Foamed middle tube, leather stuck ball and manufacturing method

A production method and foam technology, which are applied in the field of vulcanization-free and grinding-free foamed intermediate tires and sticking balls, and the fields of foaming intermediate tires and sticking balls and manufacturing, can solve problems such as inability to use volleyballs, and improve softness. , ball bounce and good softness, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

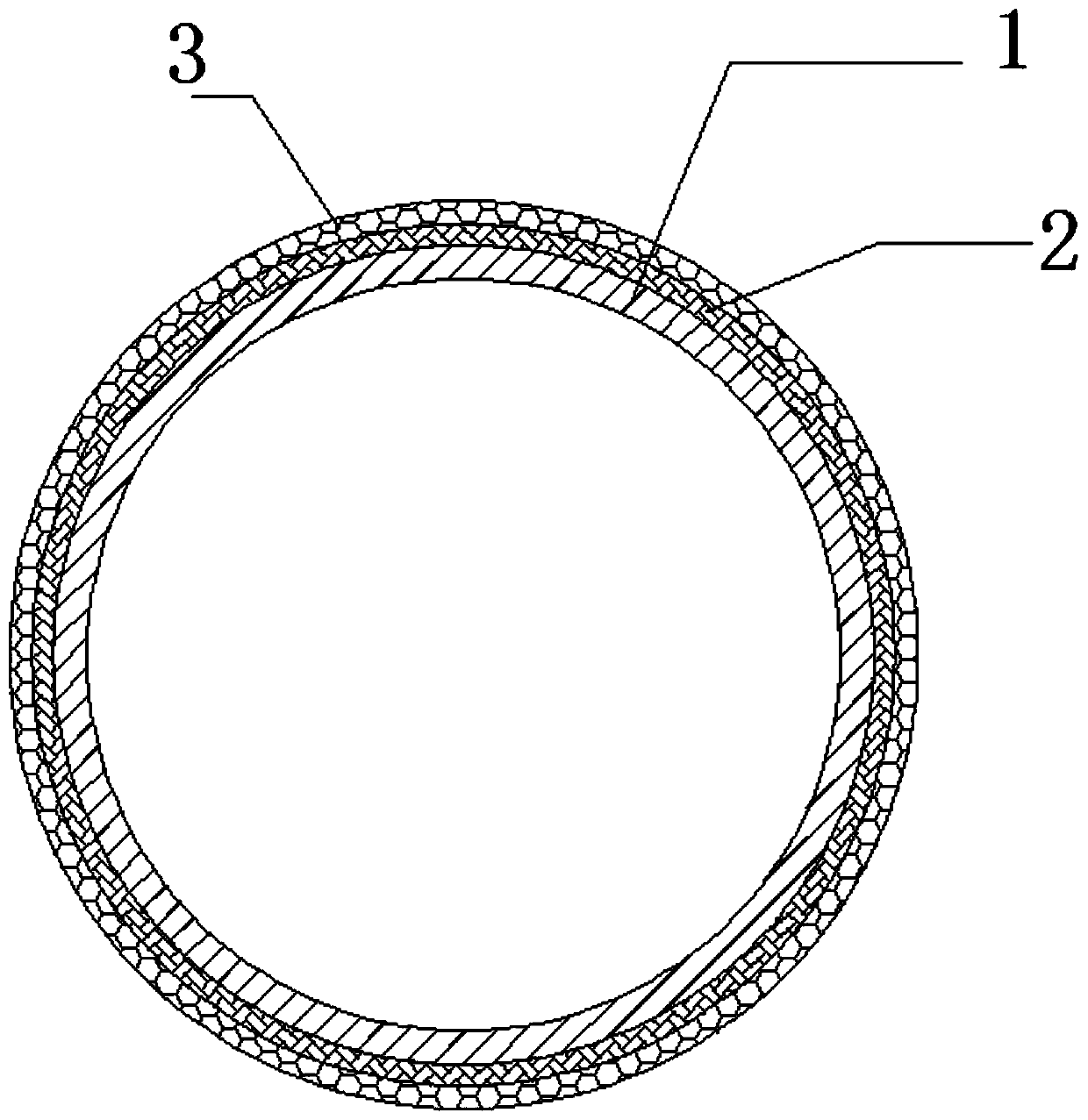

[0076] Such as figure 1 As shown, the present embodiment provides a foamed middle tire, including an inner container 1, an anti-inner container deformation layer 2 and a foam layer 3, the anti-inner container deformation layer 2 is wrapped on the outer surface of the inner container 1, and the foam layer 3 covers It is arranged on the outer surface of the anti-deformation layer 2 of the liner.

[0077] As a preferred embodiment, the anti-deformation layer 2 of the liner adopts a yarn layer or a first patch layer. The yarn layer or the first patch layer is arranged on the outer surface of the inner tank, which can fix the circumference of the inner tank, prevent the inner tank from expanding infinitely during the inflation process, and prevent the inner tank from being deformed. However, the material of the anti-deformation layer of the liner is not limited to yarn or patch, and other fabric layers that prevent the deformation of the liner also belong to the scope of protectio...

