Method for crystallizing phenylacetyl-7-amino-3-deacetoxycephalosporanic acid controllable in particle size and crystal habit

A technology of deacetoxy cephalosporanic acid and phenylacetyl, which is applied in the field of crystallization of phenylacetyl-7-amino-3-deacetoxy cephalosporanic acid, and can solve the problem of low product purity, coalescence, unevenness, etc. problems, to achieve the effect of reducing toxic side effects, reducing the water content of impurities, and reducing the generation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

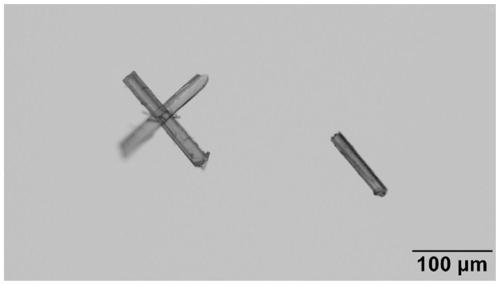

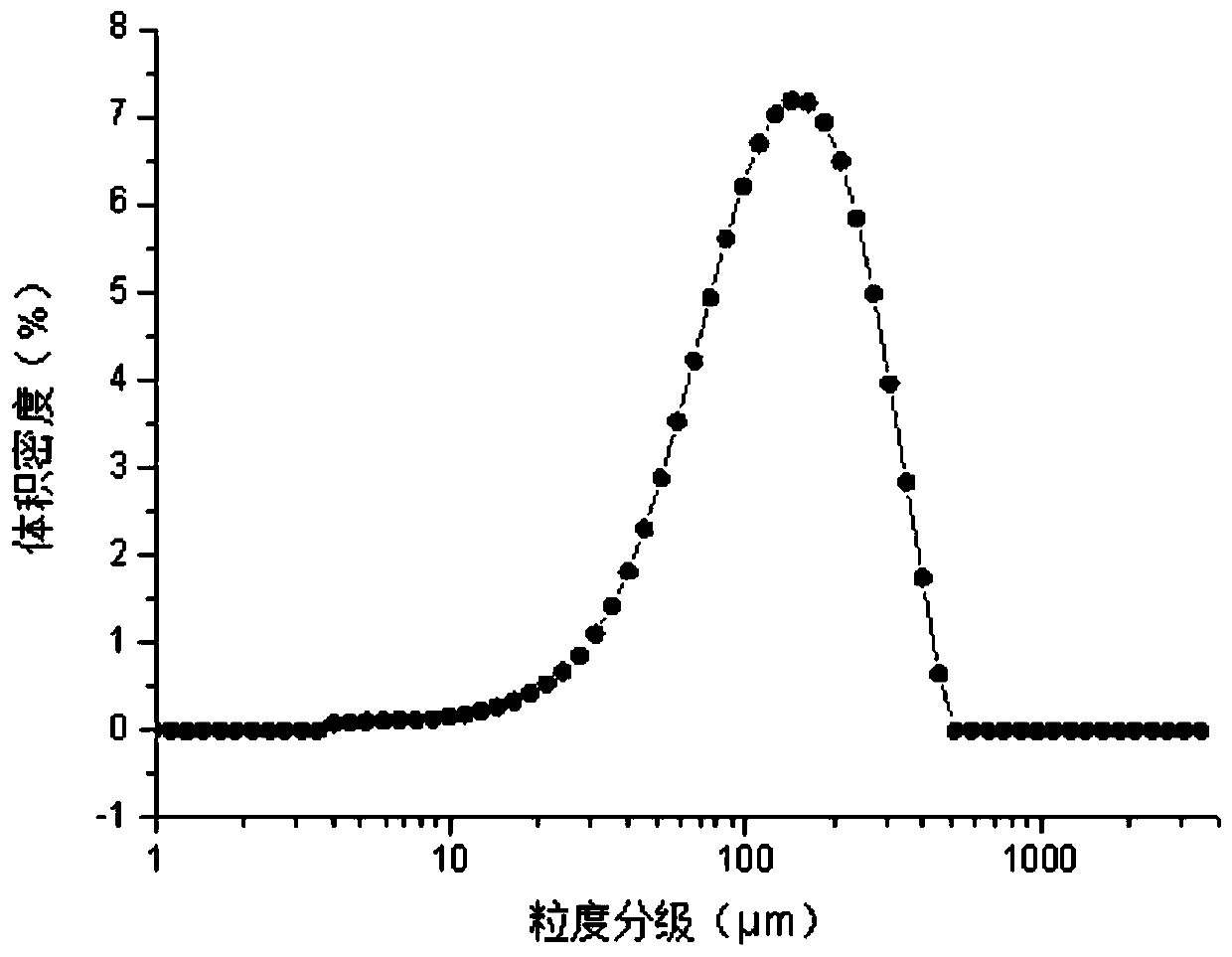

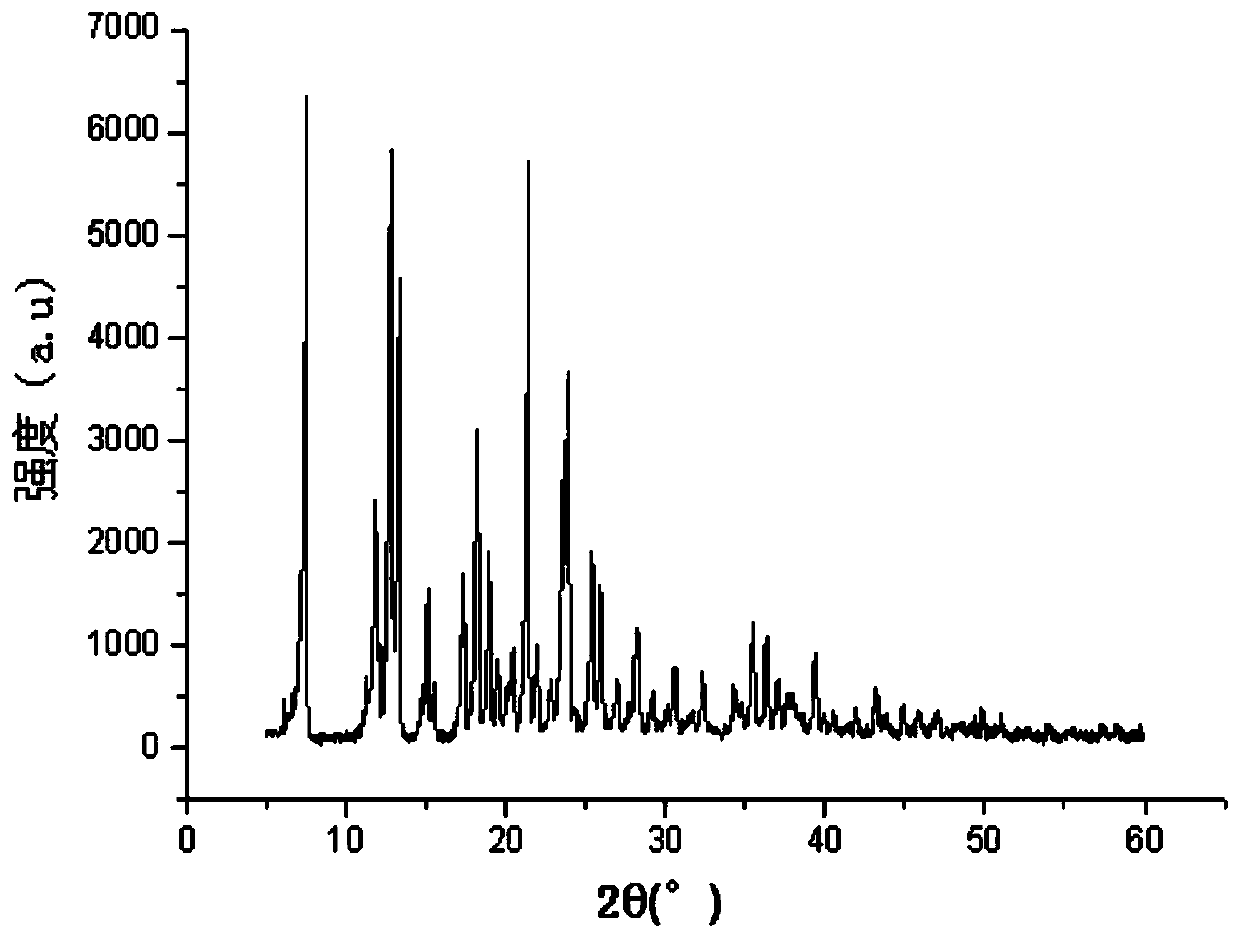

[0035] A crystallization method of phenylacetyl-7-amino-3-desacetoxycephalosporanic acid with controllable particle size and crystal habit:

[0036] Step 1. Weigh 3.02 g of fully dried crude phenylacetyl-7-ADCA and place it in a beaker, add 100 g of dilute ammonia solution with a mass fraction of 1%, stir to dissolve, and filter with a 0.45 μm mixed filter membrane to remove insoluble impurities. Obtain phenylacetyl-7-ADCA solution;

