Multistage super junction structure and self-alignment preparation method thereof

A self-alignment, super-junction technology, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of deep trench etching and low etching selection that are difficult to achieve super-junction, and achieve the effect of dynamic mask thickening , performance improvement, high verticality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

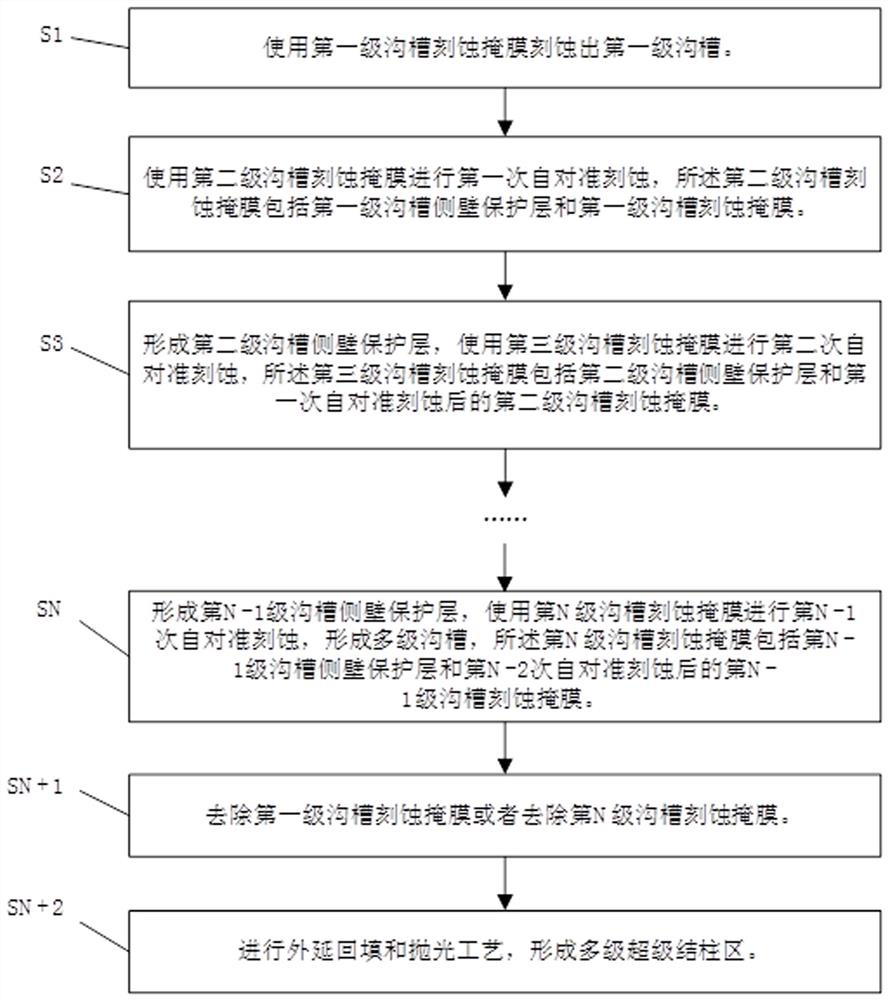

[0030] figure 1 It is a flowchart of a self-aligned preparation method of a multilevel super junction structure according to an embodiment of the present invention. The flow of the self-aligned preparation method of the multilevel super junction structure may include step S1 to step SN+2, where N is a natural number greater than or equal to 2, or N is a natural number greater than or equal to 3.

