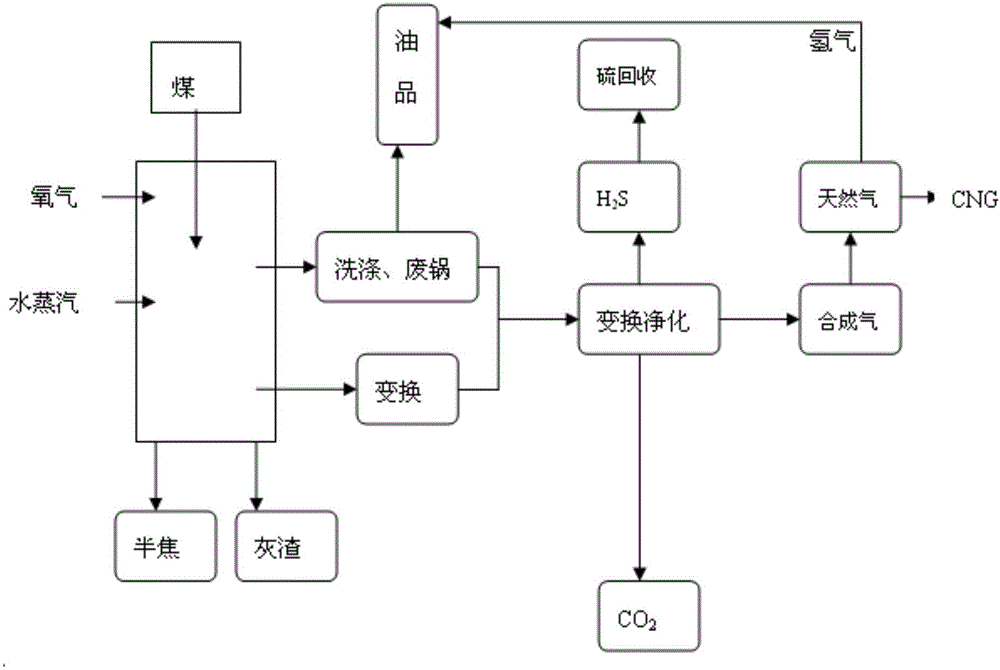

Method and system for preparing gas by fixed bed gasifier

A technology of fixed bed gasifier and gasification agent, applied in the field of coal chemical industry, can solve problems such as environmental pollution and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

