Hard coating toughening structure and toughness evaluation method

A hard coating and coating technology, applied in the direction of coating, metal material coating technology, strength characteristics, etc., to achieve the effects of wide application range, convenient and easy design, and intuitive and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

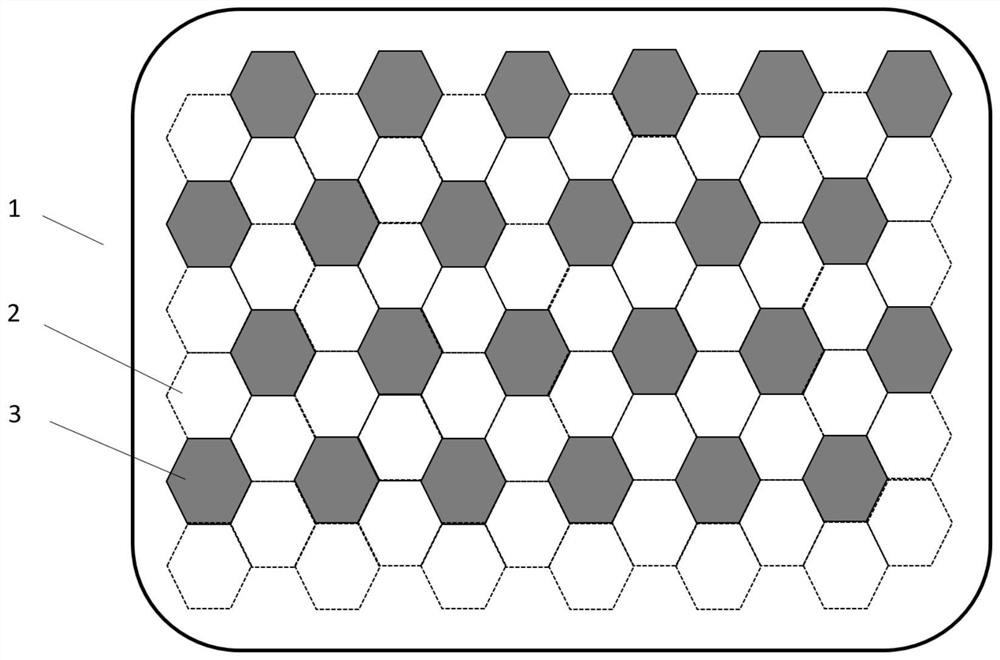

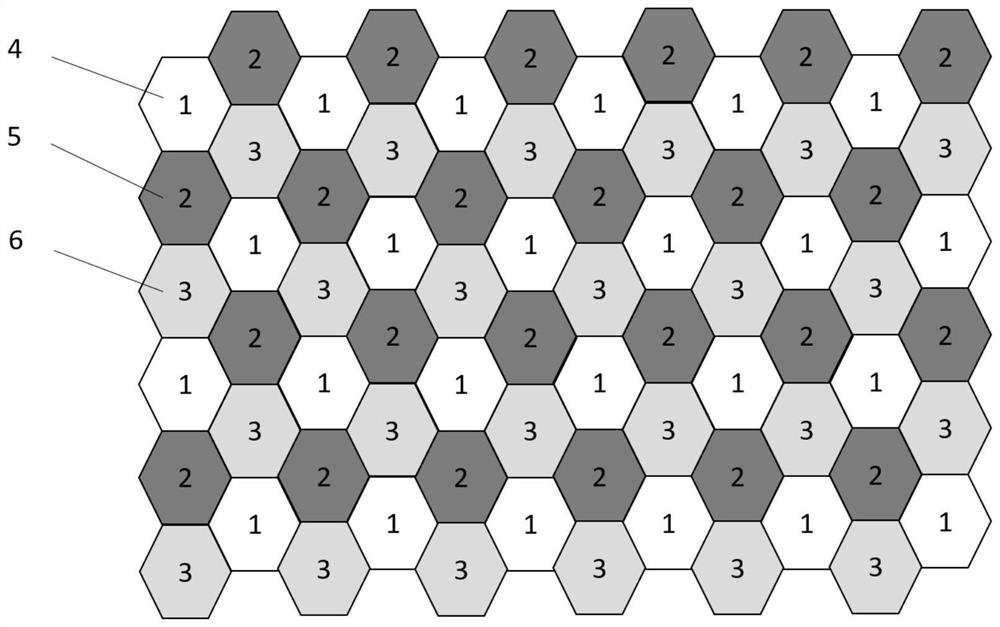

[0034] In order to illustrate the design and toughening method of the multi-layer hexagonal structure of the hard coating, the ultra-thick CrN coating was prepared by applying the magnetic filtered cathodic vacuum arc deposition system (FCVA) on the steel substrate as an example. .