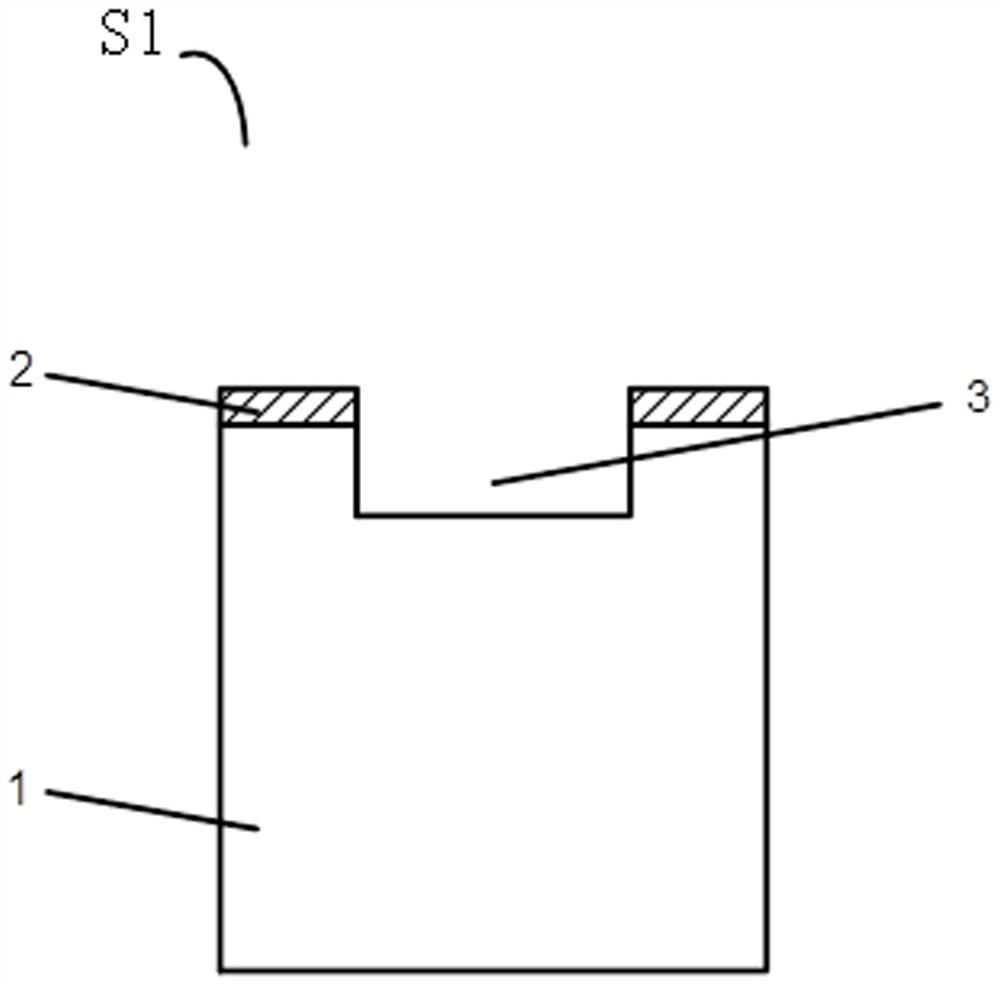

[0031] In step S1, a first-level trench is etched using a first-level trench etching mask. The depth of the first-level groove is determined by the depth of the multi-level groove and the total number of stages, wherein the total number of stages is N.

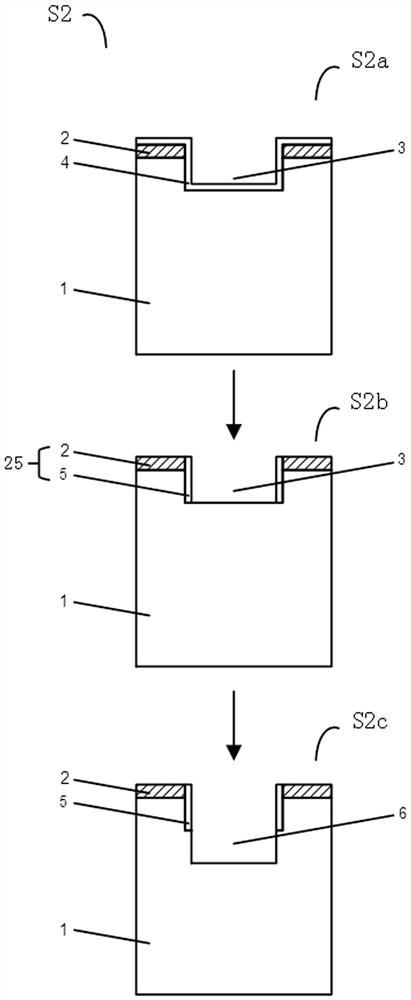

[0032] Step S2, forming a first-level trench sidewall protective layer, and performing the first self-aligned etching using a second-level trench etching mask, the second-level trench etching mask including the first-level trench The trench sidewall protection layer and the first level trench etch mask.

[0033] Step S3, forming a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com