Plain bearing

A technology for sliding bearings and bearing alloys, applied in bearings, bearing components, shafts and bearings, etc., can solve problems such as poor adaptability, seizure, and insufficient retention of solid lubricants in the internal strength of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

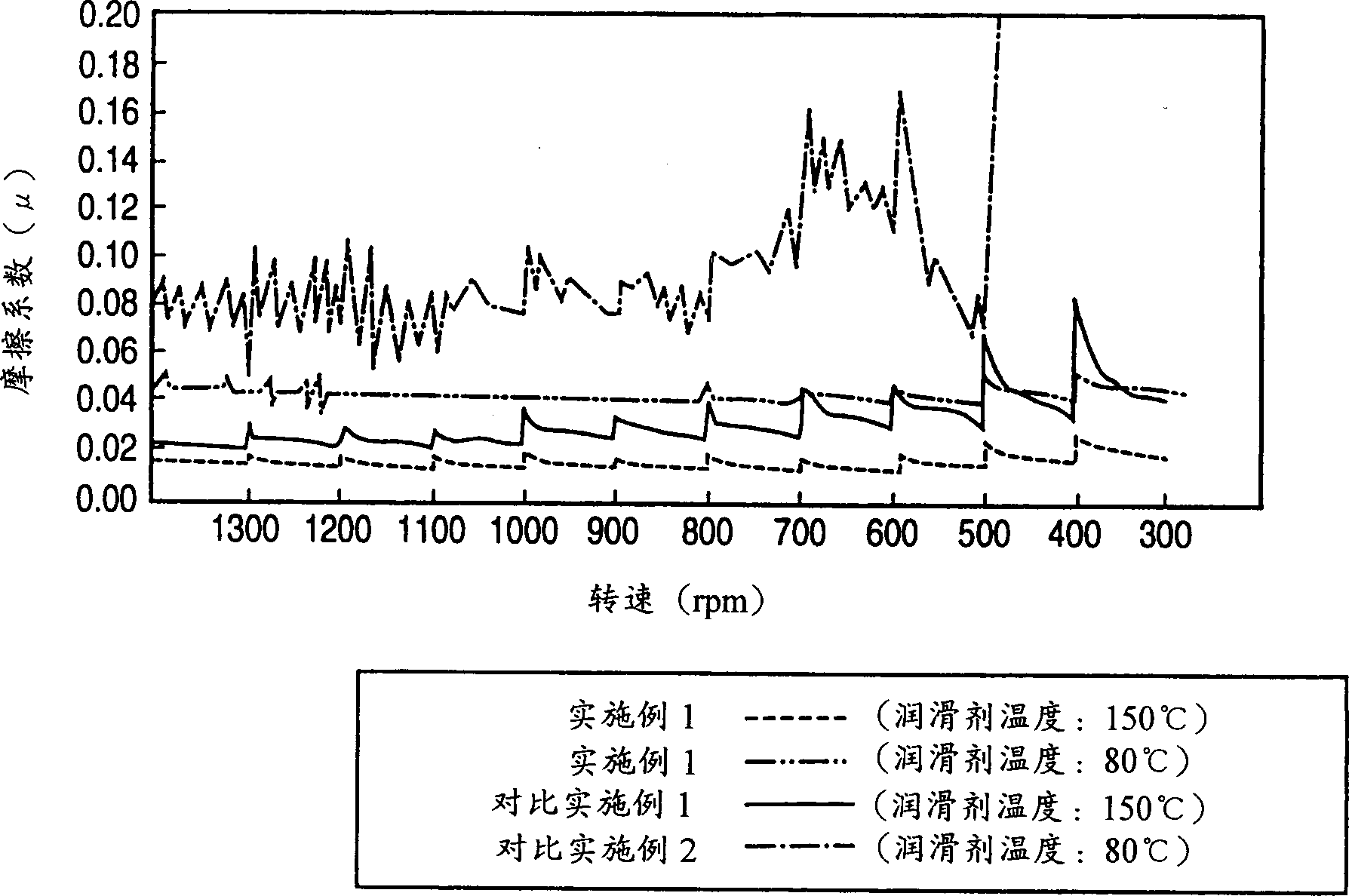

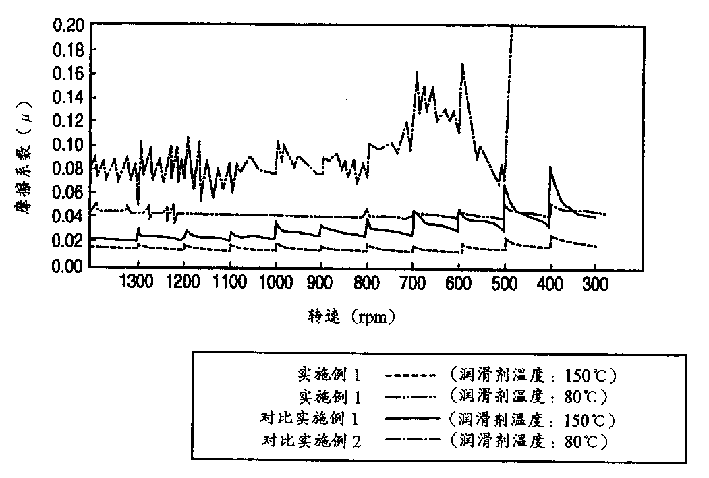

Embodiment 1、 comparative Embodiment 1 and 2

[0046] 60 volume % of polyamide-imide resin A (Hitachi Chemical Co., Ltd. production) as shown in table 1, 40 volume % of molybdenum disulfide as solid lubricant and an appropriate amount of organic solvent (N-methyl- 2-pyrrolidone) was added into the ball mill, and then mixed and ground in the ball mill for 3 hours to prepare a coating solution for forming a resin coating.

[0047] Subsequently, the surface of the bearing in the shape of a semi-cylindrical, etc., containing a liner material made of an aluminum alloy (Al-11Sn-1.8Pb-1Cu-3Si) tightly bonded to a backing steel plate is degreased, and then Sandblasting to obtain a roughness Rz of 1 μm. Subsequently, the above-mentioned coating solution was air-sprayed onto the bearing to a thickness of about 6 μm, and then thermally cured at 180° C. for about 60 minutes to form a resin coating on the bearing. Thus, a sliding bearing (covered with metal) is produced. (Example 1)

Embodiment 2-5 and comparative Embodiment 3 and 4

[0050] Resin coating was formed in the manner of Example 1 to prepare sliding bearings, except that the type and amount of polyamideimide resin (PAI) used were changed, the amount of molybdenum disulfide (MoS2), and optionally used as an extreme pressure additive The amount of zinc sulfide (ZnS) and aluminum oxide (Al 2 o 3 ) consumption, as shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com