Art for manufacturing Austempered Ductile iron gear for diesel engine

A kind of Aube ductile iron and manufacturing process technology, applied in the field of mechanical parts, can solve difficult problems, both in technology and equipment, poor processability of Aobei ductile iron material, complex structure and other problems, to achieve a good comprehensive Mechanical properties, good spheroidization rate, effect of reducing cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

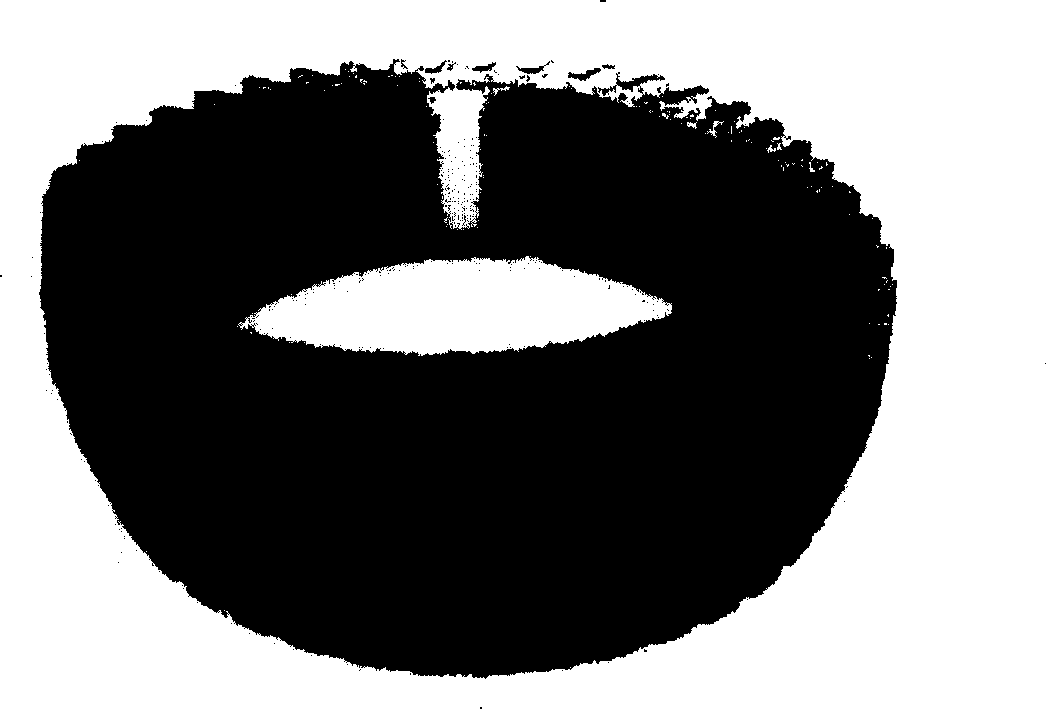

[0026] In the embodiment of the present invention, 1005037AB-6DF1 Aubey (upper) nodular iron crankshaft timing gear is as figure 2 As shown in the photo: the main technical requirements and dimensions of the gear are: modulus m n =3, number of teeth Z=42, tooth profile angle α=20°, gear inner hole size φ104H7( 0 +0.035 ), roughness 1.6, addendum circle size φ132h11 ( -0.25 0 ), gear width 36±0.1, end surface roughness 3.2, effective tooth width 17 0 +0.5 , tooth surface roughness 0.8.

