Long-service-life high-temperature-resistant textile motor bearing

A motor bearing, high temperature resistant technology, used in bearings, bearing components, shafts and bearings, etc., can solve problems such as non-lubricated state, loud beating sound, and grease failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

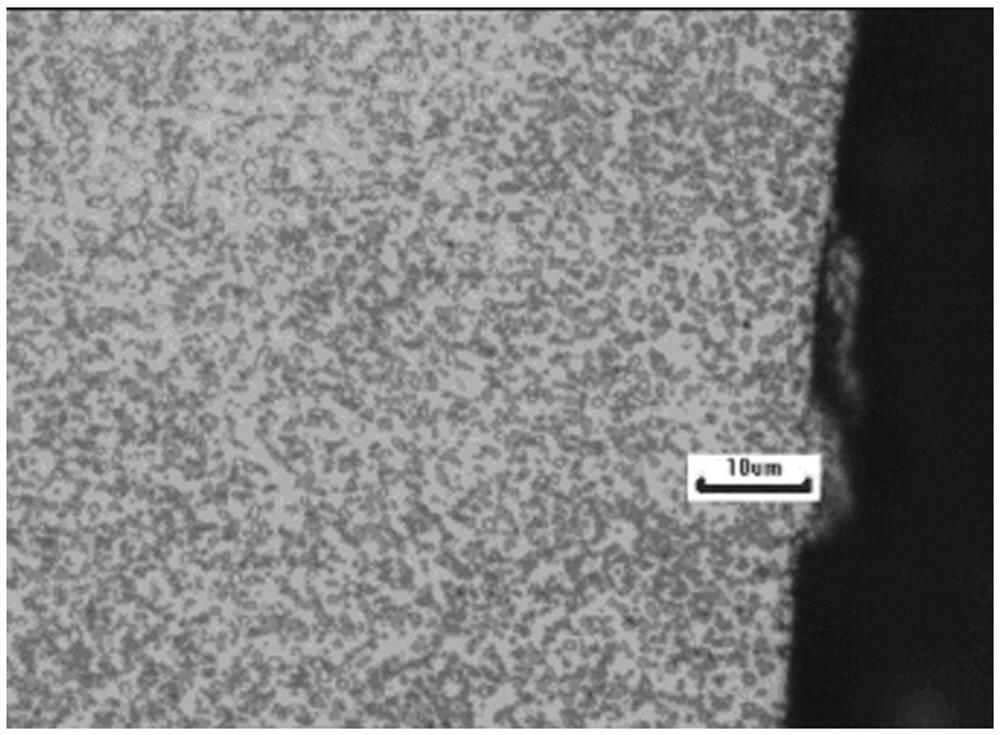

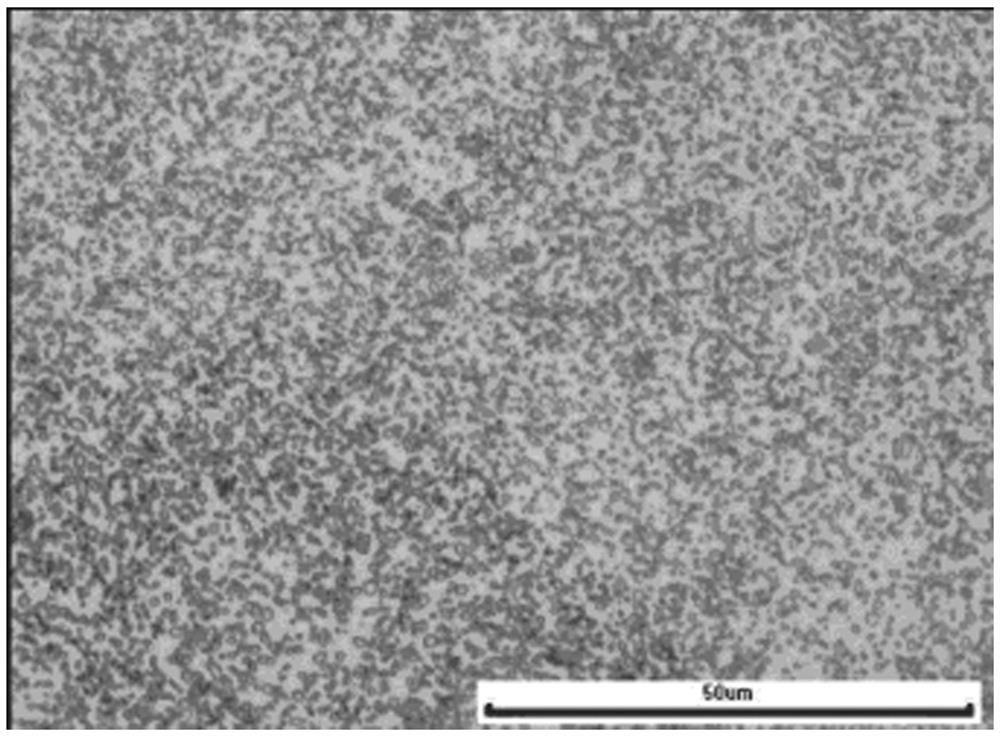

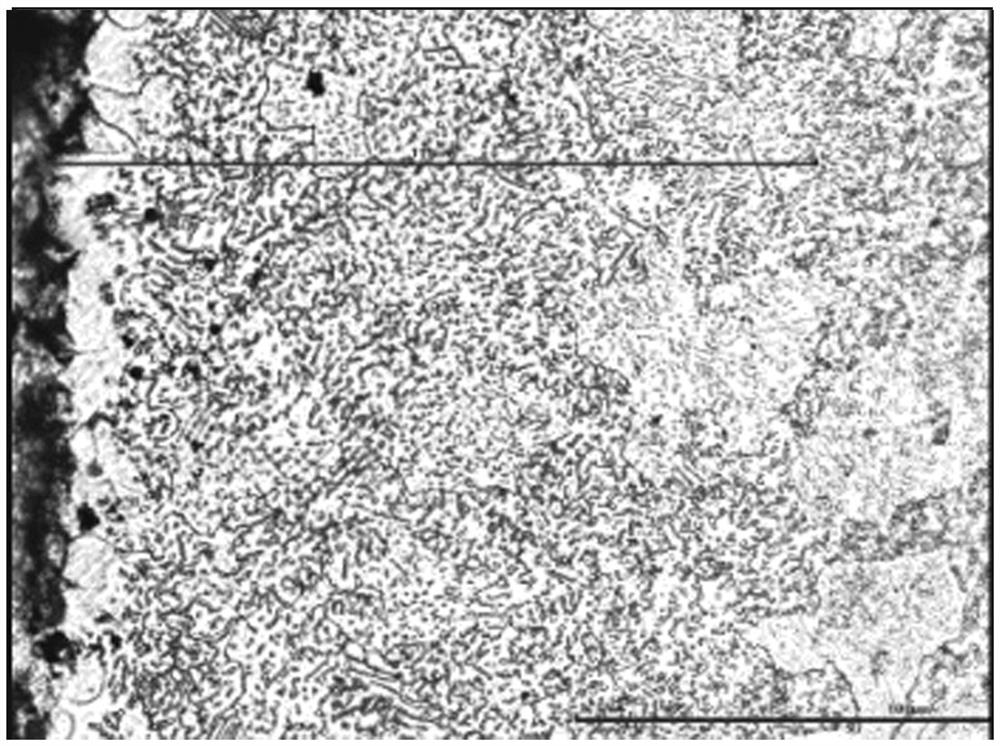

Image

Examples

Embodiment Construction

[0082] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with the examples, but the content of the present invention is not limited to the following examples, and the examples should not be regarded as limiting the protection scope of the present invention.

[0083] The invention has been improved from the four aspects of technical design, manufacturing process, bearing lubricating grease selection, and bearing manufacturing materials. The improved bearing can significantly extend the service life, and is wear-resistant and high-temperature resistant.

[0084] (1) The working clearance Gr of the bearing is calculated and selected according to the following steps:

[0085] ①Calculate the maximum contact stress according to the maximum load:

[0086]

[0087] Where: Pmax — maximum Hertz contact stress;

[0088] e a — Coefficient of the major axis of the contact ellipse;

[0089] e b — Coefficient of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com