Centrifugally cast composite roll for hot rolling

一种离心铸造、复合辊的技术,应用在轧辊、制造工具、金属轧制等方向,能够解决不具备耐磨耗性、抗事故性和抗表面粗糙性等问题,达到优异抗咬合性和抗表面粗糙性、表面损伤少、抗咬合性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7、 comparative example 1 and 2

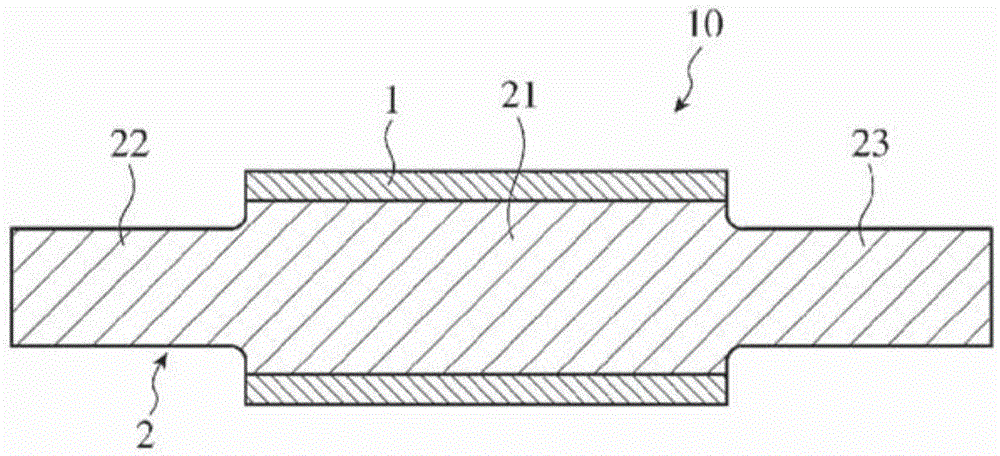

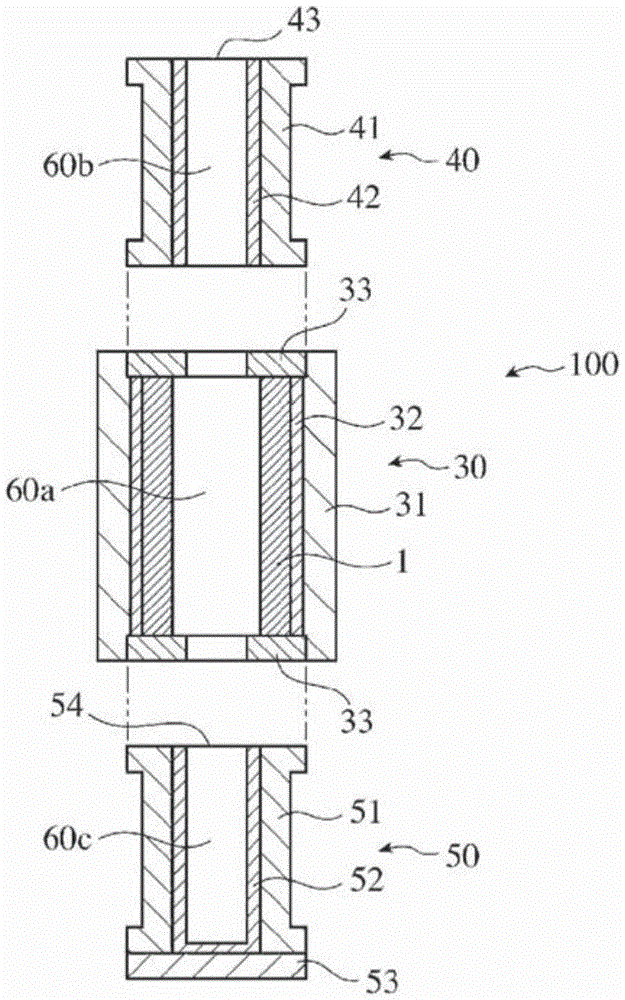

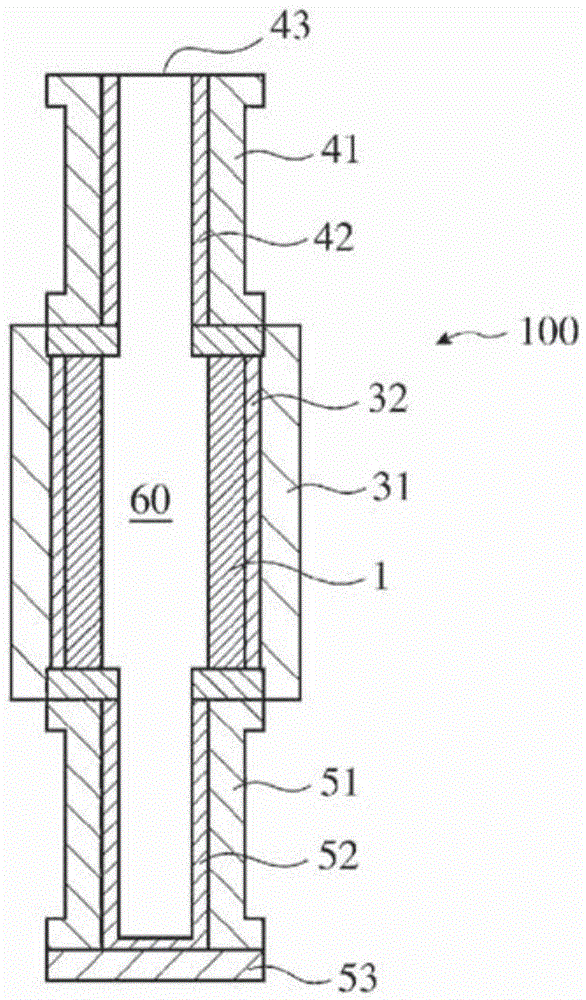

[0096] A cylindrical mold 30 (800 mm in inner diameter and 2500 mm in length) having the structure shown in FIG. . After the outer layer 1 is solidified, the cylindrical mold 30 with the outer layer 1 (thickness: 90 mm) formed on the inner surface is erected, and the hollow lower mold 50 (inner diameter 600 mm, and length 1500 mm) for forming the shaft portion 22 is erected. Cylindrical casting mold 30, on cylindrical casting mold 30, vertically set up hollow shape upper mold 40 (inner diameter 600mm, and length 2000mm) that shaft portion 23 forms usefulness, constitutes the static casting casting mold shown in Fig. 2 (b) 100.

[0097] Into the cavity 60 of the static casting mold 100, a nodular cast iron melt having a chemical composition containing C: 3.0%, Si: 2.6%, and Mn: 0.3% is poured from the upper opening 43 , Ni: 1.4%, Cr: 0.1%, Mo: 0.2%, Mg: 0.05%, P: 0.03%, and S: 0.03%, the balance is essentially Fe and unavoidable impurities, and graphite containing Si is inocu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com