Helical gear with Fibonacci helix tooth form

A technology of helical cylindrical gears and helical wires, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve problems such as difficult to meet high-speed and heavy-duty requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

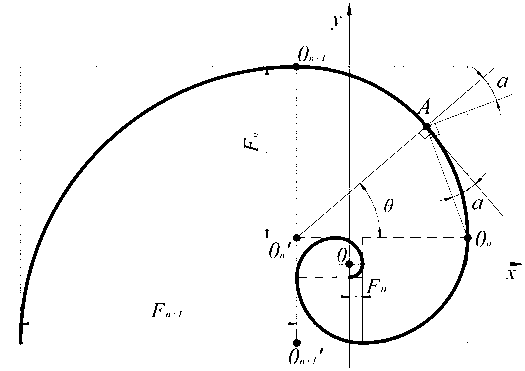

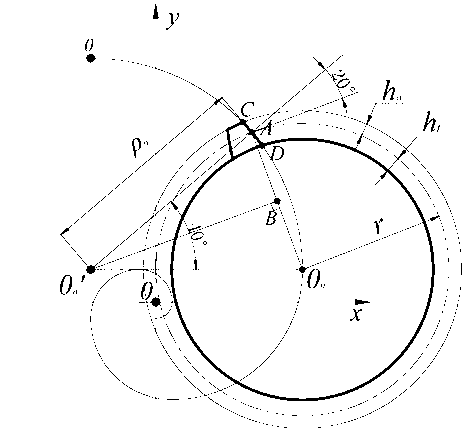

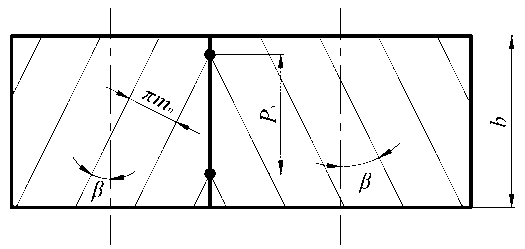

[0027] Such as figure 2 As shown, the tooth shape of the end face of the cylindrical gear of the present invention from the dedendum circle to the addendum circle is a Fibonacci spiral tooth shape, that is, a section of the pressure angle a=17°-28° is a Fibonacci spiral.

[0028] Such as figure 1 , figure 2 As shown, the Fibonacci spiral is formed by connecting a series of quarter arcs with the Fibonacci sequence as the radius value. The Fibonacci spiral is calculated by the following formula (1).

[0029] x = cos ( θ + π 2 n ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com