Support structure outside deep foundation pit

A support structure and external support technology, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of high cost, long construction period, and difficult construction of deep foundation pit support structures, so as to avoid poor water stop effect and save energy. Quantity, effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

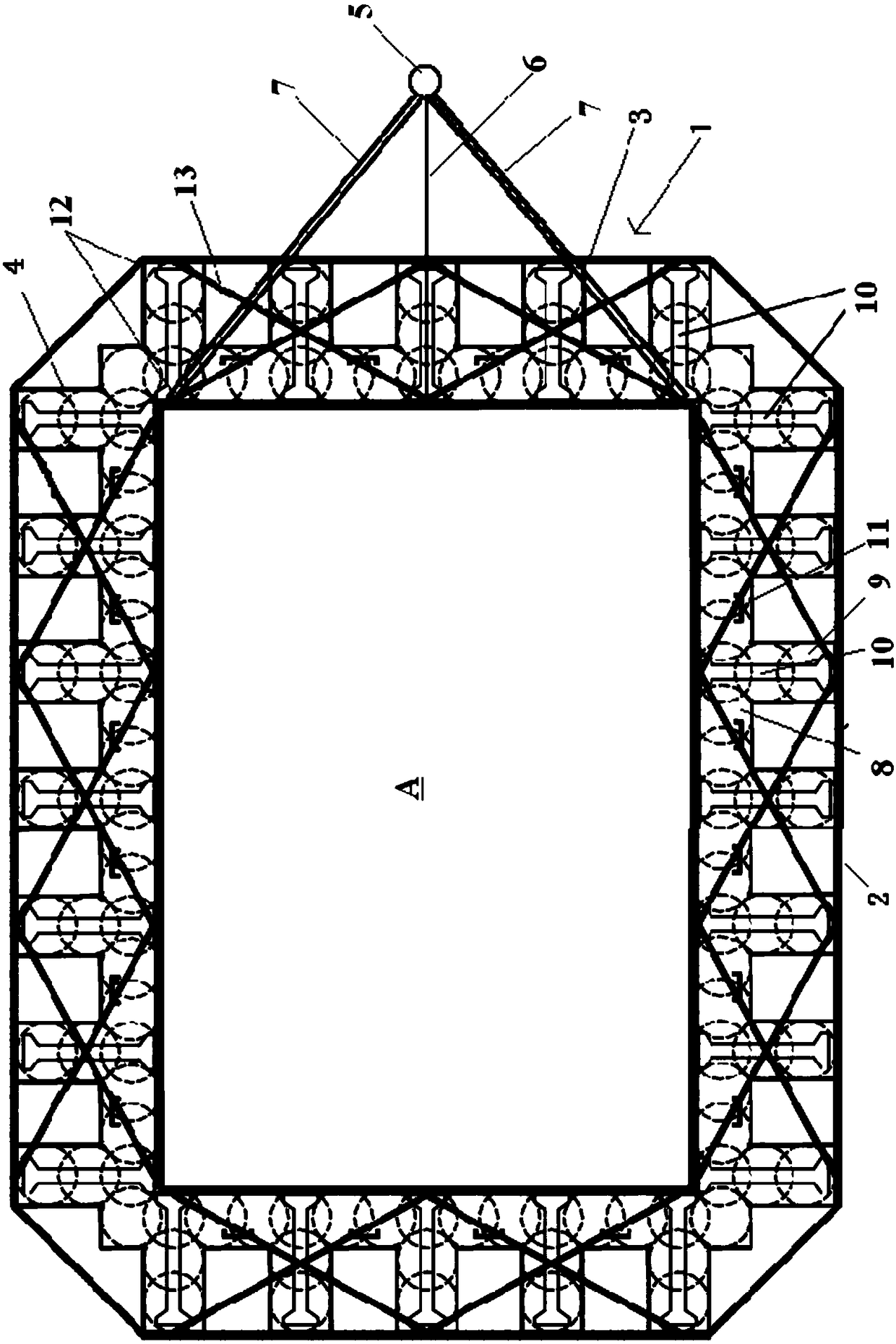

[0030] Such as figure 1 As shown, the external support structure of the deep foundation pit of this embodiment includes: an annular retaining wall structure 1, which is used to realize the function of earth retaining and / or water stop of the foundation pit A; wherein, the annular retaining wall structure 1 includes at least the first A retaining wall part 2, a second retaining wall part 3 and a third retaining wall part 4, the first retaining wall part 2 and the third retaining wall part 4 are connected to the second retaining wall part 3 respectively; The first retaining wall part 2, the second retaining wall part 3 and the third retaining wall part 4 respectively realize soil retaining and / or water sealing in different directions; and also include: a support structure 5 located at the annular retaining wall The outer side of the foundation pit of the structure 1; the tensile member 6 is connected with the support structure 5 and the second retaining wall part 3 respectively,...

