Low-cholesterol steak and manufacturing method thereof

A low-cholesterol, production method technology, applied in food ingredients as odor improvers, food ingredients as taste improvers, functions of food ingredients, etc., can solve problems such as high cholesterol and thick meat fiber, and achieve easy chewing and tender meat The effect of smooth and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method of low-cholesterol steak of the present embodiment comprises the following steps:

[0022] Step 1: Thaw the beef, and control the temperature of the center of the beef at -2 to 5°C during the thawing process;

[0023] Step 2: Remove the fat layer and fascia layer on the surface of the raw material, slice the beef, and control the thickness of the slice between 1 and 4 cm;

[0024] Step 3: Sorting the meat slices, removing blood congestion and bone fragments, and removing thick tendons. After sorting, the meat slices are squeezed and massaged with equipment in turn;

[0025] Step 4: Put the squeezed and massaged meat slices into a vacuum tumbler, add pickling solution and vacuum tumble. When tumbling, the vacuum degree is 0.05MPa-0.1MPa, the temperature is 0-8°C, the rotation speed is 40rpm, the tumbling time is 20-50min, and the tumbling is completed and rested for 10-20 minutes.

[0026] Wherein, 70-90 parts of beef, 30-10 parts of pickli...

Embodiment 2~4

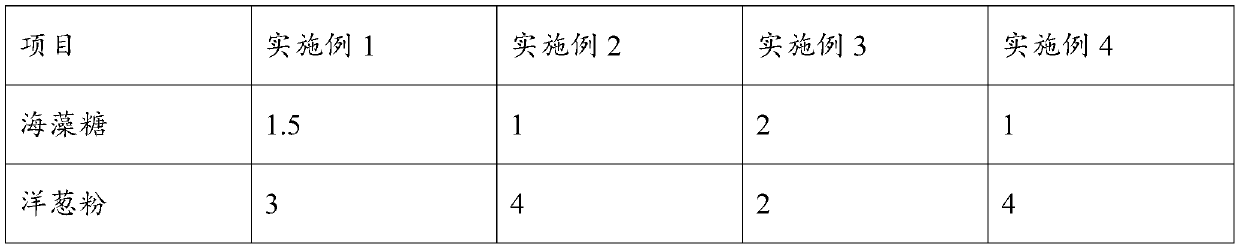

[0030] In Examples 2-4, the amounts of trehalose, onion powder, black garlic paste, and lemon juice in the marinade were adjusted, and the rest were the same as in Example 1.

[0031] Table 1

[0032]

[0033]

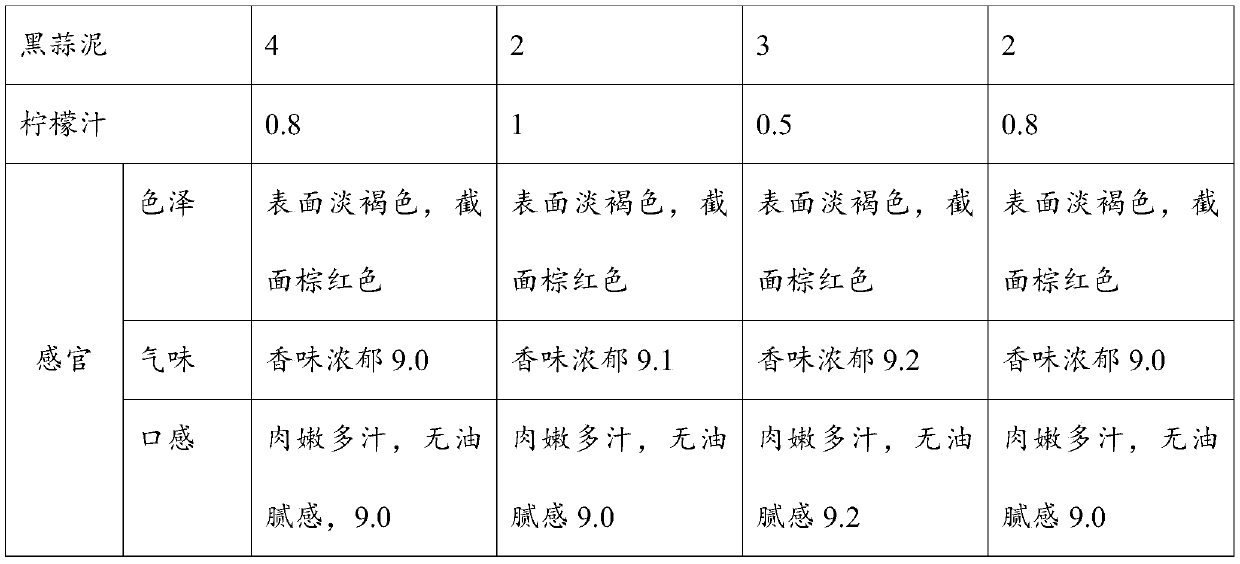

[0034] 1. The effect of pickling solution on the quality of steak

[0035] Table 2 The influence of some components in the pickling solution on the quality of steak

[0036]

[0037] The sensory evaluation scores in the above table are the average scores, among which the smell and taste are the main scoring items, and the full score is 10 points. The higher the score, the better the quality. The specific scores are as follows:

[0038] Table 3 Reference scores of odor items

[0039]

[0040] Table 4 Reference scores for mouthfeel items

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com