High carbon chromium bearing parts surface chemical heat-treatment process

A high-carbon chromium bearing and surface chemistry technology, used in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061]Embodiment 1, the processing technology of high carbon chromium bearing inner ring includes the following steps:

[0062] (1) High-carbon chromium raw materials are sequentially forged, annealed, and turned into bearing inner rings. The initial forging temperature is 1150°C, the final forging temperature is 850°C; the annealing temperature is 800°C, and the time is 15h.

[0063] (2) Set the process and process parameters on the control panel of the push rod carbonitriding production line,

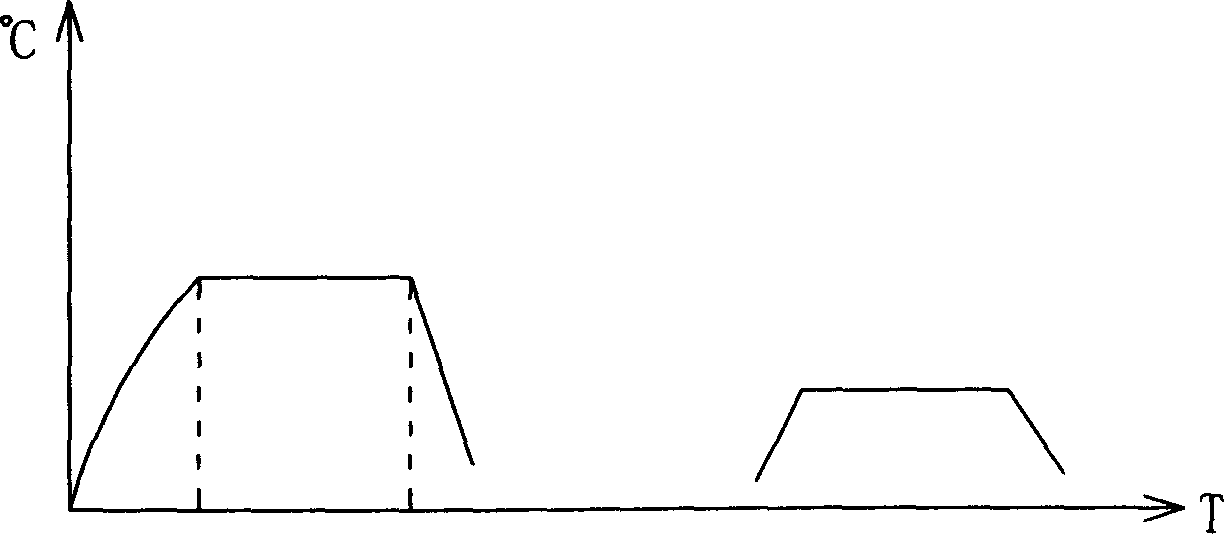

[0064] Process: pre-cleaning → pre-oxidation → carbonitriding → cooling diffusion → quenching → post-cleaning → tempering;

[0065] Parameters: pre-cleaning 0.3h; pre-oxidation temperature 350°C, time 1h; carbonitriding temperature 850°C, time 3h, carbon potential 1.4%; carbon nitrogen diffusion start temperature 850, cut-off temperature 820°C, time 2h, carbon potential 0.9%; Ammonia flow rate 0.5m 3 / h; quenching temperature 820°C, quenching oil temperature 80°C; post-cleaning 0.4h...

Embodiment 2

[0076] Embodiment 2, the processing technique of high-carbon chromium bearing steel ball comprises the following steps:

[0077] (1) High-carbon chromium raw materials are sequentially cold-headed and polished into steel balls.

[0078] (2) Set the process and process parameters on the control panel of the multi-purpose furnace,

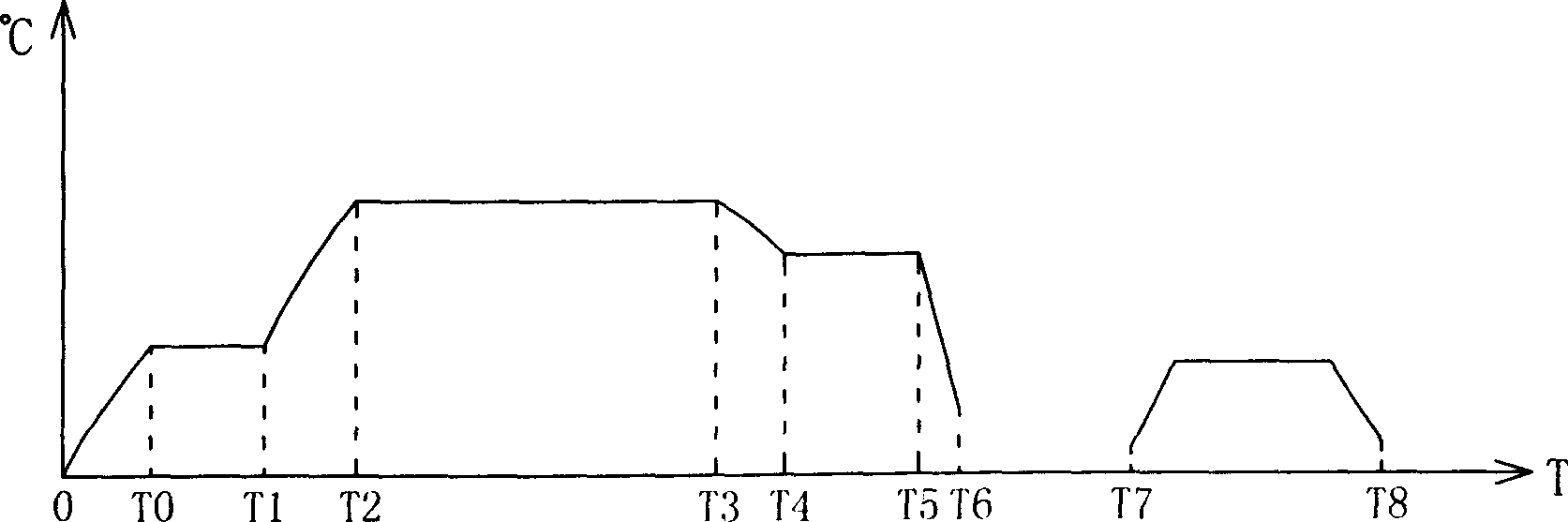

[0079] Process: pre-cleaning → pre-oxidation → carbonitriding → cooling diffusion → quenching → post-cleaning → tempering;

[0080] Parameters: pre-cleaning 0.8h; pre-oxidation temperature 400°C, time 1.5h; carbonitriding temperature 880°C, time 6h, carbon potential 1.5%; carbon nitrogen diffusion start temperature 880°C, end temperature 850°C, time 4h, carbon Potential 0.8%; ammonia gas flow 3m 3 / h; quenching temperature 850°C, quenching oil temperature 80°C; post-cleaning 1h; tempering temperature 250°C, time 4h.

[0081] (3) Load the processed bearing steel balls into the transfer car, start the program, the transfer car advances along the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com