[0035] According to the characteristics of the CrN coating process, the deposition process is described as follows:

[0036] (1) After grinding and polishing, the surface roughness of the substrate reaches 0.07±0.03μm. Put the processed substrate into an ultrasonic container filled with acetone solution for ultrasonic cleaning for 30 min, and then add ethanol for ultrasonic cleaning for 20 min. Blow dry after cleaning.

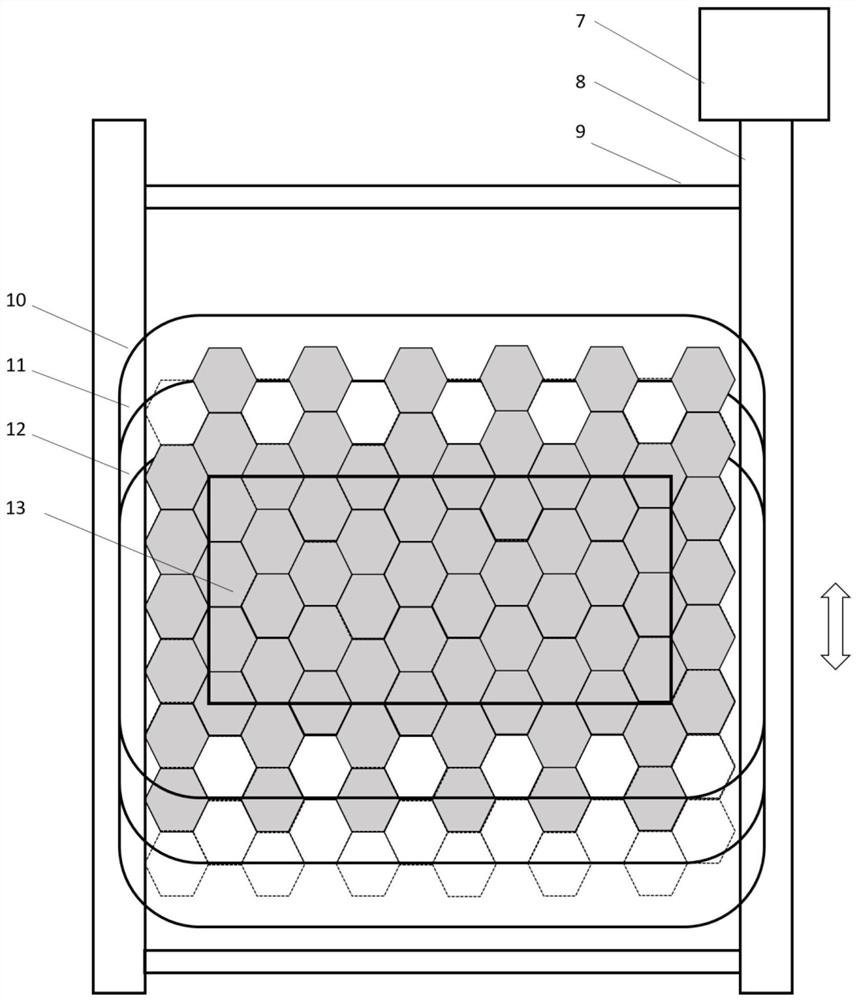

[0037] (2) Put the hexagonal structure baffle drive mechanism into the vacuum chamber of the FCVA system, such as image 3 shown. Mount the matrix on the sample stage of the FCVA system.

[0038] (3) After vacuuming, the degree of vacuum is 2.5×10 -3MPa, start Cr deposition,...

Embodiment 2

[0049] This example presents a specific implementation method of toughness assessment.

[0050] Taking the ultra-thick CrN coating prepared in Example 1 as an example, the description is as follows:

[0051] (1) The end faces A and B of the sample substrate 19 are polished to mirror surfaces and then butted together, and the surface roughness of the end faces A and B is less than 0.07 μm. into fixture 21, as in Figure 7 shown. Put the sample bottom plate 26 into the back of the substrate, and tighten the substrate fixing bolts 24 to ensure that the surface of the substrate where the coating is deposited is flat. The mounting holes of the fixture 22 are fixed on the sample stage where the coating is deposited.

[0052] (2) Deposit a CrN coating on the substrate to obtain Image 6 Coated substrate test sample 20 is shown.

[0053] (3) Loading the sample 20 Figure 9 Testing was performed on the coating toughness testing apparatus shown. First put the sample on the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com