Special composite velocity adjusting agent, adjusting agent preparation method and application method

A viscosity regulator and viscosity reducer technology, which is applied in the preparation of regulators and the field of compound viscosity regulators, can solve the problems affecting the stability and homogeneity of concrete mixture, the progress and quality of concrete pumping construction, segregation, Problems such as delamination and bleeding can be achieved to promote the development of secondary hydration, enhance the effect of resisting shrinkage, and improve the effect of volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

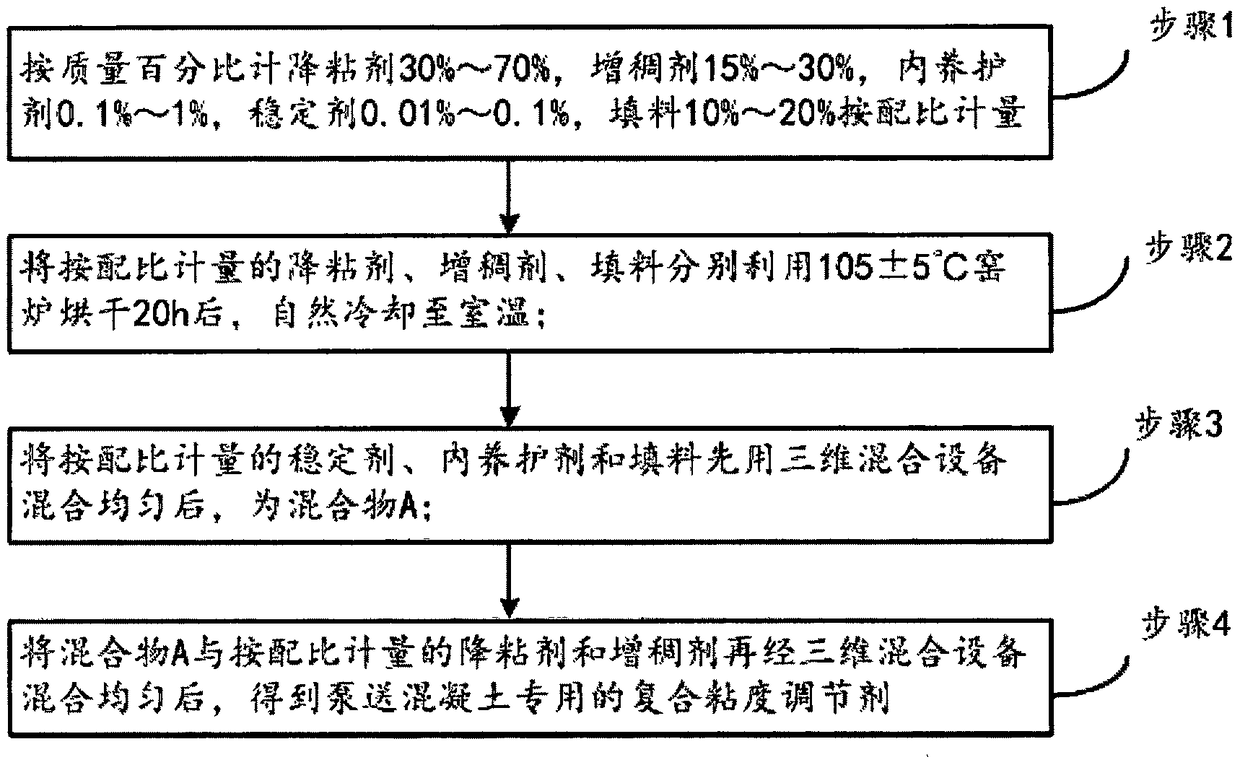

Method used

Image

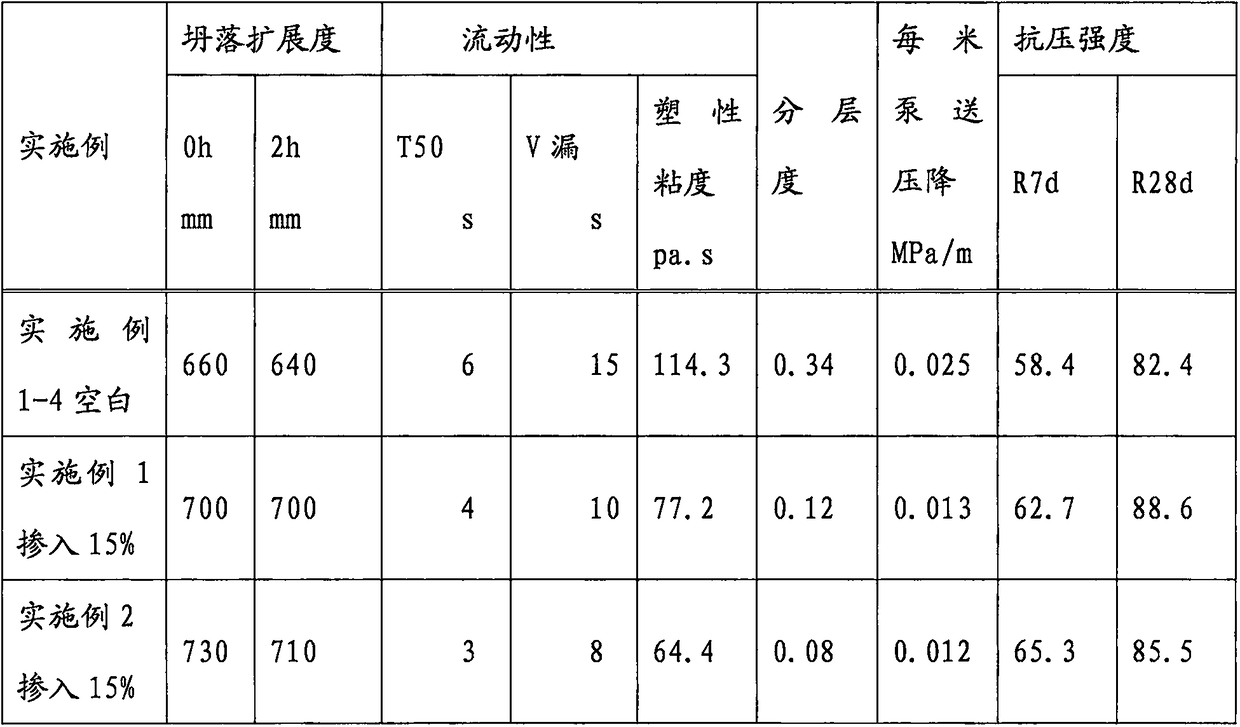

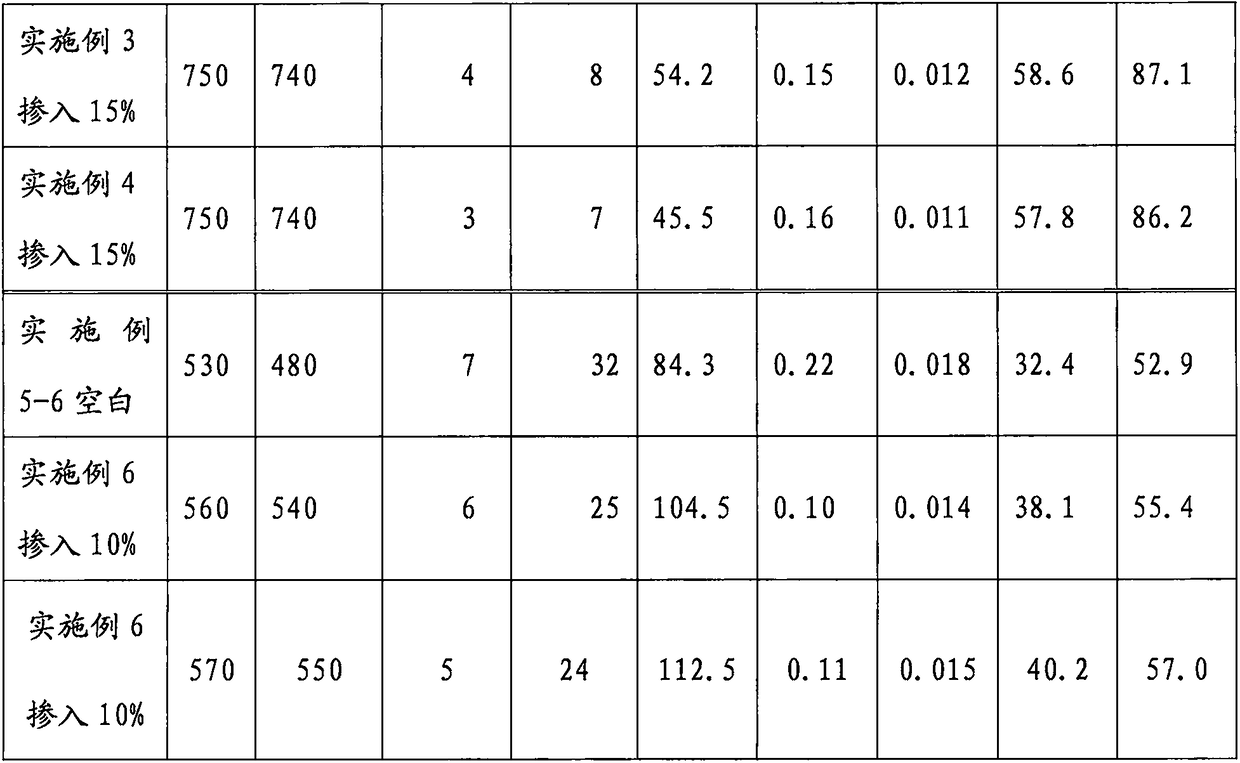

Examples

Embodiment 1

[0026] A special compound viscosity regulator for high-lift pumping concrete, which consists of the following components in percentage by weight: 69.03% of microbead fly ash, 18.60% of silica fume, 0.32% of SAP water-absorbing resin, and 0.05% of methyl cellulose ether , Class I fly ash 5.00%, S105 class active slag powder 5.00%. The mixing amount of the composite viscosity regulator is 15%, wherein the water-binder ratio of the concrete is 0.26, and the water reducer is a standard high-performance water reducer.

Embodiment 2

[0028] A special compound viscosity modifier for high-lift pumping concrete, which consists of the following components by weight percentage: 74.00% of microbead fly ash, 15.60% of silica fume, 0.35% of SAP water-absorbing resin, 3 million polyacrylamide (yin ) 0.03%, Class I fly ash 10.00%. The mixing amount of the composite viscosity regulator is 15%, wherein the water-binder ratio of the concrete is 0.26, and the water reducer is a standard high-performance water reducer.

Embodiment 3

[0030] A special compound viscosity regulator for high-lift pumping concrete, which consists of the following components by weight percentage: 79.55% of microbead fly ash, 10.00% of silica fume, 0.35% of SAP water-absorbing resin, 3 million polyacrylamide (yin ) 0.10%, Class I fly ash 10.00%. The mixing amount of the composite viscosity regulator is 15%, wherein the water-binder ratio of the concrete is 0.26, and the water reducer is a standard high-performance water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com