[0037] Step 2. Transfer the phenylacetyl-7-ADCA solution to the jacketed crystallizer, turn on the stirring device, control the rotation speed to 120r / min, turn on the constant temperature water bath device, and control the temperature of the crystallization environment in the jacketed crystallizer to 20°C. Add 0.5mol / L dilute hydrochloric acid solution dropwise to the phenylacetyl-7-ADCA solution at a dropping rate of 0.3mL / min, stop adding dilute hydrochloric acid solution when the pH of the detection system is 2.1, start crystal growth, and th...

Embodiment 2

[0043] A crystallization method of phenylacetyl-7-amino-3-desacetoxycephalosporanic acid with controllable particle size and crystal habit:

[0044] Step 1. Weigh 1 g of fully dried phenylacetyl-7-ADCA crude product and place it in a beaker, add 100 g of dilute ammonia solution with a mass fraction of 0.25%, stir to dissolve, and filter with a 0.45 μm organic filter membrane to remove insoluble impurities to obtain Phenylacetyl-7-ADCA solution;

[0045] Step 2. Transfer the phenylacetyl-7-ADCA solution to the jacketed crystallizer, turn on the stirring device, control the rotation speed to 90r / min, turn on the constant temperature water bath device, and control the temperature of the crystallization environment in the jacketed crystallizer to 5°C. Add 0.25mol / L dilute hydrochloric acid solution dropwise to phenylacetyl-7-ADCA solution at a rate of 0.1mL / min, stop adding dilute hydrochloric acid solution when the pH of the detection system is 3.0, start crystal growth, and the cr...

Embodiment 3

[0049] A crystallization method of phenylacetyl-7-amino-3-desacetoxycephalosporanic acid with controllable particle size and crystal habit:

[0050] Step 1. Weigh 5 g of the fully dried phenylacetyl-7-ADCA crude product and place it in a beaker, add 100 g of dilute ammonia solution with a mass fraction of 3%, stir and dissolve, and filter with a 0.22 μm mixed filter membrane to remove insoluble impurities to obtain Phenylacetyl-7-ADCA solution;

[0051] Step 2. Transfer the phenylacetyl-7-ADCA solution to the jacketed crystallizer, turn on the stirring device, control the rotation speed to 180r / min, turn on the constant temperature water bath device, and control the temperature of the crystallization environment in the jacketed crystallizer to 30°C. Add 1.25mol / L dilute hydrochloric acid solution dropwise to the phenylacetyl-7-ADCA solution at a dropping rate of 0.5mL / min. When the pH of the detection system is 1.5, stop adding the dilute hydrochloric acid solution and start c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com