Thermal treatment method for reducing secondary gear ring nitrogenized deformation

A heat treatment method and ring gear technology, applied in heat treatment furnaces, heat treatment equipment, coatings, etc., can solve problems such as inability to meet drawing accuracy, taper and end face warping, inconsistent and symmetrical structures, etc., to improve contact fatigue strength and meet performance requirements and precision requirements, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

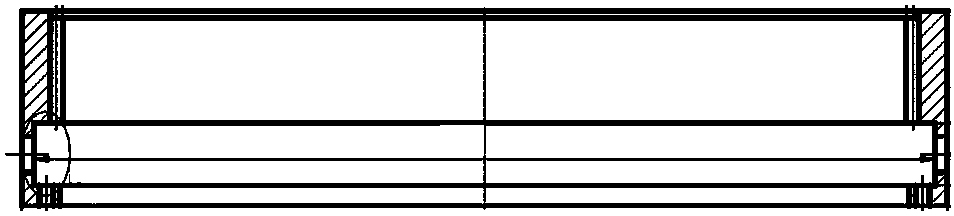

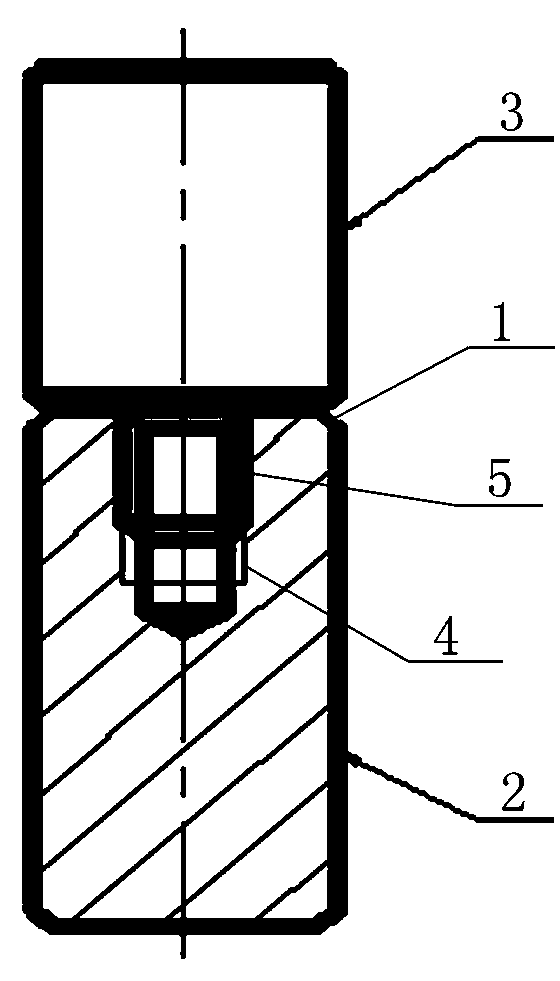

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings: the heat treatment method for reducing the nitriding deformation of the secondary ring gear according to the present invention, the heat treatment method includes the following steps: a) quenching and tempering treatment after the rough machining of the secondary ring gear ; b) tempering treatment; c) high temperature stress relief treatment after gear milling; d) gas nitriding treatment after gear grinding; the gas nitriding treatment is: first clean the ring gear, Evenly fix and support multiple columnar tooling in the ring gear groove, see figure 1 shown; then the ring gear is flat-mounted in a bell-type gas nitriding furnace, heated and heated, and passed into 8-12m 3 / h of nitrogen, time 3-5 hours; temperature rises to 400-500 ° C, ammonia gas 4-8m 3 / h, after 0.2-0.8 hours of heat preservation, the temperature is raised to 500-550°C, and the flow rate of ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com