Pickering double emulsion with interface stabilized by solid lipid as well as preparation and application of Pickering double emulsion

A technology of solid fat and double emulsion, which is applied in the fields of application, production/processing of edible oil/fat, food ingredients containing fat, etc. It can solve the problems of human health hazards and poor stability, reduce the release rate and increase the long-term Physical stability, the effect of reducing the amount of oil used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

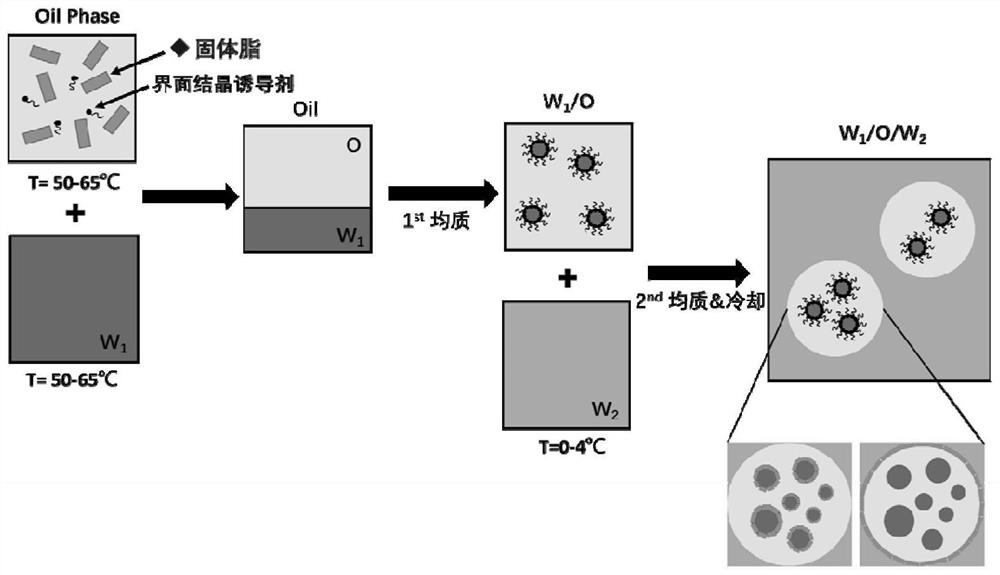

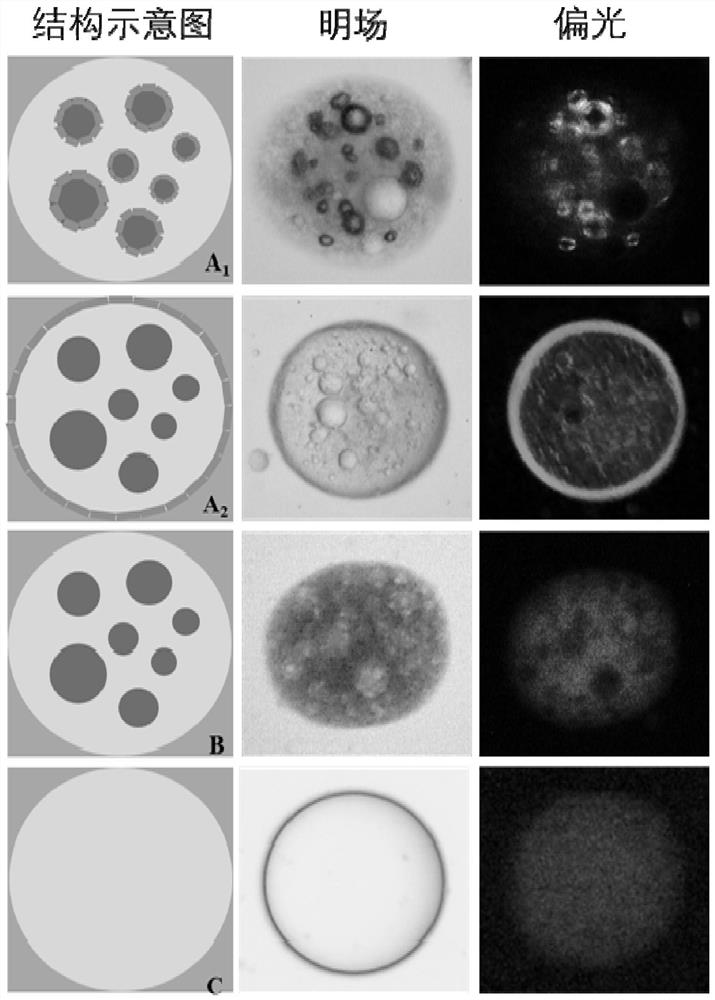

Method used

Image

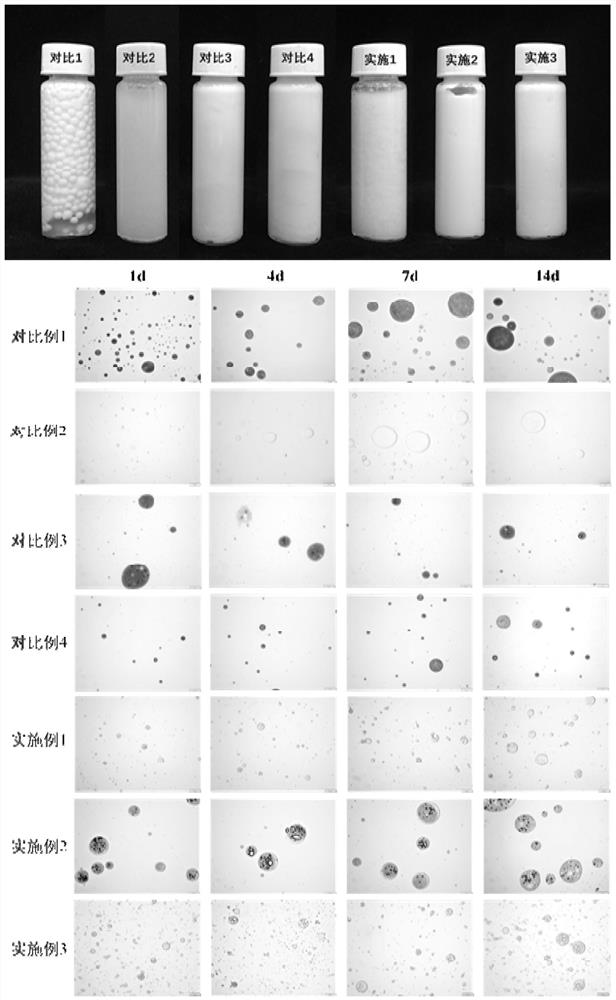

Examples

Embodiment 1

[0060] The preparation of embodiment 1 Pickering double emulsion

[0061] (1) Preparation of 0.01mol / L, pH 5.7 citric acid-sodium citrate buffer: Weigh 0.025g of citric acid and 0.112g of sodium citrate into 10mL of deionized water. Dilute the water to 50mL, adjust the pH value to 5.7 with 0.01mol / L hydrochloric acid solution, store in a refrigerator at 4°C, and set aside;

[0062] (2) Water phase W in the gel 1 Preparation: Add 0.1g of sodium alginate to 20mL of citric acid-sodium citrate buffer, fully stir until dissolved under magnetic stirring conditions, and then add 25% (v / v) of the concentration of 5mg / mL CaCl 2 Solution, get 0.4wt% sodium alginate gel, which is the inner water phase W 1 ;

[0063] (3) Preparation of solid fatty oil phase O: Add 1 mL of monoglyceride laurate heated to 60°C into 20 mL of isothermal soybean oil to obtain 5% (w / v) monoglyceride laurate; then add 0.4 mL polyglyceride laurate Glycerol ricinoleate, to obtain 2% (w / v) polyglycerol ricinol...

Embodiment 2

[0068] Embodiment 2 interface is by the preparation of the Pickering double emulsion that solid fat stabilizes

