Ultrasonic-assisted coenzyme Q10 crystallizing method

An ultrasound and coenzyme technology, applied in organic chemistry, quinone separation/purification, etc., can solve the problems of small number of crystal seeds, no description of product crystal shape indicators, and insufficient elimination of explosive nucleation, etc., to achieve uniform distribution, easy filtration and The effect of shortening the drying and crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

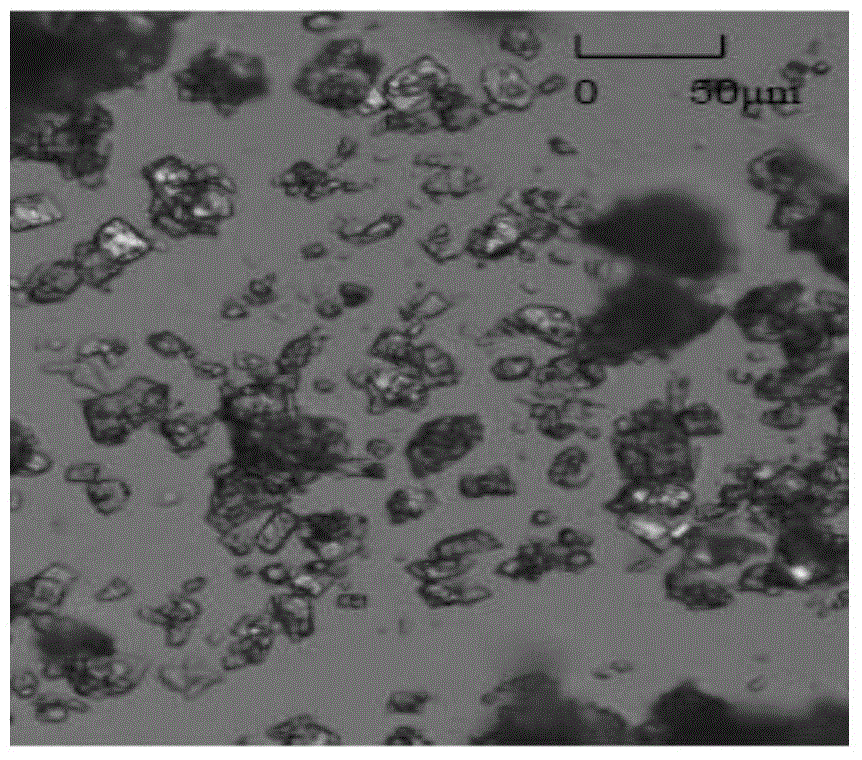

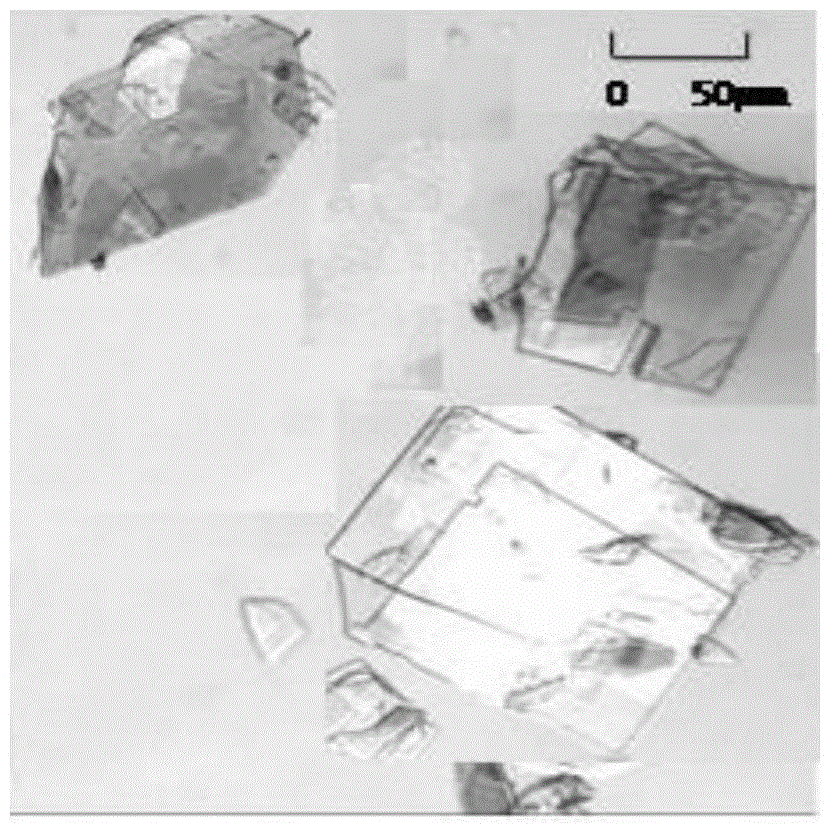

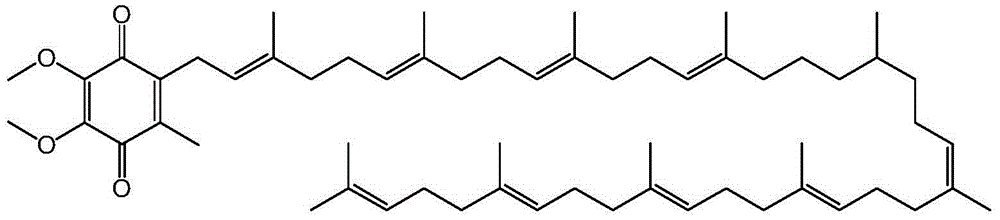

Embodiment 1

[0022] Take 95% pure coenzyme Q 10 200g of the crude product and 600g of isopropanol were stirred and heated to 60°C under the protection of nitrogen and protected from light to form a uniform solution. Then cooling crystallization was carried out, and the temperature of the solution was lowered to 38° C. at a cooling rate of 20° C. / hour. At this time, 30kHz 800W (1000W / kg solution) ultrasonic waves were used to assist crystallization for 10 minutes, and then the temperature was lowered to 20°C at a rate of 10°C / hour. After filtering, washing with 95% ethanol and drying, the coenzyme Q 10 The crystal product is 173.01g, the yield is 91.0%, the purity is 99.2%, and the main particle size is 80.2μm. The product has large particle size, good fluidity, no agglomeration phenomenon, and is easy to use.

Embodiment 2

