Material for sliding parts having self lubricity and wire material for piston ring

a technology of self-lubricating and wire material, which is applied in the field of sliding parts materials, can solve the problems of poor seizure resistance properties, unsolved problems such as cost of surface treatment and aluminum adhesion, and the second ring of steel has not made good progress, so as to improve workability and machinability of steel. , the effect of rapid precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0089] Several steels were melted in a high-frequency induction furnace in the open air, adjusted to chemical compositions in Table 1, and cast to ingots of 220 mm×220 mm in section size. In Table 1, Specimen No. 1 to 6 satisfy definitions of the present invention. Specimen No. 11 to 16 are comparative steels, wherein Specimen No. 16 corresponds to JIS SUS440B, used for conventional piston rings.

TABLE 1Chemical compositions (mass %)SpecimenMo +No.CSiMnCrAlSMoWVMo + WW + VCaNiCuCoFe10.421.852.830.250.310.290.50.50.50.00022.960.1bal.20.660.931.210.450.780.132.02.91.24.96.10.00100.22.8bal.30.791.521.980.311.480.067.25.112.312.30.00300.31.1bal.40.982.321.030.211.030.127.510.00.517.518.00.00600.51.3bal.51.422.781.010.011.910.032.93.07.97.90.00982.10.8bal.60.881.551.050.031.031.051.051.10.80.8bal.110.551.490.710.211.02.03.03.00.0003bal.121.000.250.311.481.531.83.45.25.2bal.130.551.510.721.010.354.89.914.714.70.00020.8bal.140.781.230.460.031.340.064.22.16.36.30.00502.53bal.150.551.350.55...

example 2

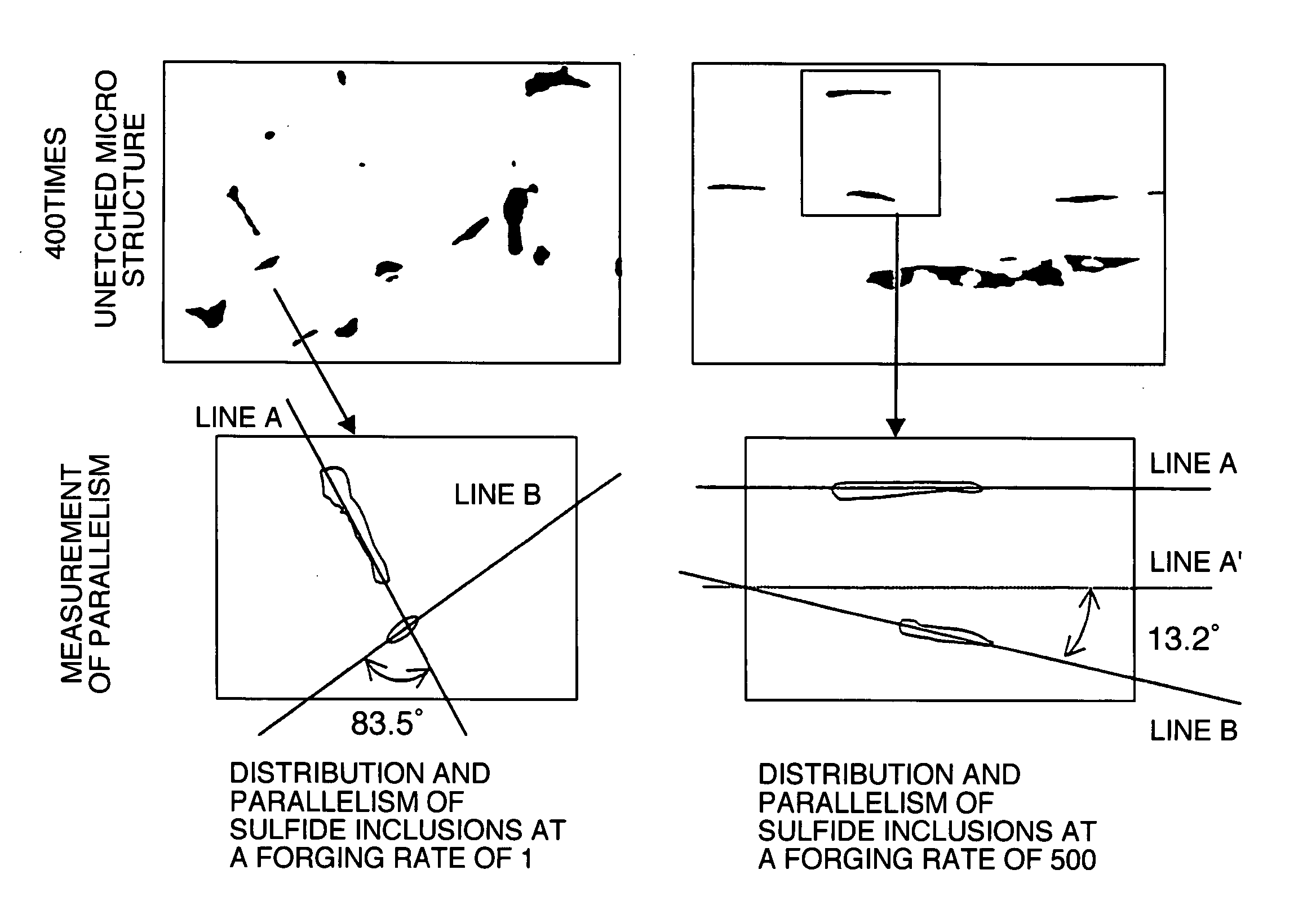

[0098] Each of Specimen No. 1 and 15 in Table 1 was hot-rolled to a coil of 5.5 mm in diameter and then processed to a flat wire profile of 1.5 mm×3.1 mm in section size by drawing and cold-rolling. Specimen No. 1 was formed to the objective profile without troubles, but Specimen No. 15 was broken in a drawing step due to its poor cold-workability. A metal structure of each billet of Specimen No. 1 and 15 was microscopically observed in an undrawn state along a direction perpendicular to a rolling direction and analyzed for measuring the area rate of nonmetallic inclusions. The area rate of nonmetallic inclusions was 1.86% in Specimen No. 1, but 2.23% in Specimen No. 15. Comparison of the observation results indicates that breakage of Specimen No. 15 was caused by excess nonmetallic inclusions at a ratio above 2.0% in addition to excess sulfur.

example 3

[0099] Each of Specimen No. 1 to 6, 11 and 12 was processed to a flat wire profile of 1.5 mm×3.1 mm in section size under the same condition as Example 2, heated 30 minutes at 1000° C., quenched and tempered to hardness of around 510 HV. The processed test piece was machined 10 times by a grinding cutter at a rotational frequency of 10000 r.p.m and a feed rate of 1 mm / second, for investigating occurrence frequency of burrs. Table 4 shows test results on the occurrence frequency of burrs.

TABLE 4SpecimenOccurrence frequency ofNo.burrsNote10Invention20specimens30405067118Comparative1210specimens

[0100] Occurrence of burrs was detected in any of Specimen No. 11 and 12, but no burrs occurred in any of Specimen No. 1-5, to which S was added at a proper ratio. The results prove that addition of S has remarkable effects on suppression of burrs. Consequently, piston rings can be manufactured with high productivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com