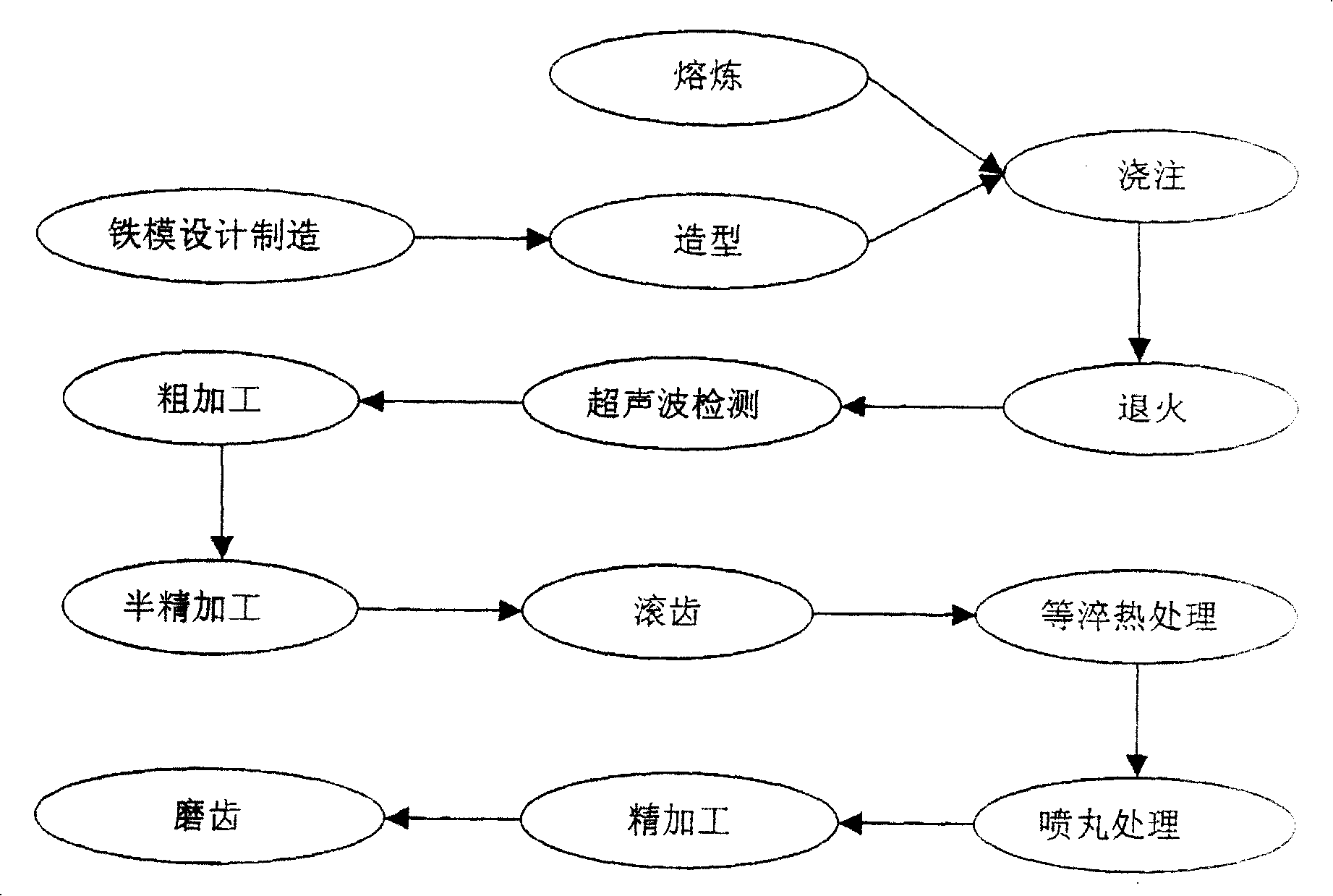

[0027] The production process steps of Aobei (Shangbei) nodular iron crankshaft timing gear are as follows:

[0028] 1. Design and manufacture of iron mold: The gear is cast with iron mold covered with sand, so first of all, according to the product drawing of the gear, add 1.5-3.5mm allowance on one side to make the rough drawing of the casting, and add 5-25mm on one side on the basis of the rough drawing Sand-covered layer design and manufacture of iron molds; chemical composition and...

Embodiment 2

[0042] The main technical requirements and dimensions of the 1006041AB-6DF1 Aube (Shangbei) nodular iron gear in the embodiment of the present invention are: modulus m n = 3, number of teeth Z = 52, tooth profile angle α = 20°, gear inner hole size φ68 0 +0.030 , roughness 1.6, addendum circle size φ162 -0.250 0 , gear width 17 ± 0.2, end surface roughness 3.2, tooth surface roughness 0.8. Electric furnace smelting molten iron: The raw material formula for smelting molten iron is 70% by weight of pig iron, 20% by weight of returned iron, and 10% by weight of scrap steel. During chemical treatment, 1.6% by weight of rare earth magnesium ferrosilicon intermediate alloy nodulizer and 0.7% by weight of 75 ferrosilicon covering agent were put into 97.2% by weight of ladle molten iron, and then put into inoculant for inoculation treatment. The inoculant formula is 0.5% by weight of 75 ferrosilicon, the chemical composition after treatment must meet the above chemical composition...

Embodiment 3

[0044] The main technical requirements and dimensions of the 1006042AB-6DF1 Aube (Shangbei) nodular iron gear in the embodiment of the present invention are: modulus m n =3, number of teeth Z=26, tooth profile angle α=20°, gear inner hole size φ52H7( 0 +0.030 ), roughness 1.6, addendum circle size φ84h11 ( -0.22 0 ), gear width 46d9( -0 142 -0.080 ), the end surface roughness is 1.6, the tooth width is 25.5±0.1, and the tooth surface roughness is 0.8. Electric furnace smelting molten iron: the raw material formula for smelting molten iron is 60% by weight of pig iron, 30% by weight of returned iron, and 10% by weight of scrap steel. During chemical treatment, put 1.3% by weight of rare earth magnesium ferrosilicon master alloy spheroidizer and 0.6% by weight of 75 ferrosilicon covering agent into 97.7% by weight of ladle molten iron, and then put inoculant for inoculation treatment. The inoculant formula is 0.4% by weight 75 ferrosilicon. The temperature of molten iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com