High solid content aqueous ceramic slurry and processing method of lithium ion battery separator

A lithium-ion battery, high solid content technology, used in battery pack parts, circuits, electrical components, etc., can solve the problems of diaphragm volume change, diaphragm shrinkage, low efficiency, etc., to improve production efficiency, improve efficiency, and reduce energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

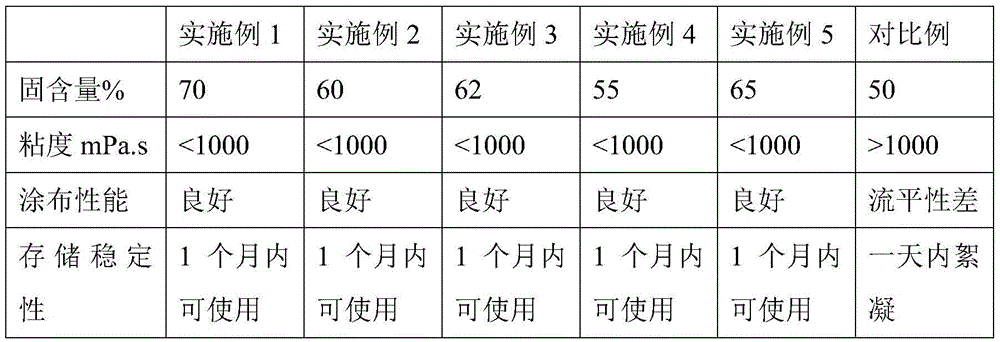

Examples

Embodiment 1

[0038]A high-solid-content water-based ceramic coating for lithium-ion batteries: comprising 65% of the composition calculated by weight percentage and 50% of water; wherein, the composition includes 5 parts of polyacrylic acid emulsion thickener calculated by weight percentage, carbon 12 parts of nanotubes, 5 parts of water-based dispersant polyethylene glycol, 5 parts of water-based wetting agent alkylphenol polyoxyethylene ether, 10 parts of water-based latex polymethyl methacrylate and D50 is 4μm, BET is 2m 2 80 parts per gram of silicon dioxide granules and ceramic granules.

[0039] The method for preparing described high solid content aqueous ceramic slurry; comprises following preparation steps:

[0040] (1), said amount of deionized water is first added to the pre-mixing tank, adjust the pH value to 8-9, add the amount of polymer emulsion thickener polyacrylic acid emulsion, water-based dispersant polyethylene glycol, stir Until the dissolution is complete, the mixtu...

Embodiment 2

[0044] A high-solid content water-based ceramic coating for lithium-ion batteries: comprising 55% of the composition and 45% of water calculated by weight percentage; wherein, the composition includes 3 parts of polymethacrylic acid emulsion thickener calculated by weight percentage , water-based dispersant sodium polyacrylate 0.2 parts, water-based wetting agent fatty alcohol polyoxyethylene ether 0.2 parts, water-based latex polybutylmethacrylate 2 parts and D50 is 0.8μm, BET is 8m 2 100 parts / g aluminum oxide ceramic particles.

[0045] The method for preparing the high-solid content water-based ceramic slurry is the same as in Example 1, except that the dispersion speed is 60 r / min.

Embodiment 3

[0047] A high solid content water-based ceramic coating for lithium-ion batteries: comprising 60% of the composition calculated by weight percentage and 40% of water; wherein, the composition includes 0.5 parts of polyacrylate copolymer emulsion thickener calculated by weight percentage , water-based dispersant potassium polyacrylate 3 parts, water-based wetting agent fatty acid polyoxyethylene ether 1 part, water-based latex polyethyl acrylate 8 parts and D50 is 0.6μm, BET is 12m 2 85 parts / g boehmite ceramic particles.

[0048] The method for preparing the high-solid content water-based ceramic slurry is the same as in Example 1, except that the dispersion speed is 40 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com