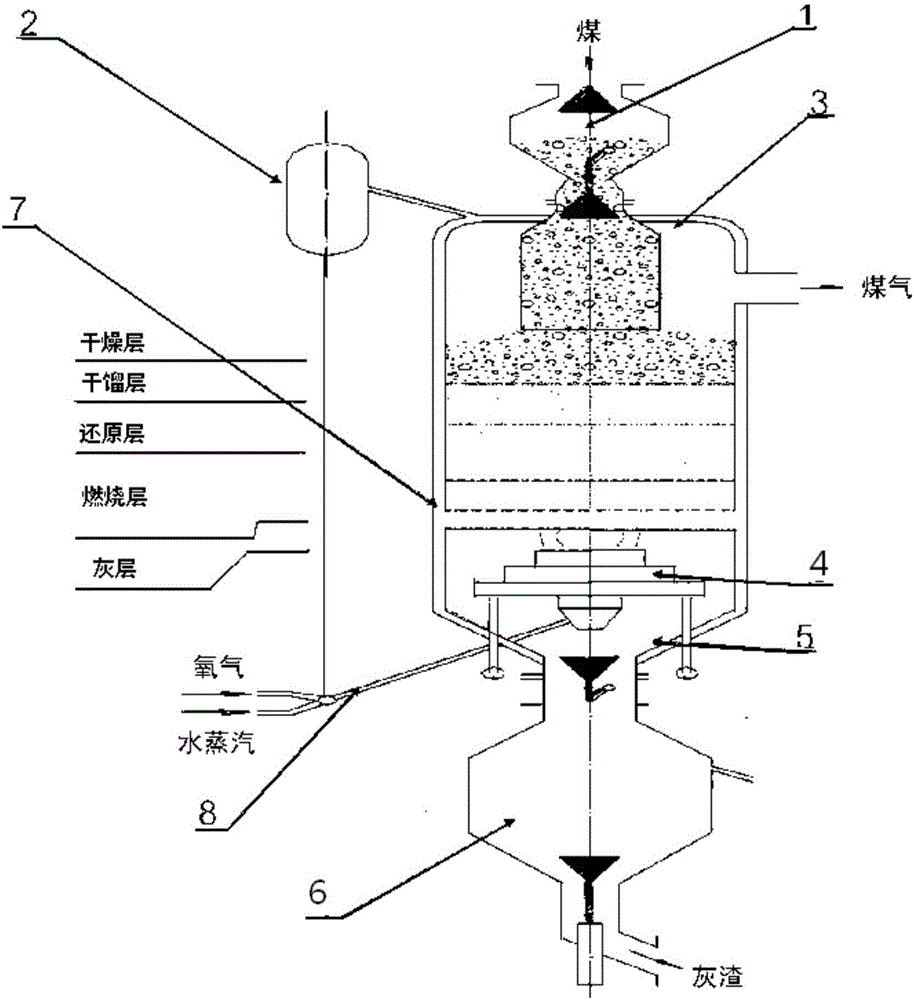

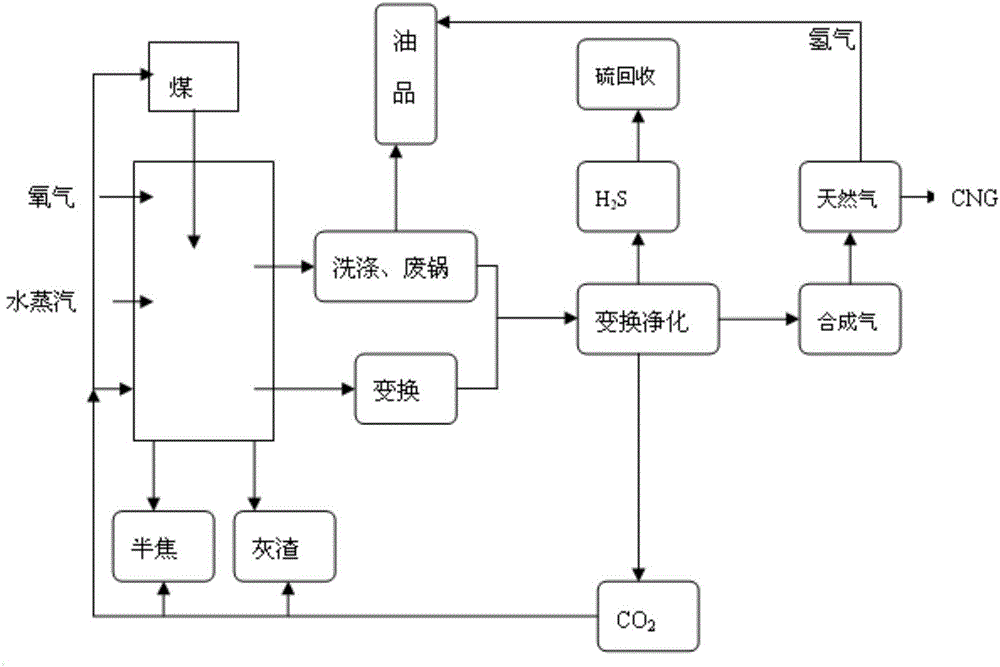

[0088] The gas system includes: a coal lock connected to a carbon dioxide waste gas pressurization pipeline;

[0089] The top of the fixed-bed gasifier body is connected to the coal lock, the lower part of the fixed-bed gasifier body is connected to a gasification agent pipeline, and the upper part has a crude gas outlet; the gasification agent pipeline has a steam inlet, so The lower part of the fixed-bed gasifier body is provided with a carbon dioxide waste gas inlet before the steam inlet;

[0090] an ash lock connected to the bottom of the fixed-bed gasifier body;

[0091] A desulfurization and decarbonization purification unit connected to the crude gas outlet of the fixed-bed gasifier body, the desulfurization and decarbonization purification unit has a synthesis gas outlet and a carbon dioxide waste gas outlet; the carbon dioxide waste gas outlet of the desulfurization and decarbonization purification unit is respectively connected to the The carbon dioxide waste gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com