Lubrication of a planetary gear device

A planetary gear and transmission device technology, applied in the direction of gear lubrication/cooling, power unit, control device, etc., can solve the problems of introduction and inability to oil, and achieve the effect of improving anti-seizure and reducing power transmission loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

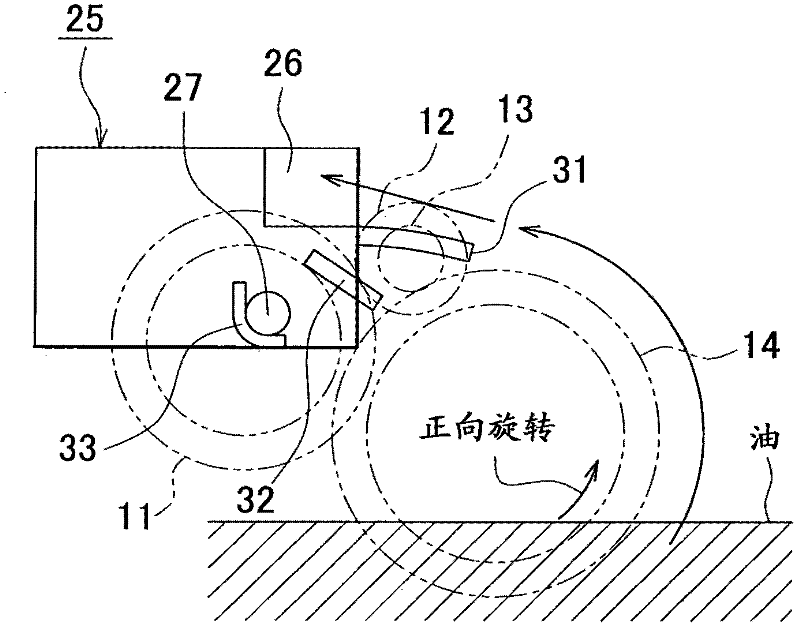

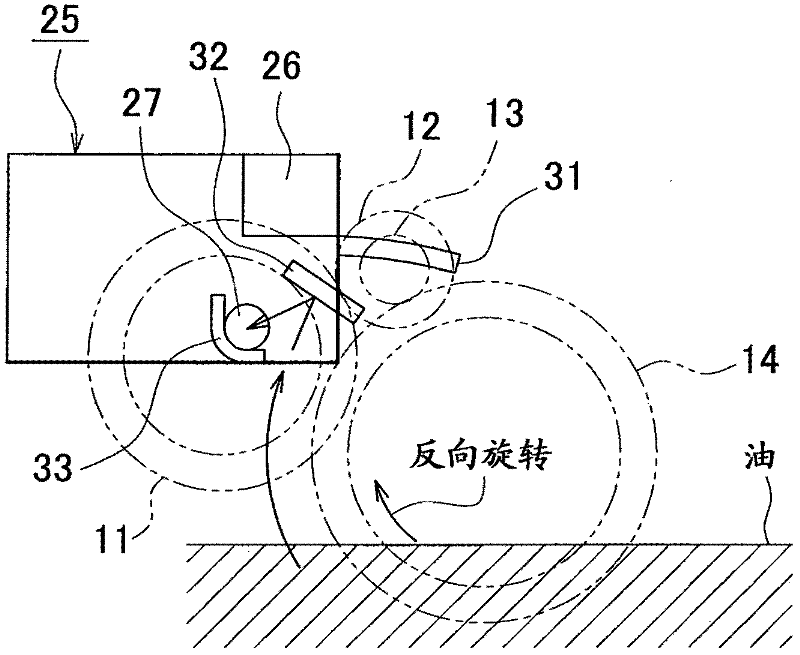

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

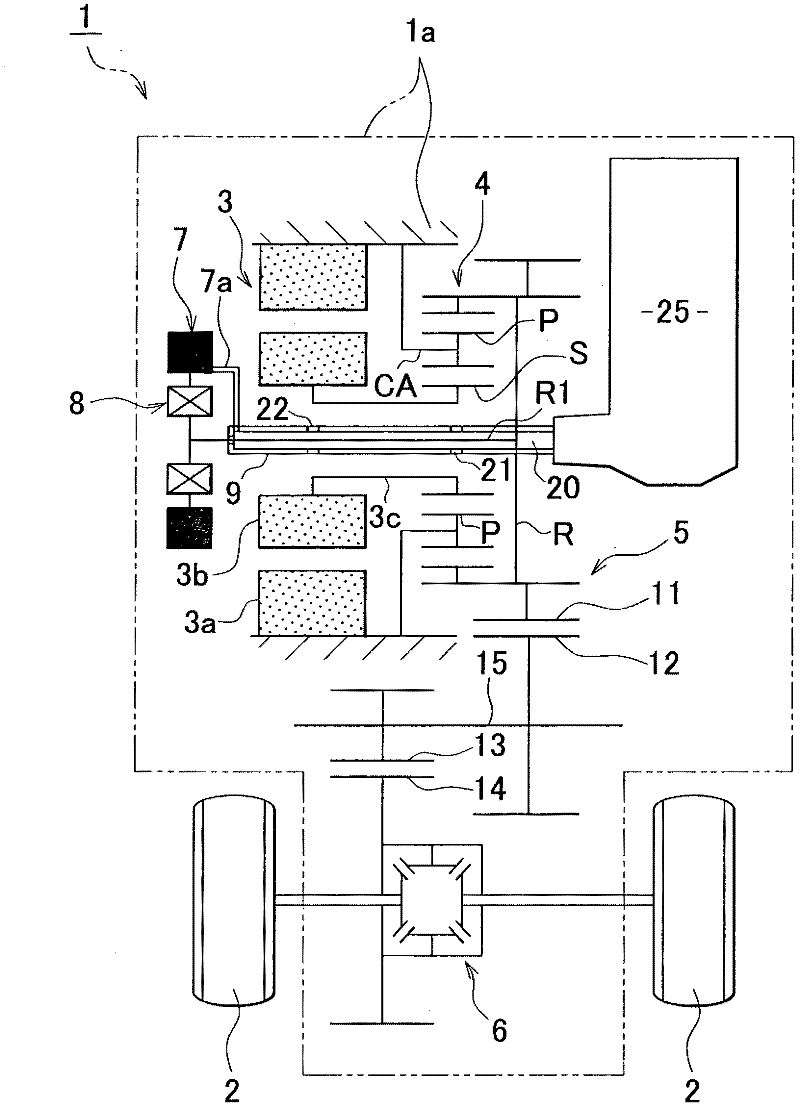

[0035] Figure 1 to Figure 3 An embodiment of the invention is shown in . First, the general structure of a transaxle for an electric vehicle as one embodiment of the vehicle power transmission device according to the present invention will be described.

[0036] figure 1 The transaxle 1 and the wheels 2 are shown in . The transaxle 1 mainly includes an electric motor 3 as a power source, a planetary gear device 4 , a reduction gear mechanism 5 , and a differential device (final drive reducer) 6 .

[0037] This transaxle 1 is configured to transmit the rotational power generated by the electric motor 3 to the differential device 6 via the planetary gear unit 4 and the reduction gear mechanism 5, and to transfer the rotational power from the differential as a forward driving force or a reverse driving force. The device 6 is transferred to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com