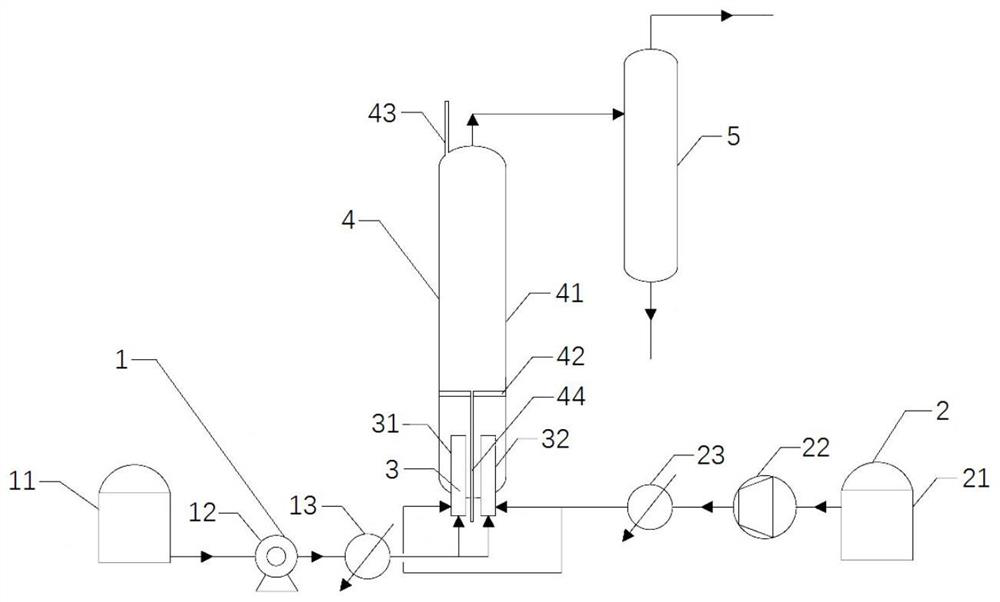

Alkane dehydrogenation reaction strengthening system and method

A technology for alkane dehydrogenation and alkane, which is applied in the field of strengthening systems for alkane dehydrogenation reaction, can solve the problems of low oxidation efficiency, insufficient mixing of oxygen and alkane, etc., to ensure reaction rate, reduce gas consumption, and reduce gas-liquid ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Cyclooctane is dehydrogenated using the method described above and using the system wherein:

[0089] The catalyst in the reactor is a chromium catalyst, the temperature is 400° C., and the pressure is 0.01 atm.

[0090] Analysis of the reacted product shows that the conversion rate of unsaturated alkanes in this example is 30.3%, and the selectivity is 96.2%.

Embodiment 2

[0092] Undecane is dehydrogenated using the method described above and using the system wherein:

[0093] The catalyst is a chromium oxide catalyst, the temperature is 550° C., and the pressure is 1.55 atm.

[0094] Analysis of the reacted product shows that the conversion rate of unsaturated alkanes in this example is 29.9%, and the selectivity is 95.8%.

Embodiment 3

[0096] Octadecane is dehydrogenated using the method described above and using the system, wherein:

[0097] The catalyst in the reactor is a chromium oxide catalyst, the temperature is 600° C., and the pressure is 3 atm.

[0098] Analyzing the products after the reaction, it can be obtained that the conversion rate of unsaturated alkanes in this example is 28.6%, and the selectivity is 93.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com