Embodiment 2

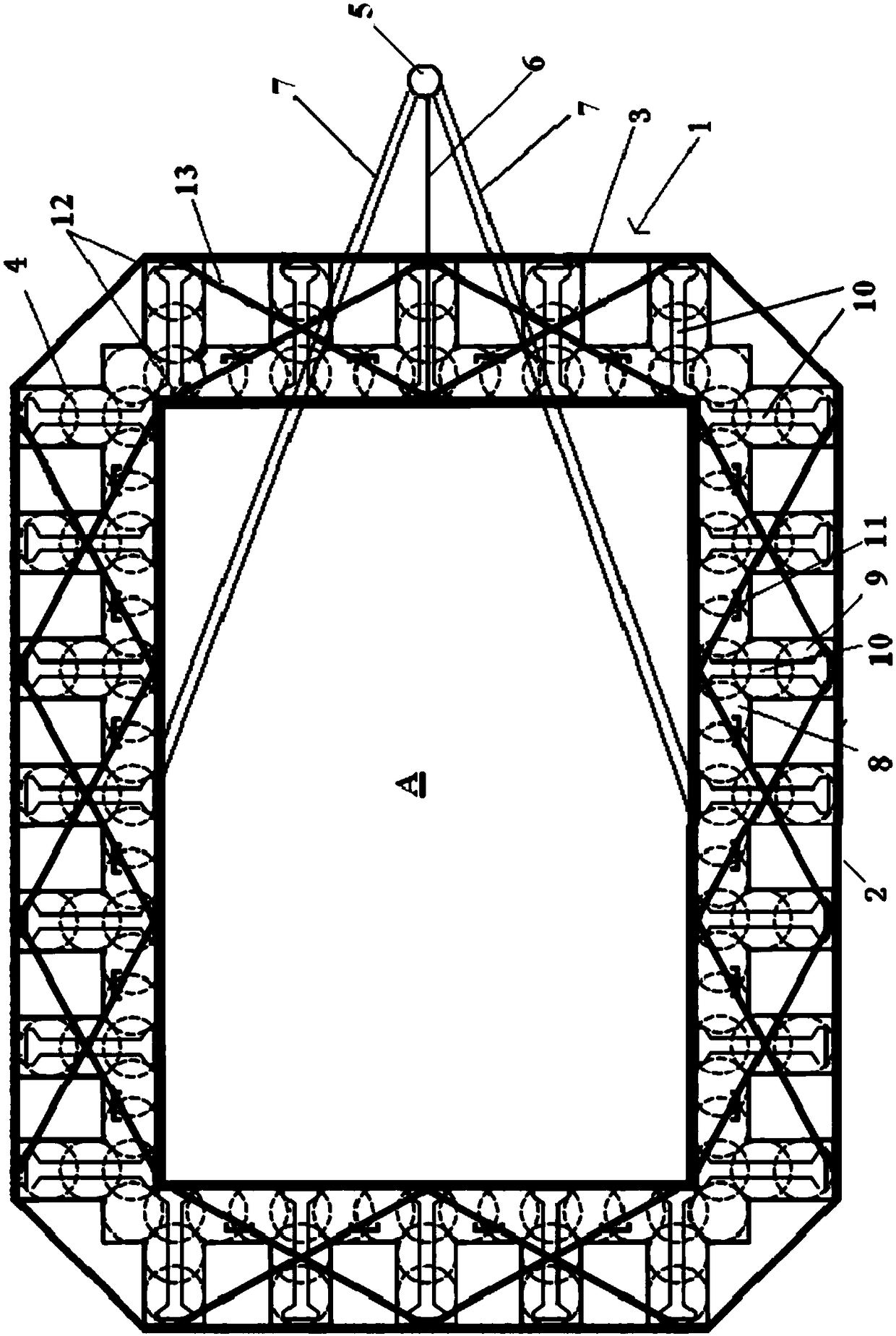

[0039] Such as figure 2 As shown, the difference between the deep foundation pit external support structure of this embodiment and that of Embodiment 1 is that the pressure-bearing parts 7 are respectively connected to the middle parts of the first retaining wall part 2 and the third retaining wall part 4 , forming a support.