[0069] (1) Preparation of 0.01mol / L acetic acid-sodium acetate buffer solution with a pH of 4: Measure 200mM acetic acid, 41mL and 9mL sodium acetate respectively, add them to 50mL deionized water, and store at 4°C after fully mixing refrigerator, spare;

[0070] (2) Inner water phase W 1 Preparation: Add 0.2g ι-carrageenan to 20mL acetic acid-sodium acetate buffer solution, fully stir until dissolved under magnetic stirring conditions, and then add 25% (v / v) at a concentration of 50mg / mL of CaSO 4 solution, to obtain 0.8wt% iota-carrageenan gel, which is the inner aqueous phase W 1 ;

[0071] (3) Preparation of oily phase O: Add 2 mL of monoglyceride stearate heated to 65° C. into 20 mL of isothermal soybean oil to obtain 10% (w / v) monoglyceride stearate; add 0.2 mL Polyglycerol ricinoleate, to obtain 1% (w / v) polyglycerol ricinoleate, stir with 500rpm magnet...

Embodiment 3

[0076] Embodiment 3 interface is by the preparation of the Pickering double emulsion that solid fat stabilizes

[0077] (1) Preparation of 0.01mol / L, pH 6.5 phosphate buffer solution: Measure 2M disodium hydrogen phosphate, sodium hydrogen phosphate solution 68.5mL and 31.5mL into 50mL deionized water respectively, after fully mixing, Store in a 4°C refrigerator for later use;

[0078] (2) Inner water phase W 1 Preparation: Add 0.06g of low-methoxyl pectin to 20mL of phosphate buffer, fully stir until dissolved under magnetic stirring conditions, and then add 25% (v / v) at a concentration of 10mg / mL of CaCO 3 solution, to obtain 0.024wt% methoxy pectin gel, which is the inner water phase W 1 ;

[0079] (3) Preparation of oil phase O: Add 1 mL of monoglyceride laurate and 1 mL of hydrogenated palm oil heated to 60° C. into 20 mL of isothermal olive oil to obtain 5% (w / v) monoglyceride laurate and 5% (w / v) hydrogenated palm oil; then add 0.2mL polyglycerol ricinoleate to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com