Admixture special for hydraulic structure permeable pointing mortar and preparation and use method thereof

A technology of hydraulic structure and admixtures, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that mortar cannot be used as jointing mortar, the fluidity and viscosity of cement slurry are poor, and the It can solve the problems of material particle bonding and other problems, so as to achieve the effect of easy jointing construction, realizing thickening effect and preventing agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

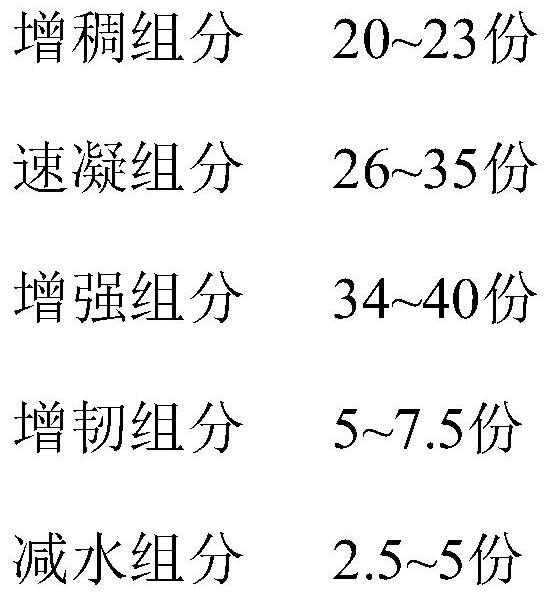

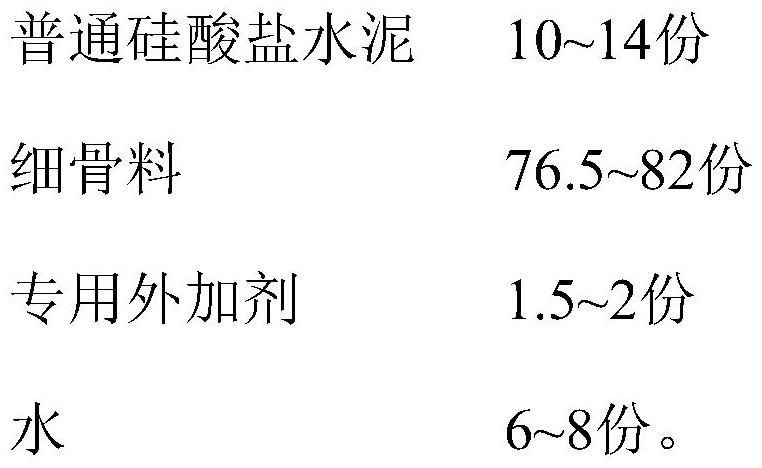

[0035] A special admixture for hydraulic structure permeable pointing mortar, which consists of the following components calculated by weight:

[0036]

[0037] The thickening component is an inorganic thickening component processed by crushing and ball milling for 30 minutes by using waste aerated concrete and quicklime. The crusher and ball mill have no special requirements, and its components are by weight:

[0038] Waste air-entrained concrete 90 parts

[0039] Quicklime 10 parts

[0040] The waste air-entrained concrete is derived from the air-entrained concrete block at the building demolition site;

[0041] Described unslaked lime is commercially available product;

[0042] The quick-setting component is a commercially available product, purchased from Hangzhou Hengshitong Building Materials Co., Ltd., and the model is HW-D;

[0043] The reinforcing component is composed of densified silicon powder, superfine slag micropowder, and metakaolin, and its component rat...

Embodiment 2~6

[0069] A special admixture for hydraulic structure permeable pointing mortar, which is composed of components calculated in parts by weight shown in Table 3, the thickening component is made of waste aerated concrete and quicklime, processed by crushing and ball milling, The ball milling time is shown in Table 3 respectively. The crusher and ball mill have no special requirements, and their components are shown in Table 3 respectively by weight ratio.

[0070] The waste air-entrained concrete is derived from the air-entrained concrete block at the building demolition site;

[0071] Described unslaked lime is commercially available product;

[0072] The quick-setting component is a commercially available product, purchased from Hangzhou Hengshitong Building Materials Co., Ltd., and the model is HW-D;

[0073] Described reinforcing component is combined by densified silicon powder, superfine slag micropowder, metakaolin, and its component ratio calculated by weight is as shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com