Embodiment 2

[0083] The difference between this embodiment and embodiment 1 is that the inner tank deformation prevention layer 2 is a composite layer composed of a yarn layer and paste or latex, or a composite layer composed of the first patch layer and paste or latex.

[0084] Further paste or latex on the outer surface of the yarn layer, the first patch layer or other fabric layers, the paste or latex can make the yarn layer, the first patch layer or other fabric layers more compact after drying and solidification, Strong, can better prevent the deformation of the liner.

[0085] Similarly, the anti-deformation layer 2 of the inner tank in this embodiment is not limited to the yarn layer or patching layer, and other composite layers composed of fabric layers and paste or rubber that prevent inner tank deformation also fall within the scope of protection of this solution.

[0086] The foamed middle tire provided by the present embodiment is made by the following method:

[0087] (1) A l...

Embodiment 3

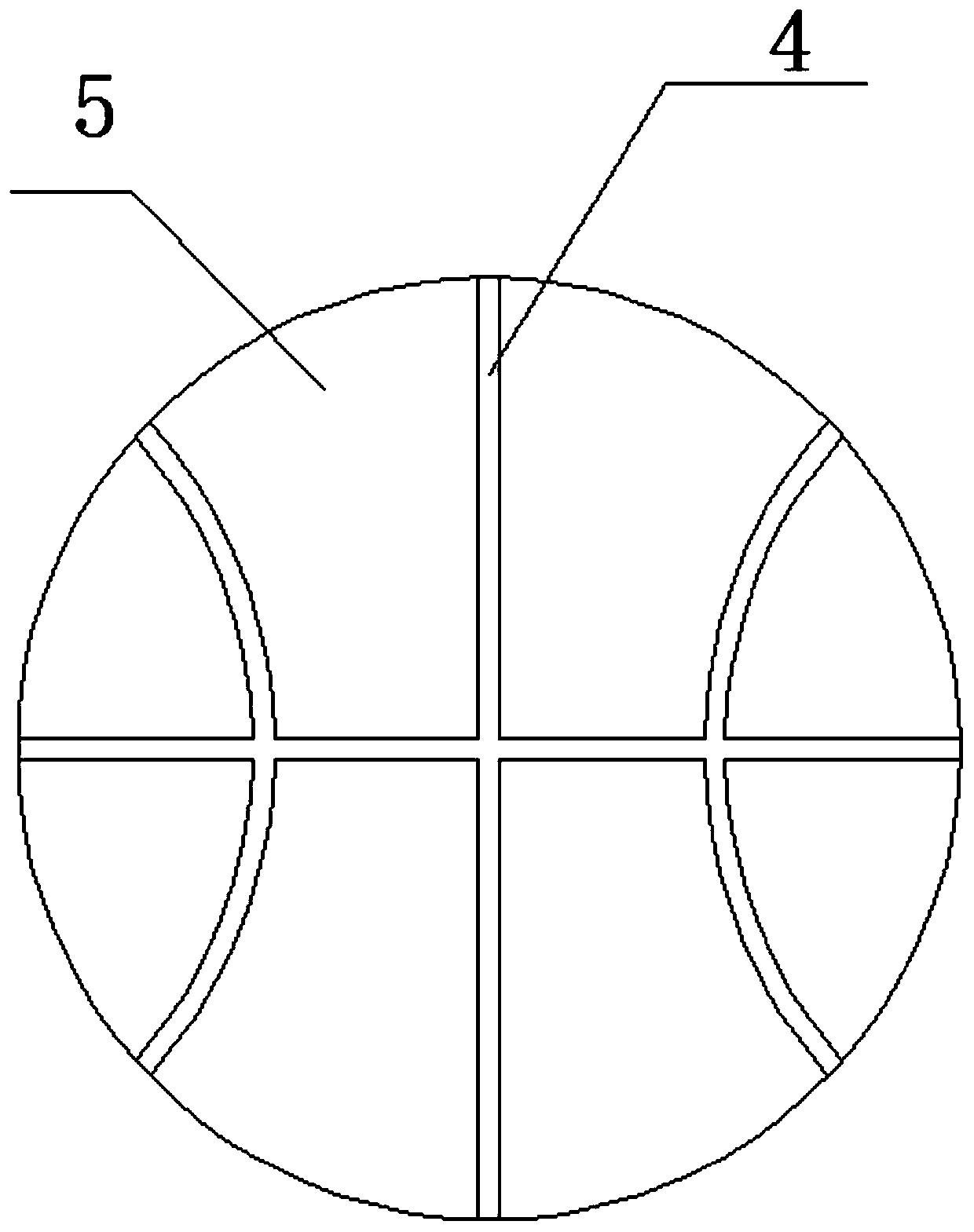

[0096] The difference between this embodiment and Embodiment 1 is that a middle tire for basketball or rugby is provided, and the outer surface of the foam layer 3 is pasted with stem lines. As a preferred embodiment, the material of the stem line is selected from synthetic materials such as PVC, PU, and fiber materials according to actual needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com