[0024] Take 90% pure coenzyme Q 10 150 g of the crude product, 600 g of 95% ethanol, stirred and heated to 55° C. under the protection of nitrogen and protected from light, completely dissolved to form a uniform solution. Then cooling crystallization was carried out, and the temperature of the solution was lowered to 36° C. at a cooling rate of 10° C. / hour. At this time, 20kHz 150W (200W / kg solution) ultrasonic waves were used for 30 seconds to assist crystallization for 5 minutes, and then the temperature of the solution was lowered to 13° C. at a cooling rate of 8° C. / hour. After filtering, washing with n-propanol and drying, the coenzyme Q 10 The crystal product is 124.68g, the yield is 92.3%, the purity is 99.6%, and the main particle size is 62.7μm. The product has large particle size, good fluidity, no agglomeration phenomenon, and is easy to use.

Embodiment 3

[0026] Take 92% pure coenzyme Q 10 200g of the crude product and 500g of ethyl acetate were stirred and heated to 60°C under the protection of nitrogen and protected from light to form a uniform solution. Then cooling crystallization was carried out, and the temperature of the solution was lowered to 40° C. at a cooling rate of 15° C. / hour. At this time, 40kHz 350W (500W / kg solution) ultrasonic waves were used for 15 seconds to assist crystallization for 20 minutes, and then the temperature of the solution was lowered to 15° C. at a cooling rate of 15° C. / hour and maintained for 1 hour. After filtering, washing with absolute ethanol and drying, the coenzyme Q 10 The crystal product is 171.02g, the yield is 92.9%, the purity is 99.3%, and the main particle size is 55.3μm. The product has large particle size, good fluidity, no agglomeration phenomenon, and is easy to use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com