Nanoscale metal ceramization lubricant additive and preparation method therefor

A lubricating oil additive, nano-scale technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of thin engine friction pair, loss of oil film adhesion, and difficulty in starting the machine, so as to restore the cylinder pressure and repair the scratched surface , the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

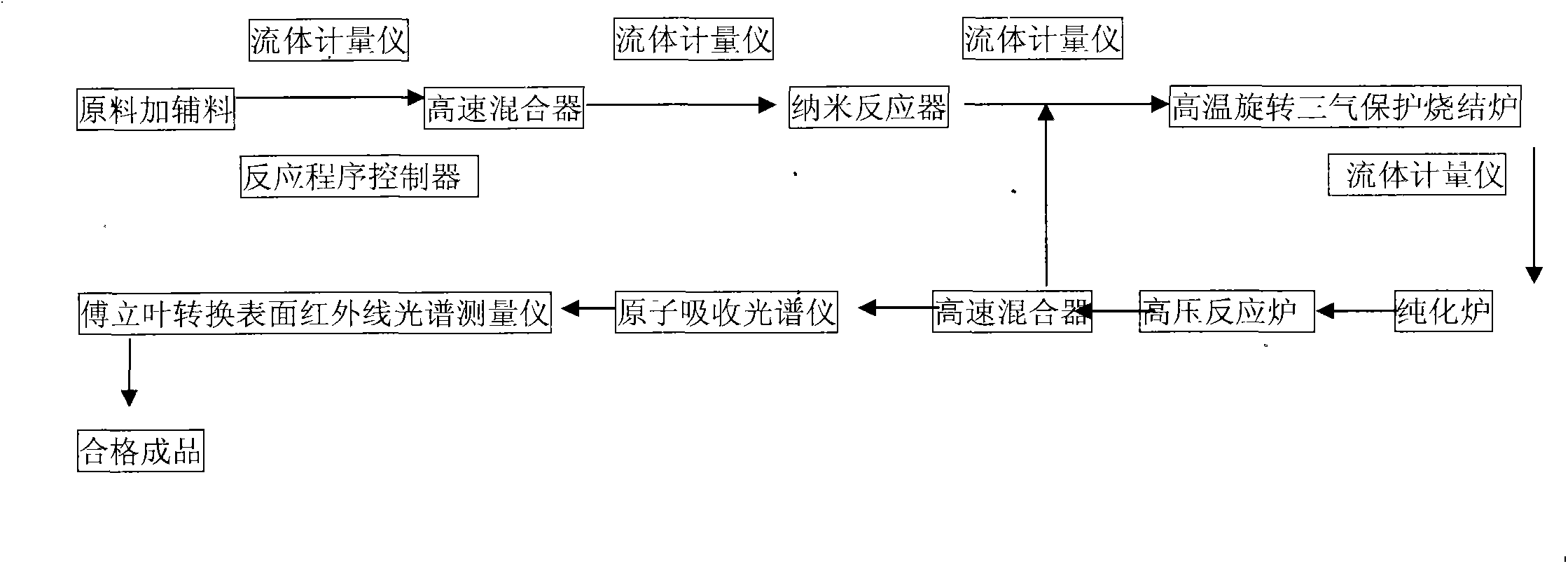

Image

Examples

Embodiment

[0018] Under the environment of normal temperature and humidity of 70% to 80%, according to the components specified in Table 1, according to any specific value in the above weight percentage, polyboramine, molybdenum dithiophosphate, and mixed earth metal , sulfonate, liquid paraffin, aromatic solvent, ceramic nanopowder, petrochemical mineral base oil (solvent), then add the above-mentioned weighed raw materials into a stirring mixer, fully stir evenly, and stir for 1-1.5 hours.

[0019] Table 1

[0020] Component content of each group (wt%)

[0021] Sulfonate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com