements in percentage by mass: 0.8-0.9% of carbon, 0.5-0.8% of tungsten, 1.0-1.2% of molybdenum, 1.2-1.5% of vanadium, 2.7-3.2% of chromium, 0.05-0.10% of niobium, 0.05-0.1% of gadolinium, 2.6-2.8% of manganese, 0.3-0.5% of nickel, not more than 0.030% of P, not more than 0.030% of S and the balance of ferrum.

Owner:马鞍山市方圆材料工程股份有限公司

High-pressure blower

ActiveCN104088809AHigh hardnessGood toughnessPump componentsPumpsAgricultural engineeringHigh pressure

The invention relates to a high-pressure blower, and belongs to the technical field of blower equipment. The high-pressure blower comprises a wind barrel and a motor, wherein the output shaft of the motor extends into the wind barrel, a wind blade is fixedly connected to the extending-in end of the output shaft, a circular bearing cover plate is fixedly connected to the outer side surface of the wind barrel on one side facing to the motor, a through hole is formed in the position of the center of a circle of the bearing cover plate, a bearing seat is arranged on the side surface of the bearing cover plate on one side facing to the motor and is arranged around the through hole, and a bearing is fixedly connected to the inner part of the bearing seat. The bearing cover plate and the bearing respectively consist of the following components by weight percent: 0.12 to 0.15% of C, 0.25 to 0.30% of Si, 0.50 to 0.80% of Mn, 0.50 to 0.80% Cr, 0.05 to 0.10% of Mo, less than or equal to 0.20% of Cu, less than or equal to 0.10% of Ni, less than or equal to 0.025% of S, less than or equal to 0.025% of P, and the balance of Fe. The high-pressure blower has the advantages of rational design and long service life.

Owner:NINGBO SHENGHONG MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com