Embodiment 3

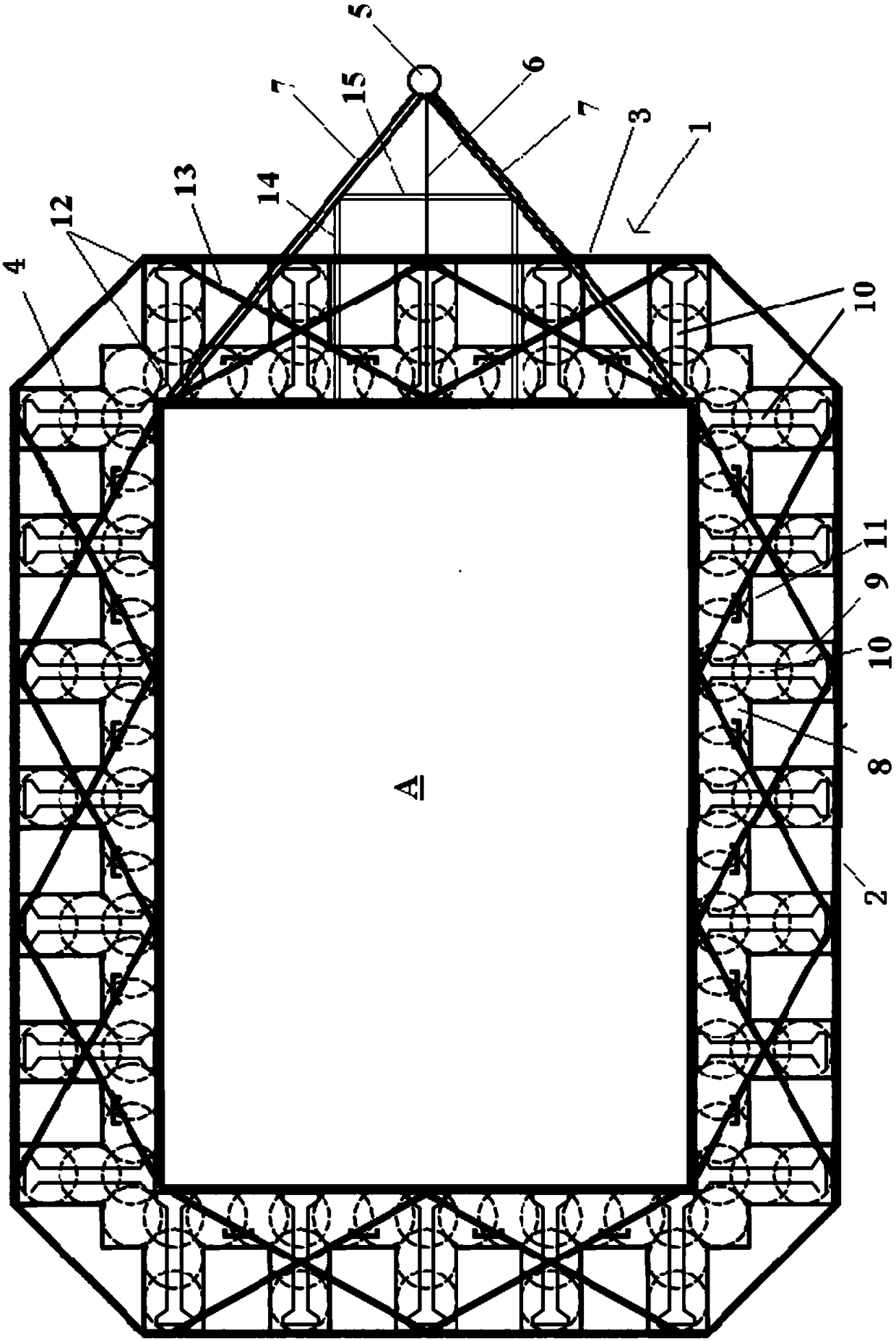

[0041] Such as image 3 As shown, the difference between the support structure outside the deep foundation pit of this embodiment and that of Embodiment 1 is that it also includes: a support assembly connected to the second retaining wall part 3 and the pressure-bearing member 7 respectively, for connecting the The pressure received by the pressure-bearing component 7 is transferred to the second retaining wall portion 3, so as to support the pressure-bearing component 7.

[0042] As a preferred embodiment, wherein, the tension member 6 is a tension rod; the pressure member 7 is a pressure rod; the support assembly includes: a first support rod 14, one end of which is connected to the pressure rod , the other end of which is connected to the second retaining wall part 3, and is used to transfer the soil mass pressure received by the second retaining wall part 3 toward the inside of the foundation pit to the pressure bearing rod, thereby forming a pair of The pulling of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com